Cylinder internal water spraying detection control system for gasoline engine and application of cylinder internal water spraying detection control system

A detection and control system, gasoline engine technology, applied in the direction of automatic control, automatic control, charging system, etc., can solve the problems of poor nozzle lubrication, nozzle failure, and the combustion process cannot be optimized, and achieve sensitive and timely control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

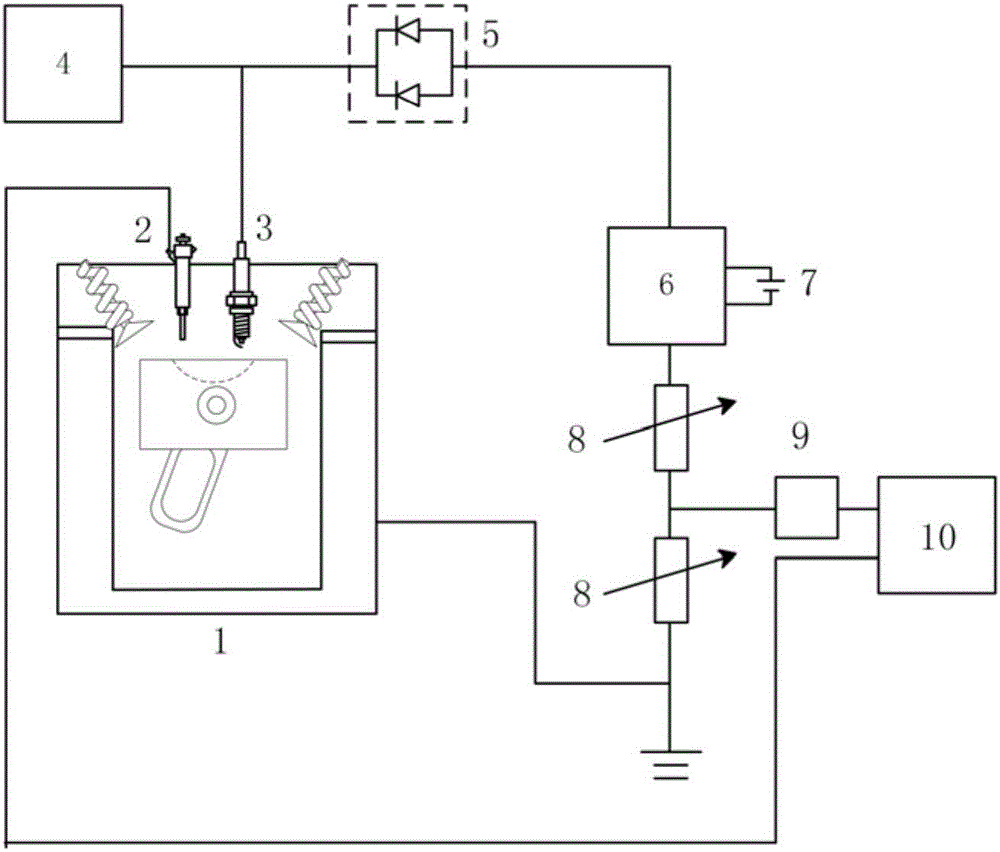

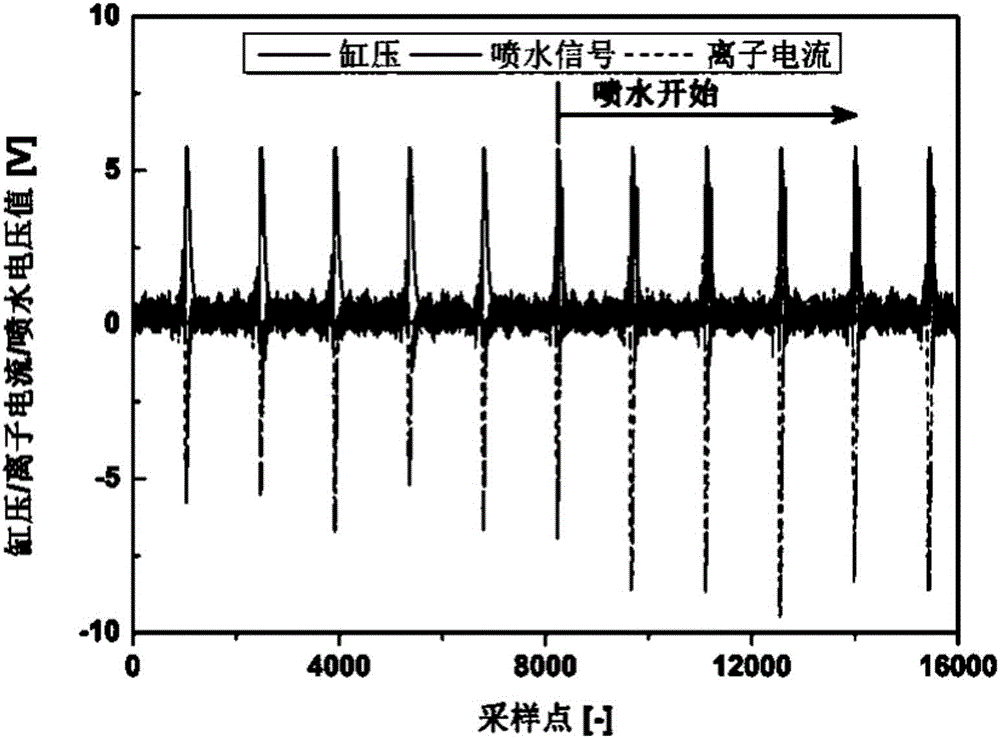

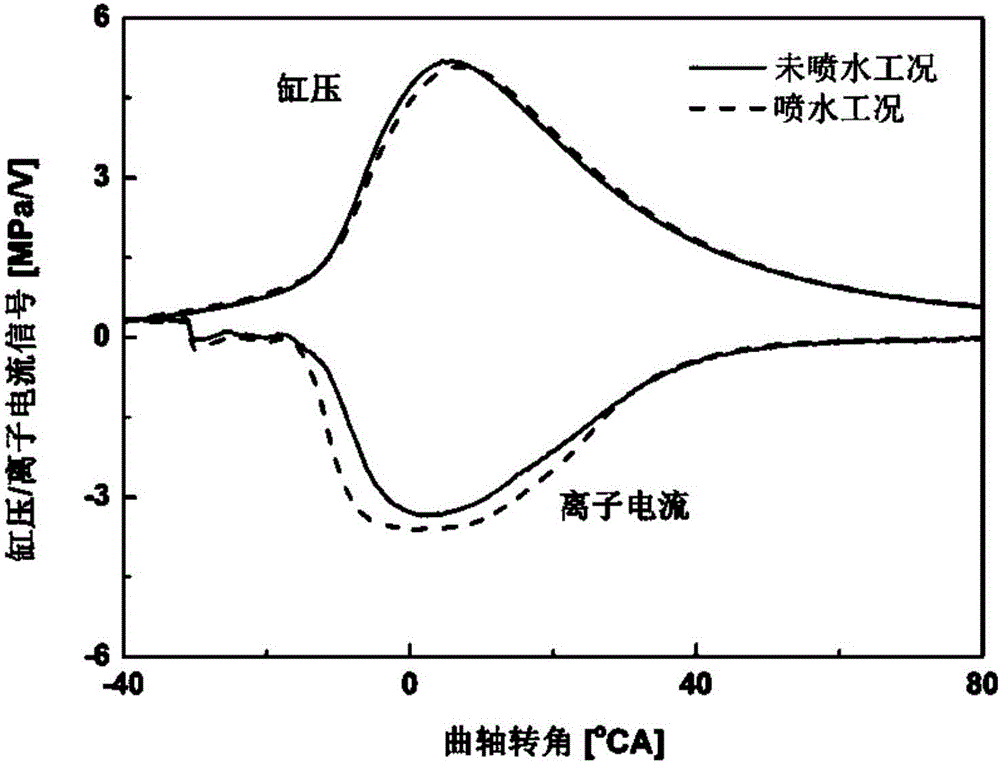

[0033] A gasoline engine water injection detection and control system, refer to figure 1 , Including gasoline engine cylinder 1, gasoline engine cylinder block 1 is equipped with spark plug 3 and water injection nozzle 2, spark plug 3 is connected to ignition device 4, also includes high voltage silicon stack 5, voltage booster 6 and battery 7 composed of voltage components, adaptive resistors 8. The signal processing device 9 and the microprocessor 10, the positive and negative poles of the battery 7 are connected to the positive and negative poles of the DC boost device 6. The DC boost device raises the battery voltage from 12V to 60V, which is adjustable. After the high-voltage isolation silicon stack 5, the spark plug 3 and the gasoline engine cylinder 1 are connected to the adaptive resistor 8, the ion current signal is reflected in the adaptive resistor 8 as a voltage signal and then transmitted to the signal processing device 9 for signal conditioning and amplification op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com