Garbage incinerator combustion chamber temperature-measuring device, incinerator temperature control system and incinerator temperature control method

A technology of waste incinerator and temperature measuring device, which is applied in the direction of combustion method, incinerator, combustion type, etc., and can solve problems such as high temperature slagging, increased burden on the furnace body, corrosion, etc., achieve stable furnace temperature, and quickly and effectively adjust furnace temperature , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

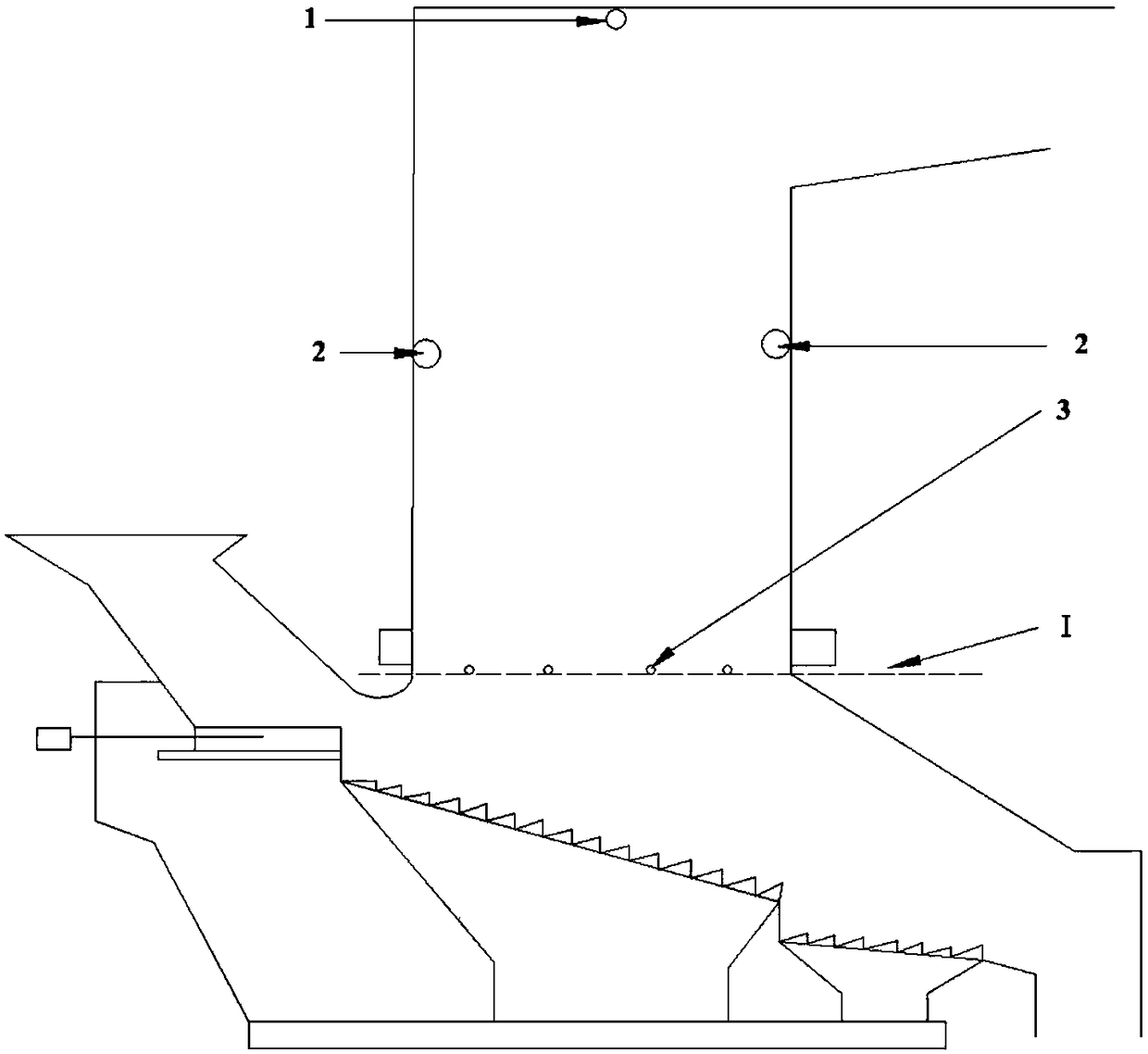

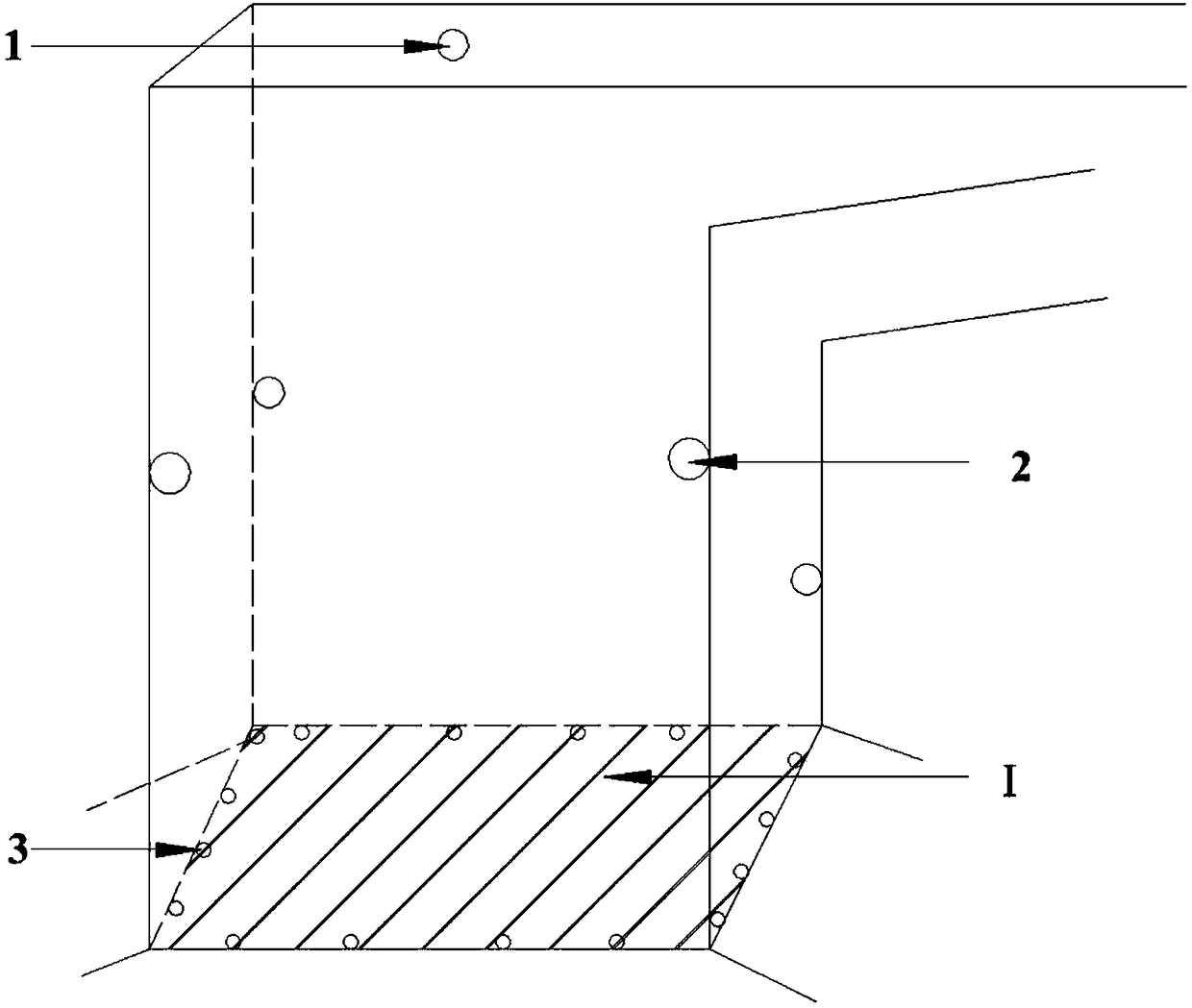

[0033] Such as figure 1 , figure 2 As shown, this embodiment provides a furnace temperature measuring device for a waste incinerator, the center of the top of the furnace is provided with a first infrared thermal imager 1 that can rotate 360 degrees in a horizontal plane, and can look down on the entire furnace, and vertically view it from multiple angles. Measure the temperature in the furnace; the joints between the four walls inside the furnace are each equipped with a second infrared thermal imager 2 that can move longitudinally in the furnace, and each second infrared thermal imager adopts a dynamic sealing method, not only It can ensure that the temperature in the furnace will not be lost, and it can also move and monitor the temperature of each height area in the furnace in real time, realizing the measurement of the transverse temperature on different height sections of the furnace; each of the four walls of the main combustion area in the furnace is equipped with a...

Embodiment 2

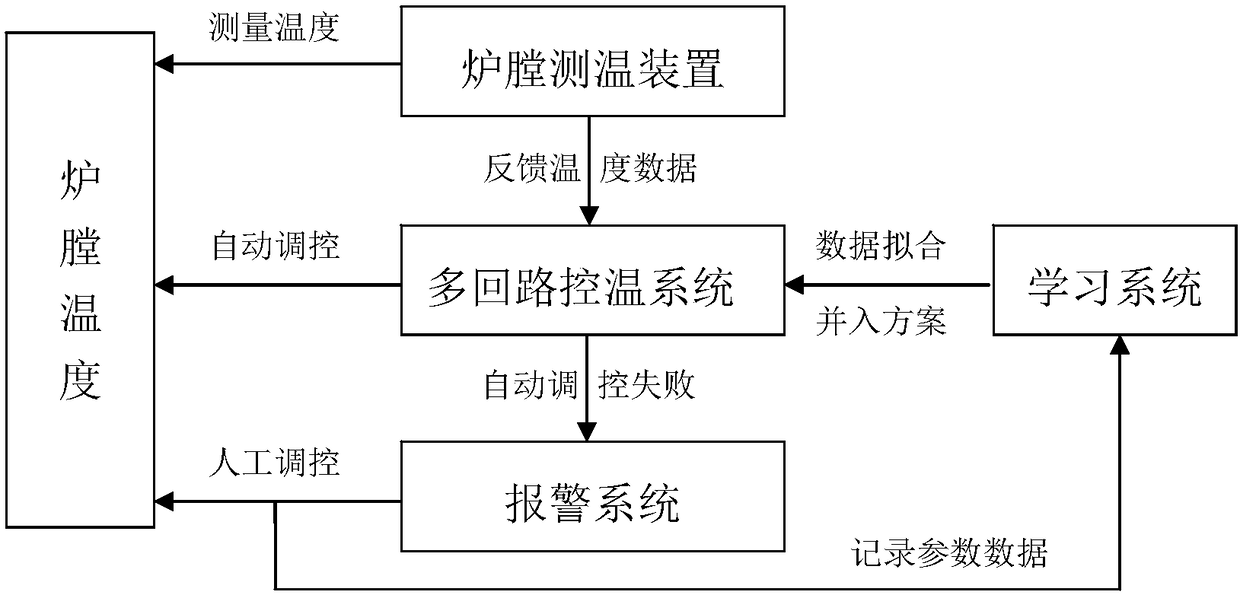

[0039] Such as image 3 As shown, this embodiment provides a furnace temperature control system using the furnace temperature measuring device of the waste incinerator in Embodiment 1, including the furnace temperature measuring device of the waste incinerator, a multi-loop temperature control system, an alarm system and a learning system. Among them, the furnace temperature measuring device of the garbage incinerator is used to detect the temperature in the furnace of the garbage incinerator, and feed back the obtained temperature data to the multi-loop temperature control system.

[0040] The multi-loop temperature control system is used to adjust the furnace temperature of the garbage incinerator by adjusting the operating parameters of the garbage incinerator. It includes a main loop and a secondary loop, and each loop has a different function of adjusting the furnace temperature of the garbage incinerator. parameter.

[0041] The alarm system is used to send an alarm whe...

Embodiment 3

[0044] Such as image 3 , Figure 4 As shown, this embodiment provides a furnace temperature control method using the furnace temperature control system of Embodiment 2, and the main steps are as follows:

[0045] S1. The furnace temperature measuring device of the garbage incinerator detects the temperature in the furnace of the garbage incinerator, and feeds back the obtained temperature data to the temperature control system;

[0046] S2. The temperature control system compares the obtained temperature data with the preset temperature range value, if the temperature data is outside the preset temperature range value, adjust the use parameters of the waste incinerator so that the temperature in the furnace can be adjusted within the preset temperature range; if the temperature in the furnace cannot be adjusted accurately within the preset time, an alarm will be issued to manually adjust the operating parameters of the waste incinerator.

[0047] Wherein, the temperature co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com