Controller gain scheduling for mass flow controllers

A technology of mass flow and controller, which is applied in the direction of using electric device flow control, flow control, general control system, etc., and can solve problems such as complexity and oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

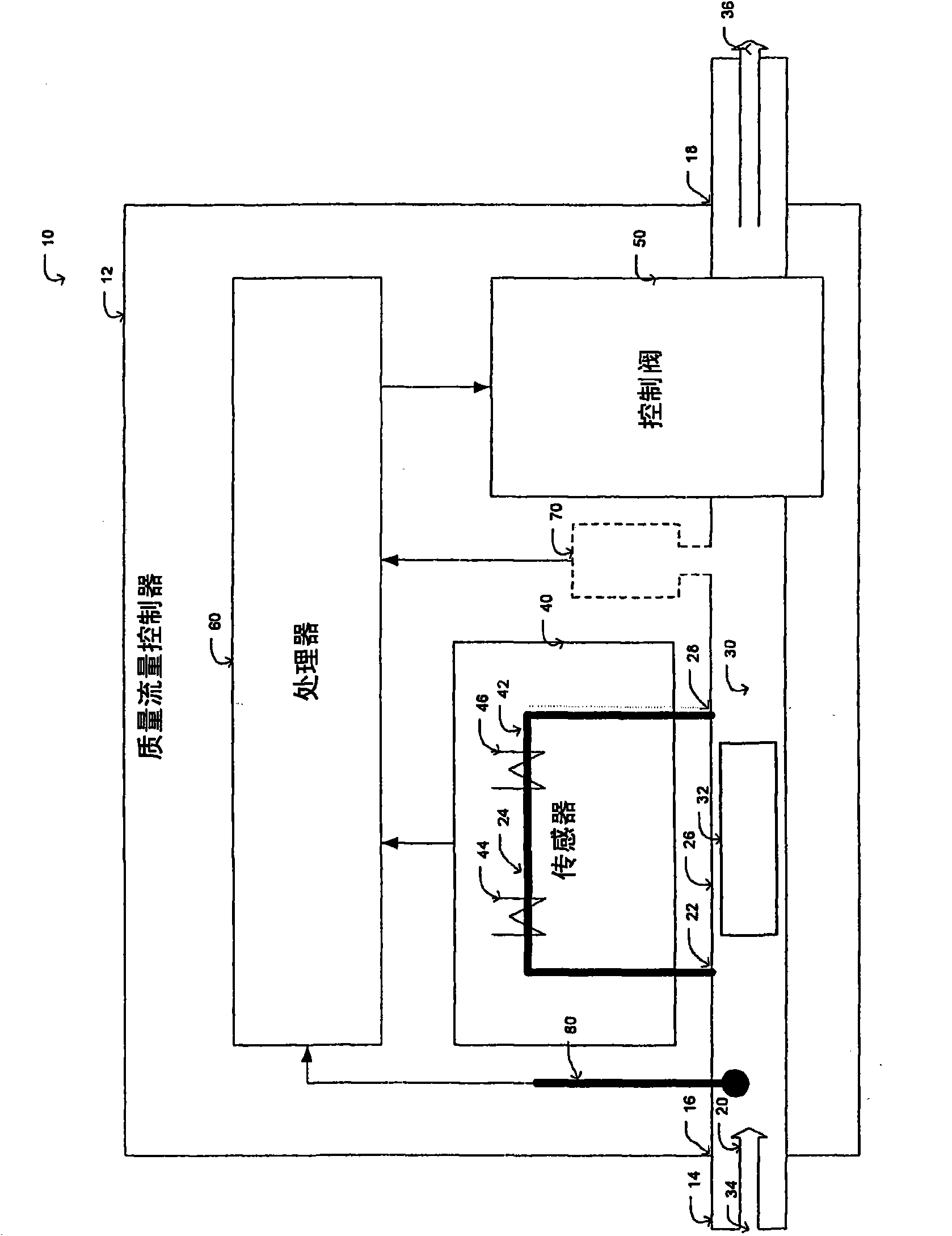

[0018] refer to image 3 In the embodiment shown in , the block diagram of the MFC control system 100 includes a negative feedback control loop. Feedback control systems generally include inputs and outputs, and associations combining the outputs and inputs. In the feedback control loop, Q sp 102 (desired set point flow rate) is input. The obtained actual flow rate Q indicated at reference numeral 116 is an output. In the description below, for example Q(t) and Q sp All time-domain variables of (t) are transformed into such as Q(s) and Q sp (s) Laplacian domain variables, which is a common means used in the control domain.

[0019] The physical model of the control system 100 includes a controller K(s), indicated at 104 , and a valve V(s), indicated at 110 . The feedback controller K(s) generates a control command current I(s) indicated at reference numeral 108 to regulate the opening of the valve such that the output of the valve, the actual flow rate Q(s), tracks the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com