Method for comprehensively treating oil field waste by using physicochemical and biochemical technologies

A technology for comprehensive treatment of oil field waste, applied in the field of comprehensive treatment and utilization of oil field waste, which can solve problems such as ecological and environmental protection pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

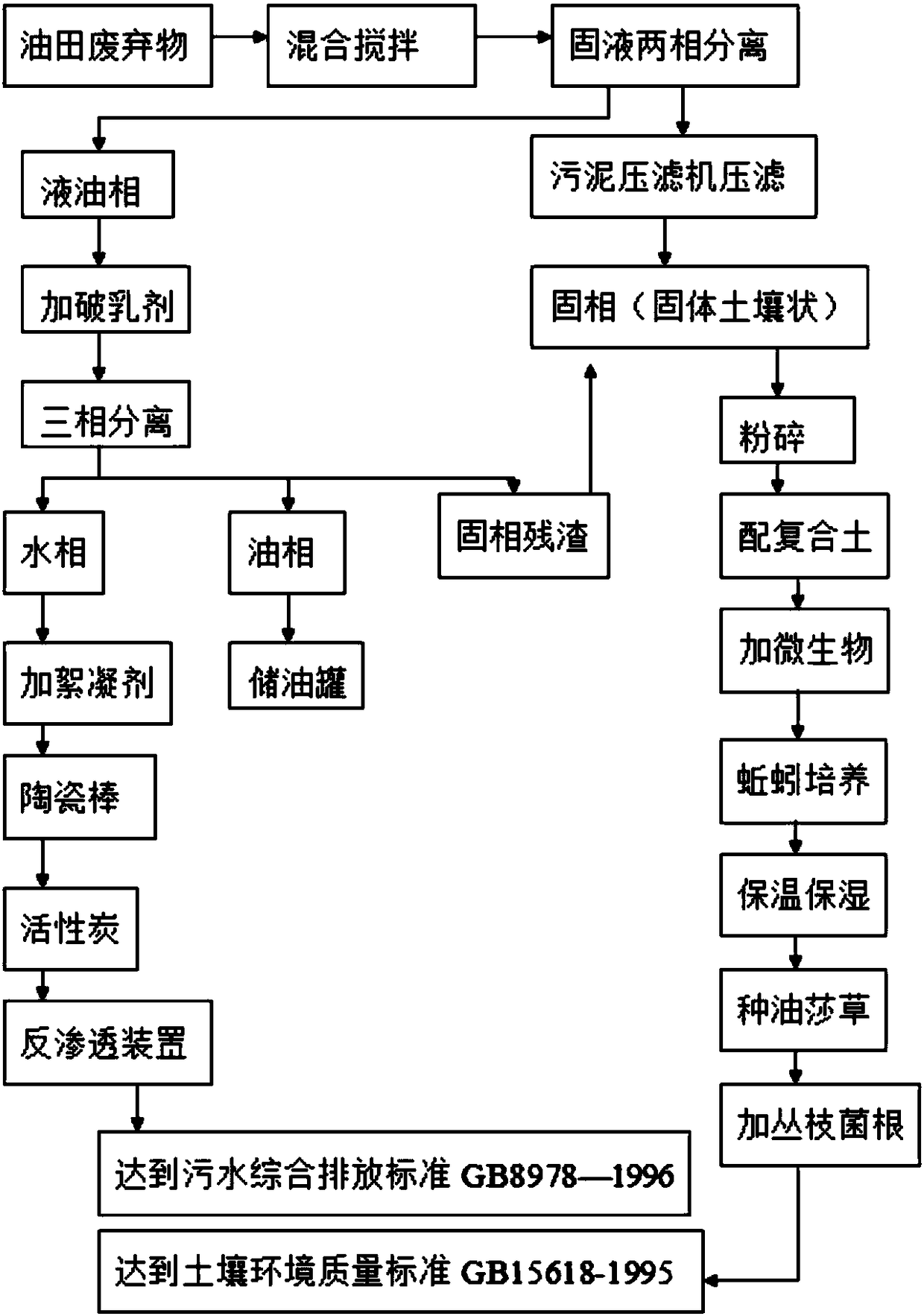

[0026] Such as figure 1 As shown, the method for comprehensively treating oilfield waste by using physical, chemical and biochemical technologies in this embodiment is carried out in the following steps:

[0027] (1) Solid-liquid separation: collect and stir oilfield waste, and separate solid phase and liquid-oil phase through solid-liquid two-phase separation;

[0028] (2) Three-phase separation: In the step (1), the solid phase is filtered by a sludge filter press to form solid soil, and the liquid-oil phase is then fully mixed and flocculated with a demulsifier, and then sent to the solid-liquid-liquid three-phase separation Oil phase, water phase and solid phase residue; the water phase is waste liquid;

[0029] (3) Oil phase treatment: the oil phase is input to the oil storage tank;

[0030] (4) Water phase treatment: after the water phase is added with flocculant, it is filtered through ceramic rod, activated carbon, and reverse osmosis device in sequence, and the effl...

Embodiment 2

[0043] The difference between the method of comprehensively treating oilfield waste by using physical, chemical and biochemical technologies in this embodiment and that of Embodiment 1 is that:

[0044] Activated carbon is 20~100 meshes in the step (4) water phase treatment of the present embodiment; The inoculum amount of high temperature resistant Bacillus subtilis is 5g / m in the step (5) 3 , the temperature of aerobic fermentation is 50°C, and the fermentation time is 30 days. After the fermentation is completed, flatten the heat to reduce the temperature to 28°C; when cultivating earthworms, the amount of earthworms is 450 / m 3 ; The heat preservation and moisturizing is to keep the temperature at 30°C and keep the humidity at 60%; the addition of the mycorrhizae from the branches is 2g / m 3 .

Embodiment 3

[0046] The difference between the method of comprehensively treating oilfield waste by using physical, chemical and biochemical technologies in this embodiment and that of Embodiment 1 is that:

[0047] Activated carbon is 100~200 meshes in the step (4) water phase treatment of the present embodiment; In the step (5), the inoculum amount of the high-temperature-resistant Bacillus subtilis is 5g / m 3 , the temperature of aerobic fermentation is 60°C, and the fermentation time is 30 days. After the fermentation is completed, flatten the heat to reduce the temperature to 26°C; when cultivating earthworms, the amount of earthworms is 500 / m 3 ; The heat preservation and moisturizing is to keep the temperature at 25°C and keep the humidity at 60%; the addition of the mycorrhizae from the branches is 2g / m3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com