Preparation method and device of phosphorus-doped nano silicon material

A nano-material and nano-silicon technology, which is applied in the direction of silicon, can solve the problems of uneven size of nanoparticles, low production capacity of nanoparticles, and difficulty in avoiding cross-contamination of chemical components, so as to increase the area, improve the uniformity, and increase the production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

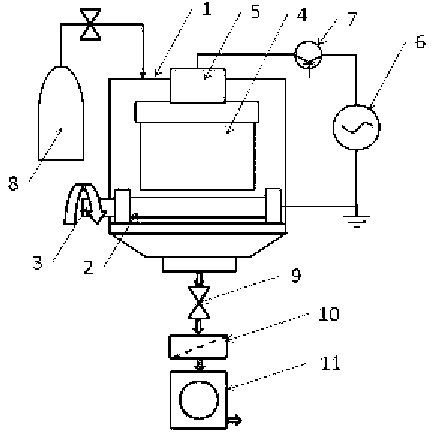

[0033] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and four preferred embodiments.

[0034] Device example:

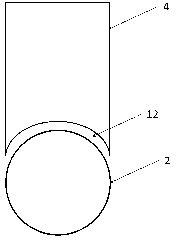

[0035] like figure 1 and figure 2 Shown: a device for preparing nanoparticles by controllable spark discharge, including a cavity 1 for accommodating spark discharge, one end of the cavity 1 is connected to a pipeline for a dielectric material 8 to enter, and the other end is connected to a particle collector through a valve 9 10. It also includes a first electrode 2 placed in the cavity 1, a second electrode 4, and a power supply 6 connected to the first electrode 2 and the second electrode 4; the first electrode 2 is connected with a A rotating rotary motor 3, the second electrode 4 is connected with a stepper motor 5 that moves the second electrode 4 back and forth.

[0036] The first electrode 2 is a block of nanomaterials to be prepared, and the shape is a cylinder.

[0037] The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com