Method and device for preparing boron-doped nano silicon material

A technology of nanomaterials and nanosilicon, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as uneven size of nanoparticles, low production capacity of nanoparticles, and difficulty in avoiding cross-contamination of chemical components, etc., to achieve Improve the area, improve the uniformity, improve the effect of production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

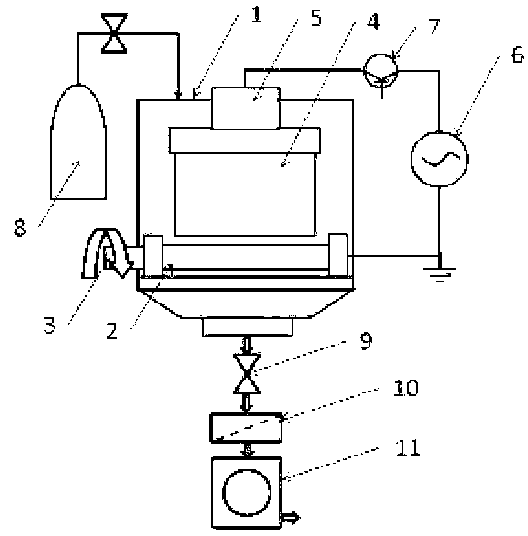

[0034] Such as figure 1 and figure 2Shown: a device for preparing nanoparticles by controllable spark discharge, including a cavity 1 for accommodating spark discharge, one end of the cavity 1 is connected to a pipeline for a dielectric material 8 to enter, and the other end is connected to a particle collector through a valve 9 10. It also includes a first electrode 2 placed in the cavity 1, a second electrode 4, and a power supply 6 connected to the first electrode 2 and the second electrode 4; the first electrode 2 is connected with a A rotating rotary motor 3, the second electrode 4 is connected with a stepper motor 5 that moves the second electrode 4 back and forth.

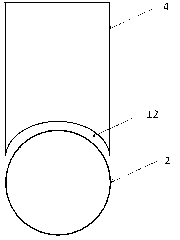

[0035] The first electrode 2 is a block of nanomaterials to be prepared, and the shape is a cylinder.

[0036] The second electrode 4 is a block of nanomaterials to be prepared, and the side close to the first electrode 2 is a concave cylindrical surface.

[0037] In a preferred embodiment of the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com