Lithium ion battery positive plate water coating adhesive and preparing method thereof

A lithium-ion battery, water-based coating technology, applied in the direction of battery electrodes, adhesives, adhesive types, etc., can solve problems such as insufficient adhesion and imperfect adhesion of adhesives, and achieve uniform dispersion and good appearance Brighter and more beautiful, strong adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In this example, the positive electrode material is LiCoO 2 (CITIC Guoan), the adhesion promoter is JN-105A (titanate fat coupling agent).

[0051] The following ingredients are LiCoO2: conductive agent: gelatin: PEO: SBR: JN-105A = 100: 3: 2: 0.7: 1: 0.5. First, dissolve PEO in 300ml of water for later use. Then dissolve the gelatin in 400ml of clean water. Then add 1000 grams of LiCoO2 powder to the gelatin solution and stir it. Finally, add SuperP carbon black in three batches and stir at high speed for 2-3 hours. Then add 10 grams of SBR in turn, the pre-prepared PEO solution and JN-105A continue to stir for 2-3 hours. After defoaming treatment and sieving, the slurry available for coating is obtained.

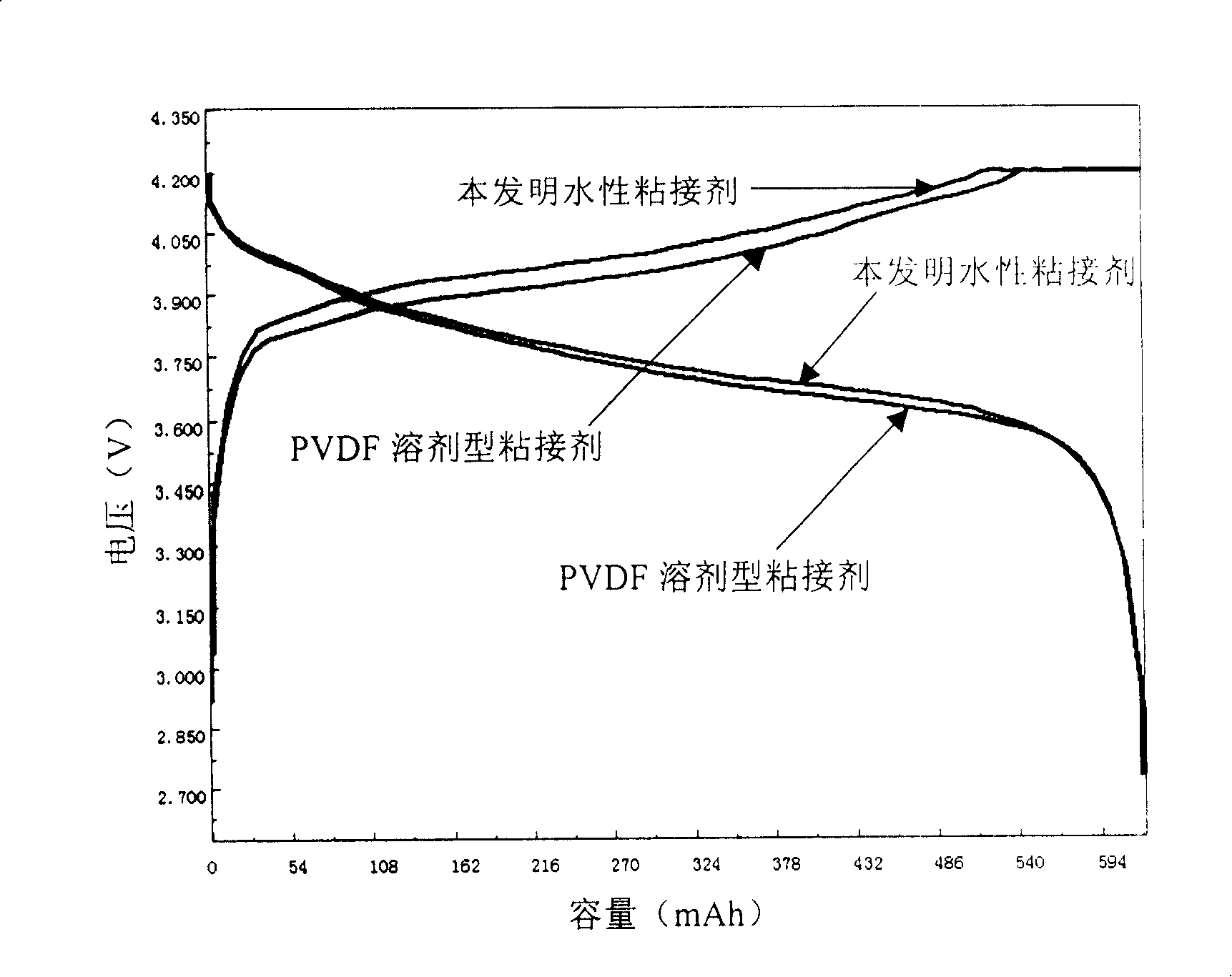

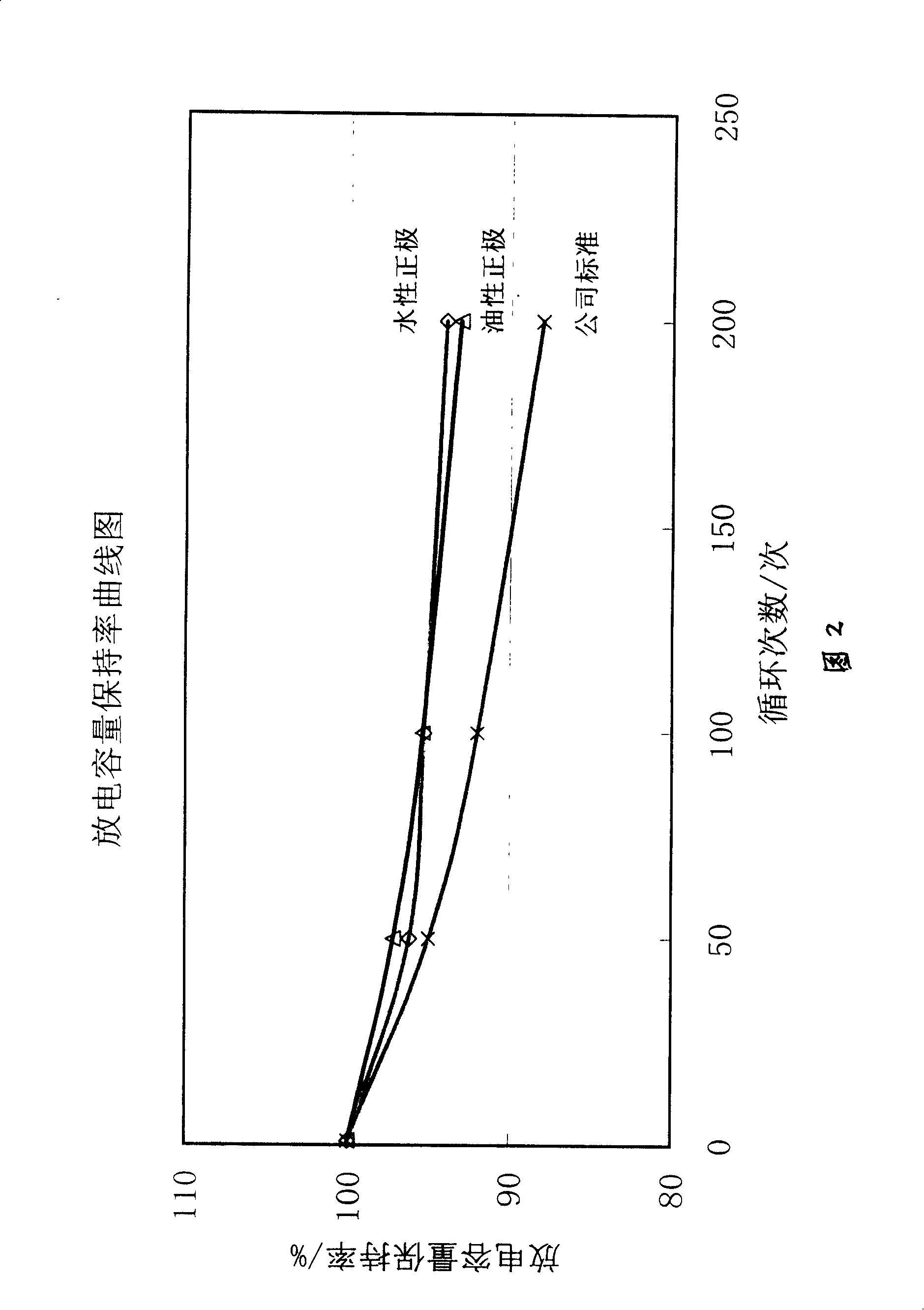

[0052] The resulting slurry is not easy to sink, uniformly dispersed, no fine particles at the bottom, black and shiny. The electrochemical performance of the positive sheet battery obtained with such a slurry is comparable to that of the oil-phase battery. F...

Embodiment 2

[0054] In this example, the positive active powder is Lithium Iron Phosphate (LiFePO 4 ). Same as Comparative Example 1, PEO is also used as thickener, and SBR latex is used as auxiliary adhesive. Although the slurry prepared with the three-component adhesive of Comparative Example 1 can also be coated, the coating of the obtained pole piece is not firmly bonded to the aluminum foil. In this example, LiFePO 4 : conductive carbon black: gelatin: PEO: SBR: titanate coupling agent (JN-AT) = 100:3:3:1:4:0.5 ingredients.

[0055] First, dissolve 30 grams of gelatin in 1200 ml of purified water at 50°C to form a transparent solution. Then, 1000 g LiFePO 4 Slowly add to the gelatin solution under stirring, and stir for half an hour. Except that 40 grams of SBR latex and 5 grams of water-based JN-AT titanate were added in this example as an adhesion promoter, the rest of the procedures were the same as in Comparative Example 1. According to this method, more uniform dispersion, ...

Embodiment 3

[0057] Polyacrylamide with a molecular weight of 430,000 is used as a thickener, and water-based titanate is used as an adhesion enhancer, according to LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 : conductive agent: gelatin: polyacrylamide: SBR: titanate = 100:3:1:0.7:1.5:0.5 ingredients.

[0058] First, dissolve 10 grams of gelatin with 400ml of pure water to obtain a transparent gelatin solution, then slowly add LiNi under stirring 1 / 3 co 1 / 3 mn 1 / 3 o 2 Ternary cathode material powder. After the addition is complete, stir at a high speed of 300 RPM for half an hour. Then add 20 grams of conductive agent Superp and 10 grams of KS2 to the above mixed liquid three times and continue to stir at high speed for 2 hours. After the slurry is roughly mixed, add 15 grams of SBR and 5 grams of JN-AT titanate and stir for another half an hour. Finally, a pre-made solution of polyacrylamide dissolved in 300 ml of water was added. After stirring for another 2-3 hours, the resulting slurry has goo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com