Patents

Literature

35 results about "Cross ply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

• CROSS-PLY (adjective) The adjective CROSS-PLY has 1 sense: 1. of or relating to an older kind of automobile tire that had a flexible tread and relatively stiff sidewalls. Familiarity information: CROSS-PLY used as an adjective is very rare.

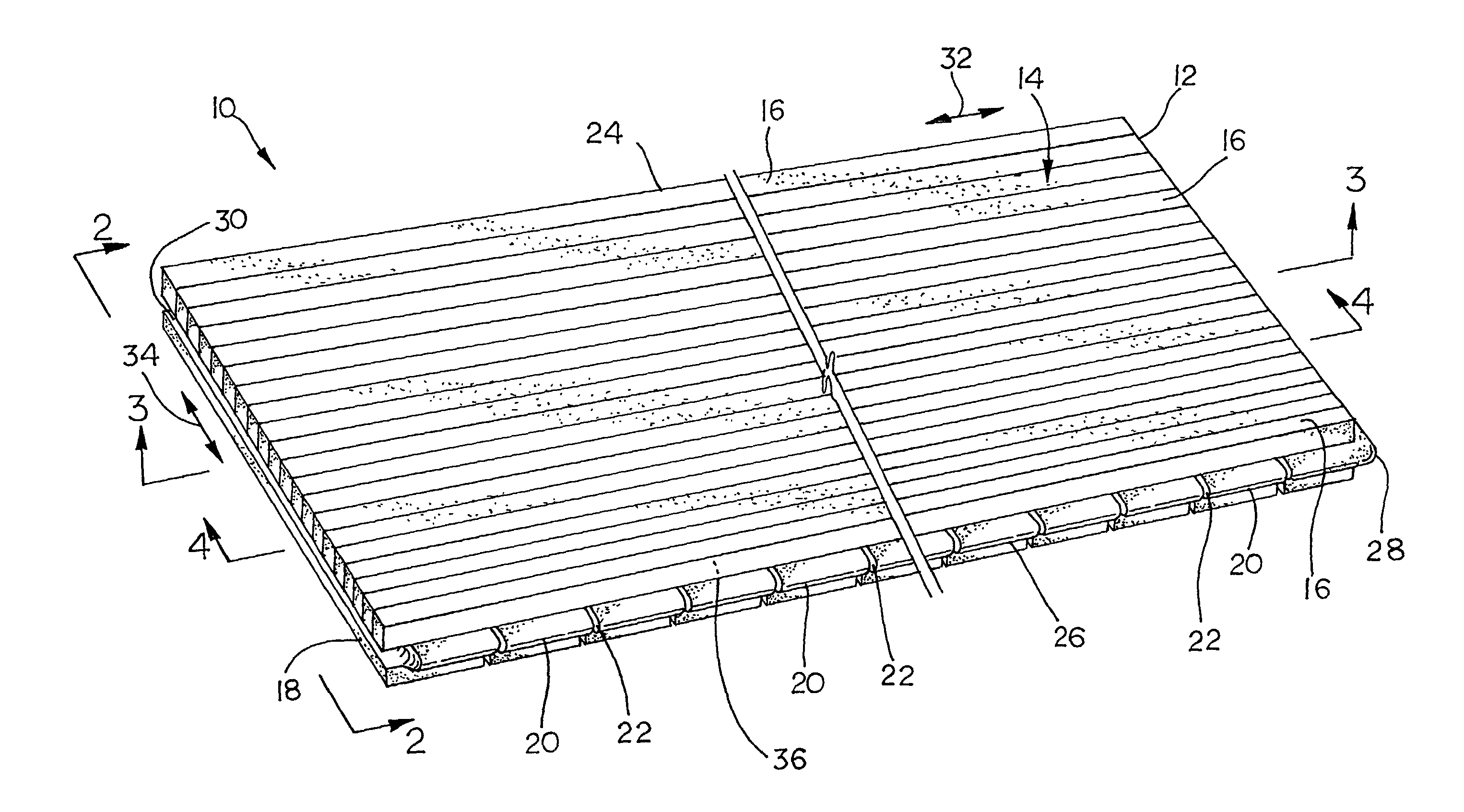

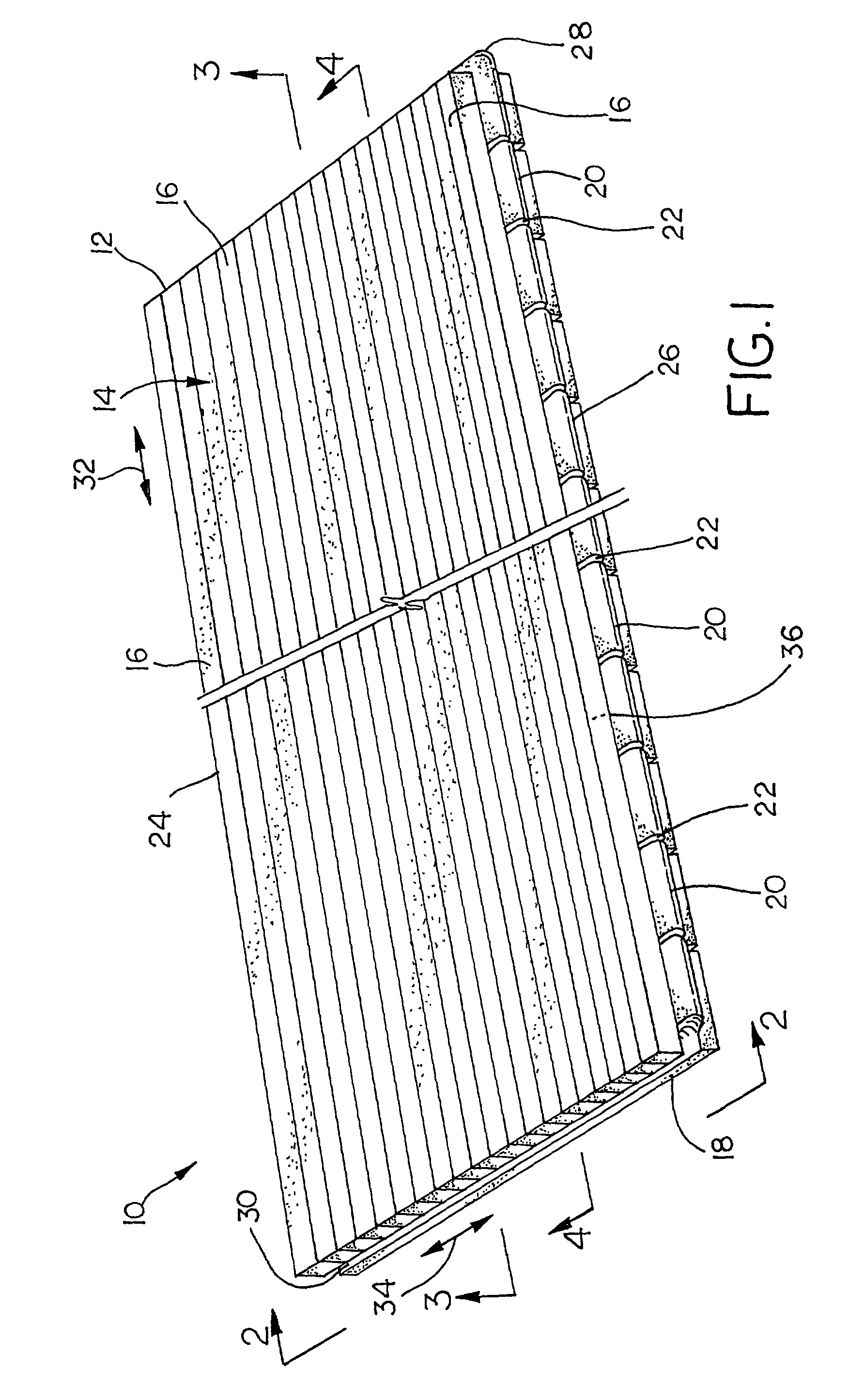

Ballistic-resistant panel including high modulus ultra high molecular weight polyethylene tape

A ballistic-resistant panel in which the entire panel or a strike-face portion thereof is formed of a plurality of sheets of high modulus high molecular weight polyethylene tape. The sheets of high modulus polyethylene tape can be in the form of cross-plied laminated layers of tape strips or a woven fabric of tape strips. The strips of UHMWPE tape include a width of at least one inch and a modulus of greater than 1400 grams per denier. The ballistic-resistant panel may include a backing layer of conventional high modulus fibers embedded in resin. A wide variety of adhesives were found acceptable for bonding the cross-plied layers of high modulus polyethylene tape together for forming the ballistic-resistant panels of the present invention.

Owner:DUPONT SAFETY & CONSTR INC

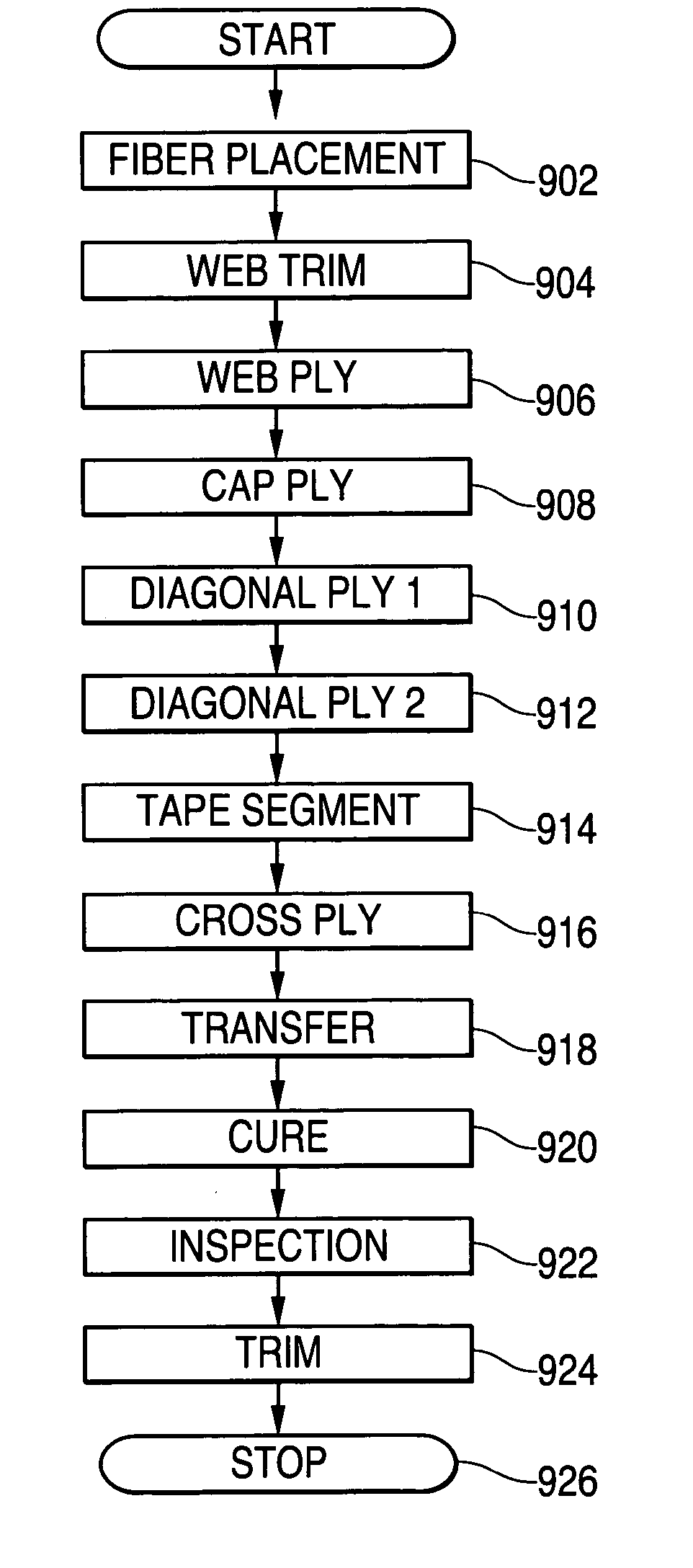

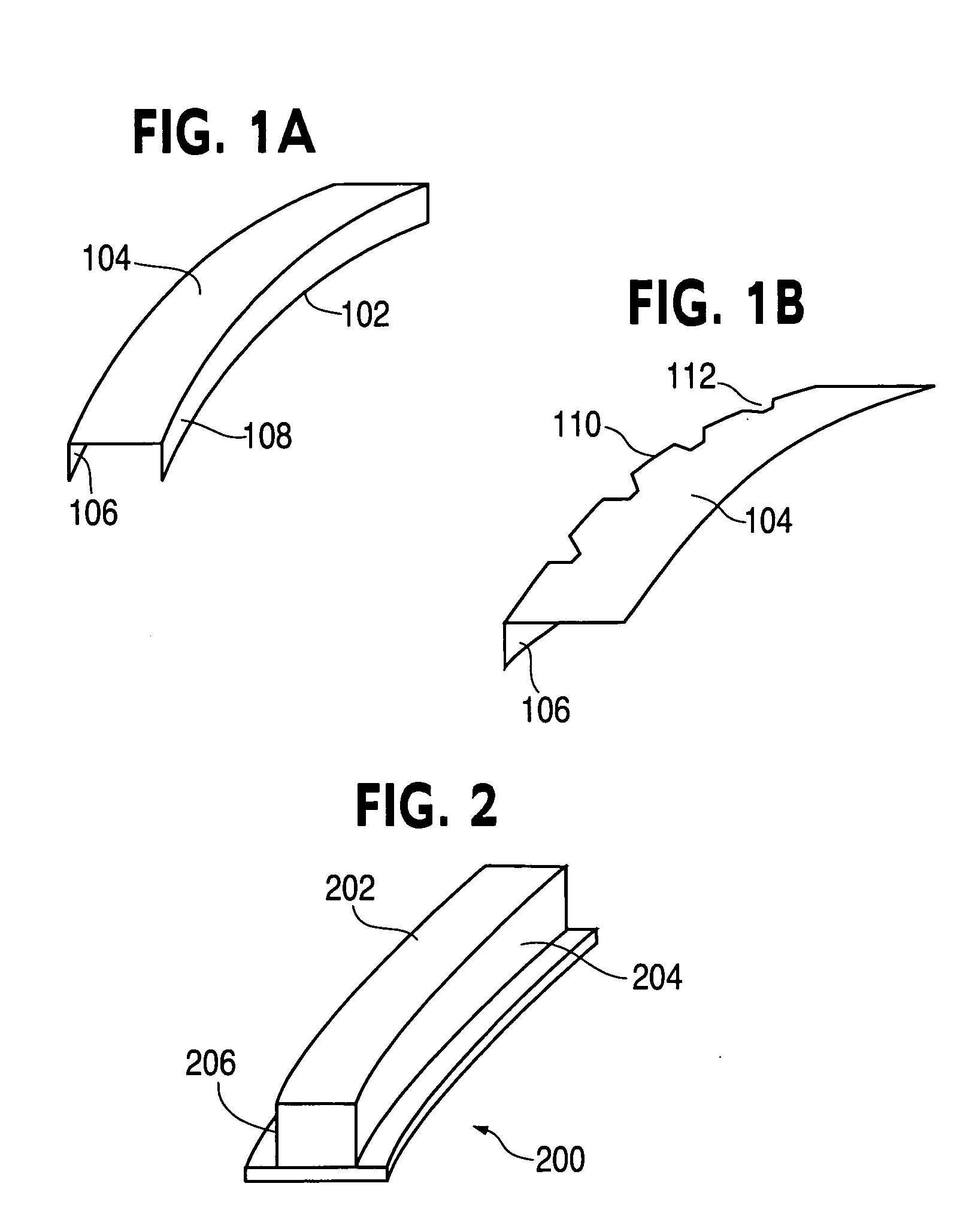

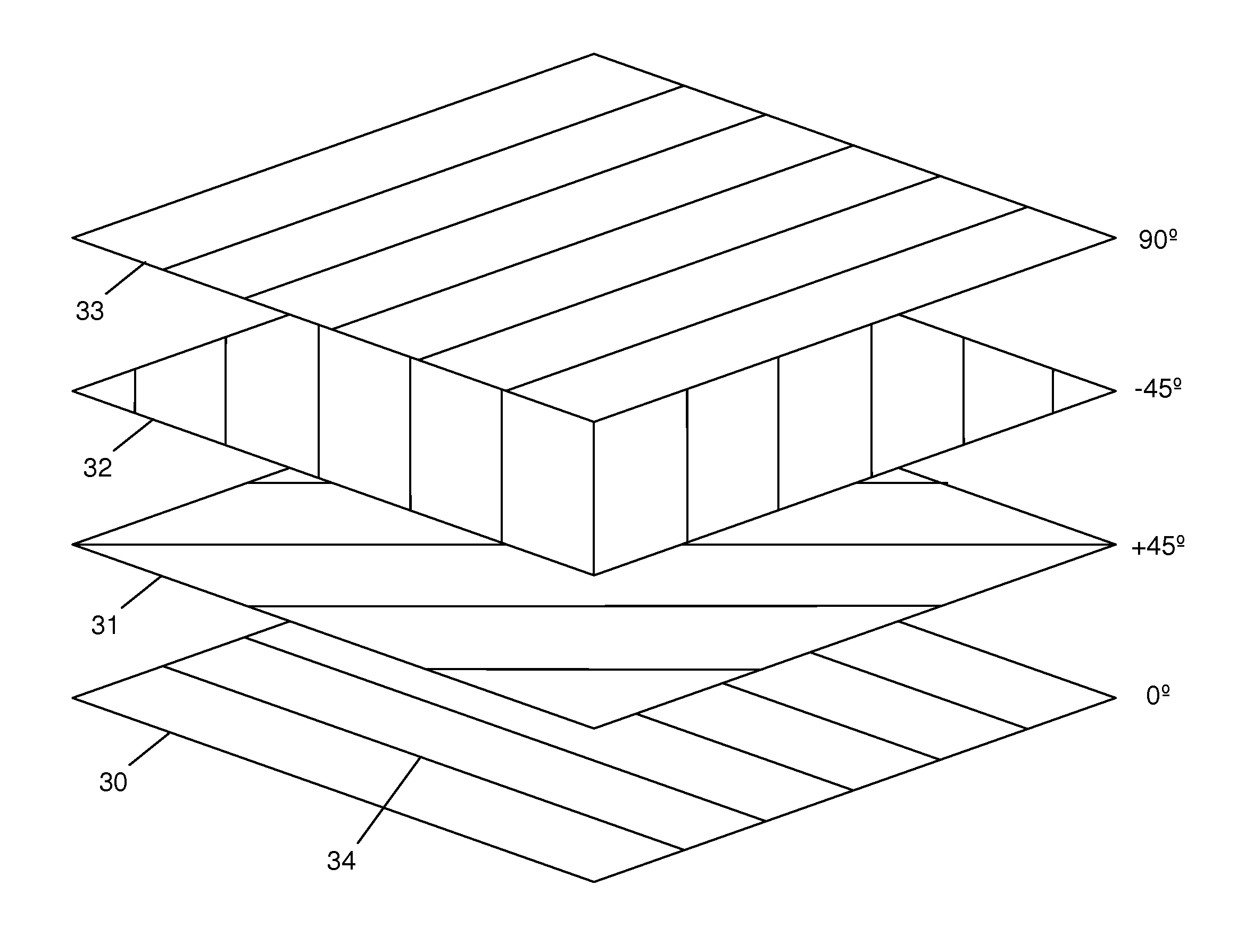

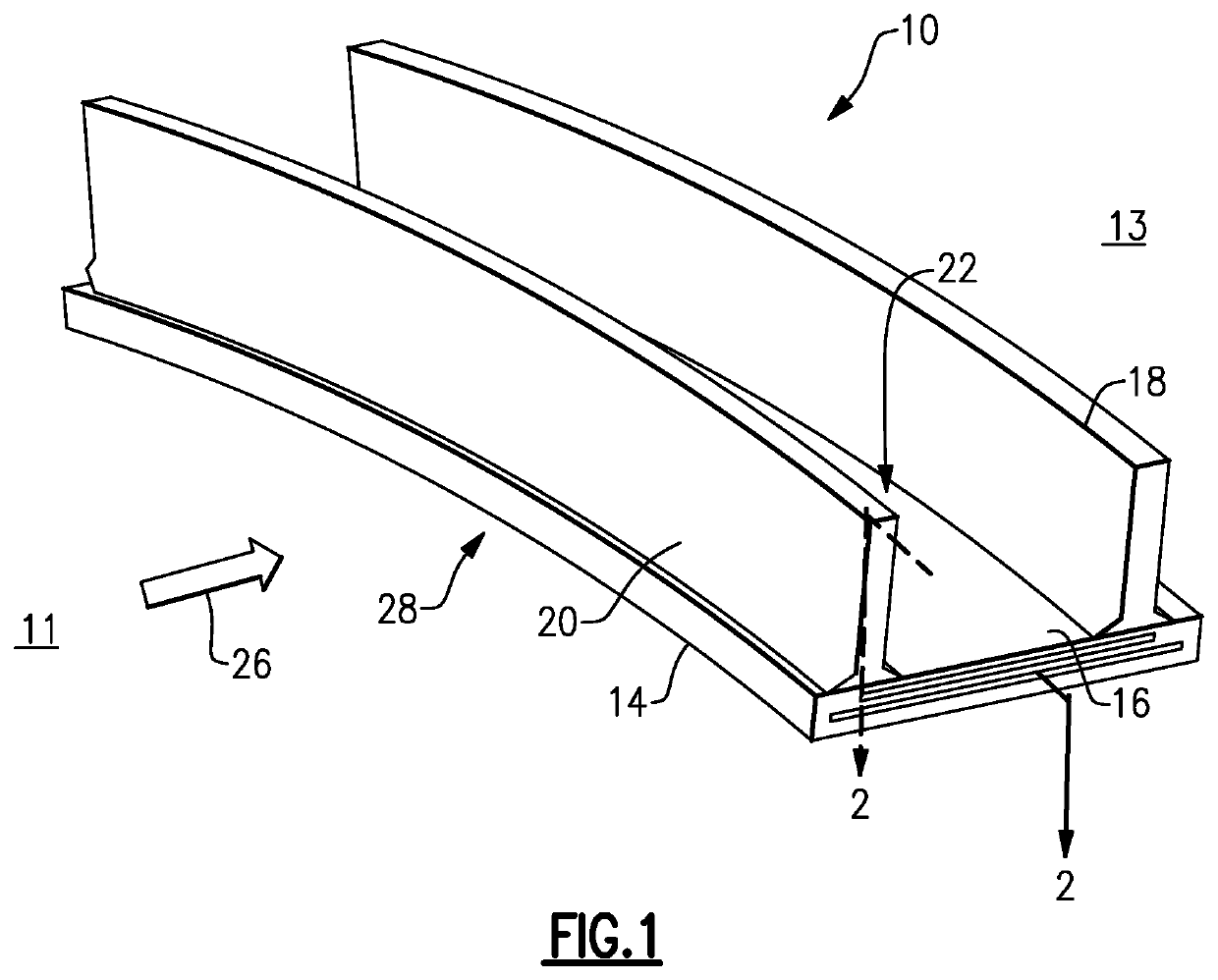

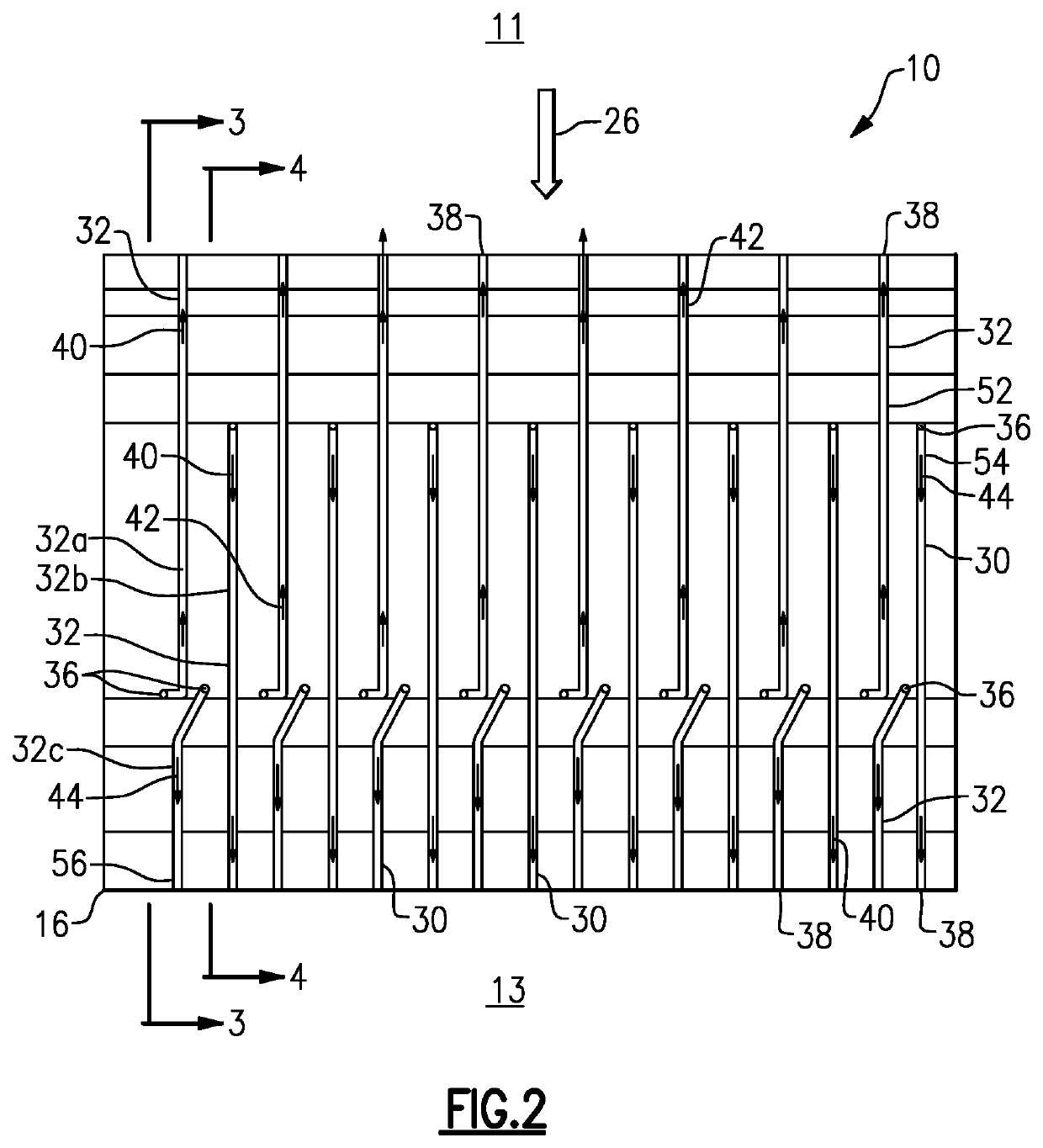

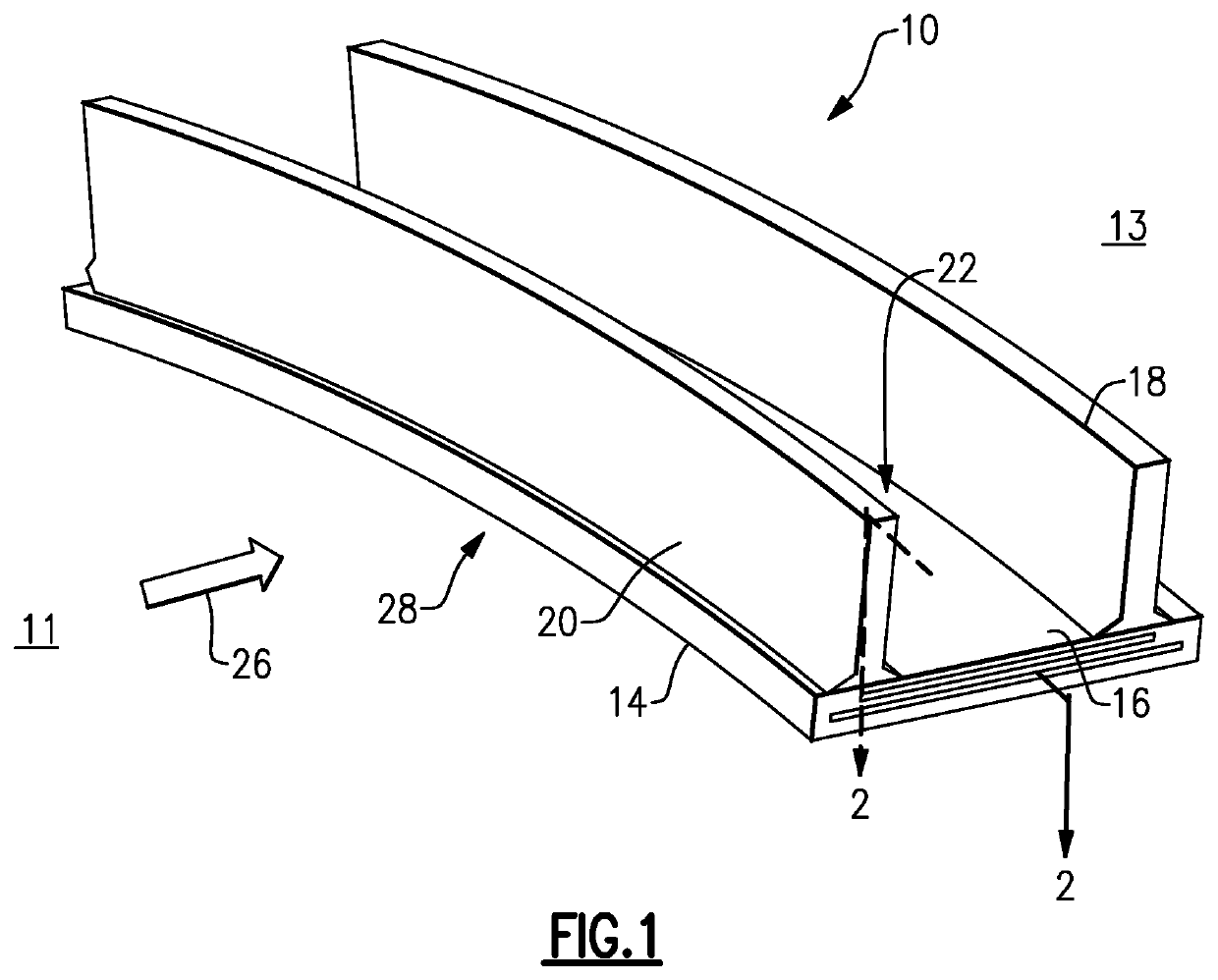

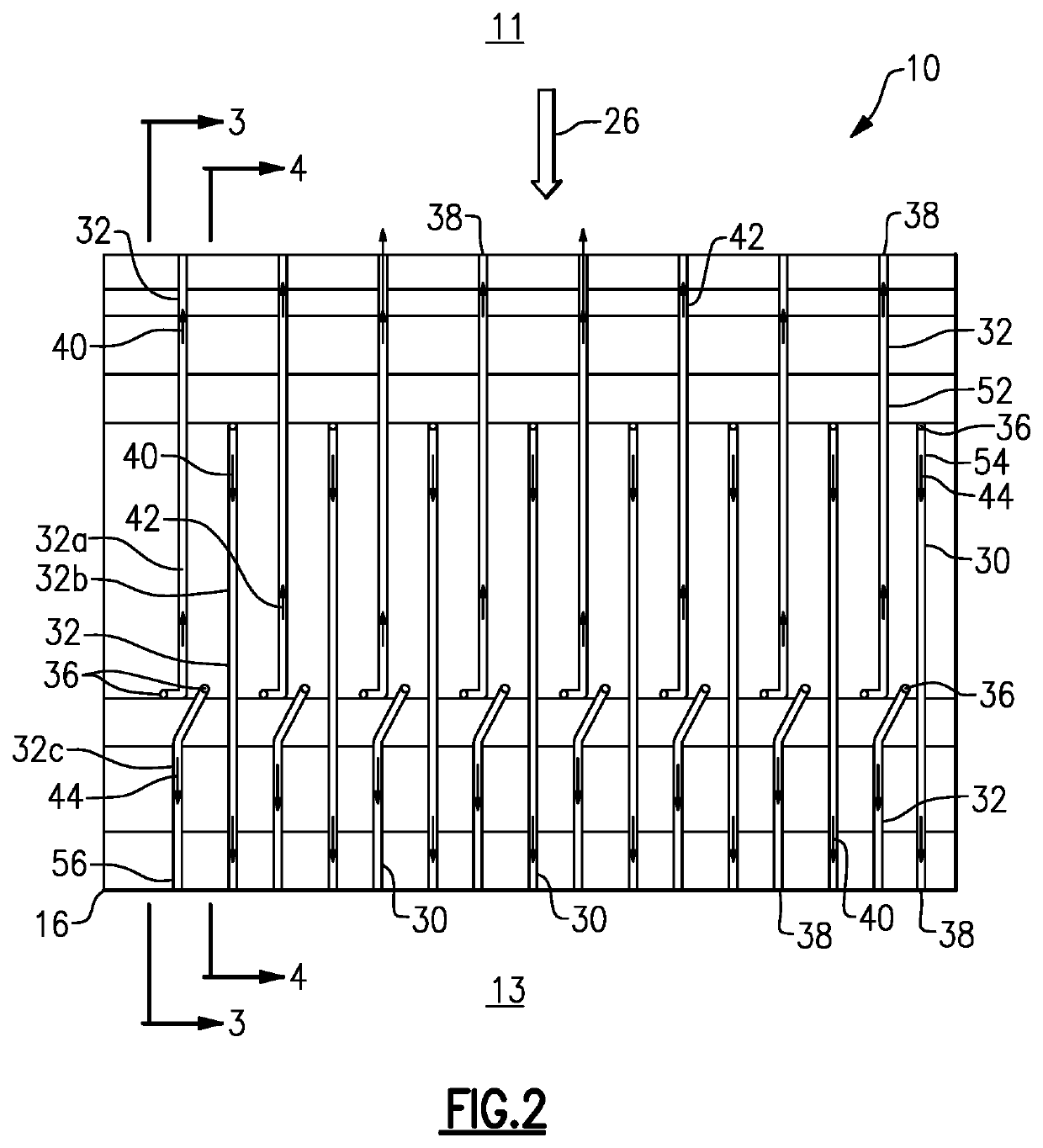

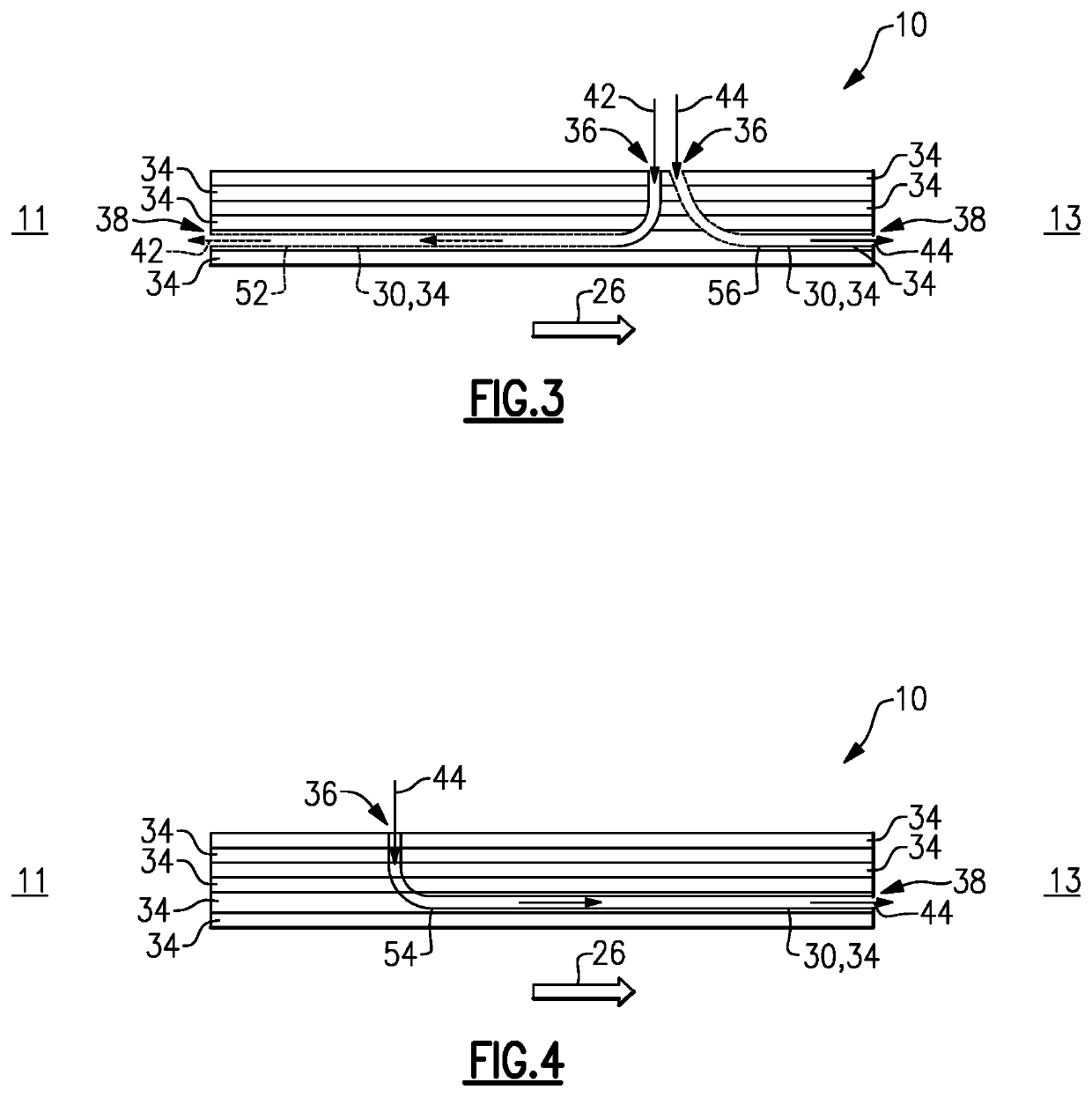

Method of manufacturing curved composite structural elements

A method of manufacturing curved composite structural elements can include fabricating a web ply in a flat curve over a removable substrate and laying up the ply on a curved web surface of a manufacturing tool. The method also can include laying up a diagonal ply with fibers oriented at + / −45° from the centerline of the web surface. The method further can include cutting a unidirectional composite tape into segments and laying up the tape segments to form a cross ply with a fiber orientation normal to the centerline of the web surface. One or both edges of the diagonal and cross plies may be folded over one or two sides of the manufacturing tool to form one or two flange surfaces. Additionally, a cap ply can be laid up on one or both flange surfaces using composite tape. The structural element layup can then be inspected and any excess composite material can be trimmed away.

Owner:THE BOEING CO

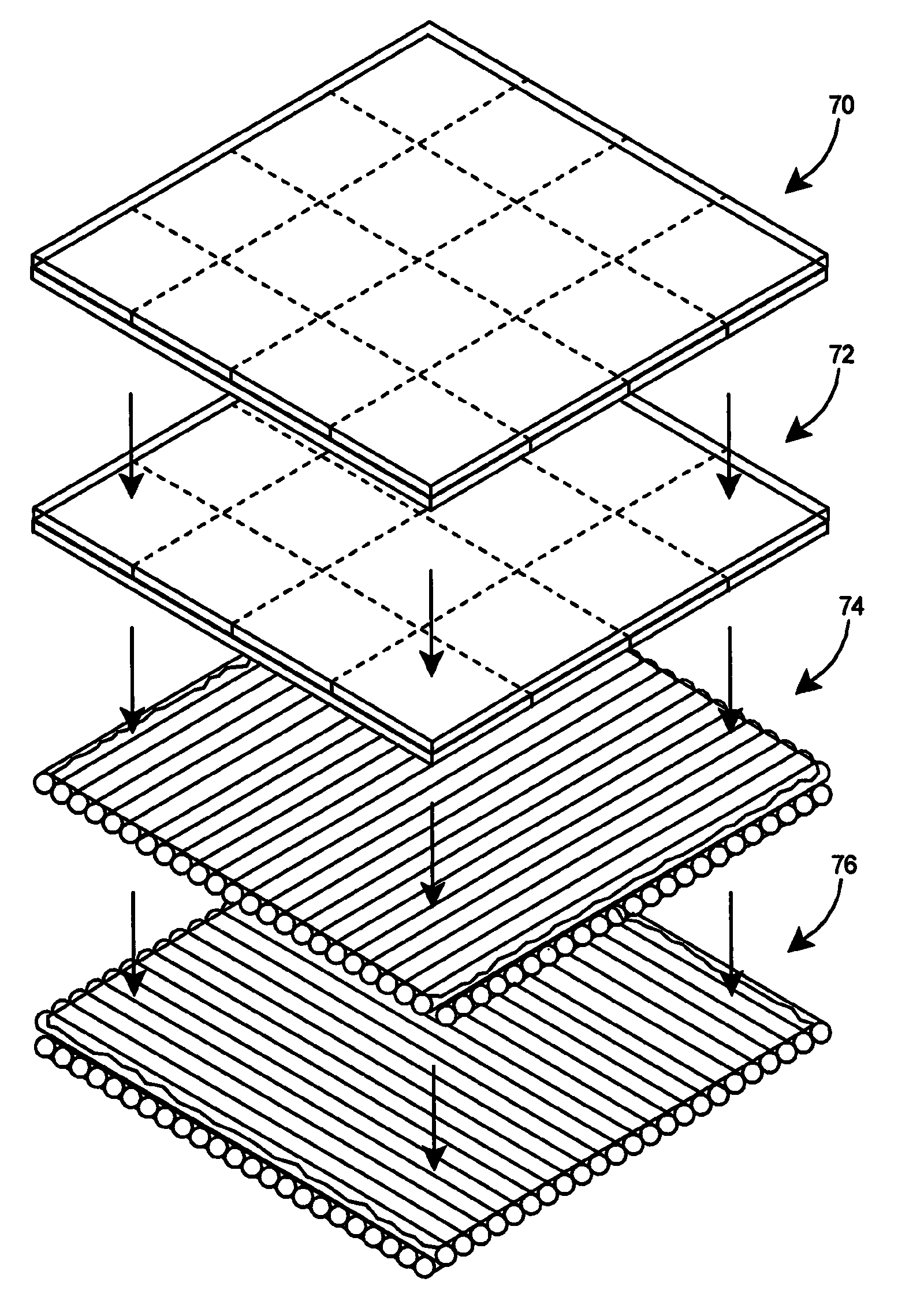

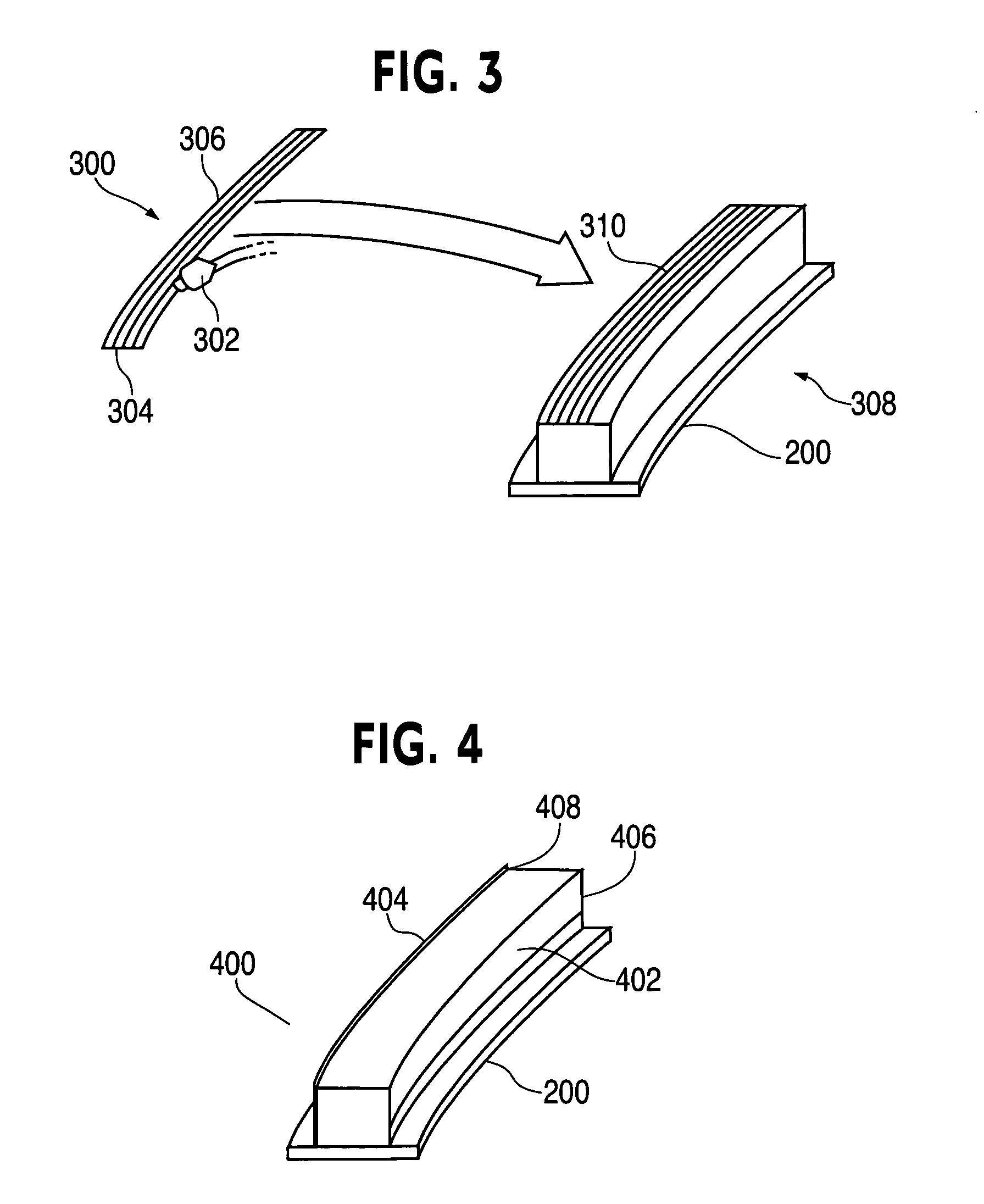

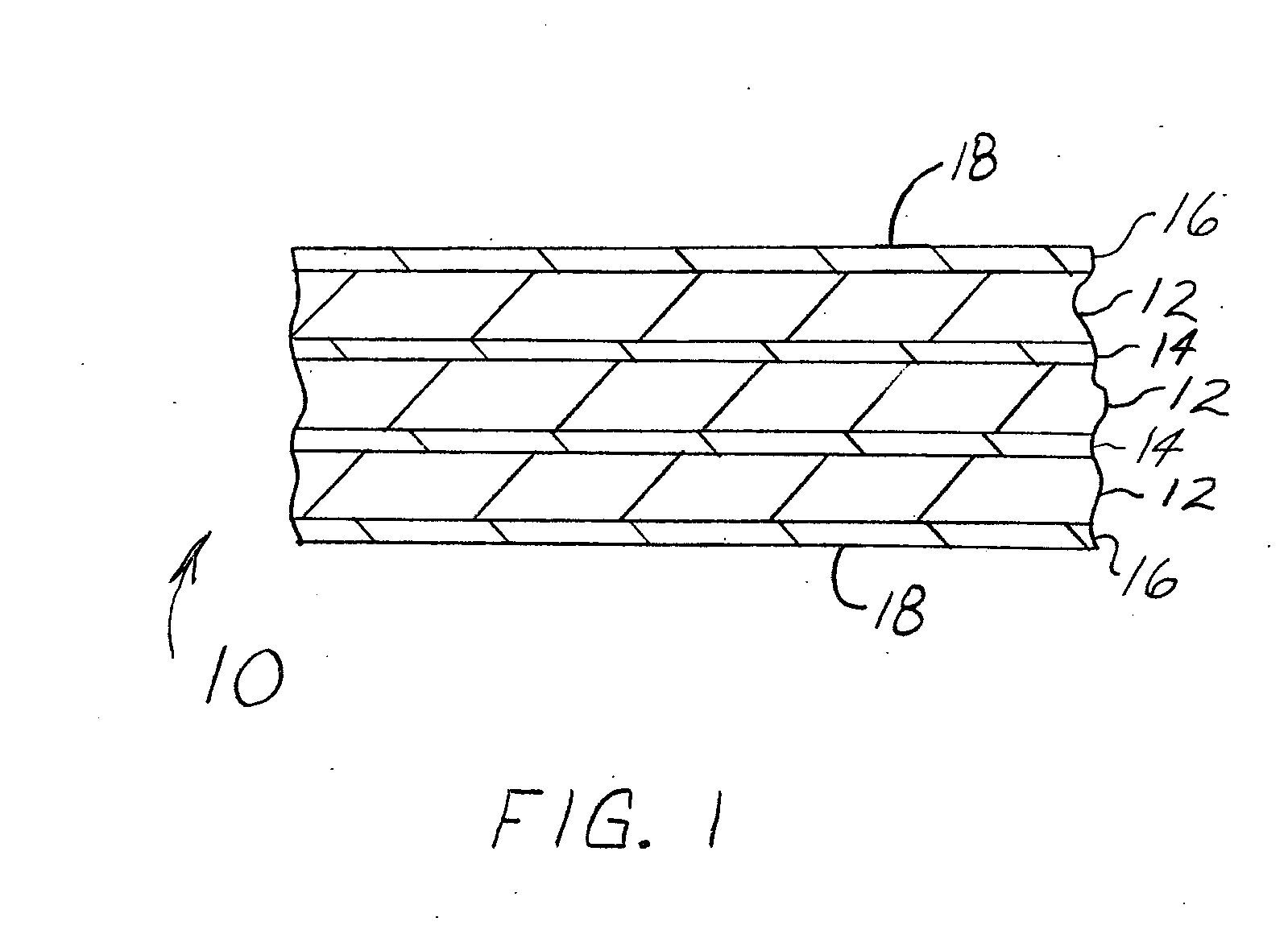

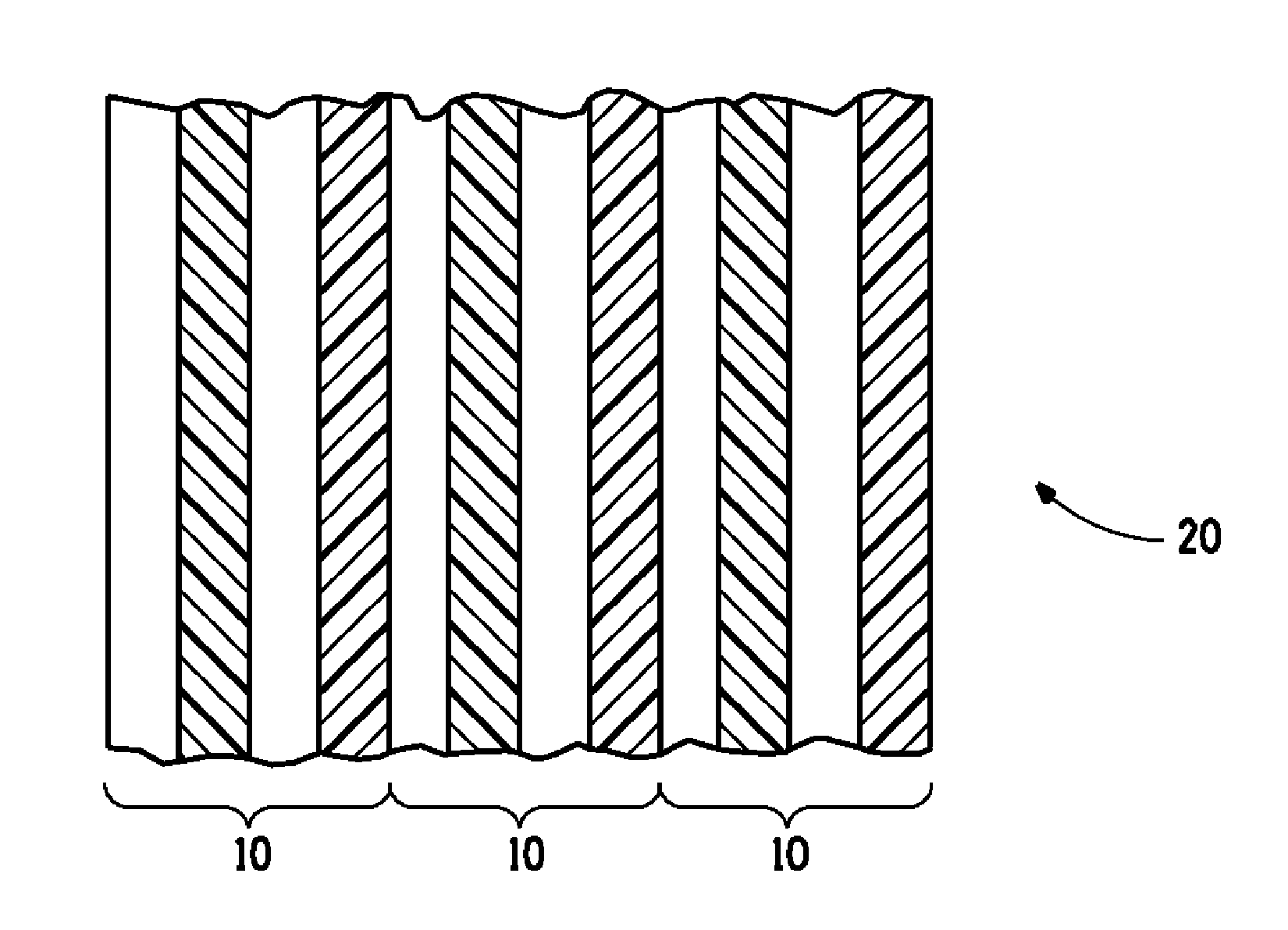

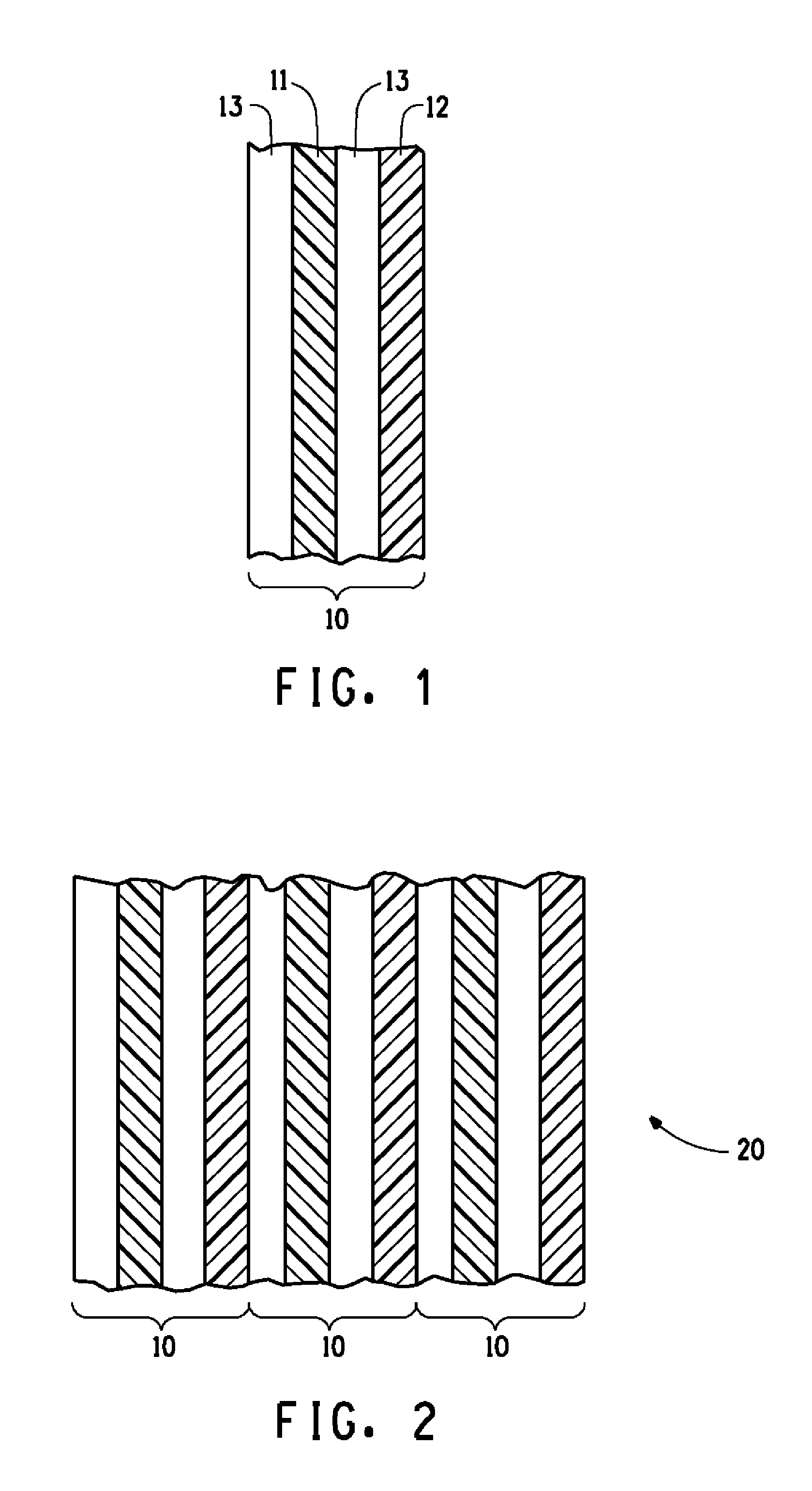

Multilayered polyethylene material and ballistic resistant articles manufactured therefrom

The present invention relates to polyethylene material that has a plurality of unidirectionally oriented polyethylene monolayers cross-plied and compressed at an angle to one another, each polyethylene monolayer composed of ultra high molecular weight polyethylene and essentially devoid of resins. The present invention further relates to ballistic resistant articles that include or incorporate the inventive polyethylene material and to methods of preparing the material and articles incorporating same.

Owner:AVIENT PROTECTIVE MATERIALS BV

Multilayered polyethylene material and ballistic resistant articles manufactured therefrom

InactiveUS7993715B2ArmourPedestrian/occupant safety arrangementPolymer scienceUltra-high-molecular-weight polyethylene

The present invention relates to polyethylene material that has a plurality of unidirectionally oriented polyethylene monolayers cross-plied and compressed at an angle to one another, each polyethylene monolayer composed of ultra high molecular weight polyethylene and essentially devoid of resins. The present invention further relates to ballistic resistant articles that include or incorporate the inventive polyethylene material and to methods of preparing the material and articles incorporating same.

Owner:AVIENT PROTECTIVE MATERIALS BV

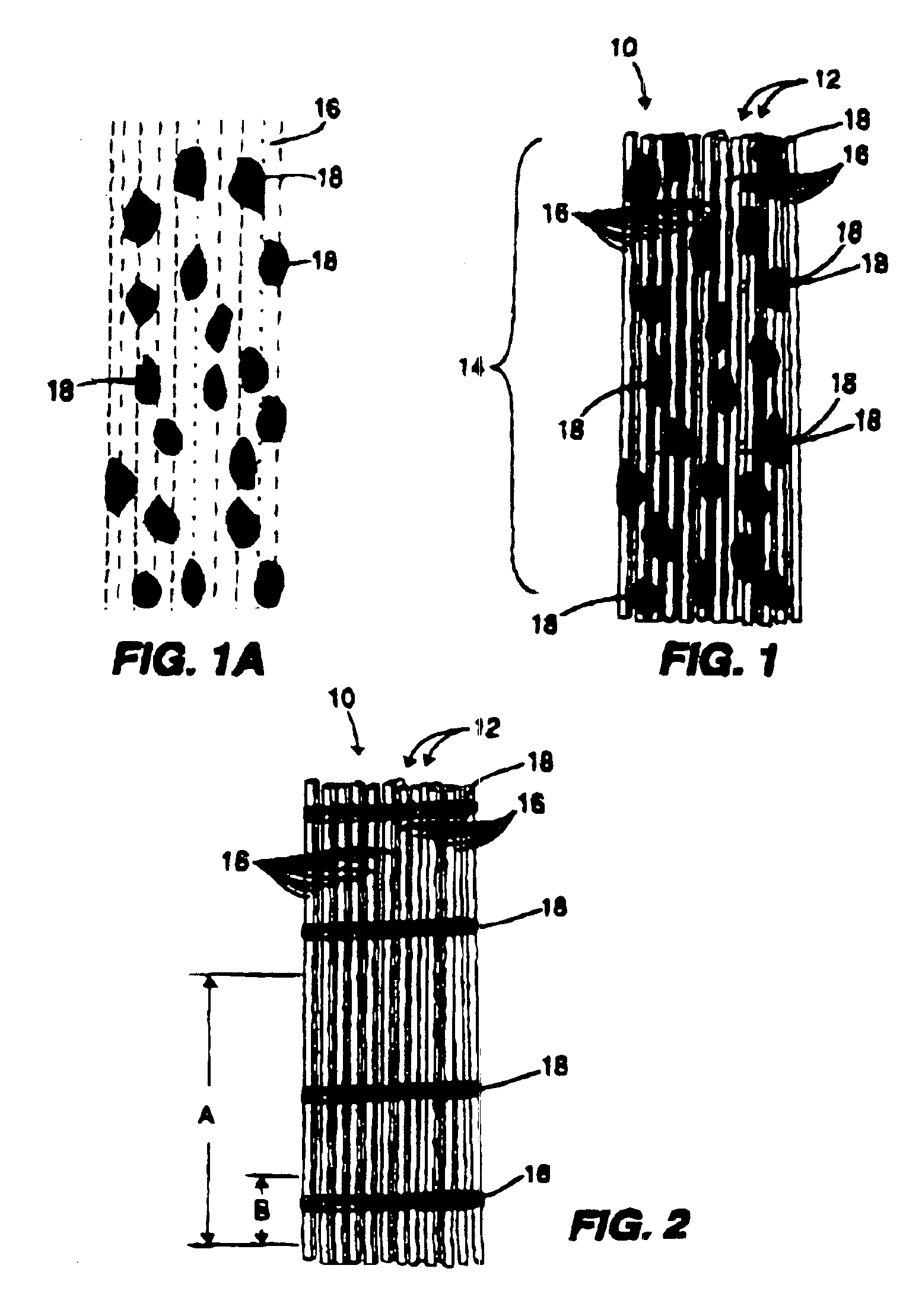

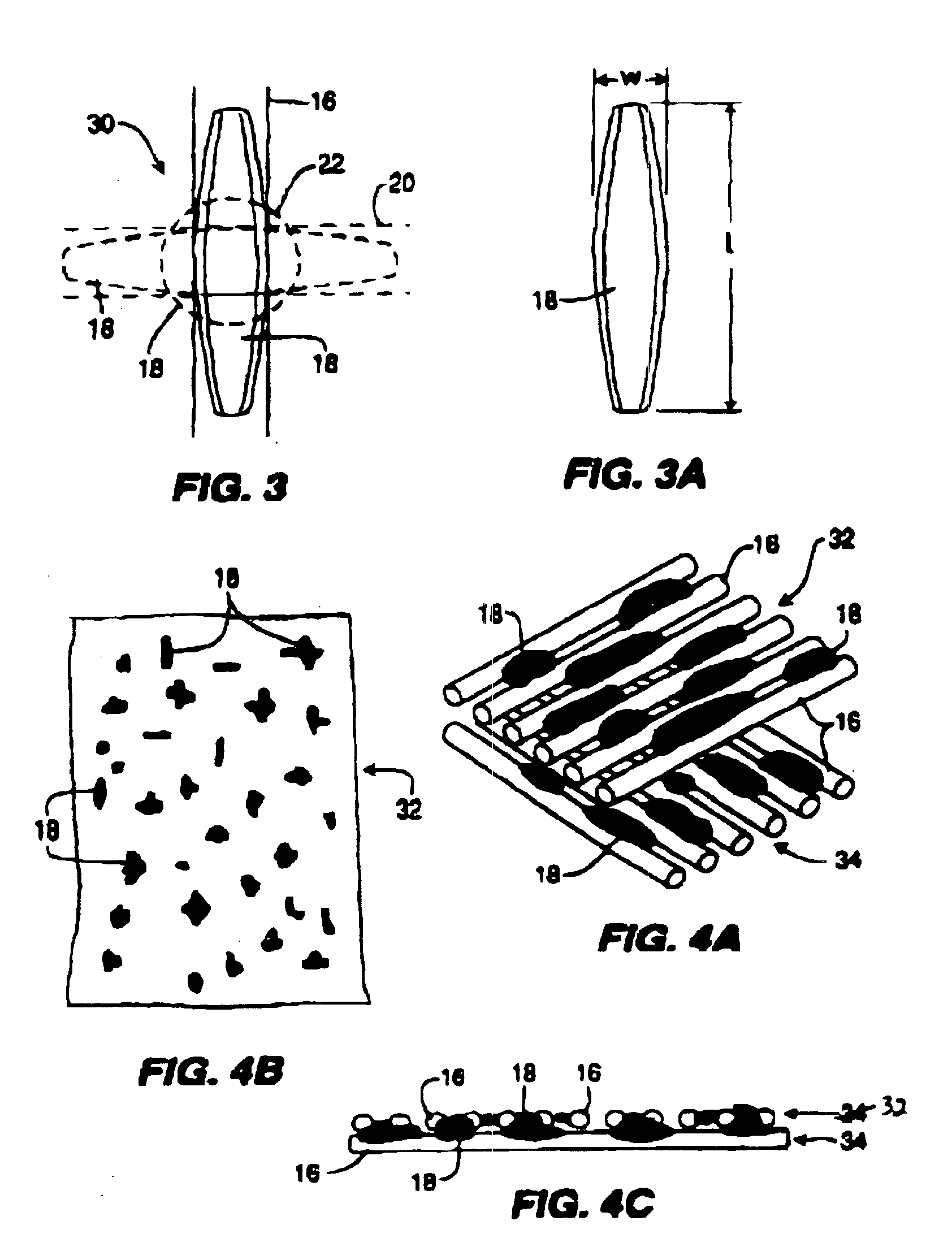

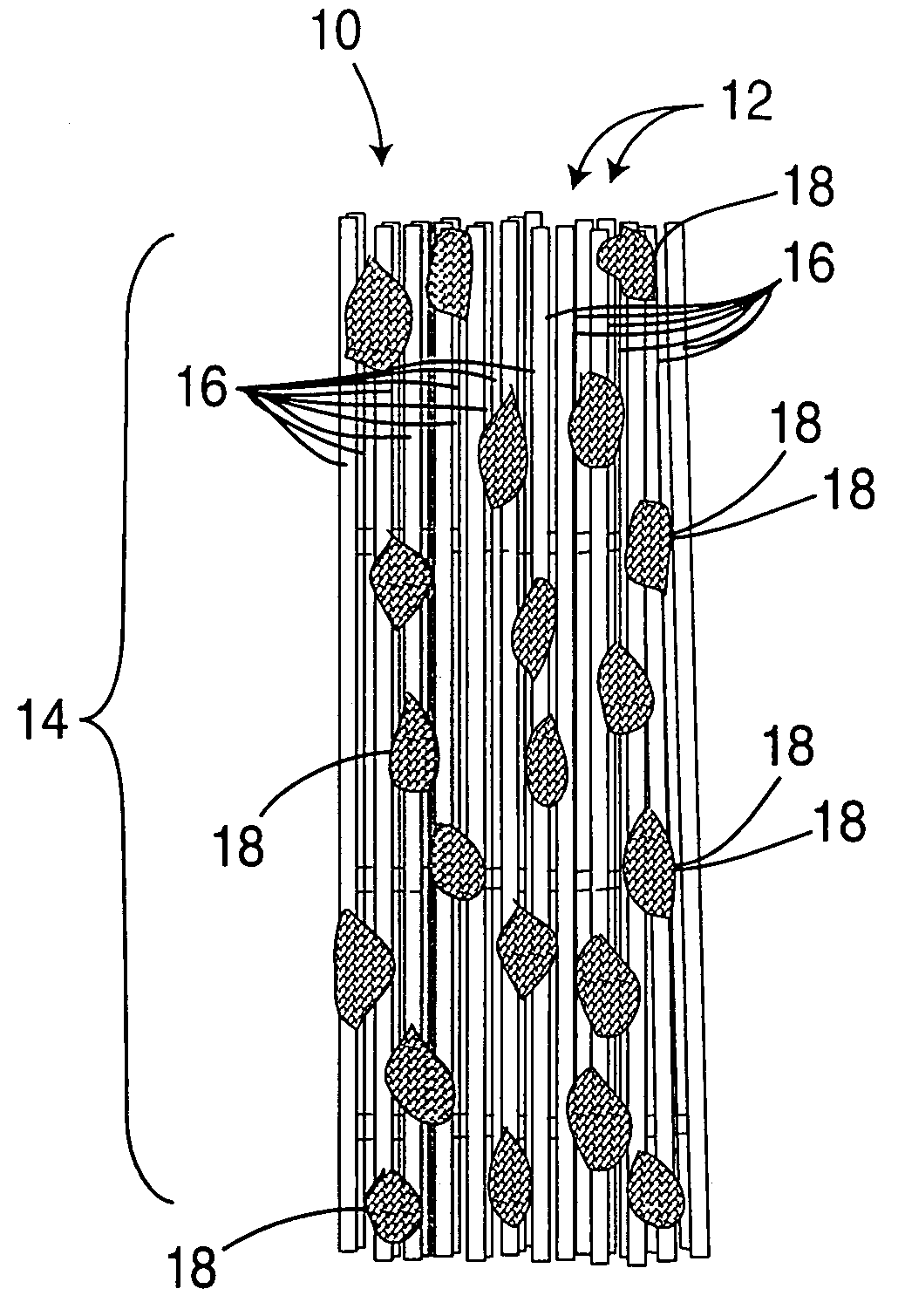

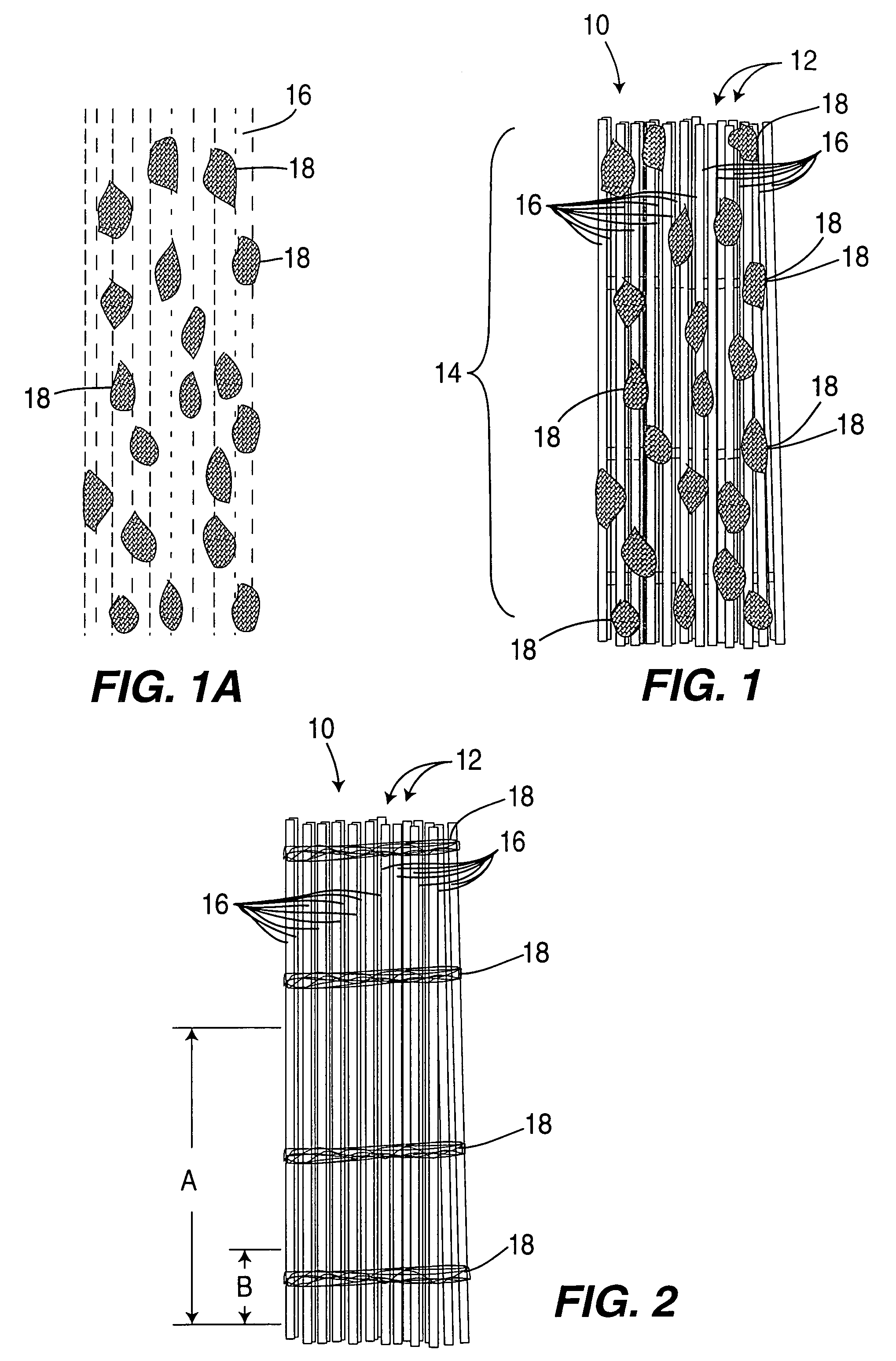

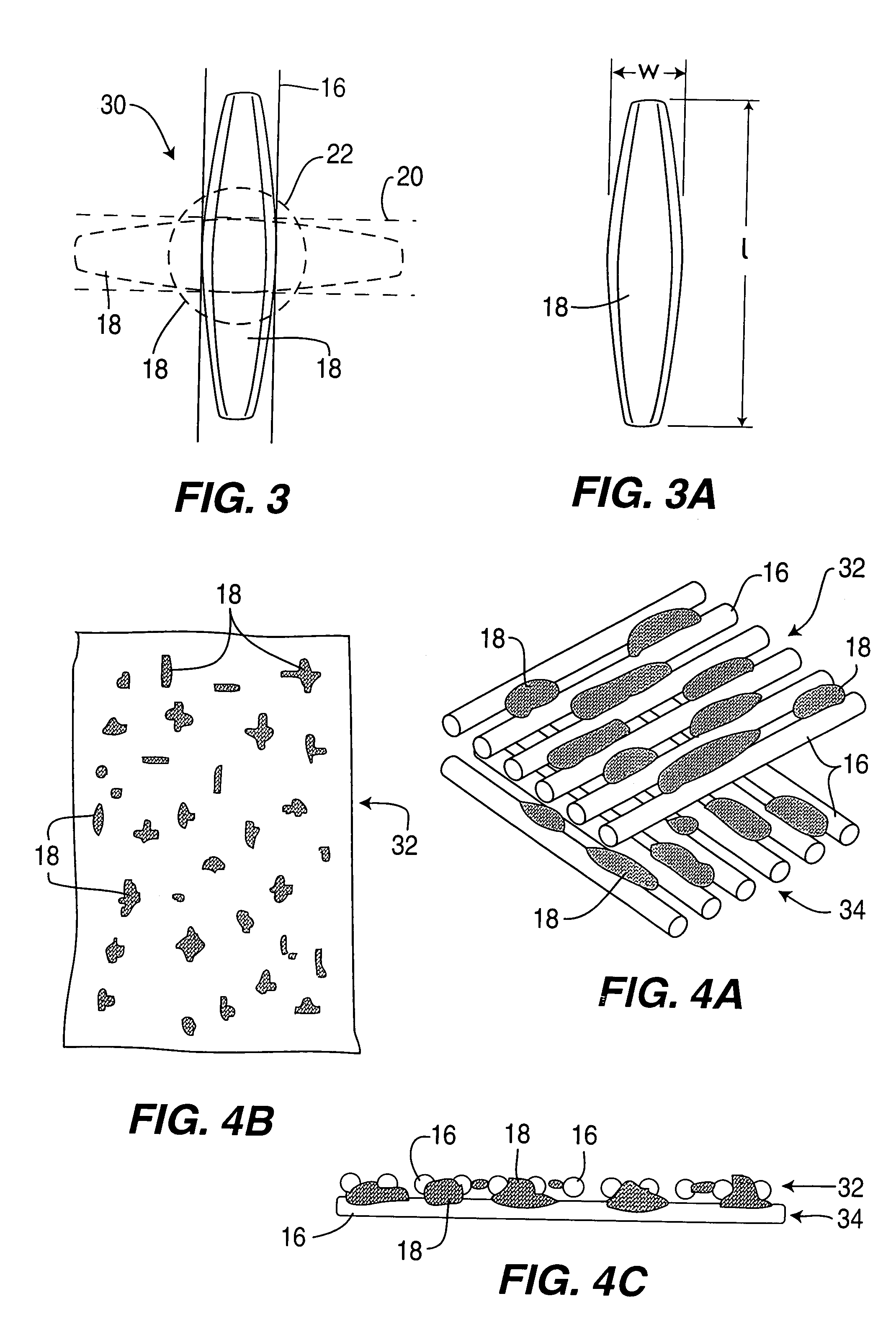

Flexible fabric from fibrous web and discontinuous domain matrix

InactiveUS6846548B2Increase the volume ratioBallistically efficientSynthetic resin layered productsAnimal housingPliabilityEngineering

A composite having a plurality of filaments arranged in a fibrous web that is held together in a unitary structure by a domain matrix. The domain matrix comprises a plurality of matrix islands that individually connect, or bond, at least two filaments, to thereby hold the filaments in a unitary structure. Portions of the filament lengths within the unitary structure are free of matrix islands, causing the domain matrix to be discontinuous. The composite possesses a greater flexibility than coated structures. The composite may be formed into cross-plied structures. A method of making the composite also is disclosed.

Owner:HONEYWELL INT INC

Flexible fabric from fibrous web and discontinuous domain matrix

InactiveUS7211291B2Increase the volume ratioBallistically efficientSynthetic resin layered productsWoven fabricsPliabilityMechanical engineering

Owner:HONEYWELL INT INC

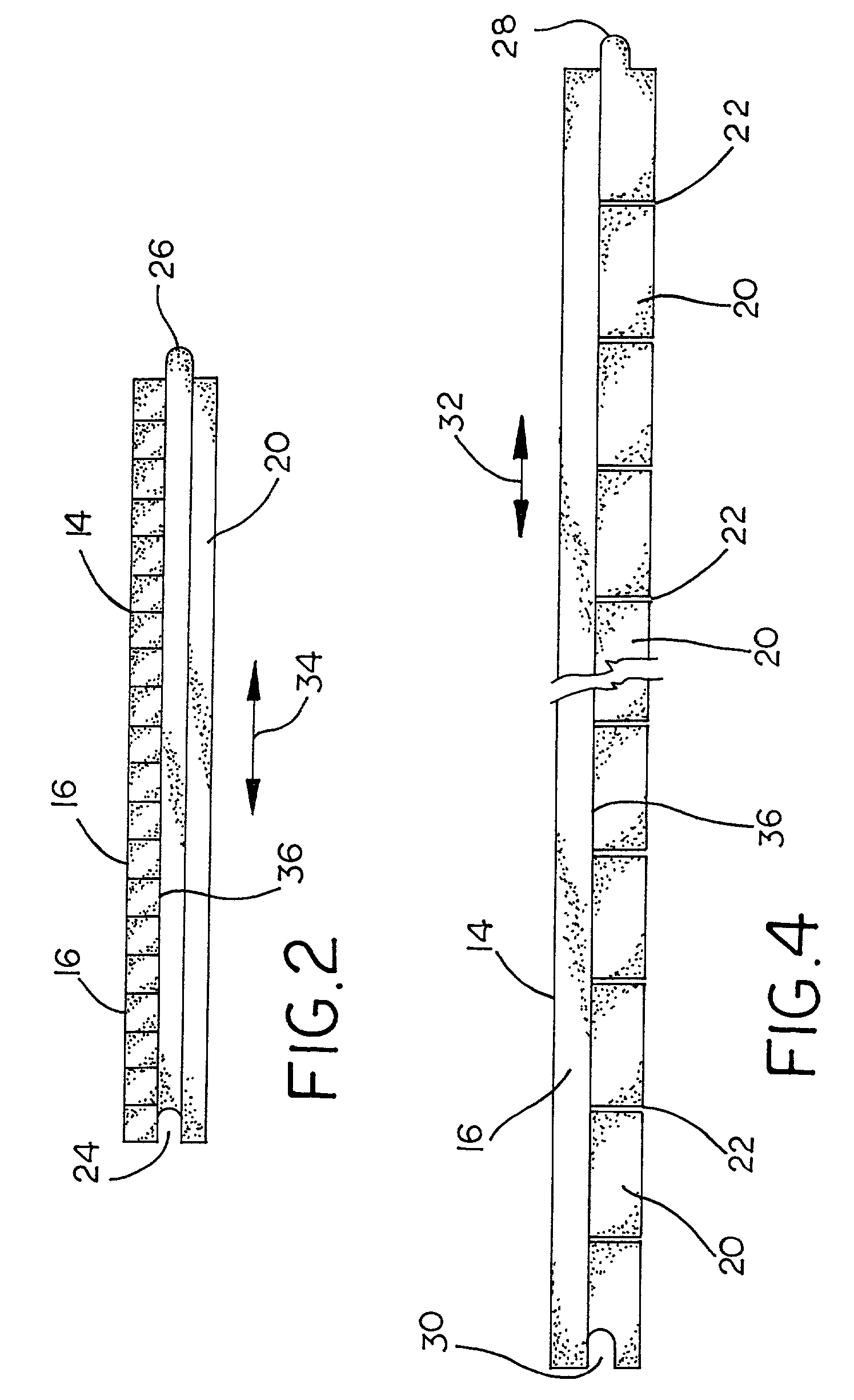

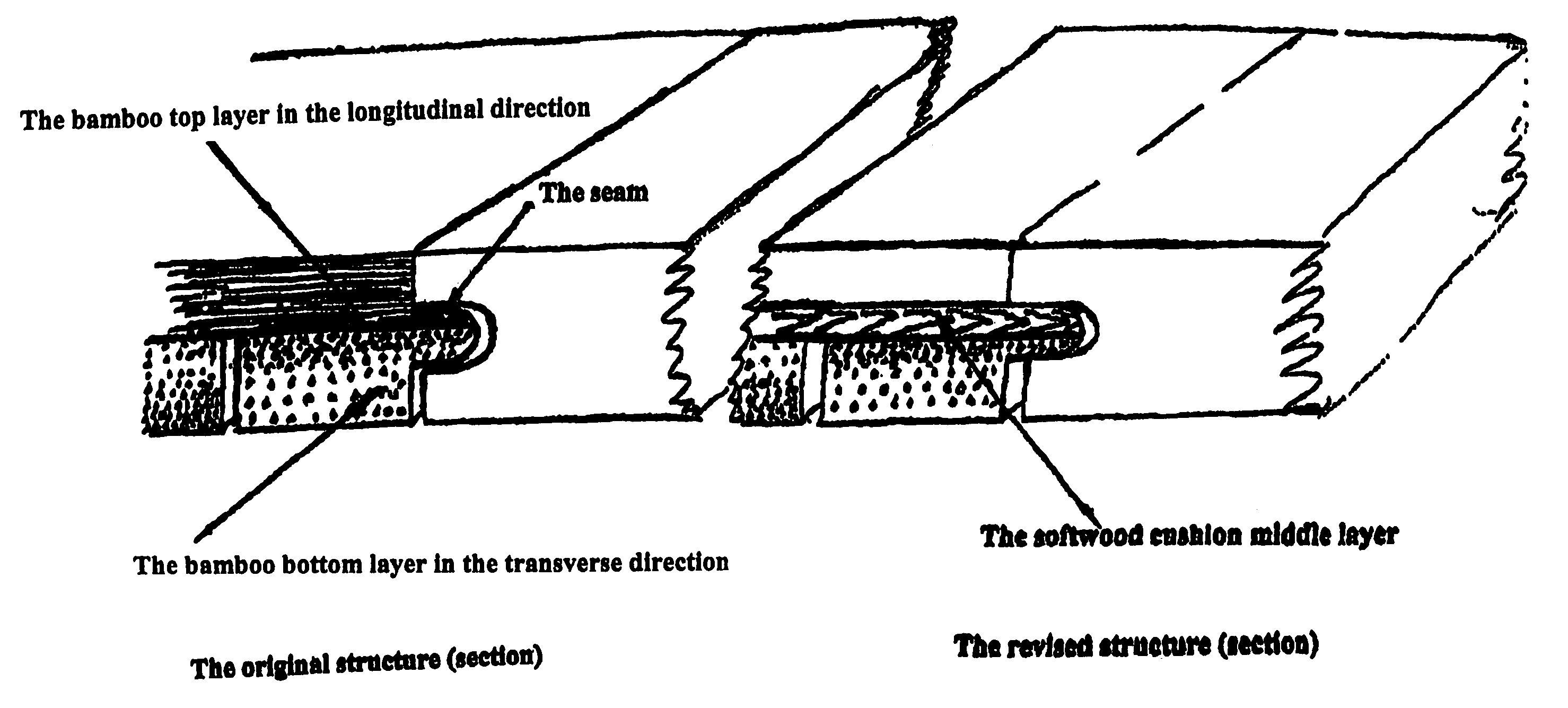

Two-ply flooring having a cross-grain bottom ply

A two-ply flooring plank is disclosed having two layers or “plies” with a bottom layer having a grain that runs generally transverse to a top layer (i.e., “cross-ply”) to provide dimensional stability to the plank. The bottom layer includes a number of strips secured to the bottom of the top layer. The bottom layer strips are also placed with gaps between the individual strips of the second layer to allow flexibility of the flooring plank, which allows the flooring to more easily conform to irregularities in a subfloor upon which the flooring plank is mounted.

Owner:DASSO INDASTRIAL GRUP KO LTD +1

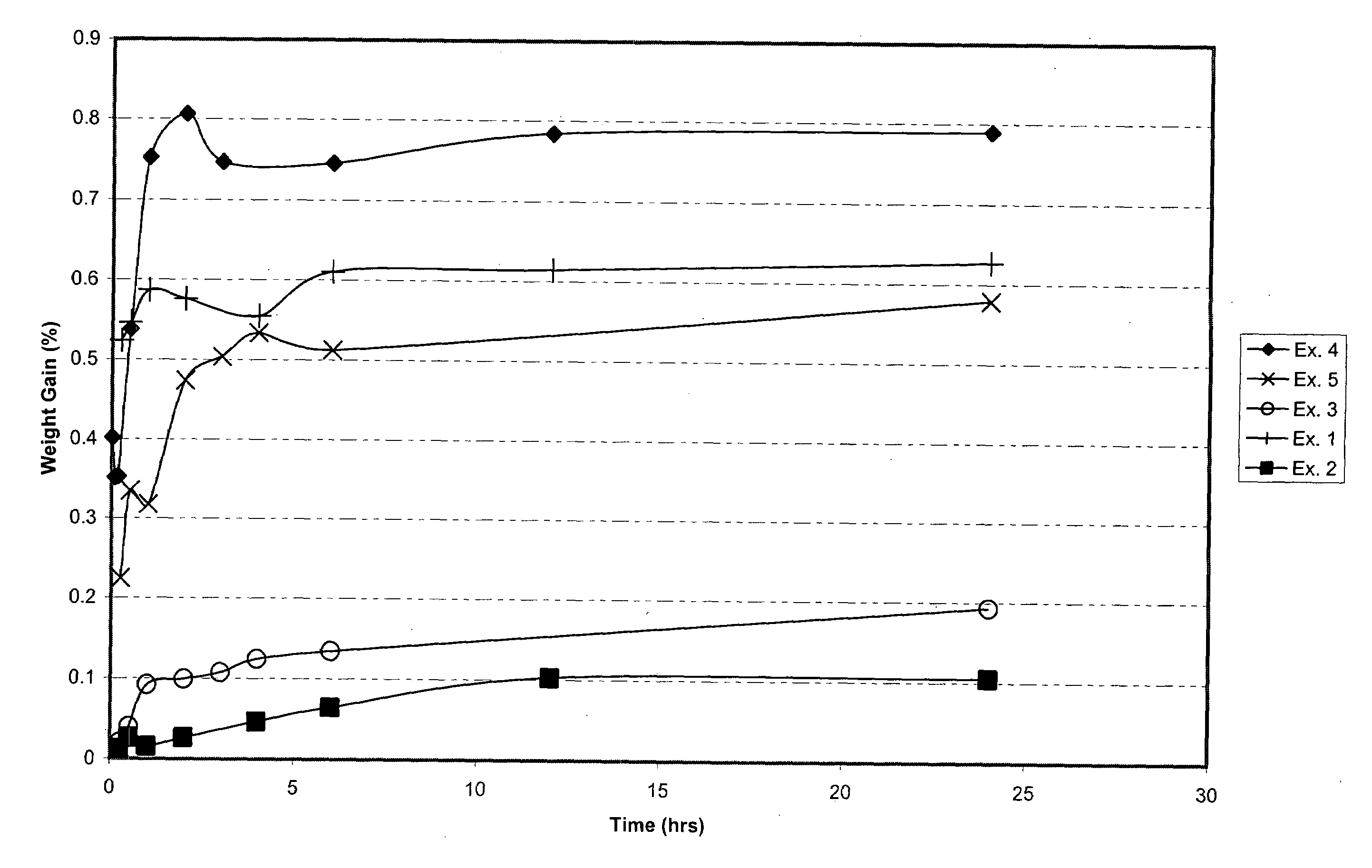

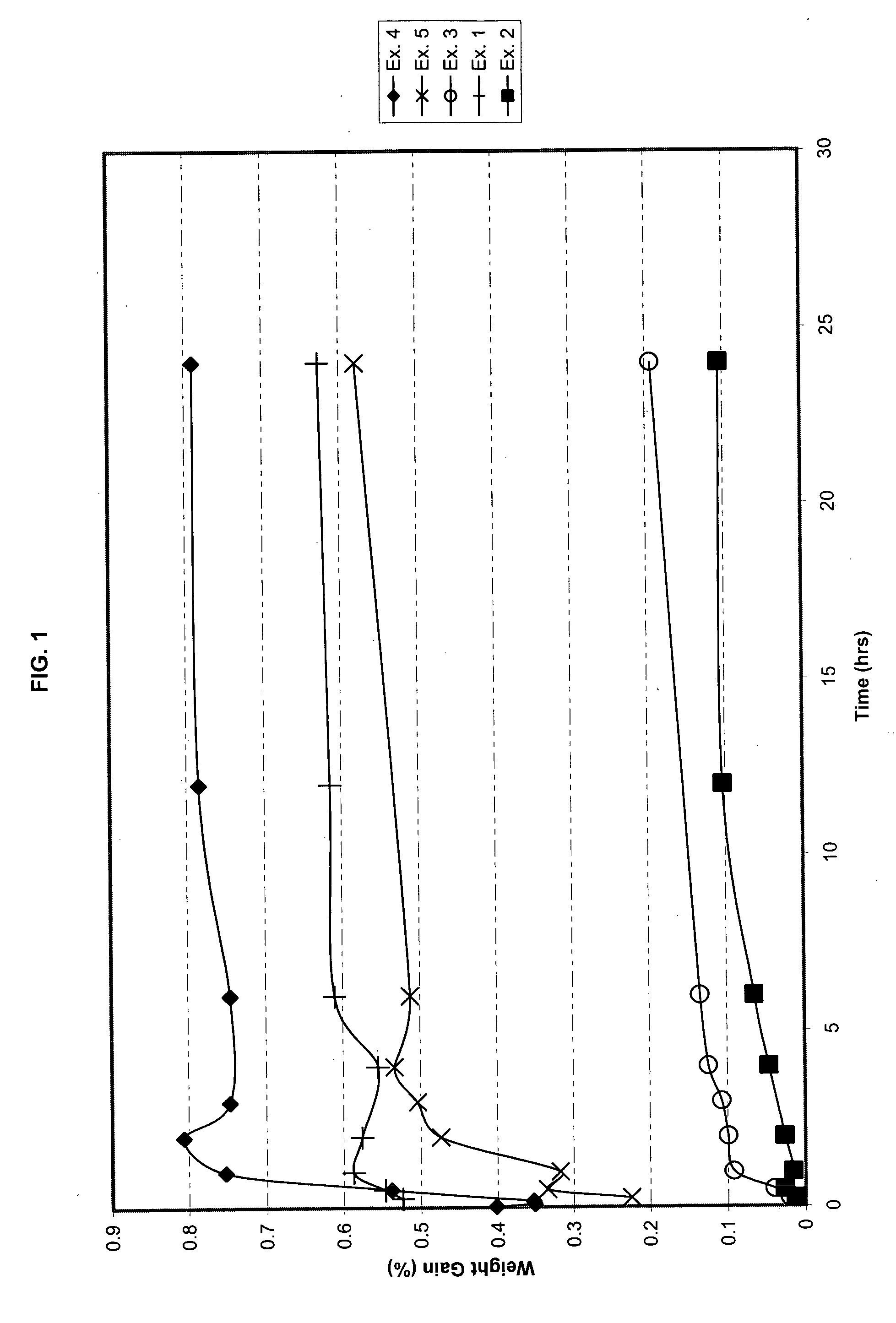

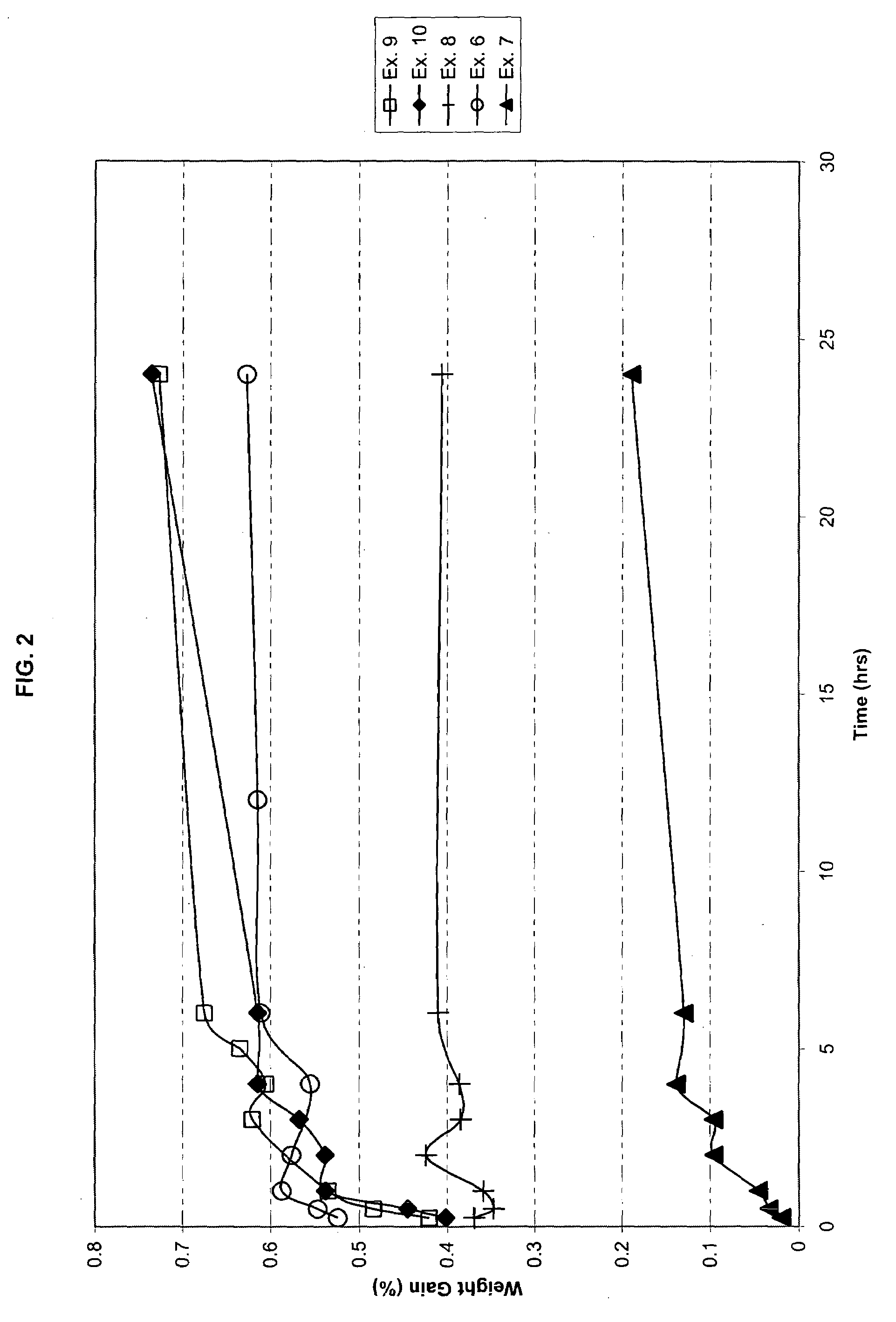

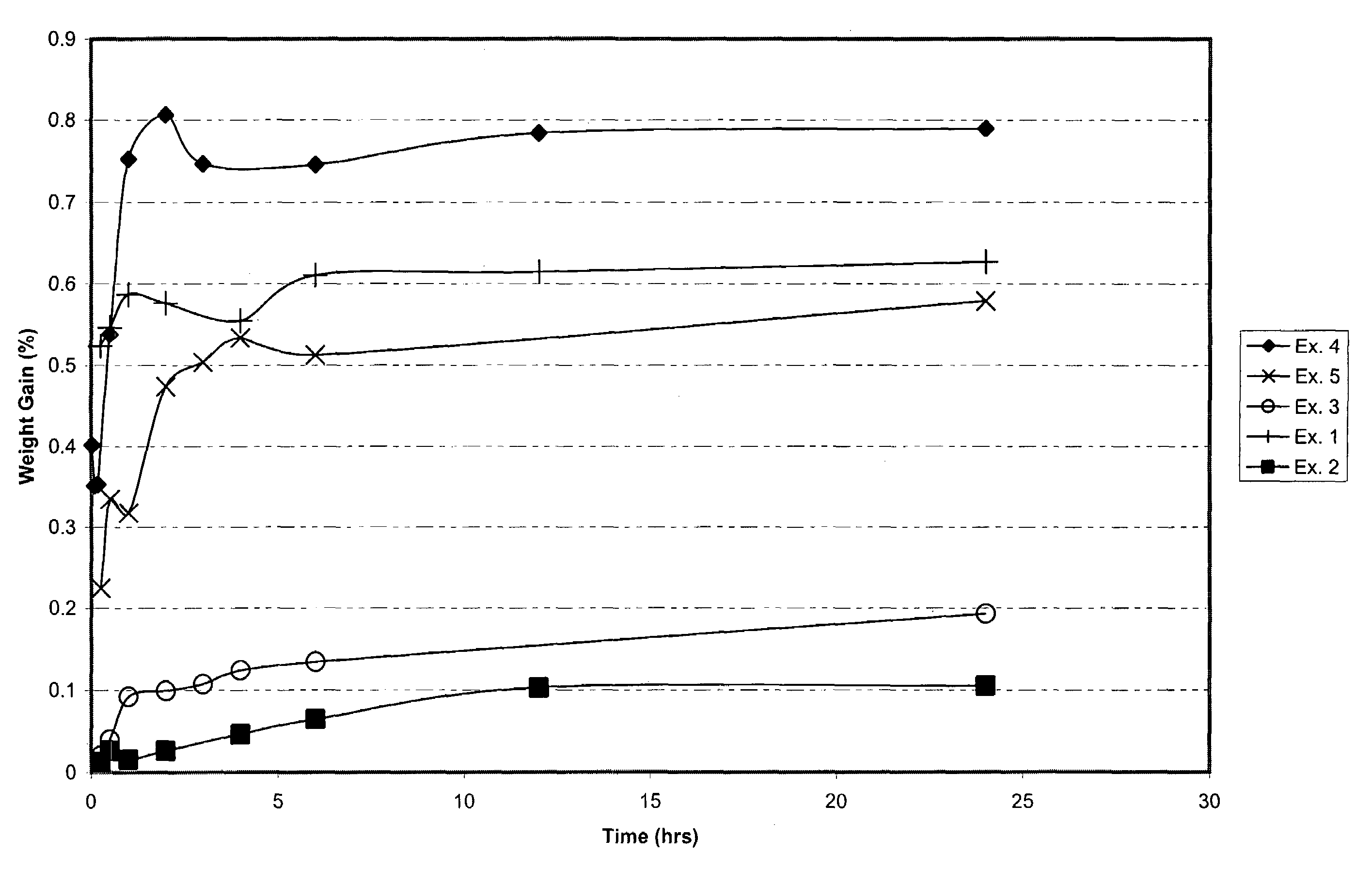

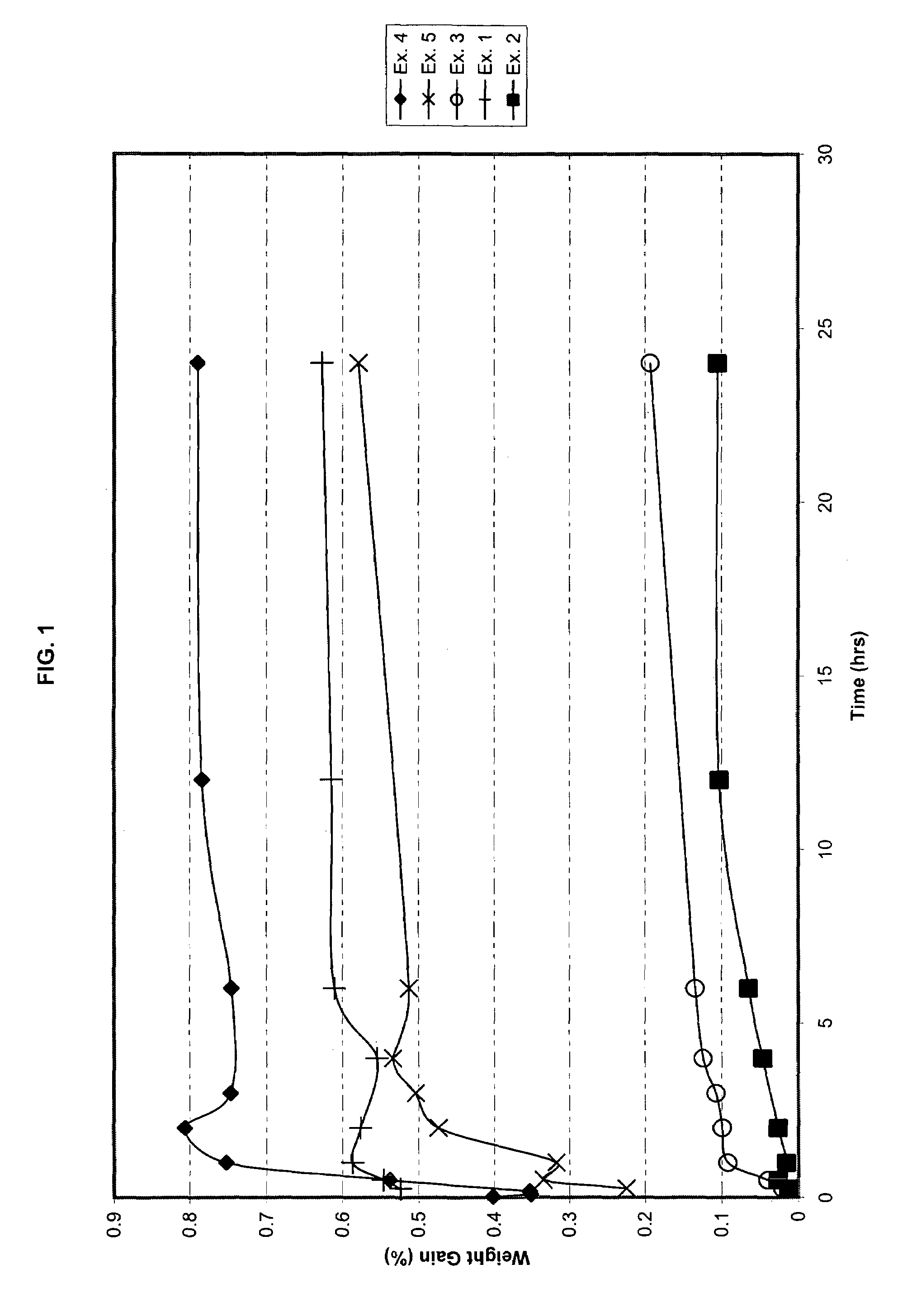

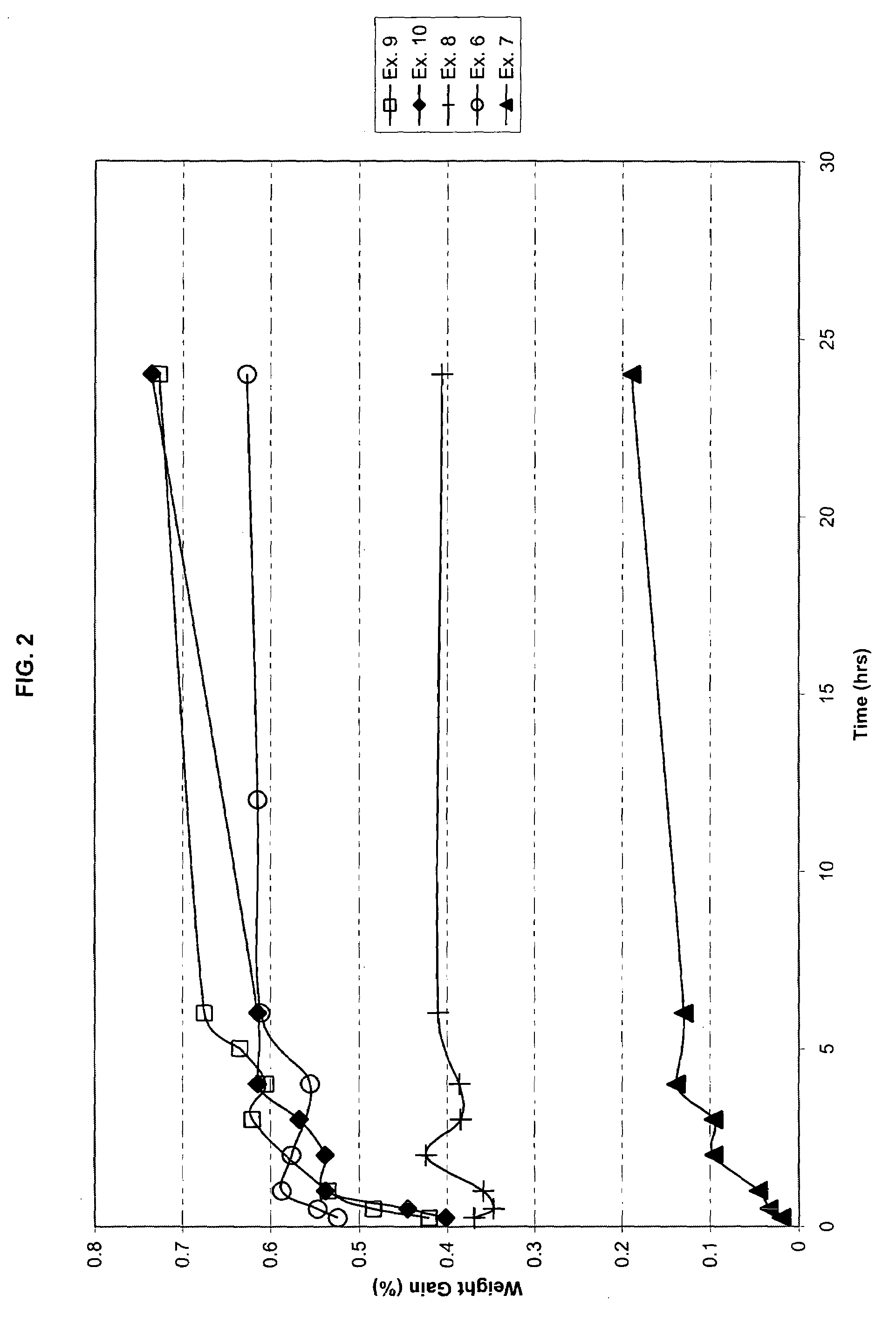

Flexible ballistic composites resistant to liquid pick-up method for manufacture and articles made therefrom

InactiveUS20090025111A1Improved resistance to liquid pick-upImprove the immunityProtective equipmentSynthetic resin layered productsPolymer scienceAramides

Flexible ballistic resistant composite material that has improved resistance to pick-up of water and other liquids, the composite material comprising a plurality of non-woven fibrous layers. The fibrous layers are formed from a network of high tenacity fibers (aramid fibers, extended chain polyethylene fibers and / or rigid rod fibers). The fibers are embedded in a matrix of a thermoplastic polyurethane resin. Preferably, at least two adjacent fiber layers are oriented in a cross-ply arrangement with respect to each other. Flexible armor, such as body vests, are provided which are formed at least in part from the flexible composite material.

Owner:HONEYWELL INT INC

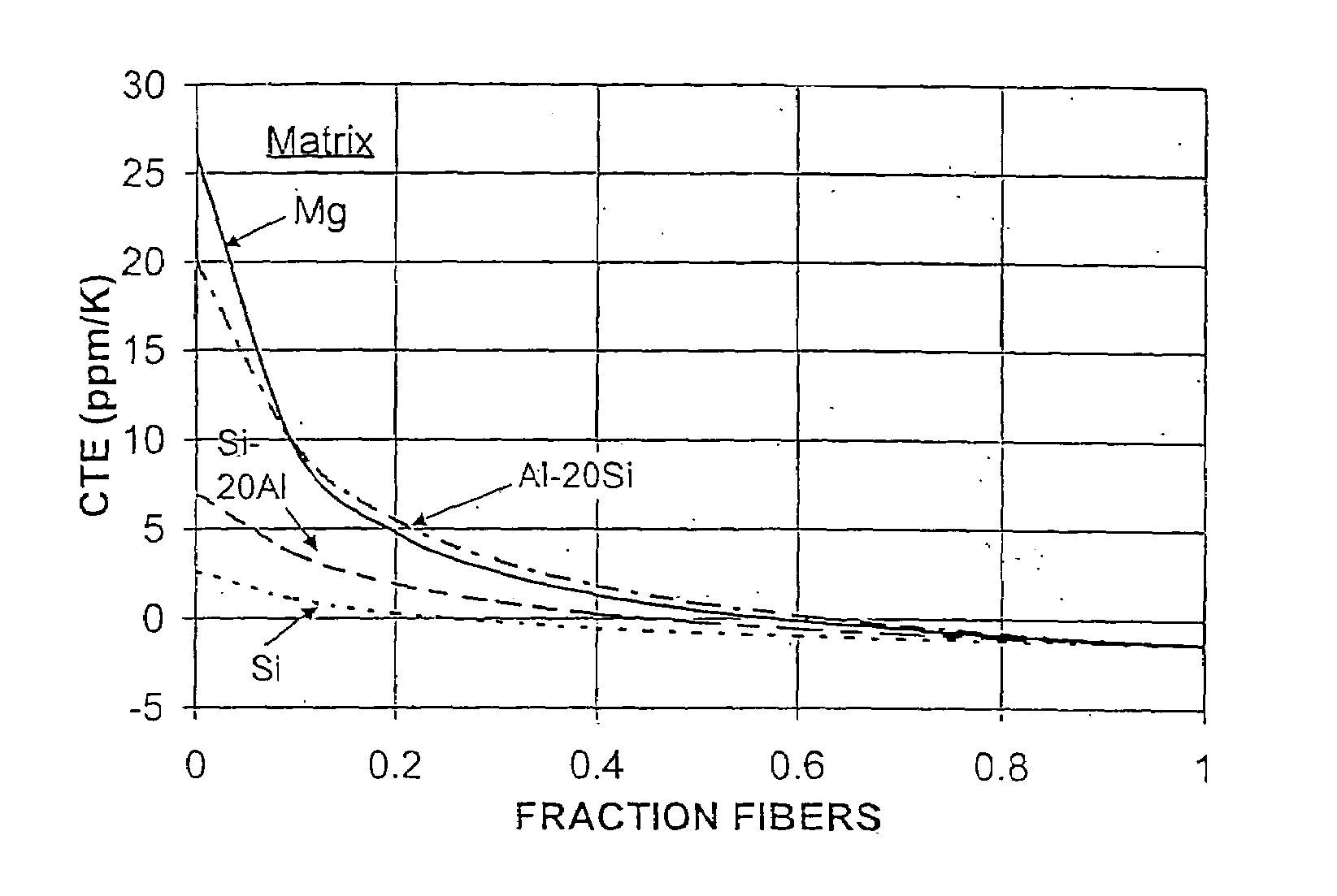

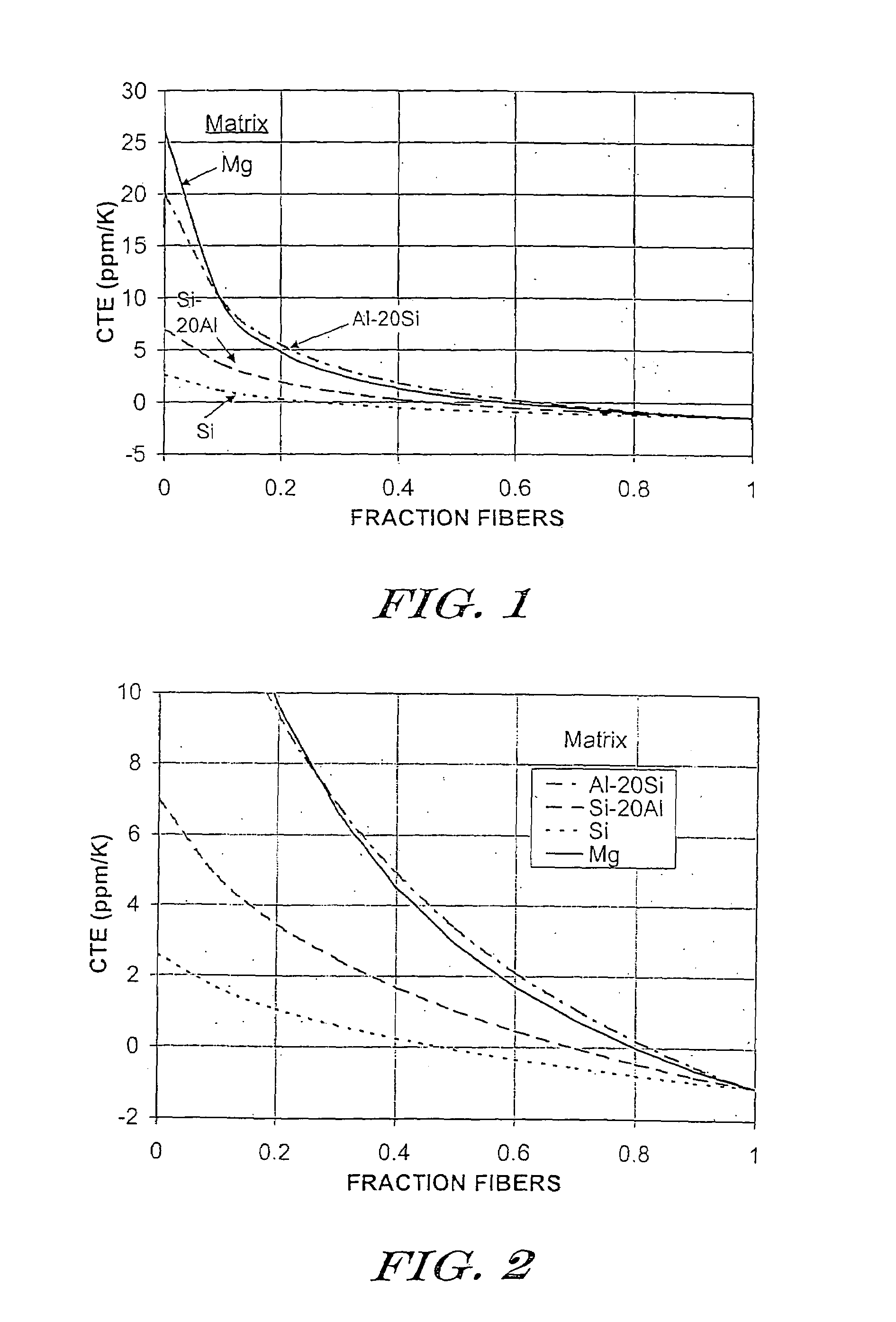

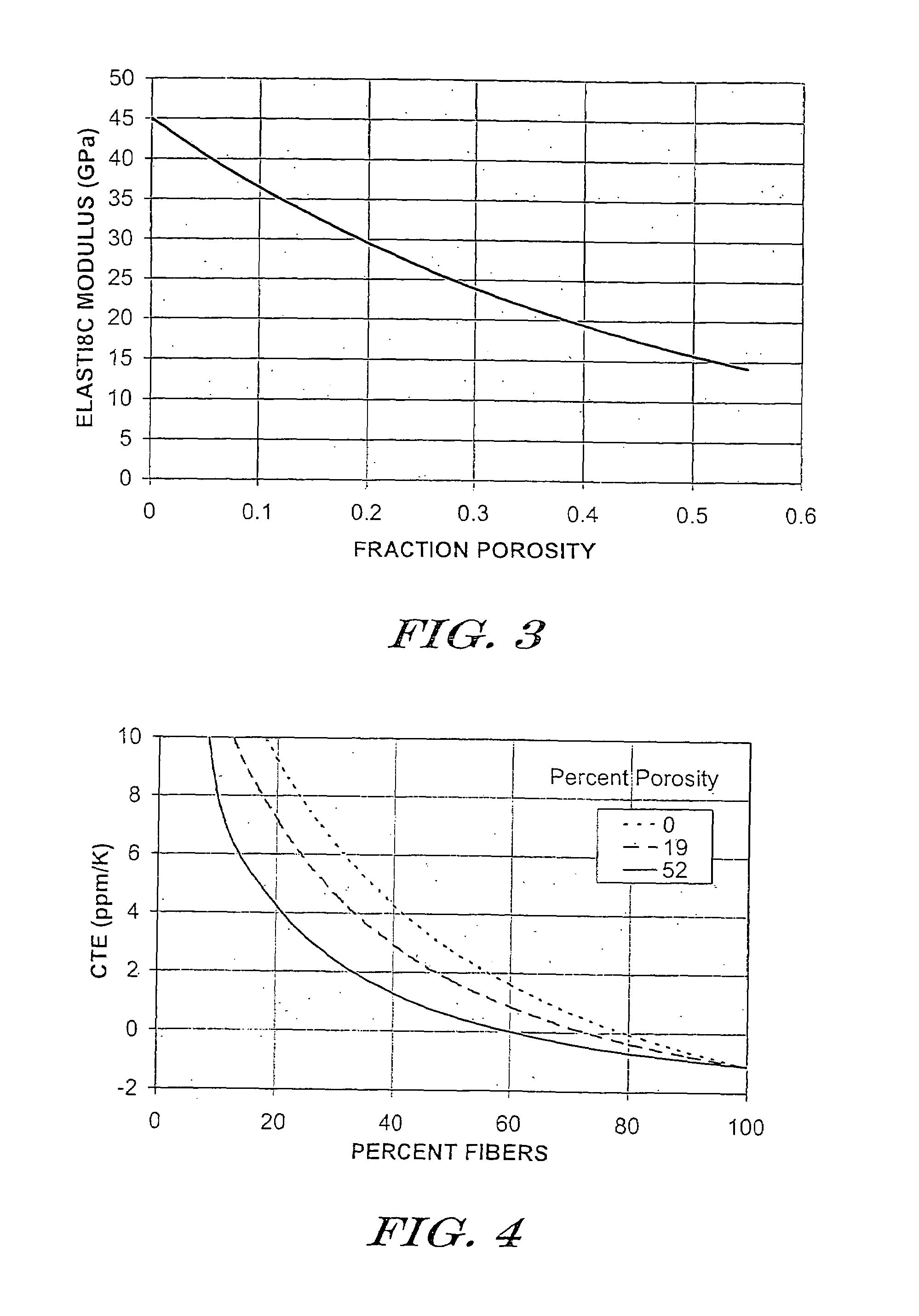

Low expansion metal-ceramic composite bodies, and methods for making same

InactiveUS7169465B1Reduce bloatMore impactMaterial nanotechnologyNatural cellulose pulp/paperFiberCeramic composite

A low CTE metal-ceramic composite material featuring carbon fibers reinforcing a matrix featuring silicon metal or silicon alloy. The fibers have a low coefficient of thermal expansion (CTE) in the axial direction, and preferably negative. The principles of making Si / SiC composites can be adapted to produce the instant Si matrix composites. The CTE of the composite body depends not only upon the relative CTE's of the fibers and matrix, and their relative amounts (e.g., loadings), but also upon the relative elastic moduli of the fibers and matrix. Thus, Si / SiC matrices produced by a reaction-bonding process inherently possess low CTE, but the instant inventors prefer to make such composites having relatively large fractions of unreacted silicon, thereby driving composite CTE lower still. Here, the carbon fibers are protected from reaction with the silicon infiltrant with one or more materials disposed between the fibers and the infiltrant. Providing at least a degree of toughness or impact resistance can also be realized in these composites. Laminates produce Isotropic or quasi-isotropic properties in the composite body can be realized by, for example, providing the fibers in the form of cross-plied laminates featuring the fibers in parallel or woven arrays.

Owner:II VI DELAWARE INC

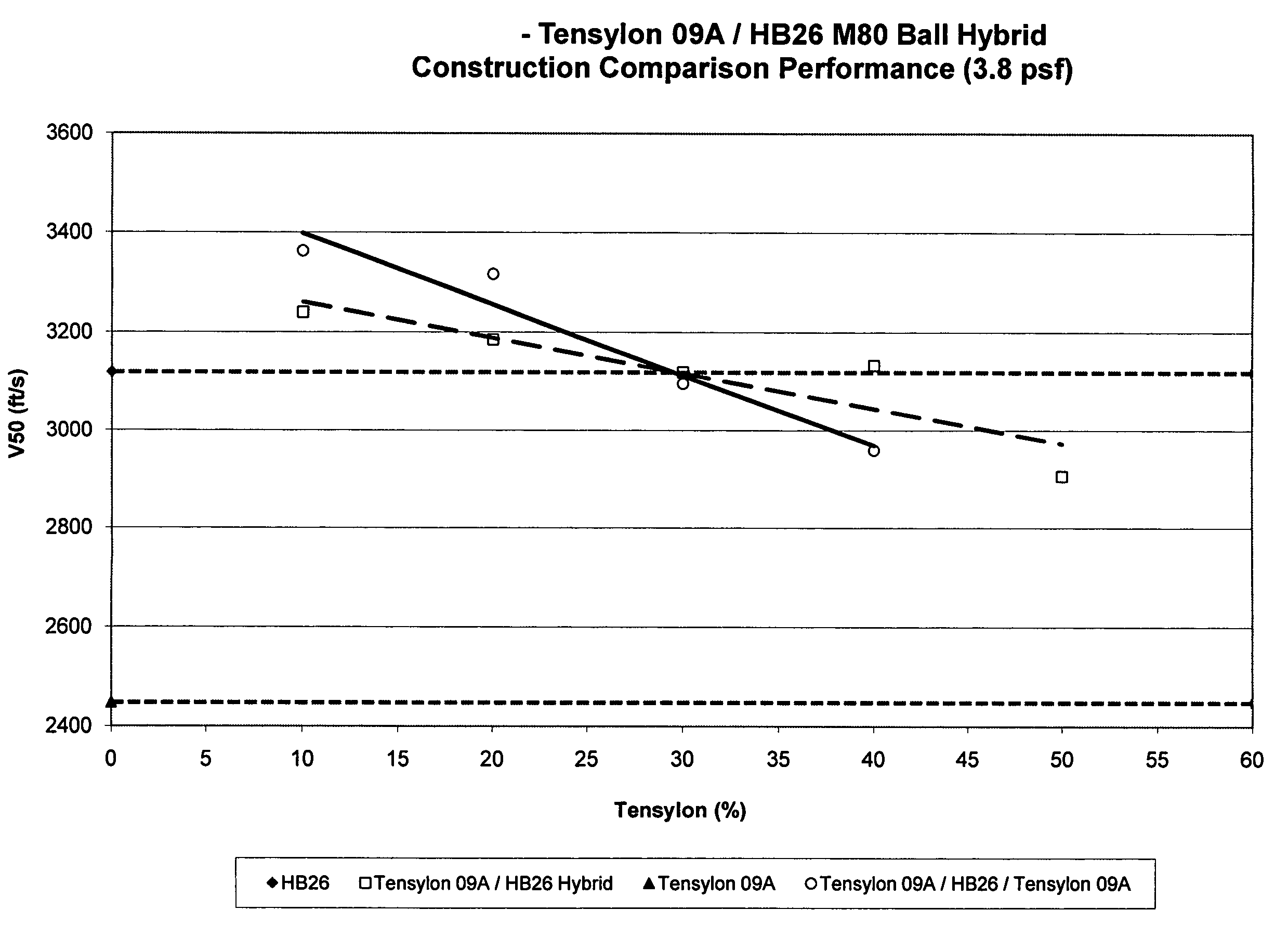

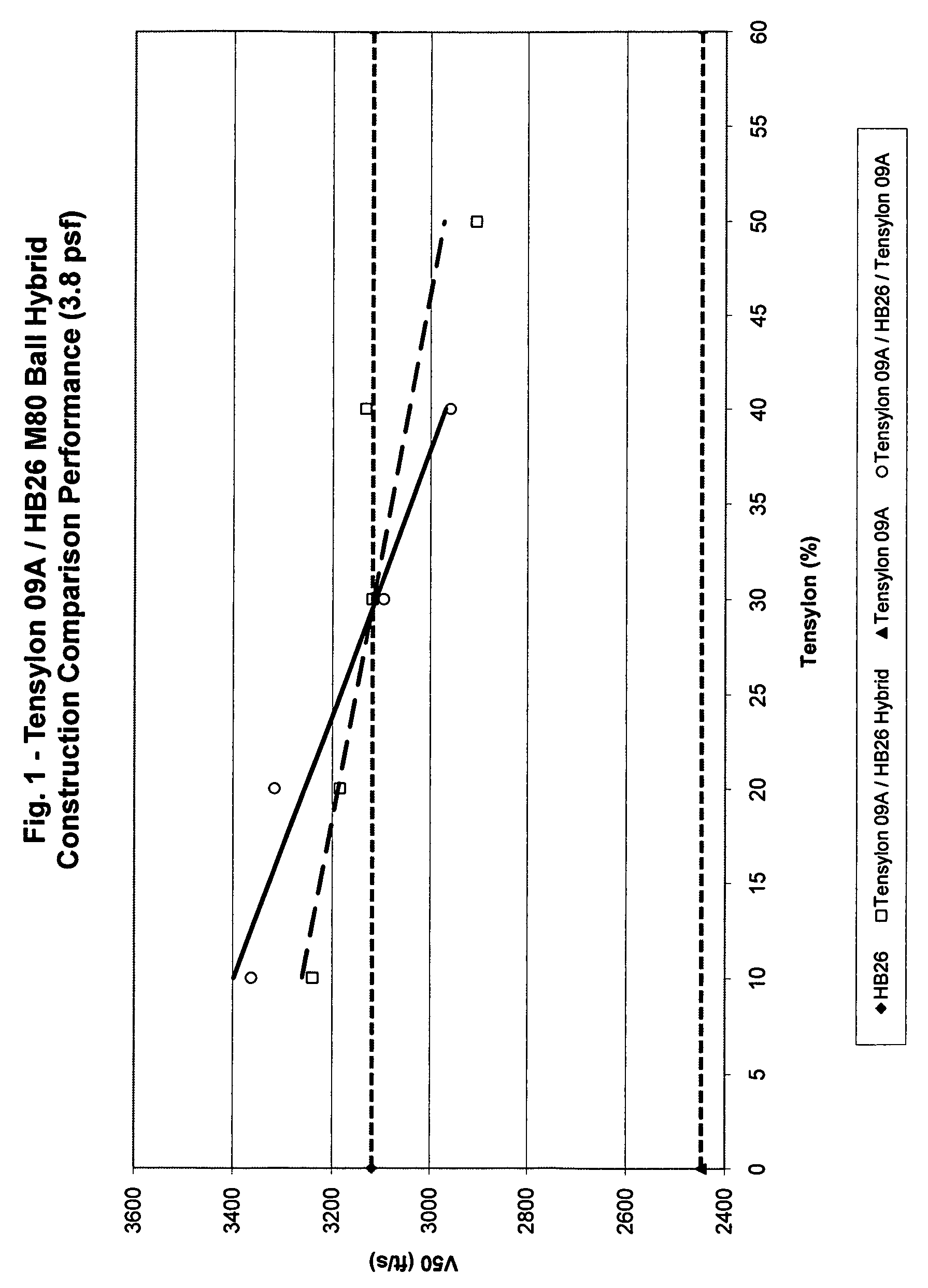

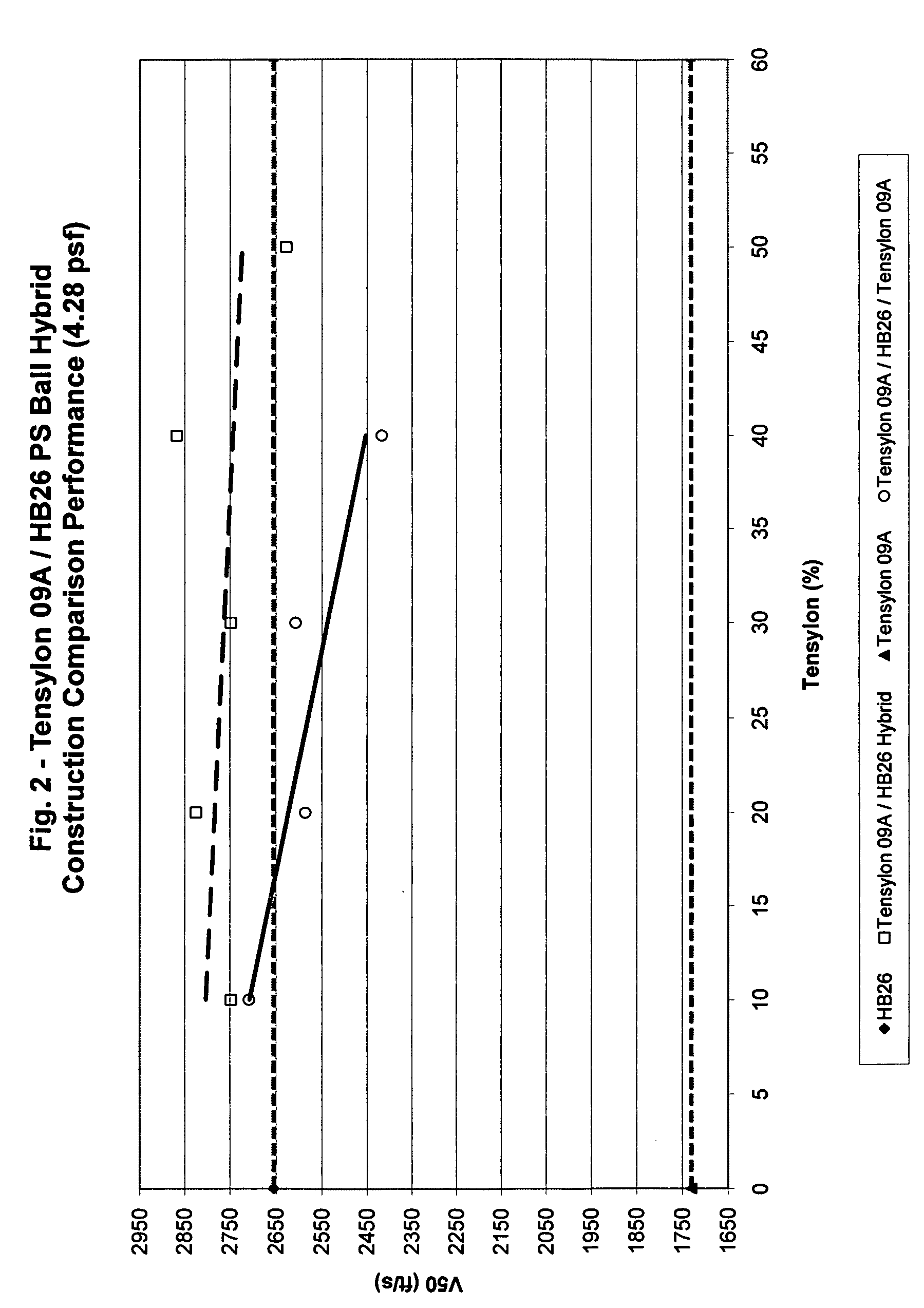

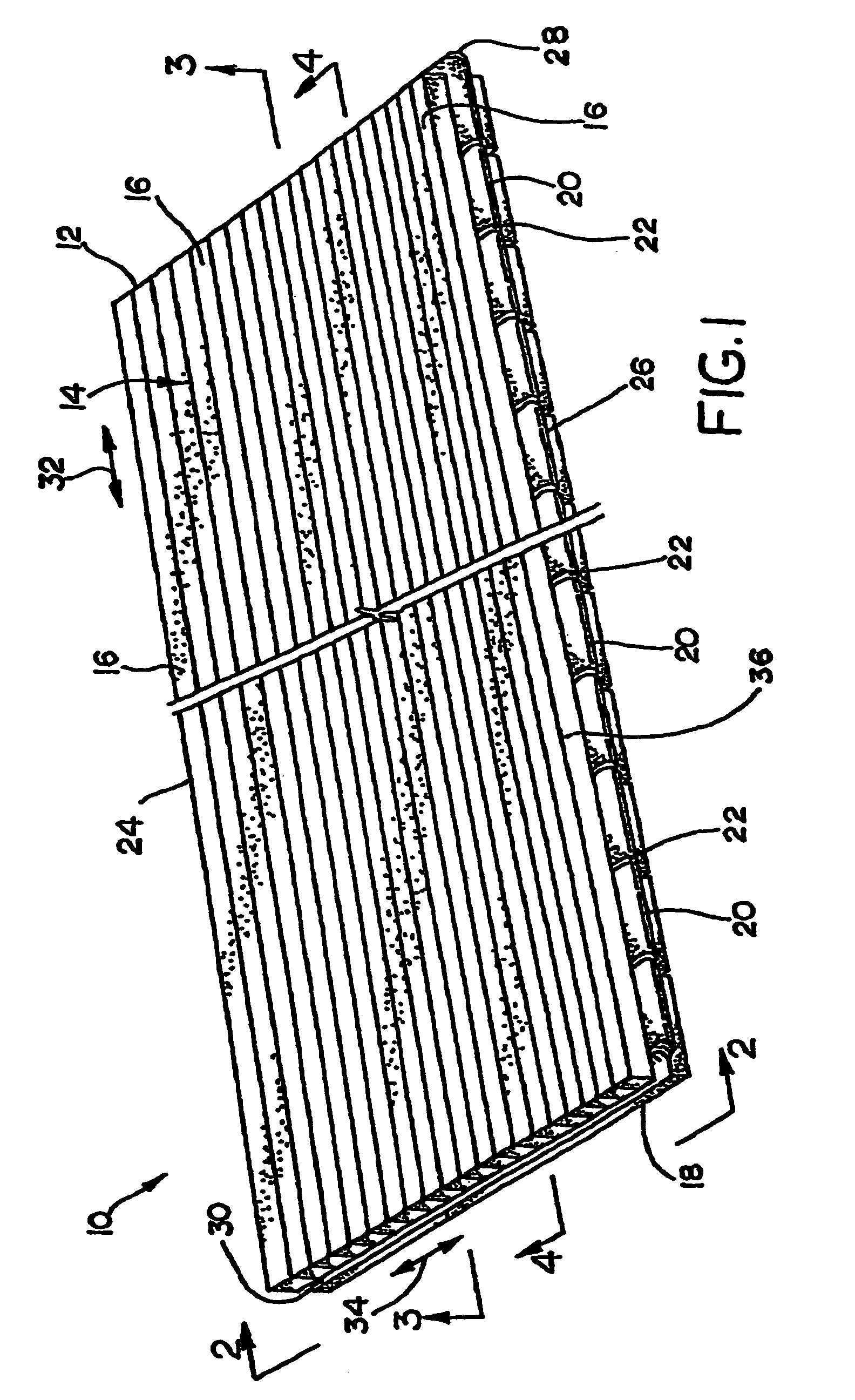

Ballistic-resistant article including one or more layers of cross-plied uhmwpe tape in combination with cross-plied fibers

A ballistic-resistant molded article having a sandwich-type structure including two outer portions of a first high modulus material surrounding an inner portion of a second high modulus material. The outer portions are comprised of a plurality of interleaved layers of adhesive coated cross-plied non-fibrous ultra high molecular weight polyethylene tape. The inner portion is comprised of a plurality of interleaved layers of high modulus cross-plied fibers embedded in resin. The stack of interleaved layers is compressed at high temperature and pressure to form a hybrid sandwich ballistic-resistant molded article that includes a mix of high modulus materials. It has been found that ballistic resistance is higher for the hybrid structure than for a monolithic structure of comparable areal density.

Owner:DUPONT SAFETY & CONSTR INC

Flexible two-ply flooring system

A two-ply flooring plank is disclosed having two layers or “plies” with a bottom layer having a grain that runs generally transverse to a top layer or “cross-ply” to provide dimensional stability to the plank. The bottom layer includes a number of strips secured to the bottom of the top layer. The bottom layer strips are also placed with gaps between the individual strips of the second layer to allow flexibility of the flooring plank, which allows the flooring to more easily conform to irregularities in a subfloor upon which the flooring plank is mounted.

Owner:DASSO INDASTRIAL GRUP KO LTD

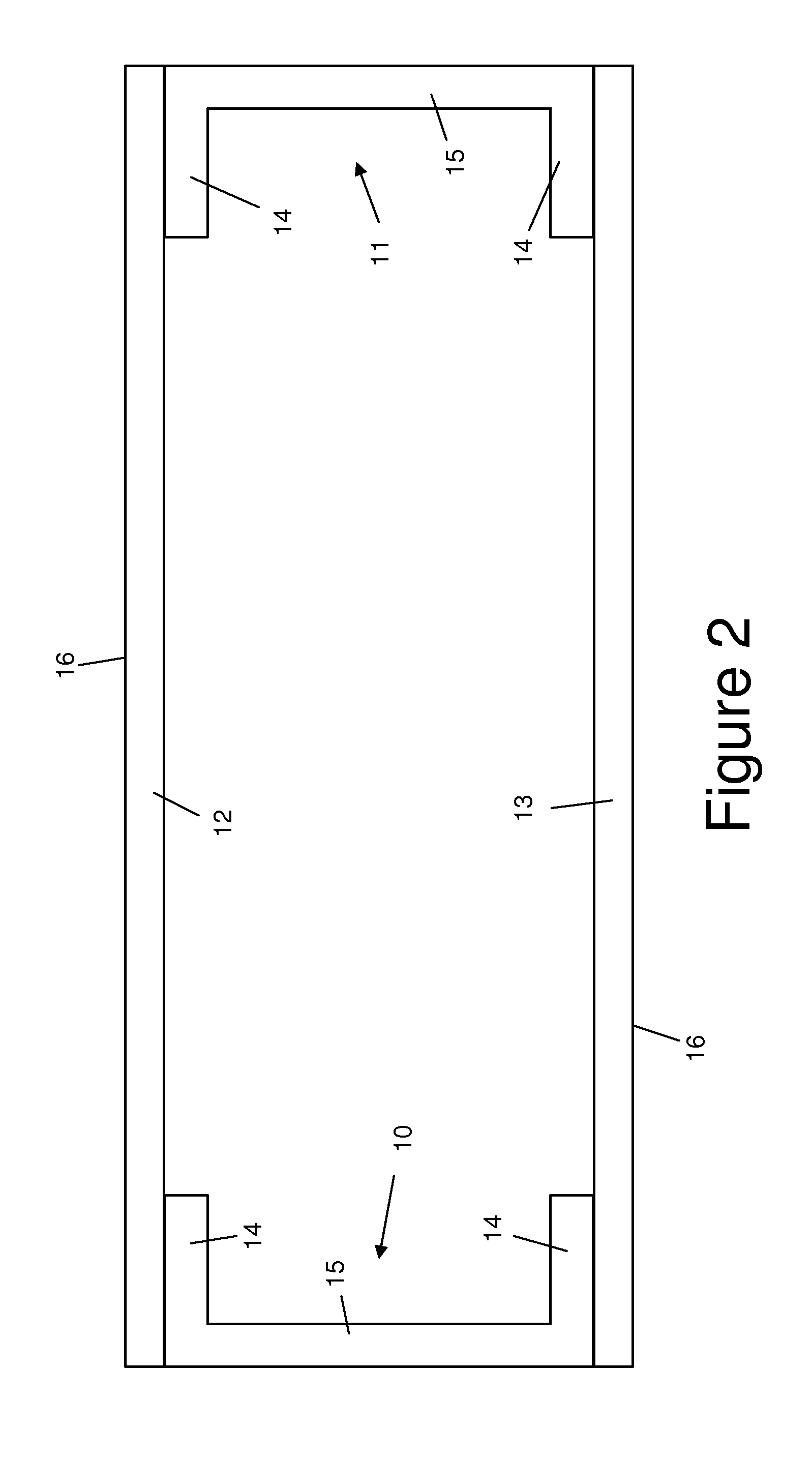

Composite structure

ActiveUS20130034684A1Simple designIncrease stiffnessLayered productsFinal product manufactureFiberAcute angle

A structure comprising a plurality of plies of fibre-reinforced composite material, each ply having a ply orientation defined by a principal stiffness direction of the ply. The structure has a first region and a second region, each region comprising N1 primary plies, N4 cross plies with a ply orientation substantially perpendicular to the primary plies, N2 positive-angled bias plies with a ply orientation at a positive acute angle to the primary plies, and N3 negative-angled bias plies with a ply orientation substantially perpendicular to the positive-angled bias plies. The ply orientation of the primary plies in each region is more closely aligned with a primary axis of the structure than the cross plies or the bias plies. N1=N4 in the first region but not in the second N region, and N2=N3 in the second region but not in the first region. In each of the two regions, one ply set is balanced and the other ply set is un-balanced. This provides a compromise between the advantages of using un-balanced ply sets, for instance to provide bending torsion coupling, and the disadvantage that un-balanced ply sets can introduce thermally induced distortion during manufacture.

Owner:AIRBUS OPERATIONS LTD

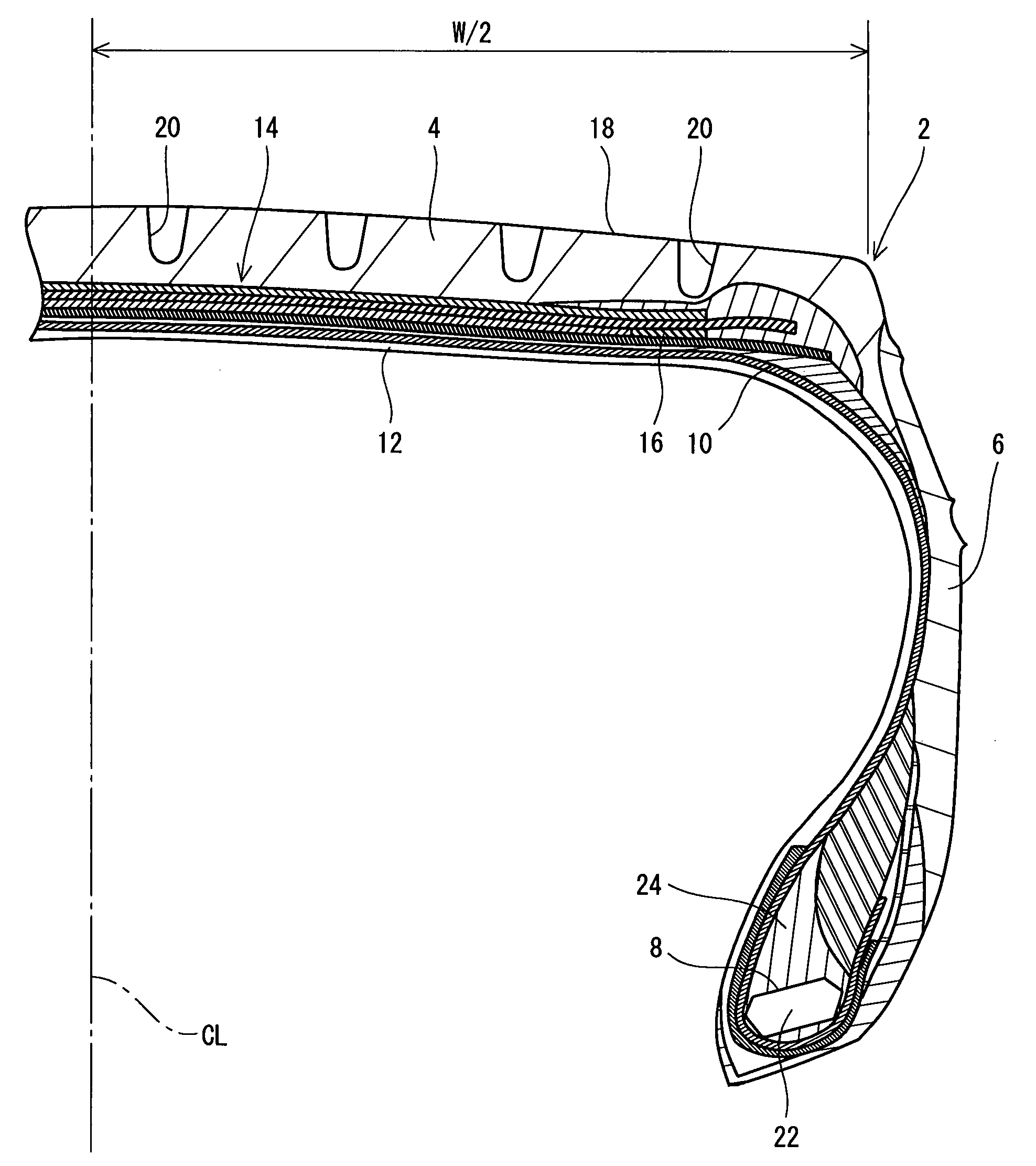

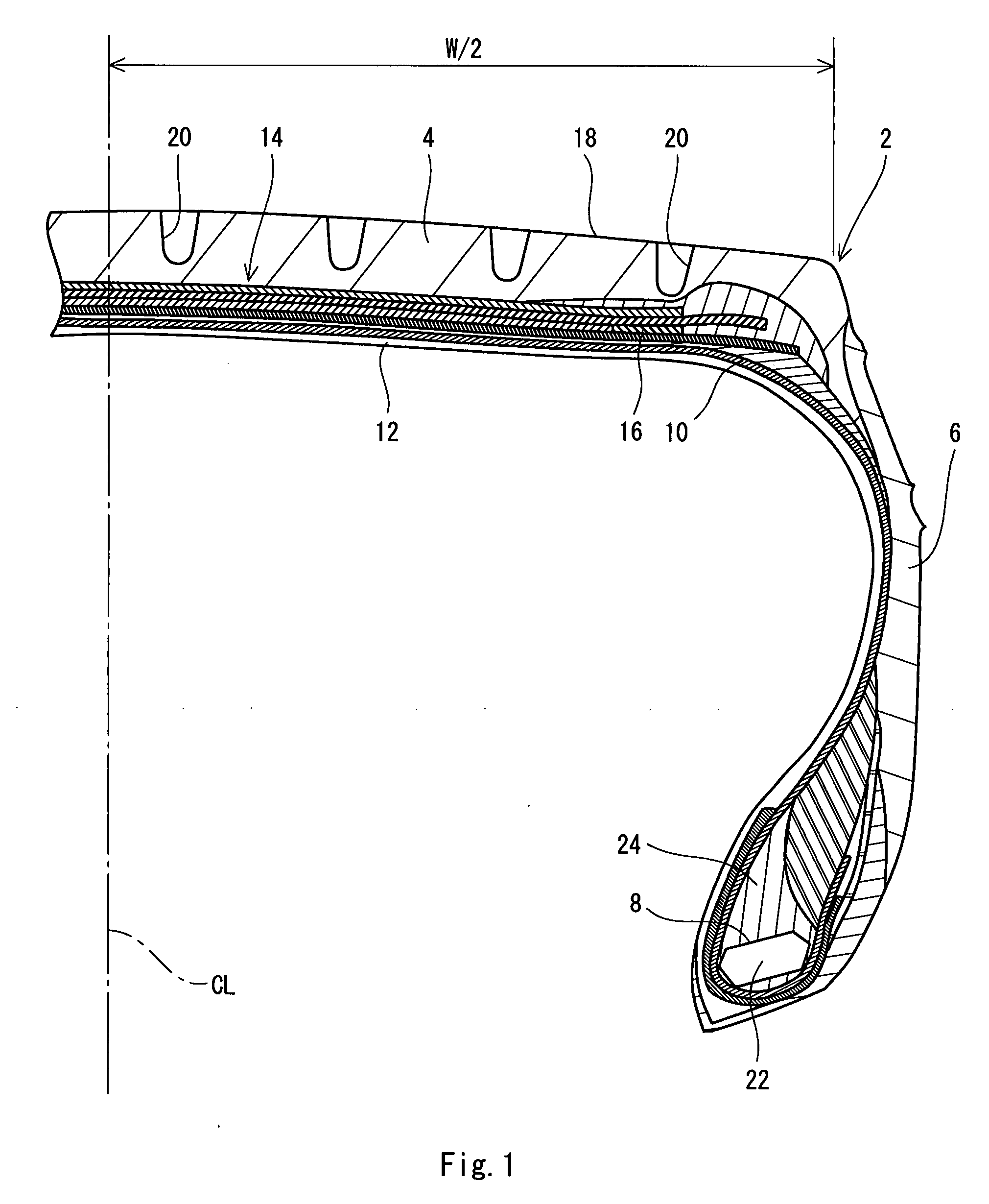

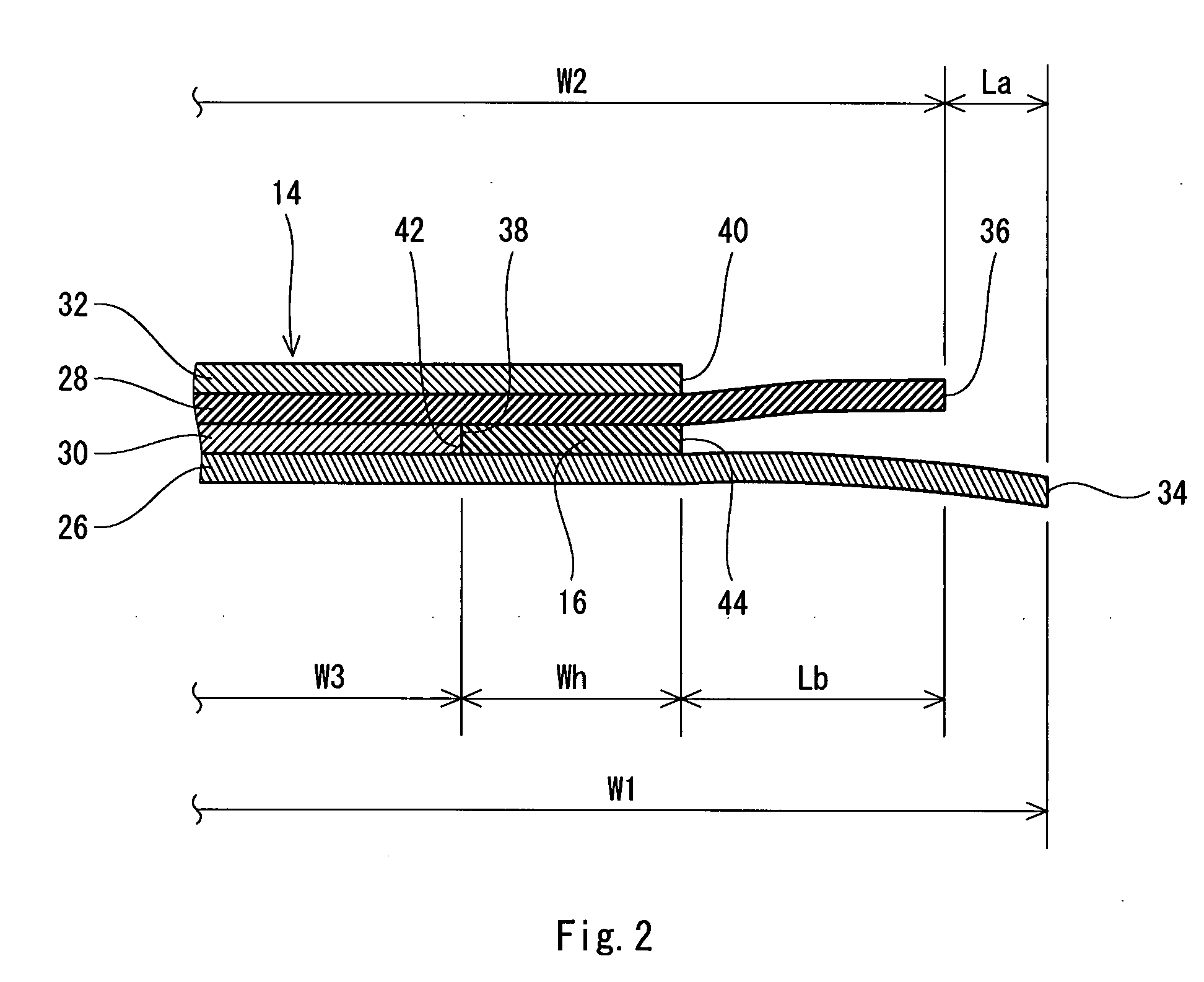

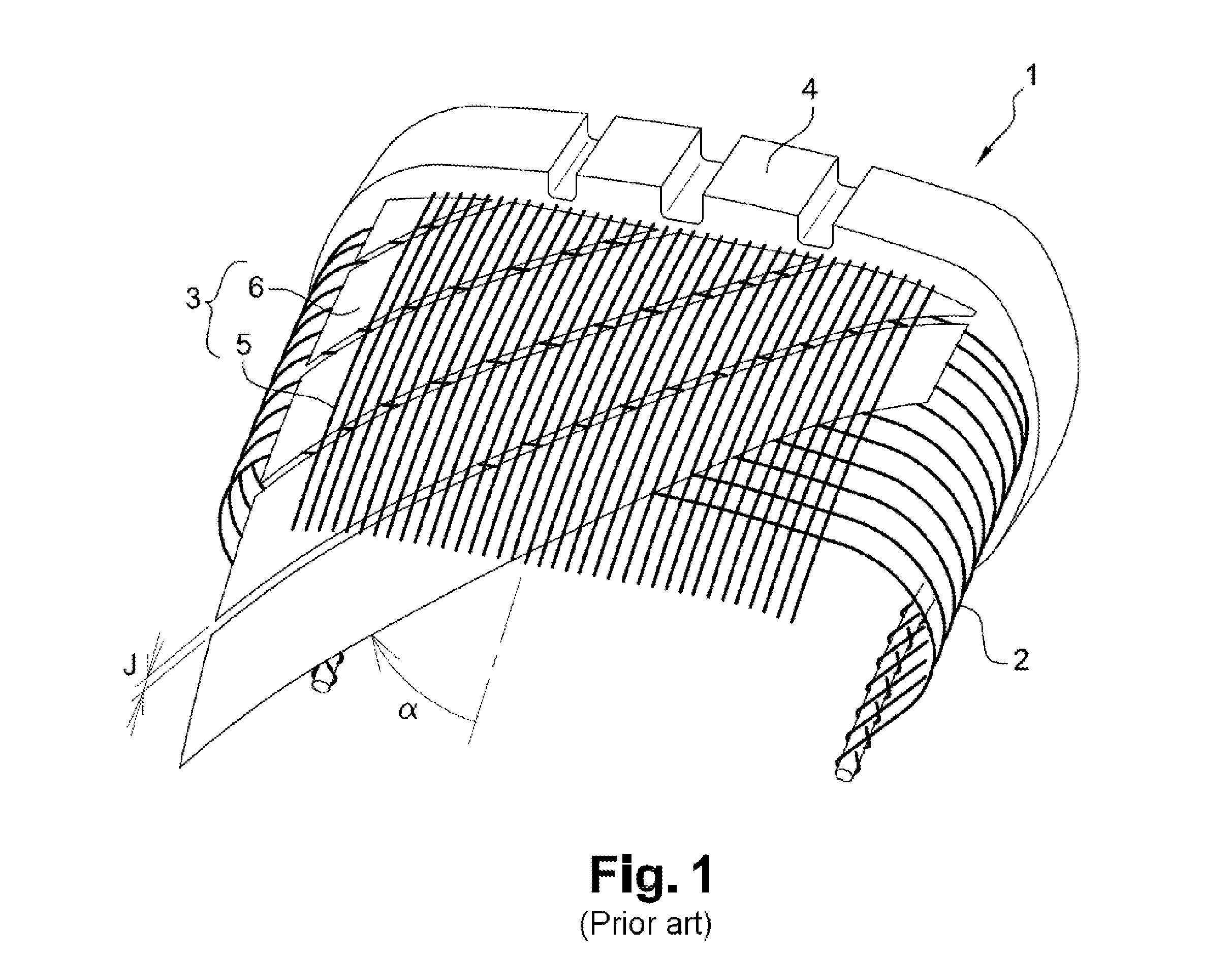

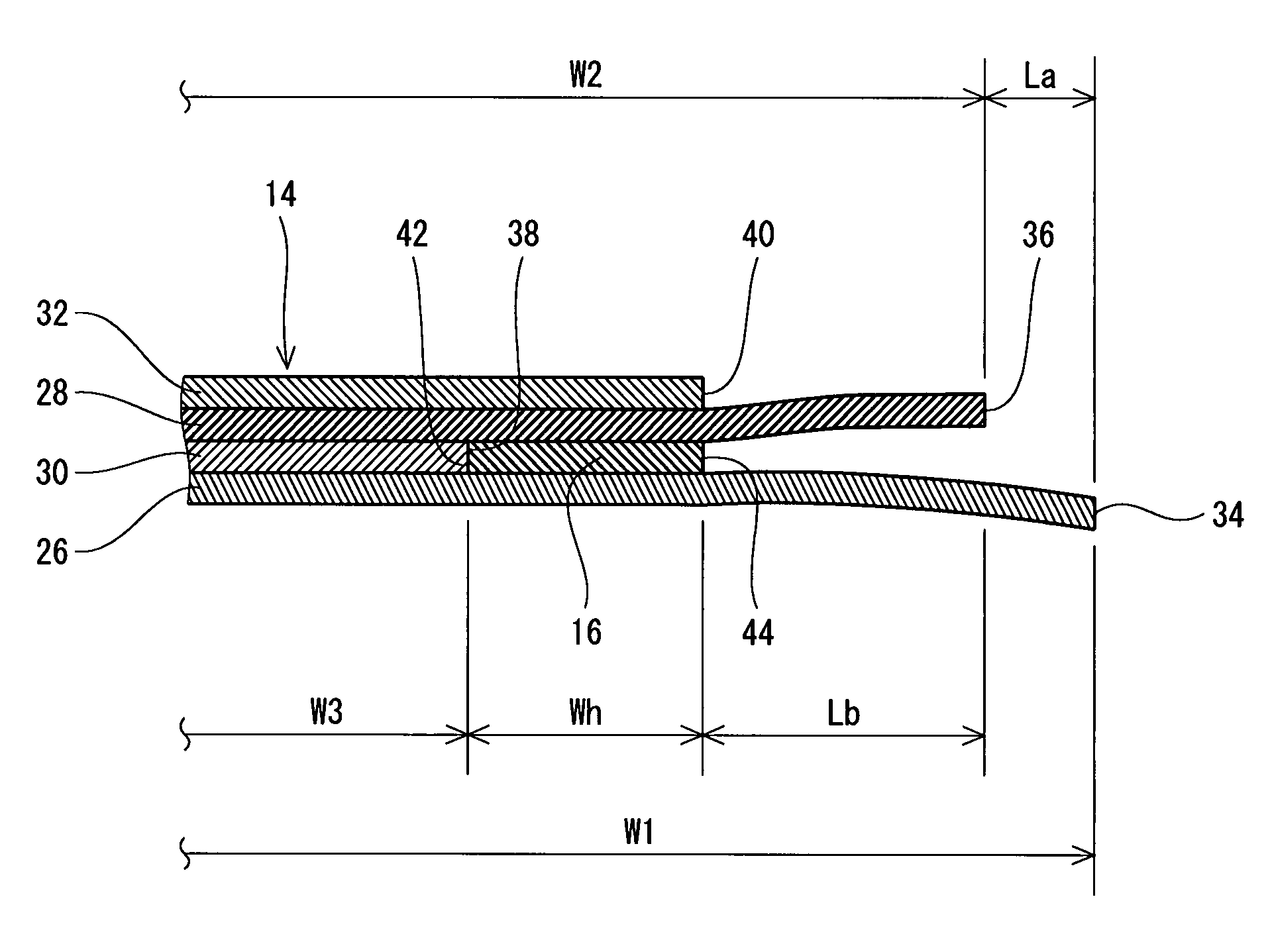

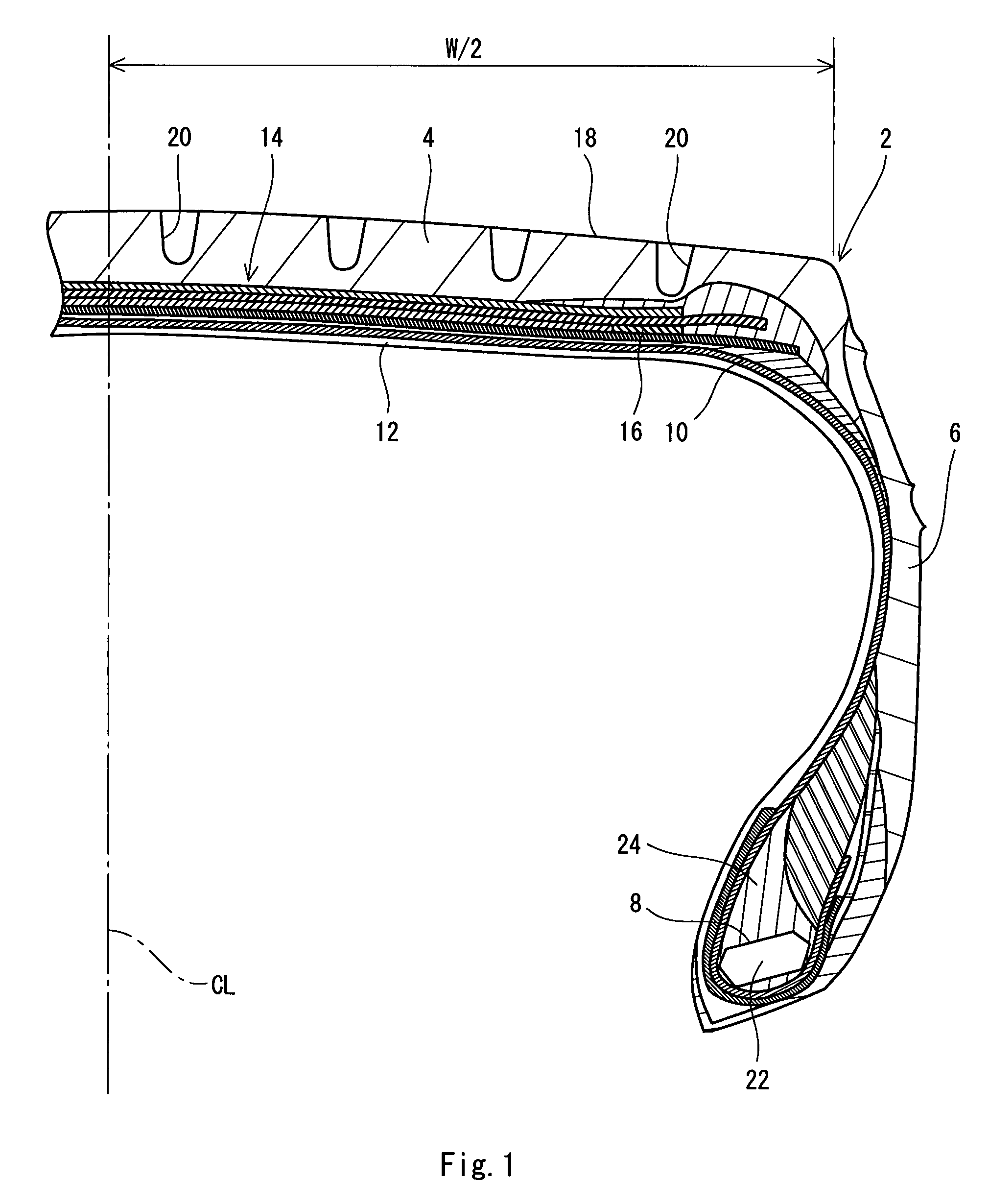

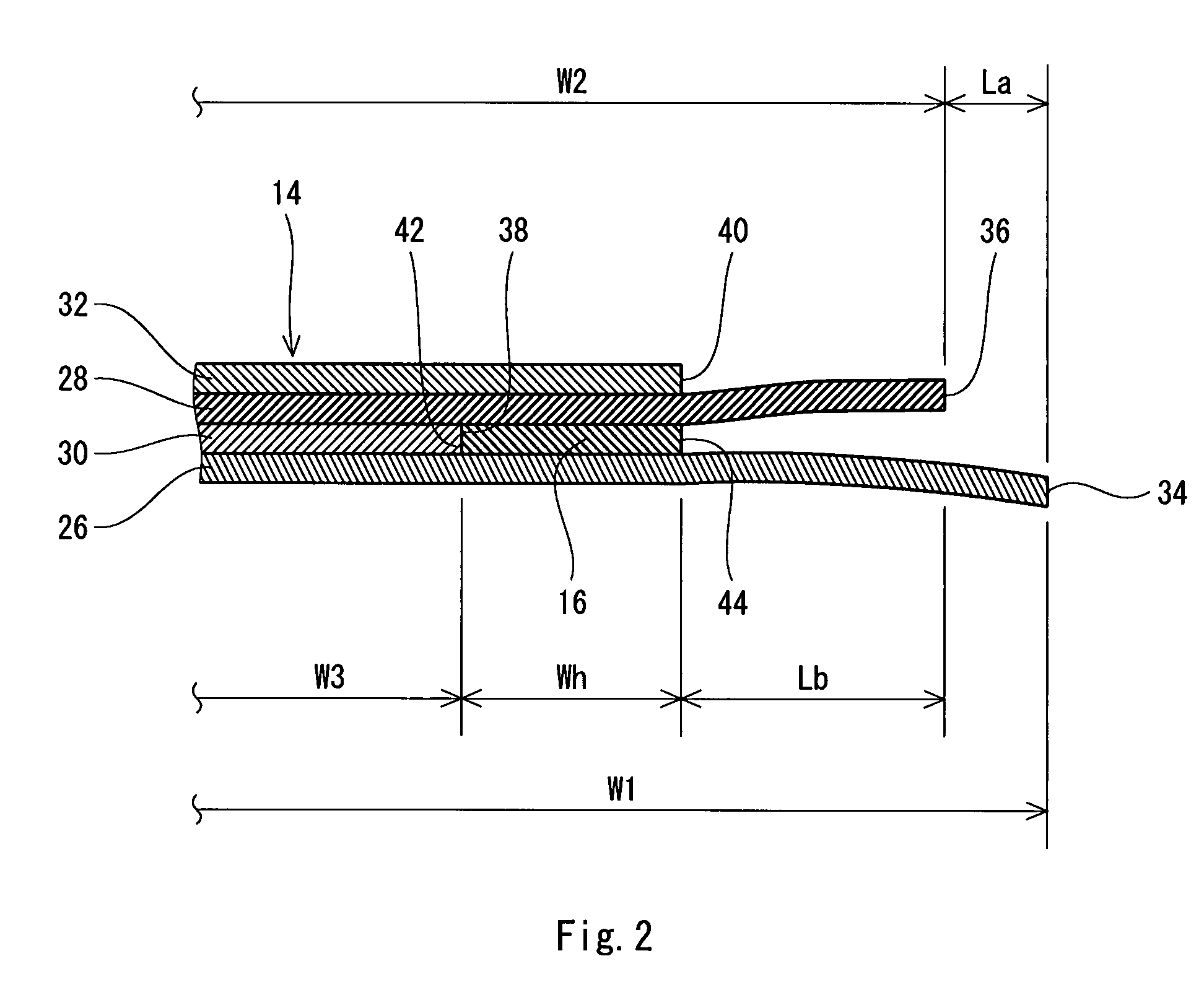

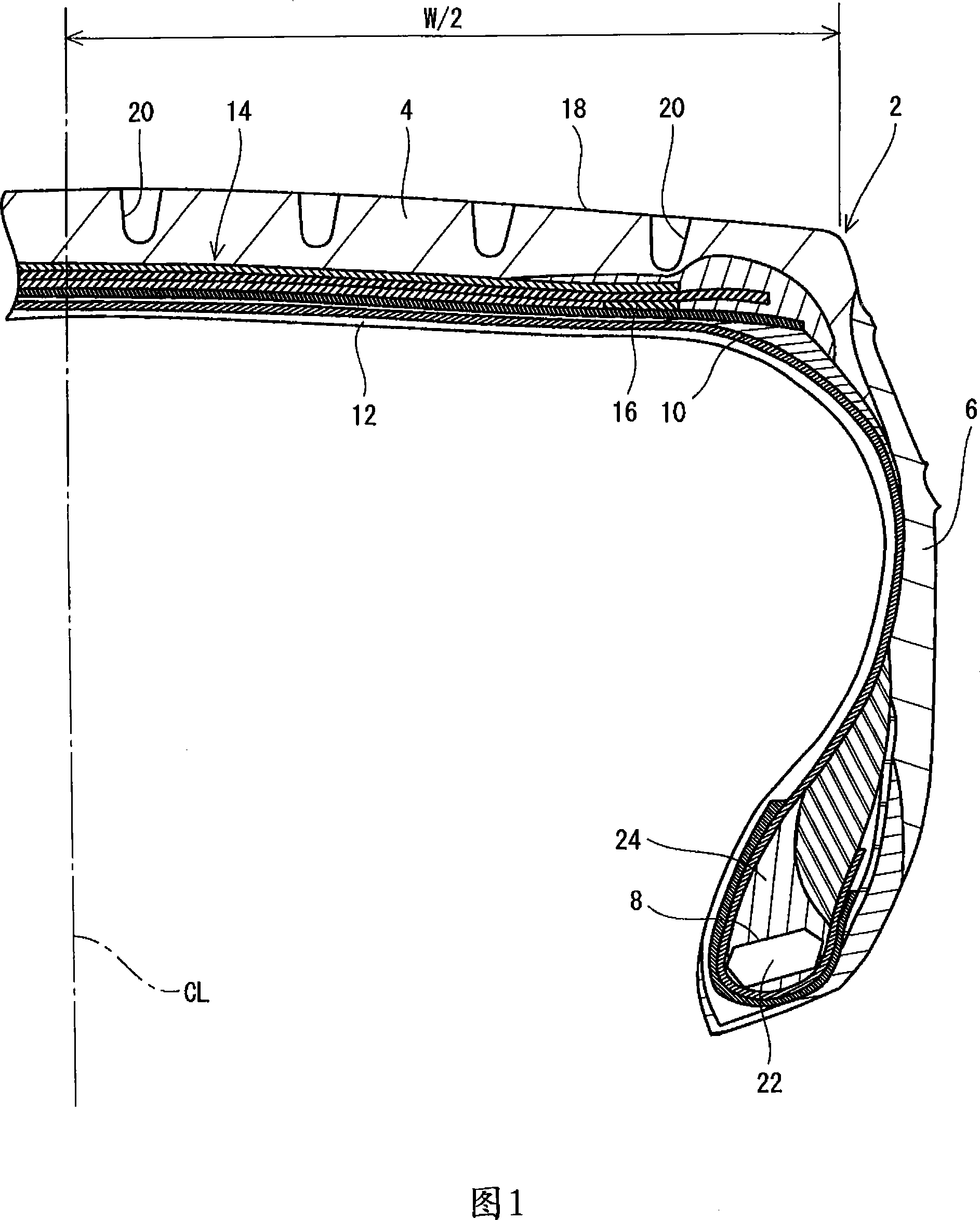

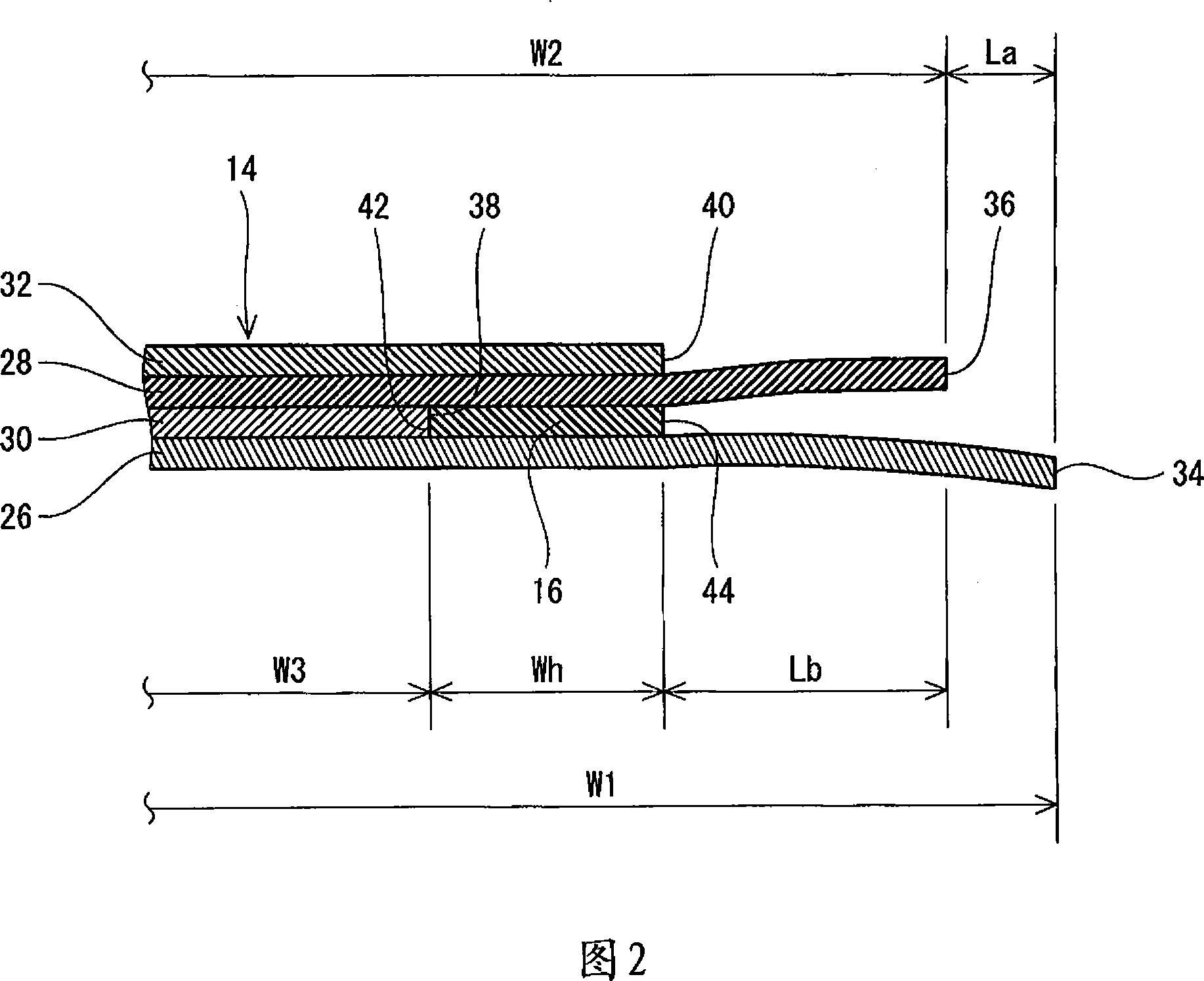

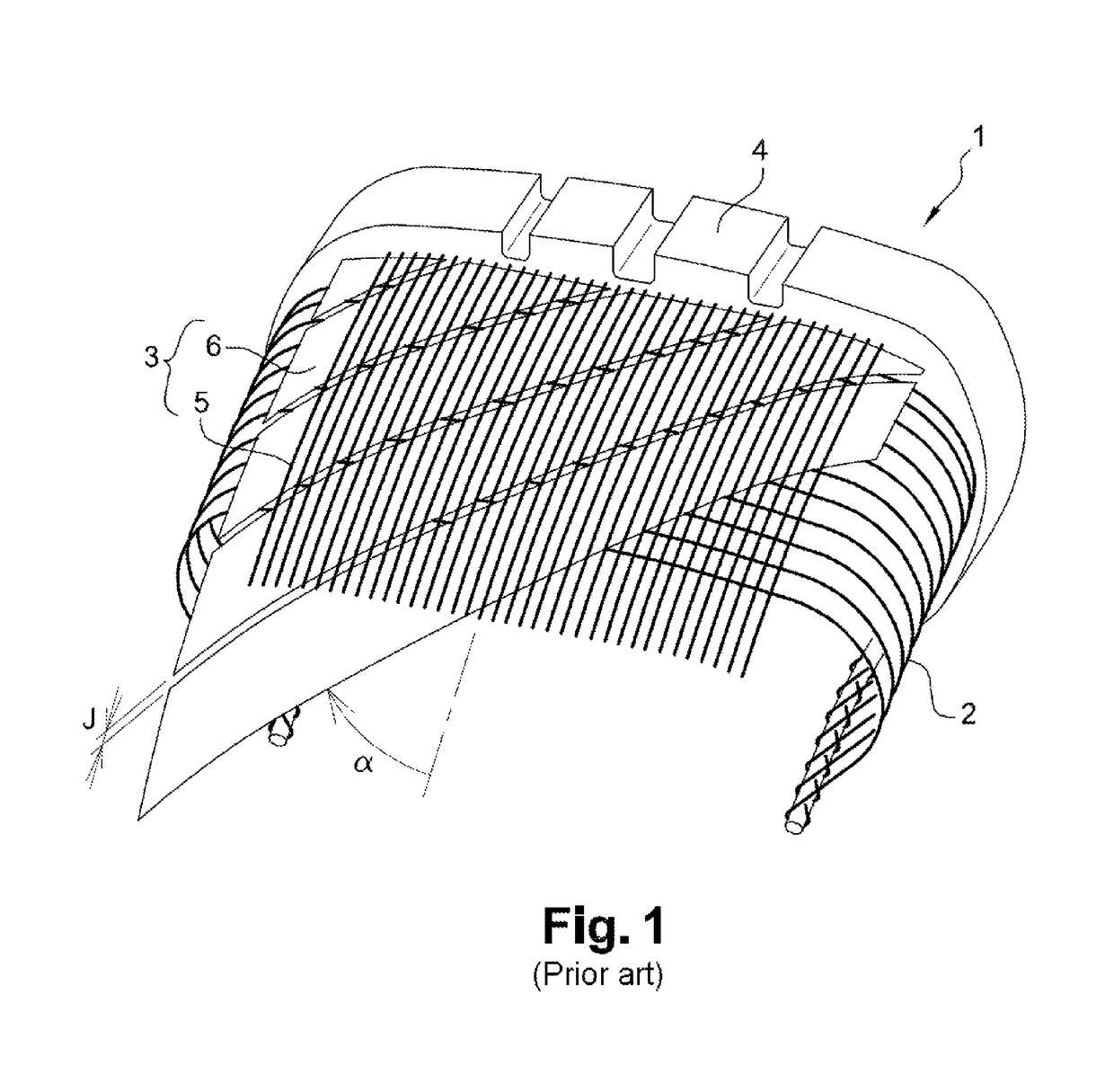

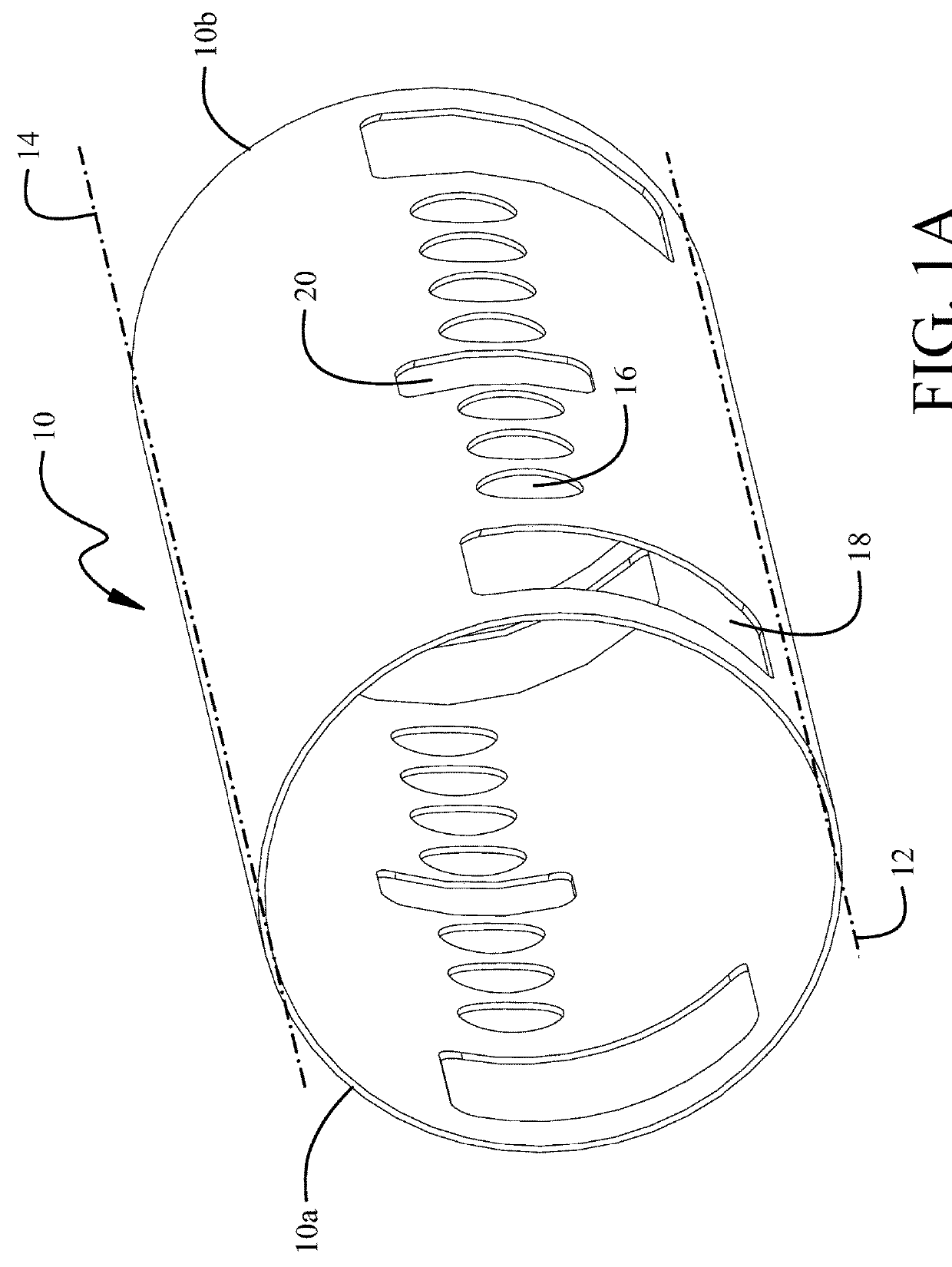

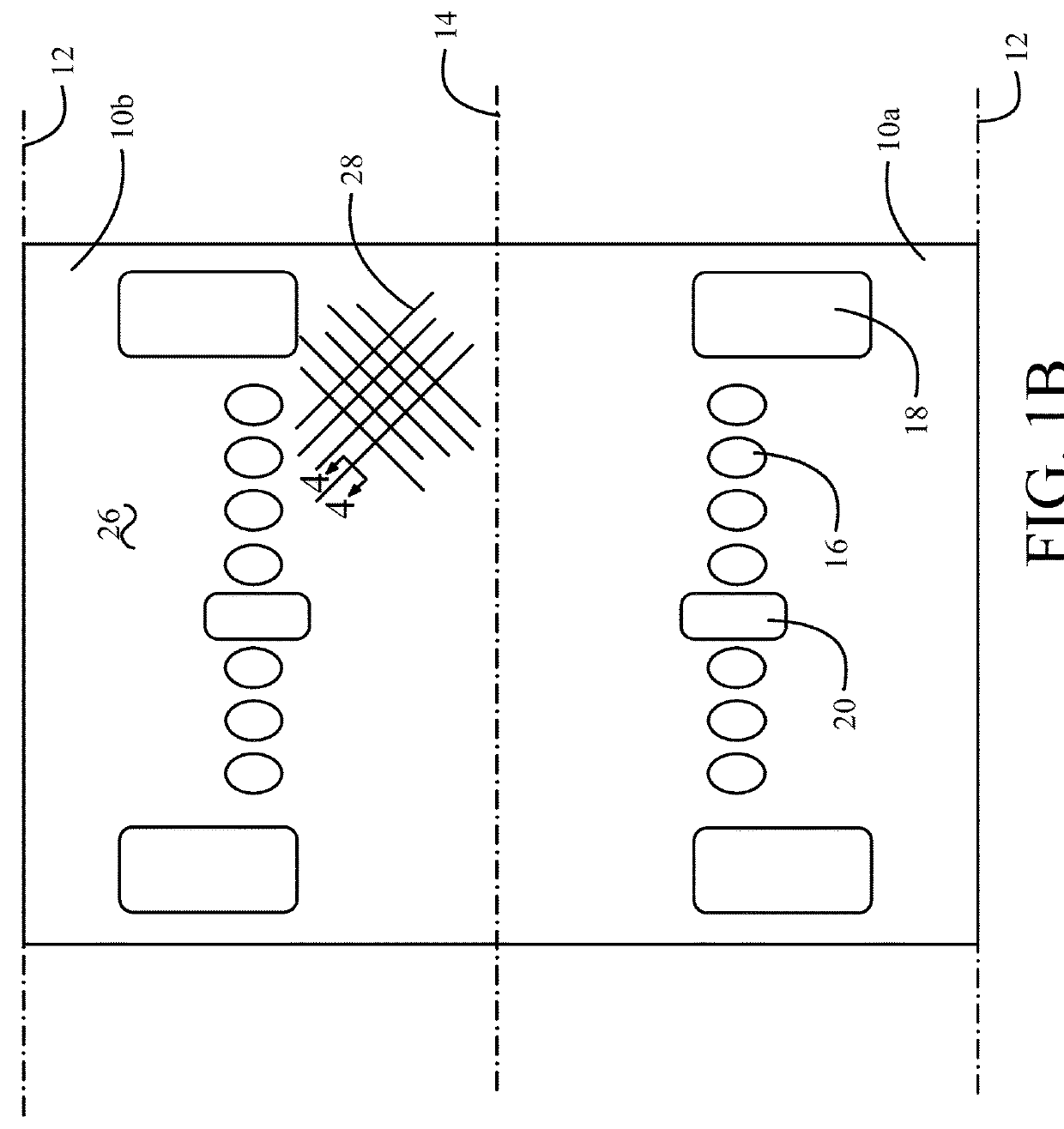

Heavy duty pneumatic tire

InactiveUS20080000566A1Add dimensionNot easily causedHeavy duty tyresHeavy duty vehicleEngineeringHeavy duty

A tire 2 has a belt 14 and a hard rubber layer 16. The belt 14 has a first ply 26, a second ply 28, a third ply 30 and a fourth ply 32. A width W3 of the third ply 30 is smaller than a width W1 of the first ply 26 and a width W2 of the second ply 28, and 75% of a width of a tread. Each of the plies 26, 28, 30, 32 has a steel cord. The first ply 26 and the second ply 28 construct a cross-ply structure. A cord of the third ply 30 is wound spirally. The third ply 30 has what is referred to as a jointless structure. The hard rubber layer 16 is positioned between the first ply 26 and the second ply 28, and outward of the third ply 30 in an axial direction. A complex elastic modulus of the hard rubber layer 16 is equal to or greater than 30 MPa.

Owner:SUMITOMO RUBBER IND LTD

Advanced anisotropic ceramic matrix composite system

InactiveUS20050136767A1Improve mechanical propertiesUniform thicknessSynthetic resin layered productsPretreated surfacesResin matrixCompound system

A ceramic matrix composite system includes multiple stacked layers of ceramic fiber cloth impregnated with resin matrix material. The resin matrix material in each of the fiber cloth layers substantially remains with the same layer during subsequent processing. Ceramic-containing material inner layers are applied between each of the fiber cloth layers enhancing the cross ply strength of the composite system.

Owner:GENERAL ELECTRIC CO

Ballistic-resistant panel including high modulus ultra high molecular weight polyethylene tape

A ballistic-resistant panel in which the entire panel or a strike-face portion thereof is formed of a plurality of sheets of high modulus high molecular weight polyethylene tape. The sheets of high modulus polyethylene tape can be in the form of cross-plied laminated layers of tape strips or a woven fabric of tape strips. The strips of UHMWPE tape include a width of at least one inch and a modulus of greater than 1400 grams per denier. The ballistic-resistant panel may include a backing layer of conventional high modulus fibers embedded in resin. A wide variety of adhesives were found acceptable for bonding the cross-plied layers of high modulus polyethylene tape together for forming the ballistic-resistant panels of the present invention.

Owner:DUPONT SAFETY & CONSTR INC

Flexible ballistic composites resistant to liquid pick-up method for manufacture and articles made therefrom

InactiveUS7687412B2Easy to optimizeLamination ancillary operationsProtective equipmentPolymer scienceAramides

Flexible ballistic resistant composite material that has improved resistance to pick-up of water and other liquids, the composite material comprising a plurality of non-woven fibrous layers. The fibrous layers are formed from a network of high tenacity fibers (aramid fibers, extended chain polyethylene fibers and / or rigid rod fibers). The fibers are embedded in a matrix of a thermoplastic polyurethane resin. Preferably, at least two adjacent fiber layers are oriented in a cross-ply arrangement with respect to each other. Flexible armor, such as body vests, are provided which are formed at least in part from the flexible composite material.

Owner:HONEYWELL INT INC

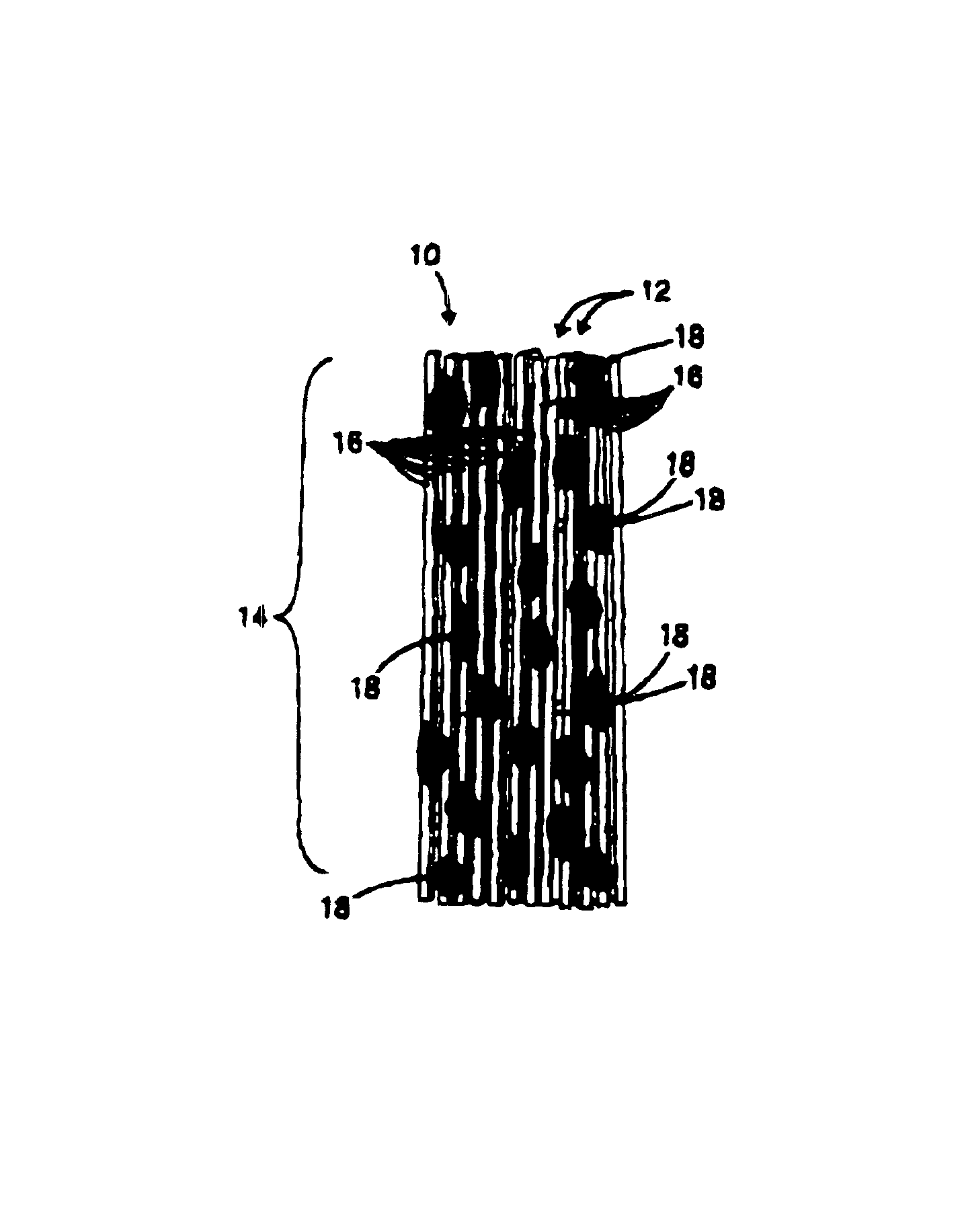

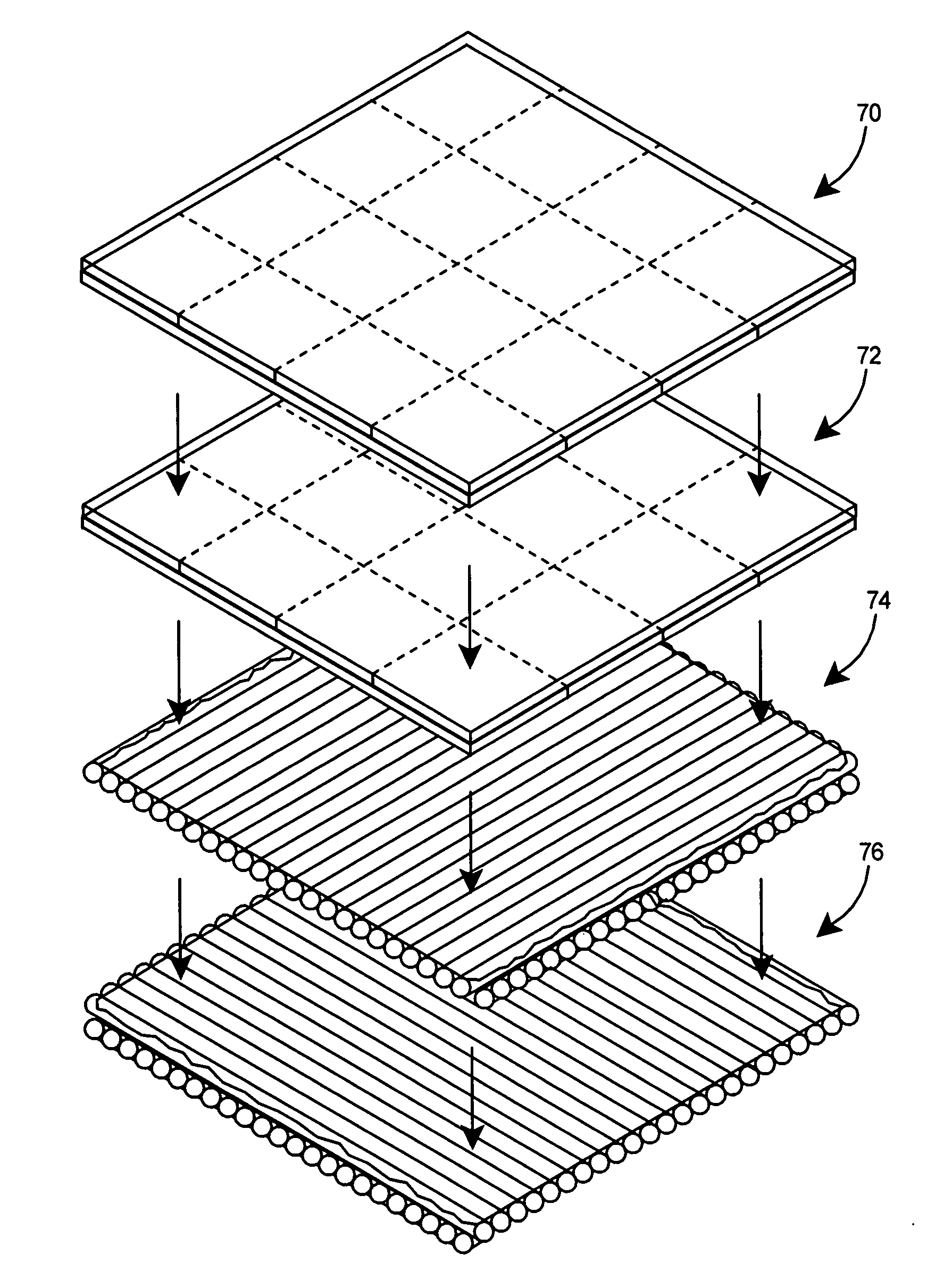

Variable areal density cross-plied fiber-reinforced composite ballistic material

ActiveUS20190128648A1Enhancing article flexibilityIncrease flexibilityProtective equipmentTransportation and packagingVolumetric Mass DensityBallistic resistance

This technology relates materials that are stab, spike and ballistic resistant and to stab, spike and ballistic resistant composite articles incorporating uniaxially oriented, non-woven fabrics. A fabric layer having a non-uniform areal density is formed having thick areas and thin areas, the thick areas having a greater filament / tape concentration compared to the thin areas. In said thick areas, agglomerated tapes / filaments will protrude from the fabric layer surface. Additional layers are then adjoined with the non-uniform layer to form a panel that has stab, spike and ballistic resistance, with protrusions at least partially spacing the additional layers from full, direct contact with the surface of the non-uniform fabric layer to thereby enhance flexibility and stab, spike and ballistic resistance of the whole.

Owner:HONEYWELL INT INC

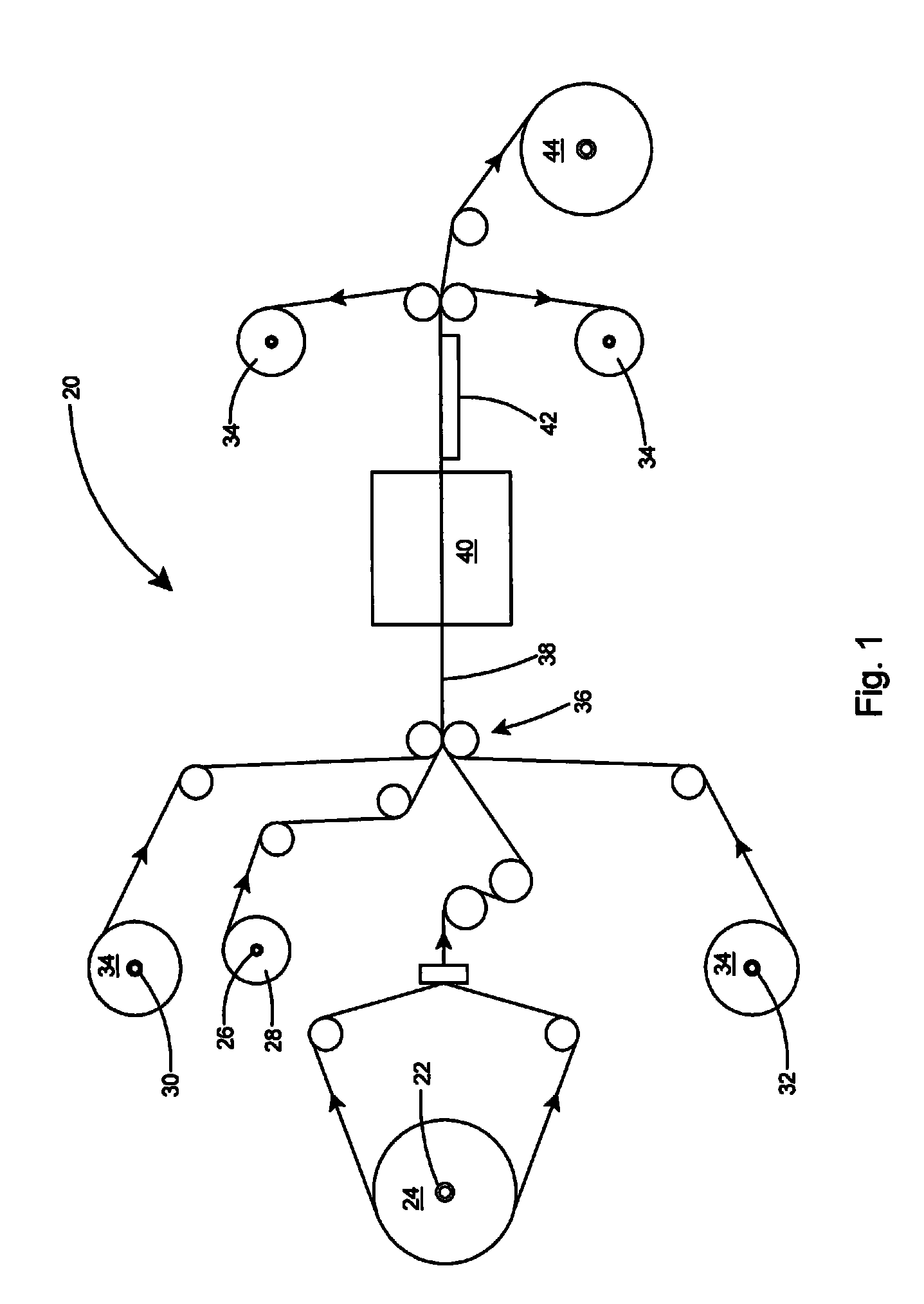

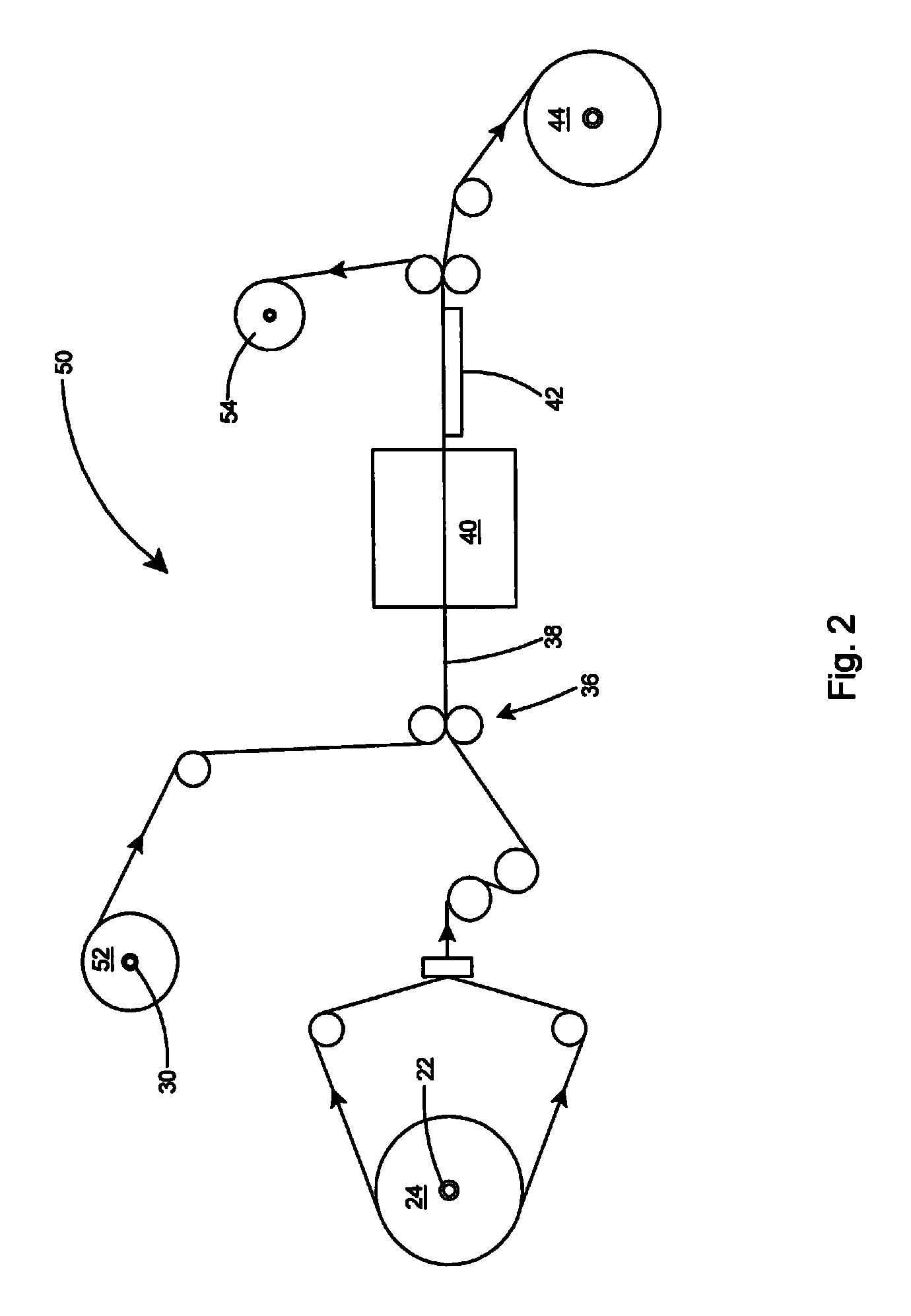

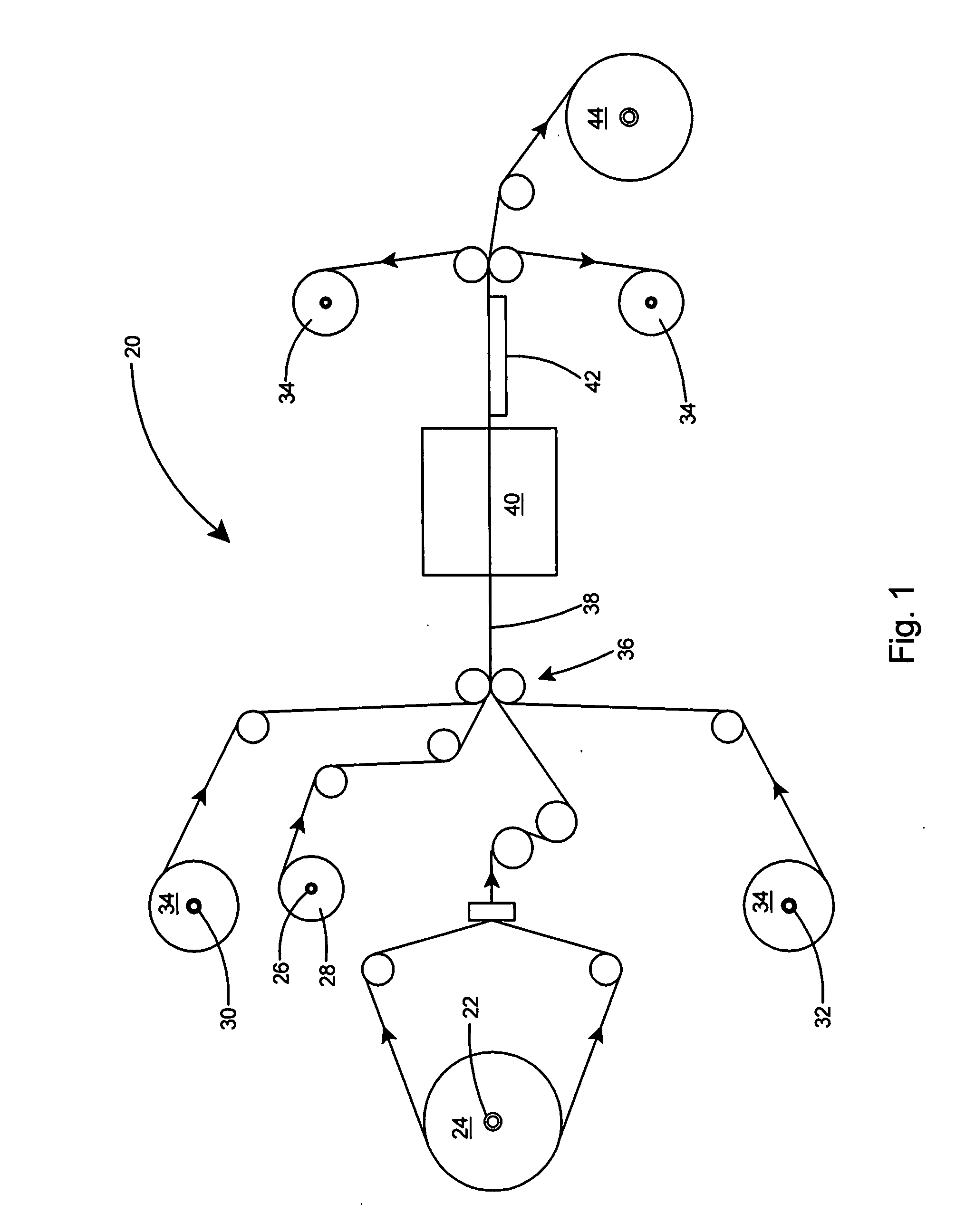

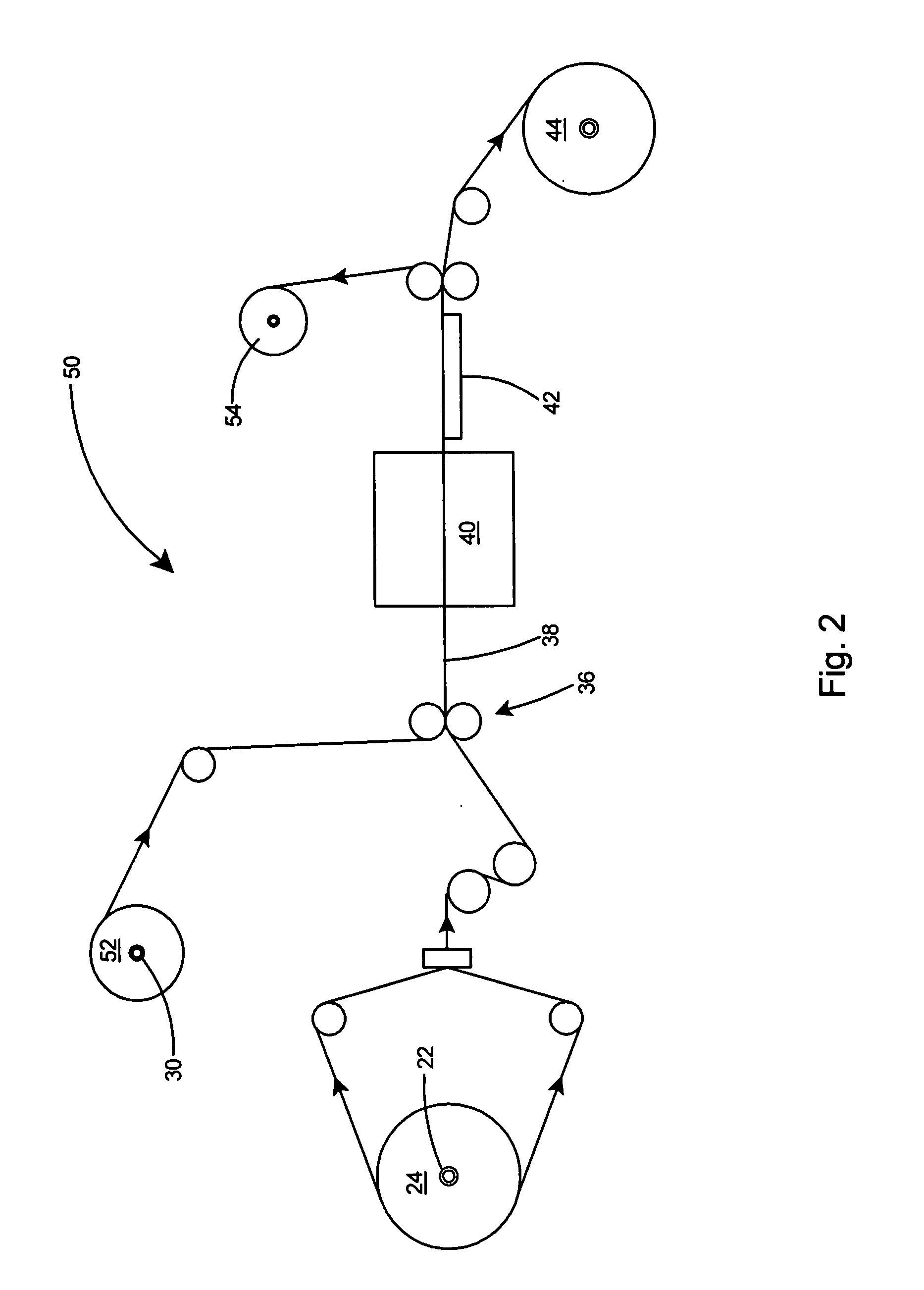

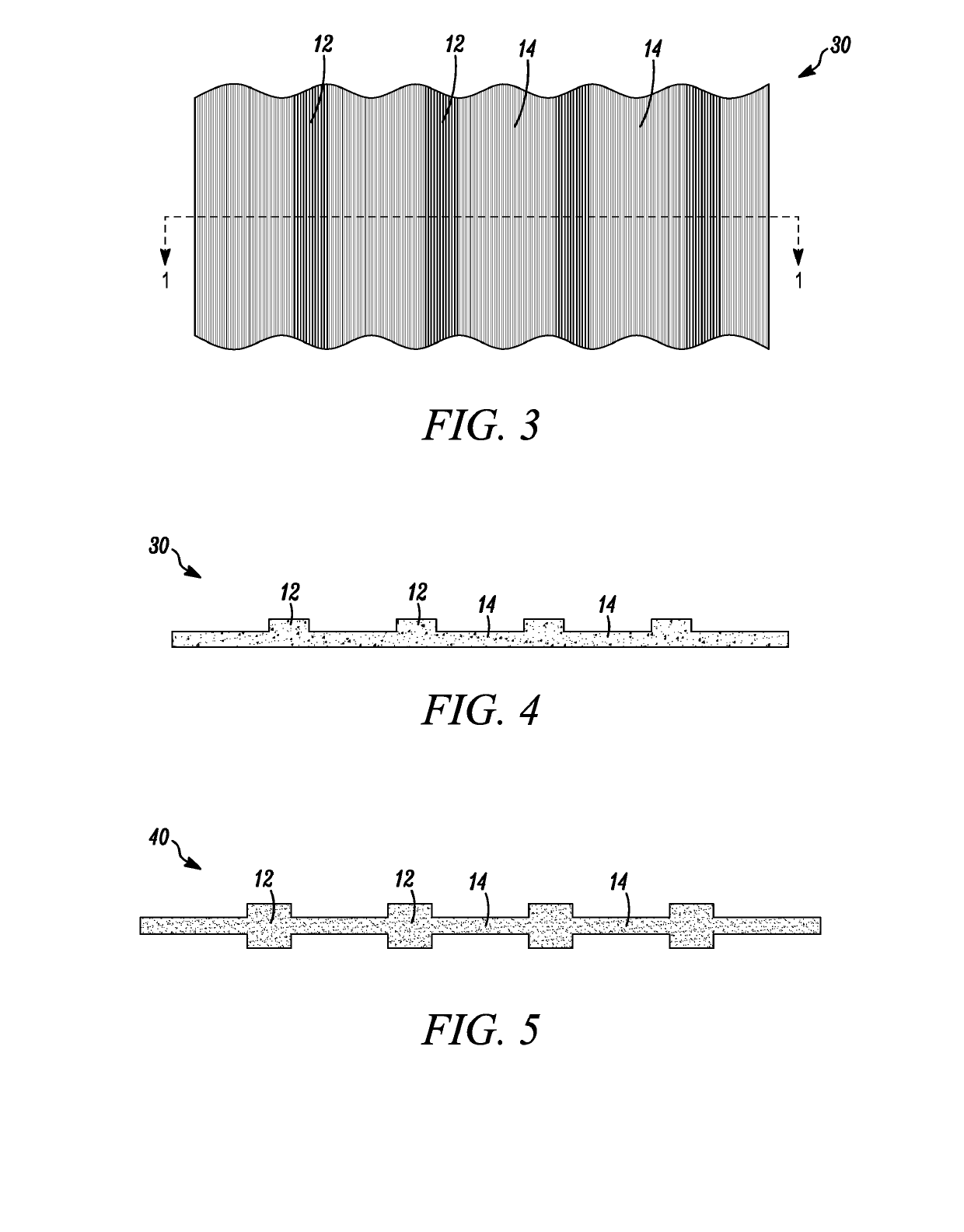

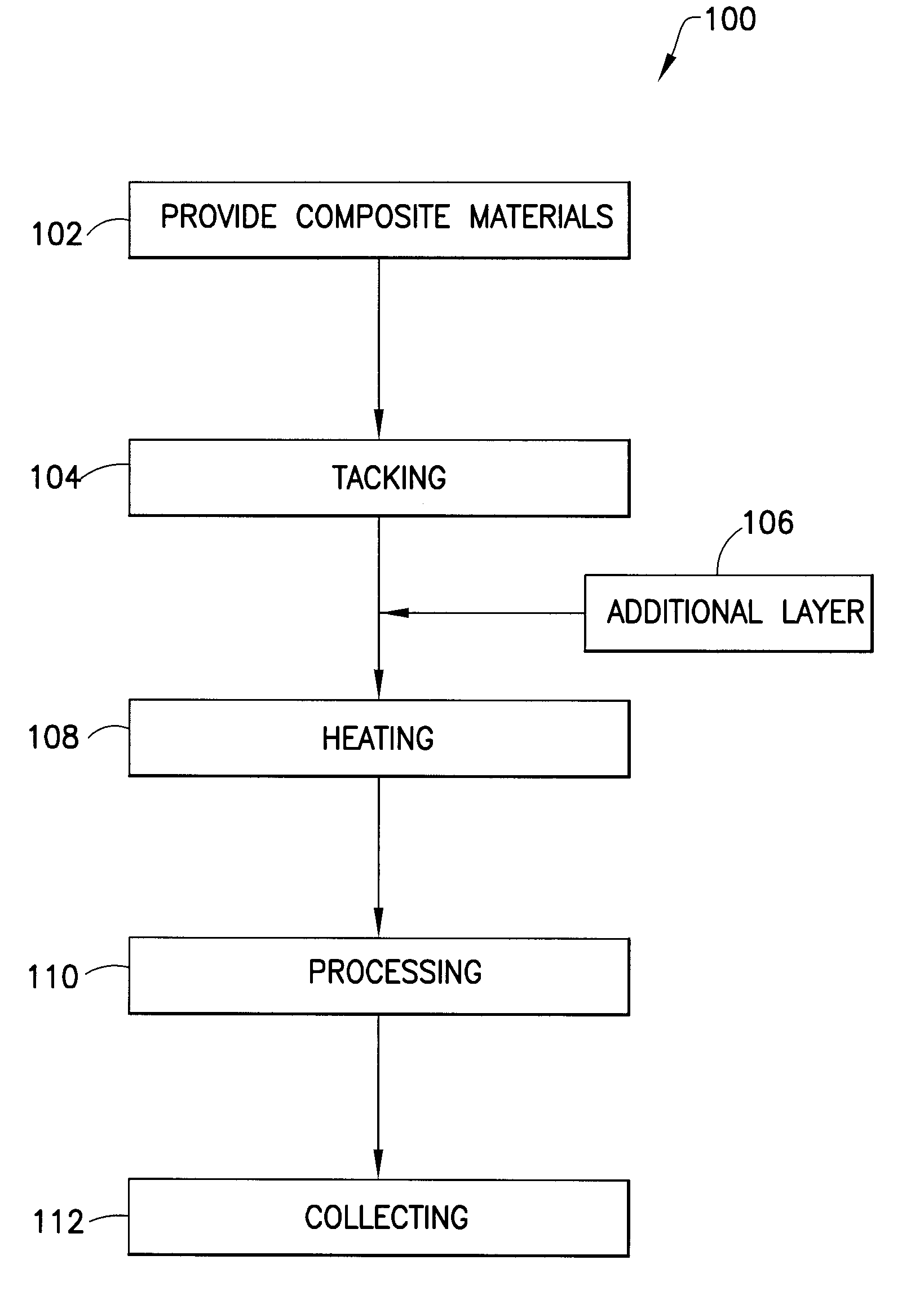

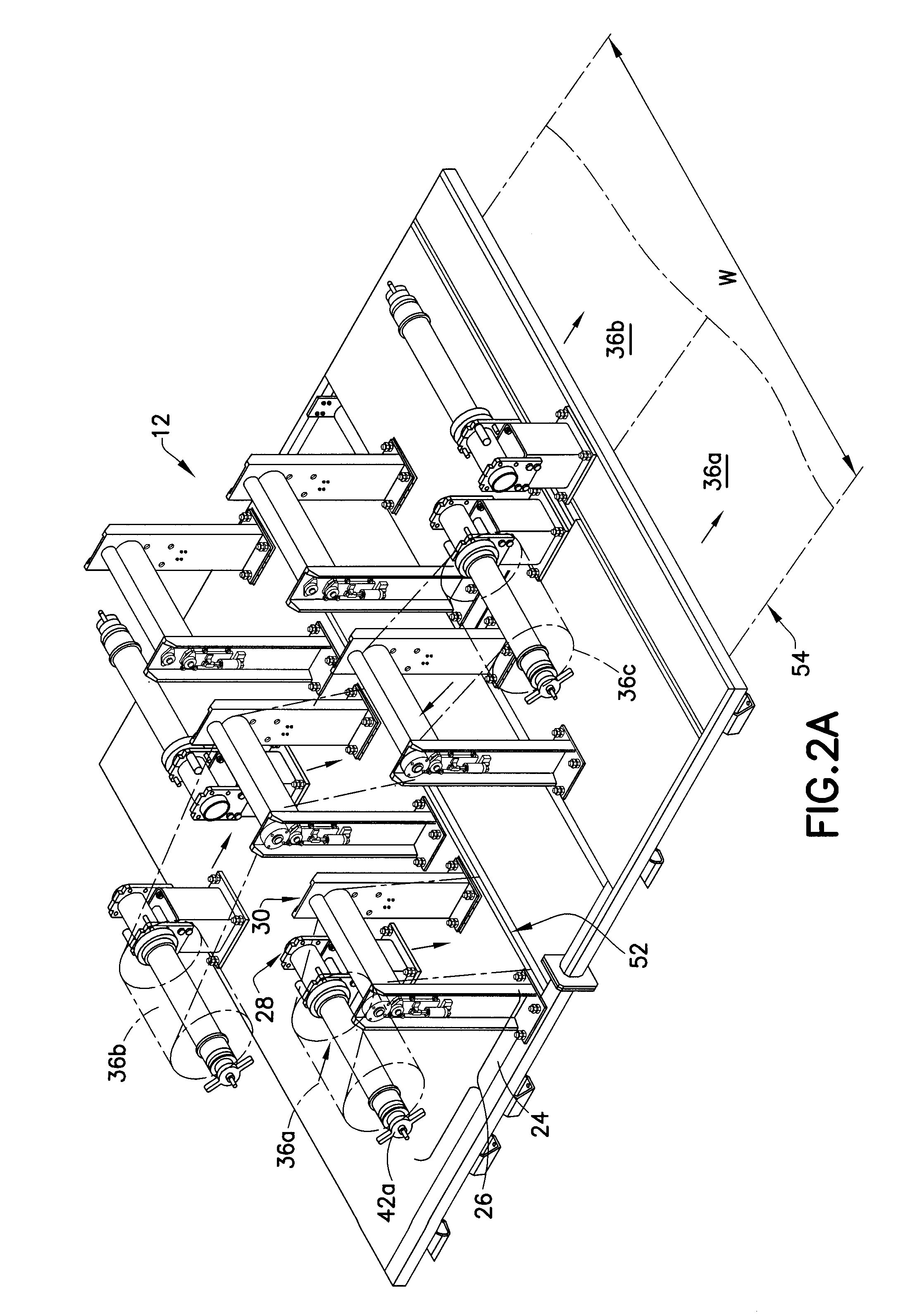

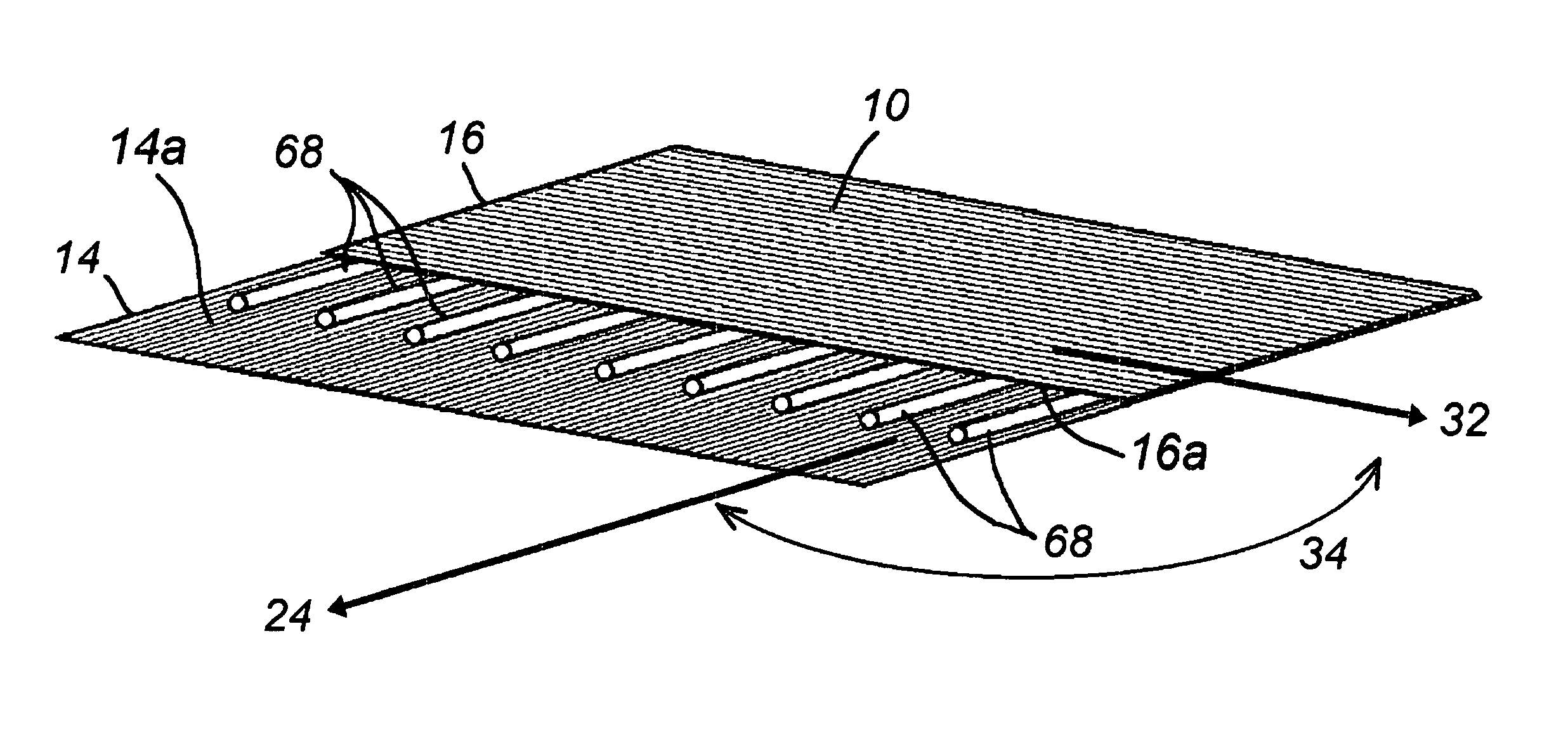

Method and apparatus for making sheets of composite material

A product sheet of composite material can be made by disposing composite materials of composite material in adjacent (side-by-side) relation with each other. The composite materials comprise fibers in a thermoplastic matrix material. The adjacent composite materials are bonded together to provide a product sheet of composite material. Preferably, a cross ply of composite material is disposed on the composite materials. The cross ply may be a unidirectional sheet and the fibers in the cross ply may be disposed in transverse relation to the fibers in the composite materials.

Owner:AVIENT CORP

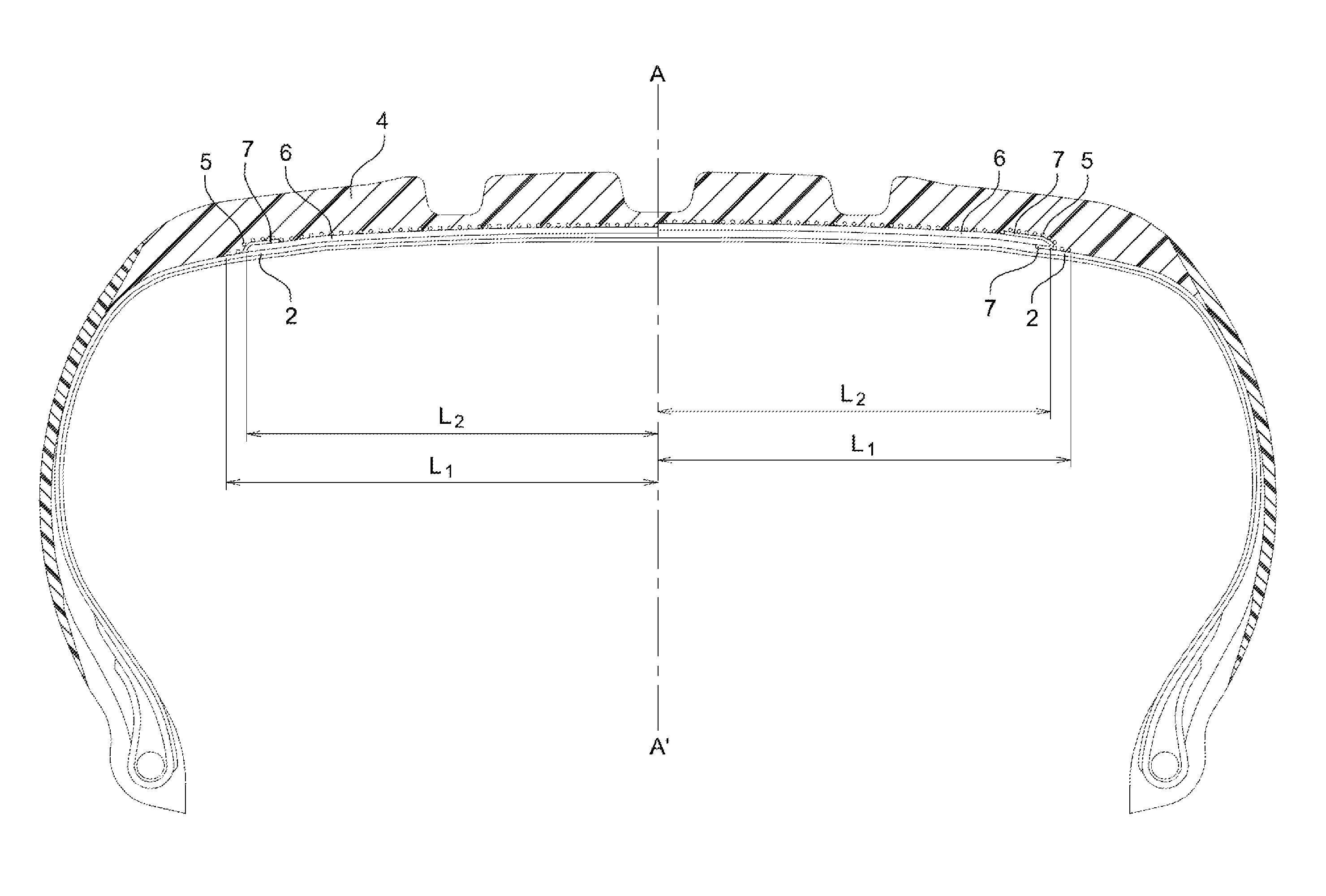

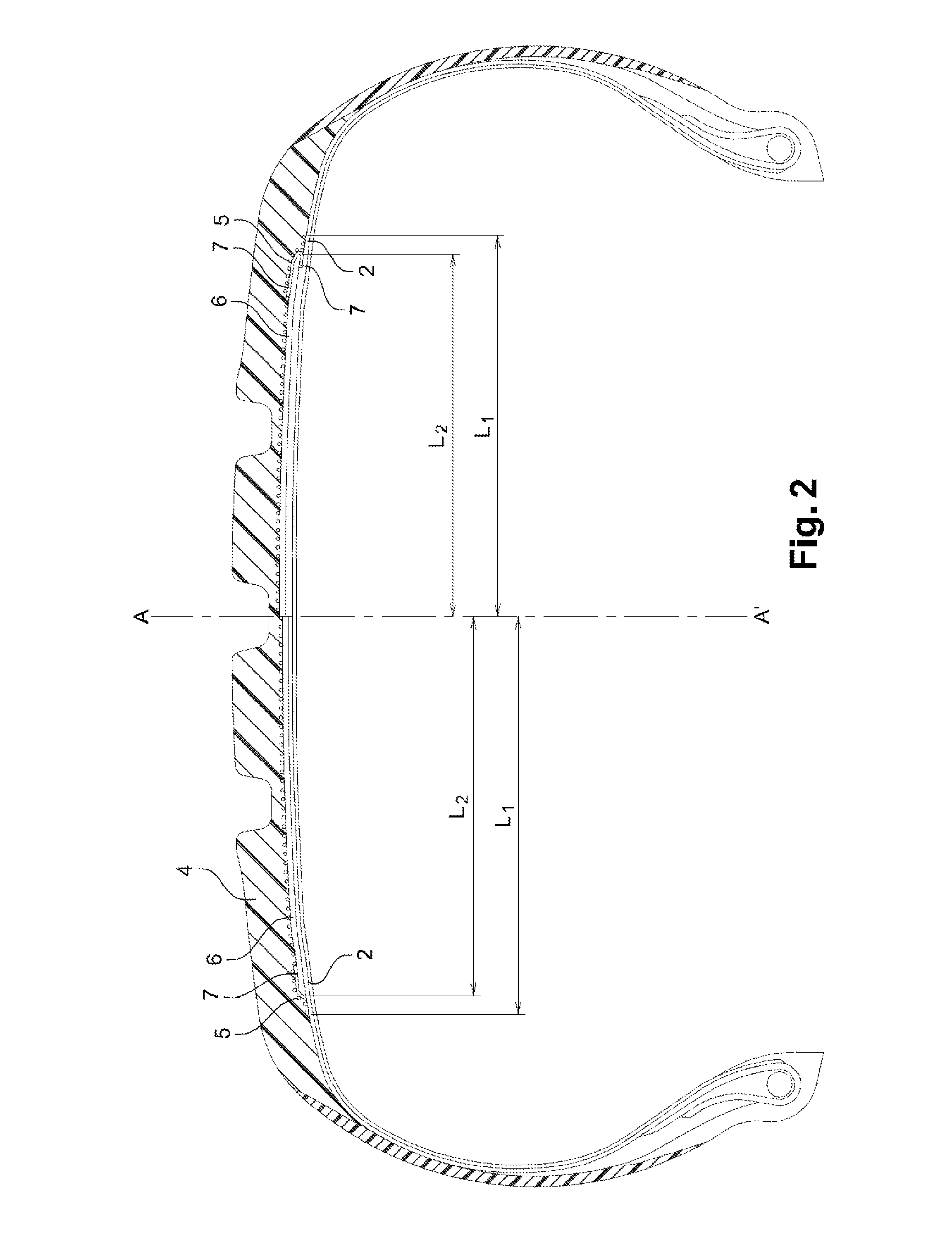

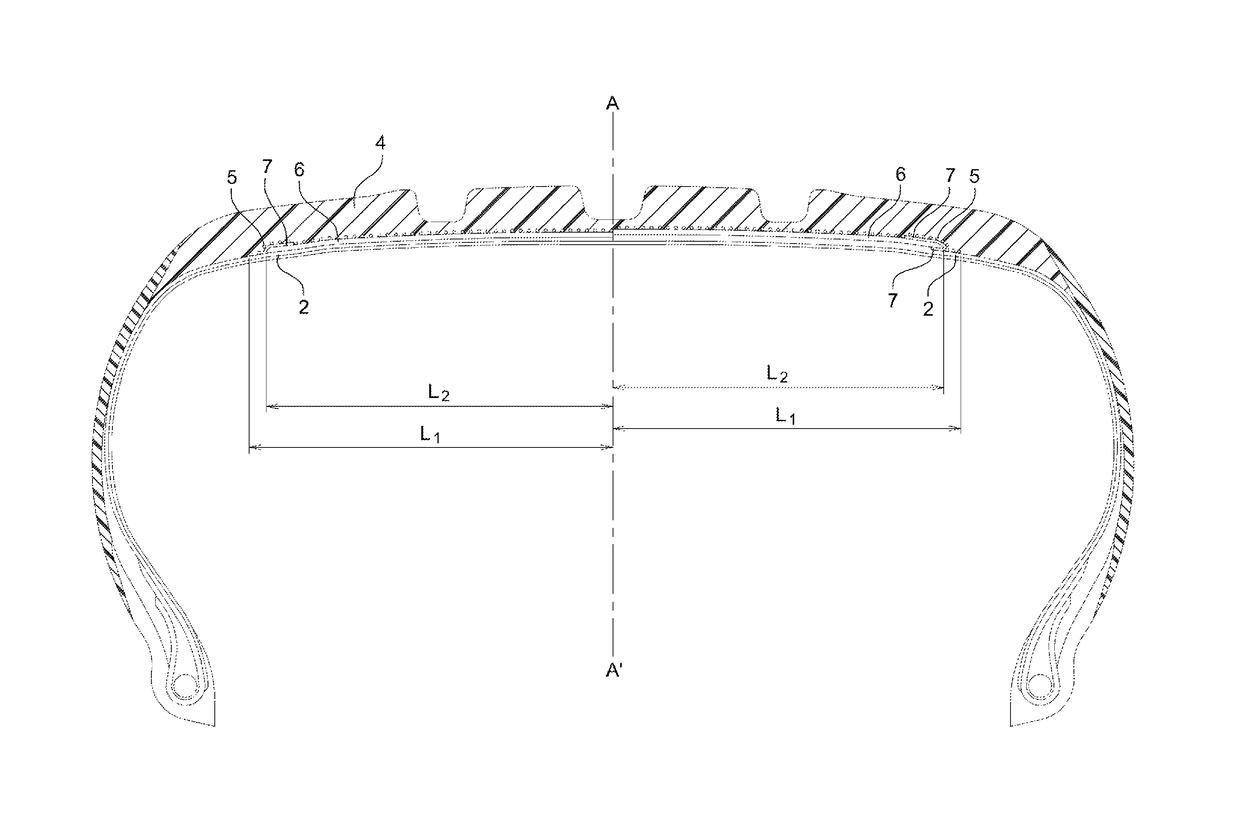

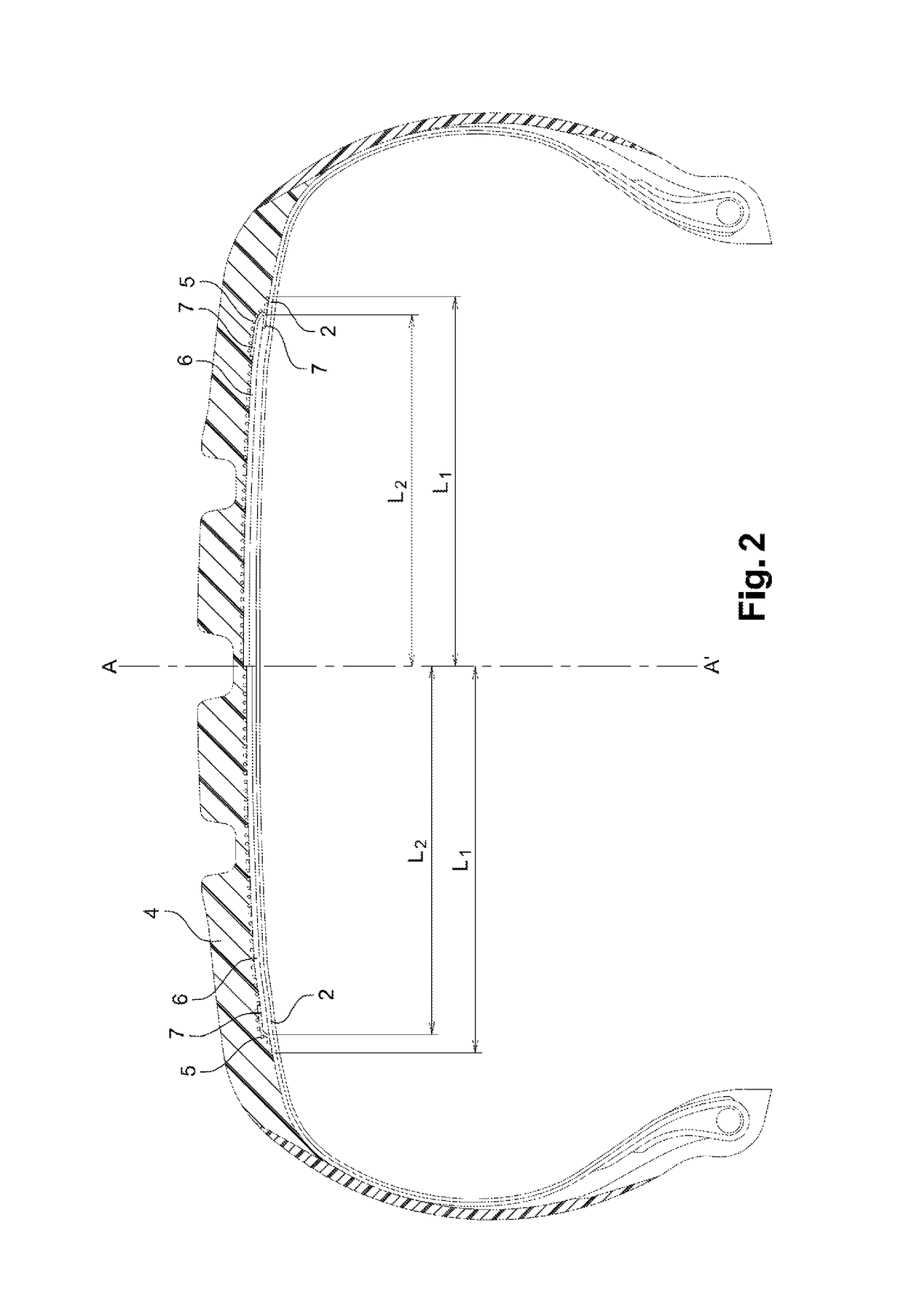

Tire with a radial or cross-ply carcass

InactiveUS20150114534A1Compromise performanceReduce movementPneumatic tyre reinforcementsYarnEngineeringTread

Tire having at least one carcass reinforcement, a tread, a belt reinforcer having a first and a second end and:a reinforcing ply, having a transverse half-width L2, having a reinforcing polymer layer between two layers of coating rubber,at least one hooping ply, surmounting the reinforcing ply, having a transverse half-width L1, and filamentary reinforcing elements, parallel two by two, forming an angle at most equal to 7° with respect to the circumferential direction,the tire having at least one layer of edge uncoupling rubber, positioned at least radially between the hooping ply and the reinforcing ply and positioned at at least one transverse end of the belt reinforcer, the layer of edge uncoupling rubber having a total length between 10 and 40 mm and a thickness between 0.2 and 1.2 mm, having at least one reinforcing ply, and at at least one end of the belt reinforcer, the half-widths L1 and L2 are different, and manifest a difference (L1−L2) between 5 and 10 mm.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

Heavy duty pneumatic tire with belt hard rubber layer

InactiveUS7735534B2Add dimensionNot easily causedHeavy duty tyresHeavy duty vehicleEngineeringHeavy duty

A tire 2 has a belt 14 and a hard rubber layer 16. The belt 14 has a first ply 26, a second ply 28, a third ply 30 and a fourth ply 32. A width W3 of the third ply 30 is smaller than a width W1 of the first ply 26 and a width W2 of the second ply 28, and 75% of a width of a tread. Each of the plies 26, 28, 30, 32 has a steel cord. The first ply 26 and the second ply 28 construct a cross-ply structure. A cord of the third ply 30 is wound spirally. The third ply 30 has what is referred to as a jointless structure. The hard rubber layer 16 is positioned between the first ply 26 and the second ply 28, and outward of the third ply 30 in an axial direction. A complex elastic modulus of the hard rubber layer 16 is equal to or greater than 30 MPa.

Owner:SUMITOMO RUBBER IND LTD

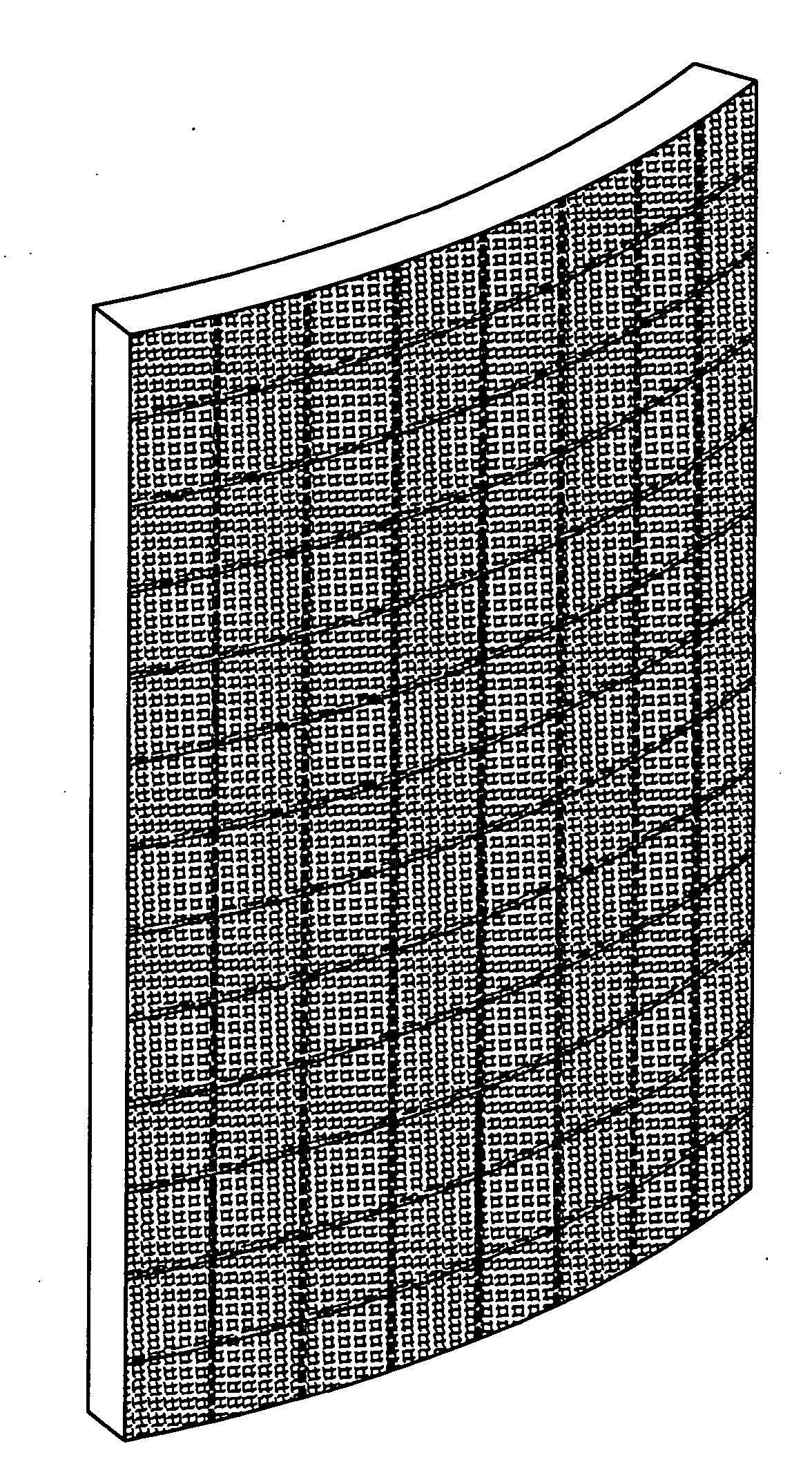

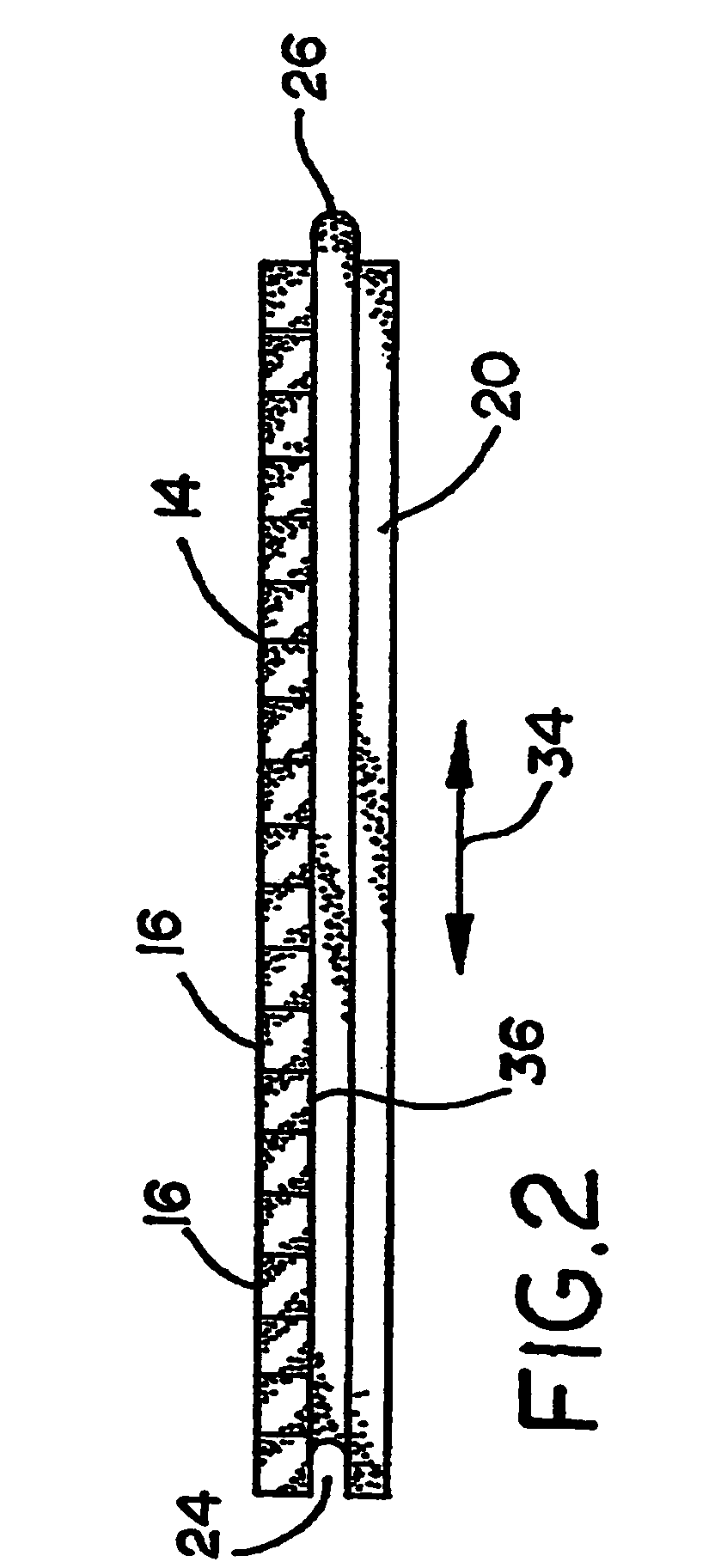

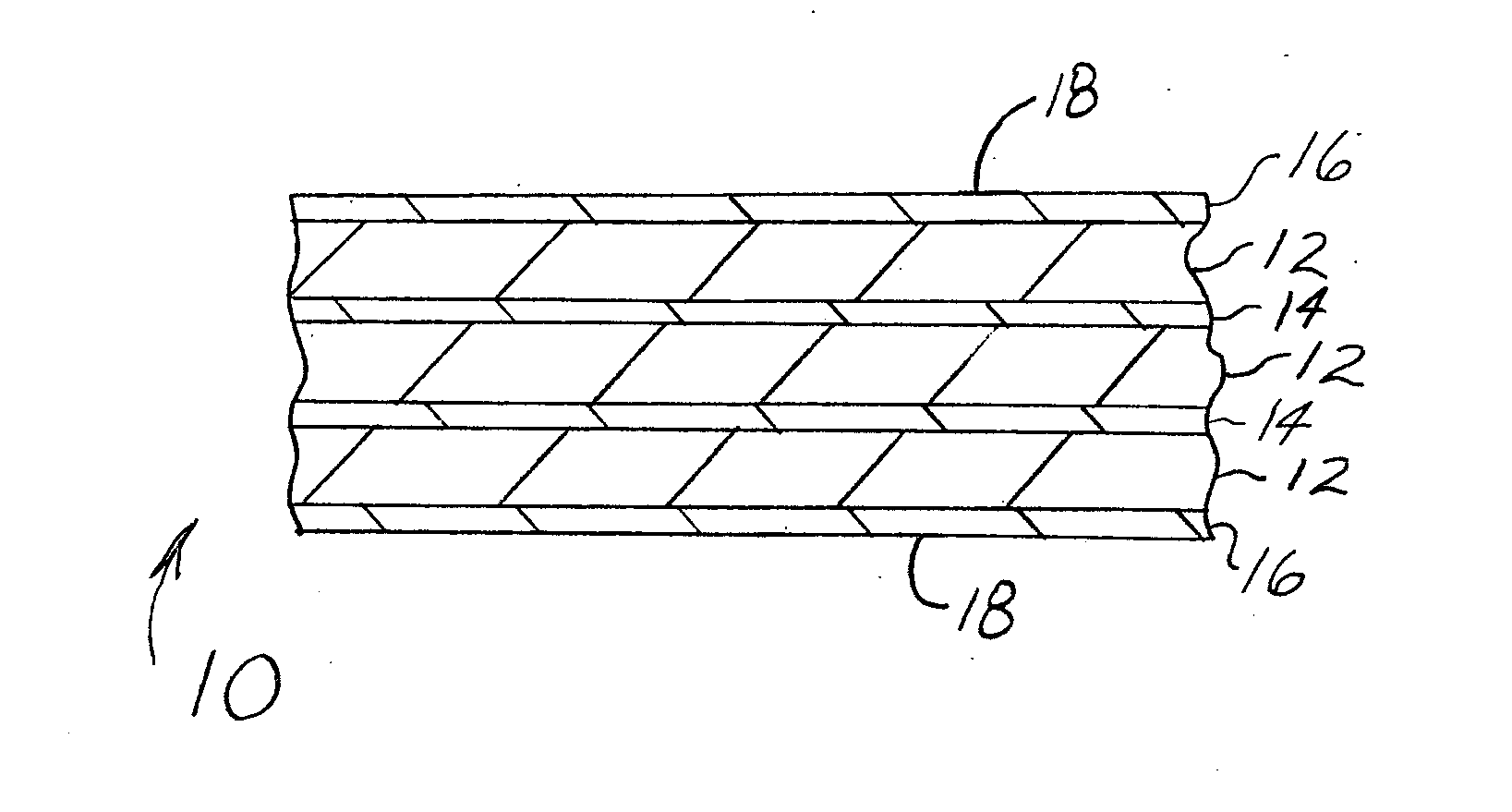

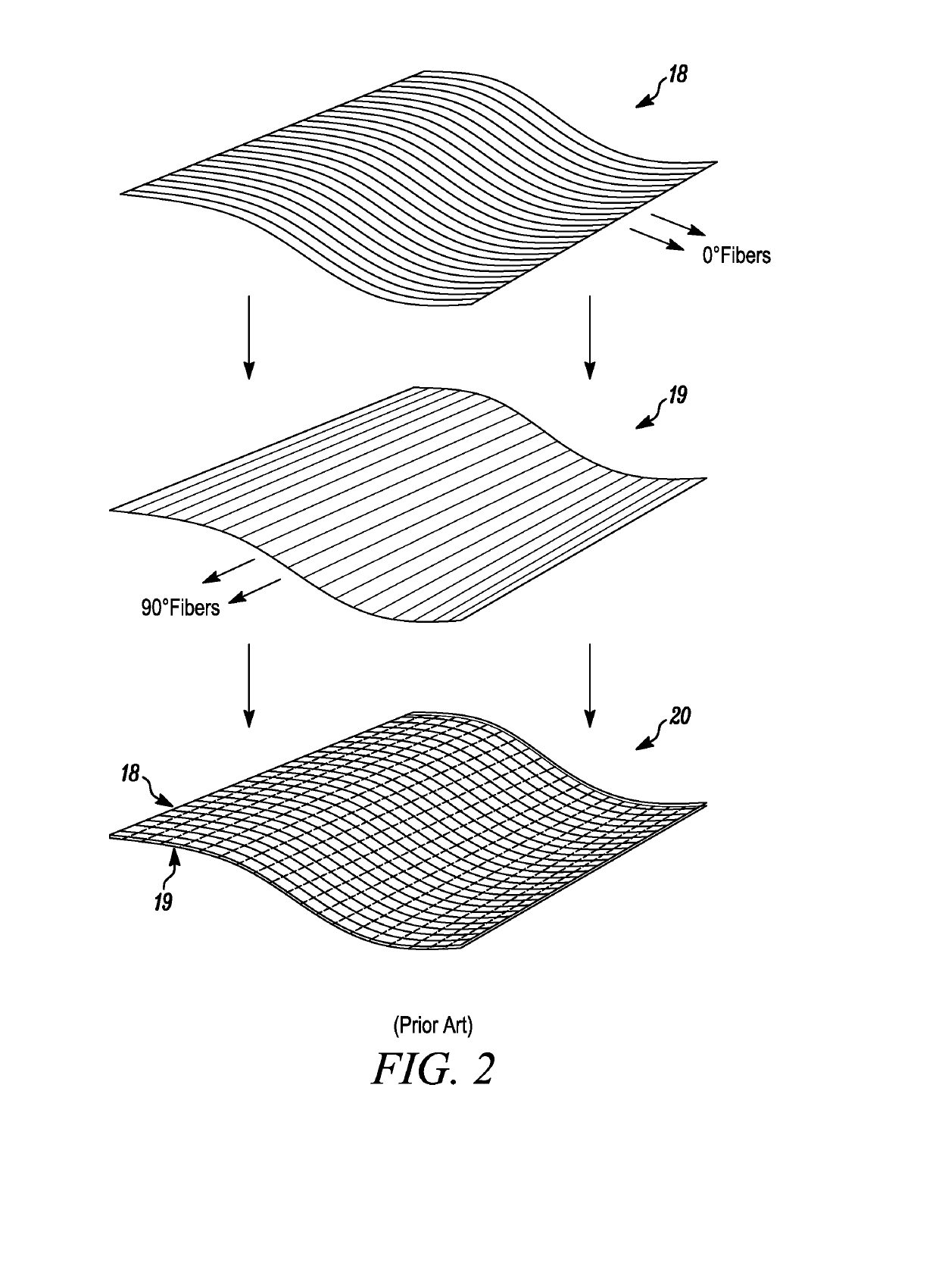

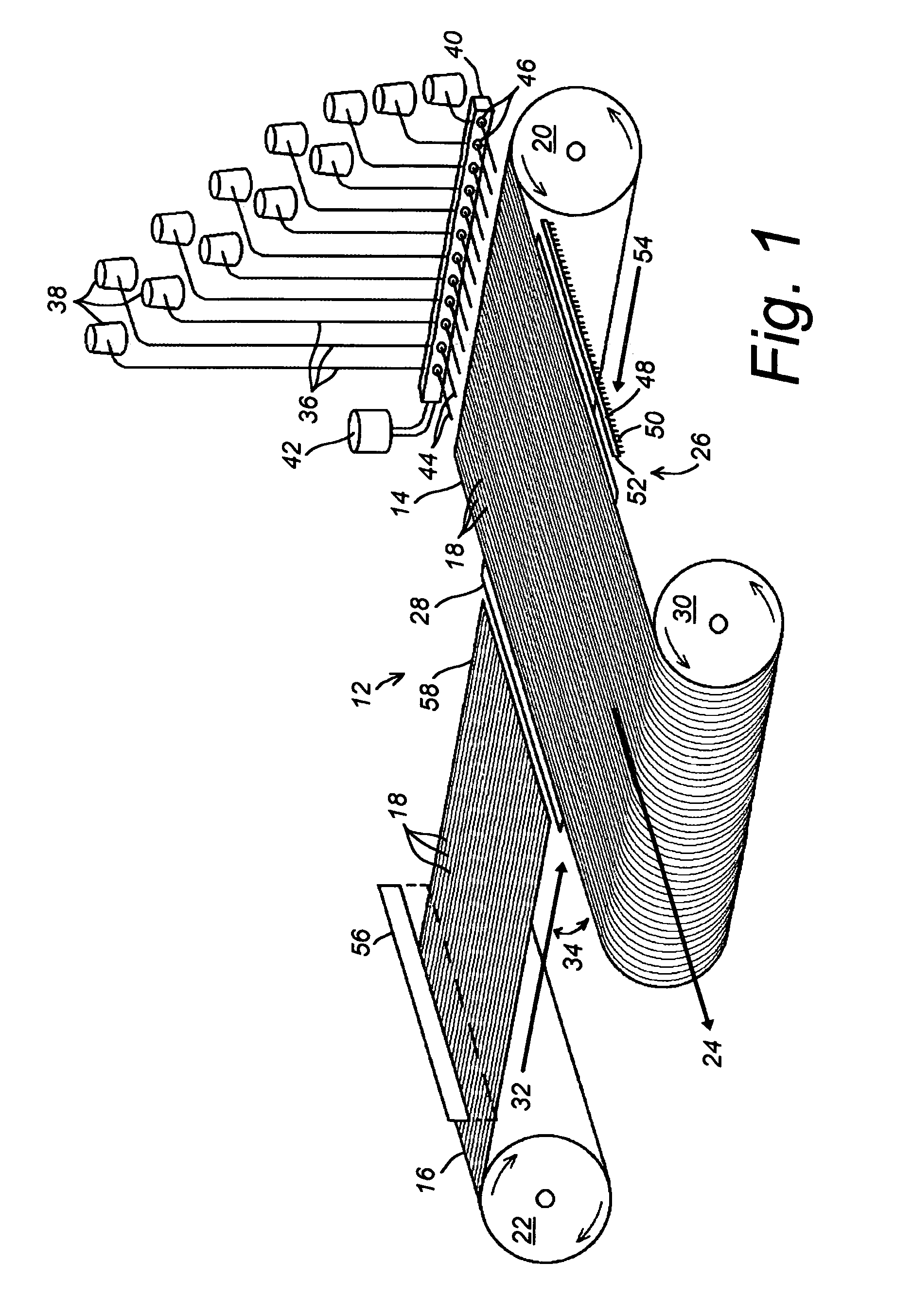

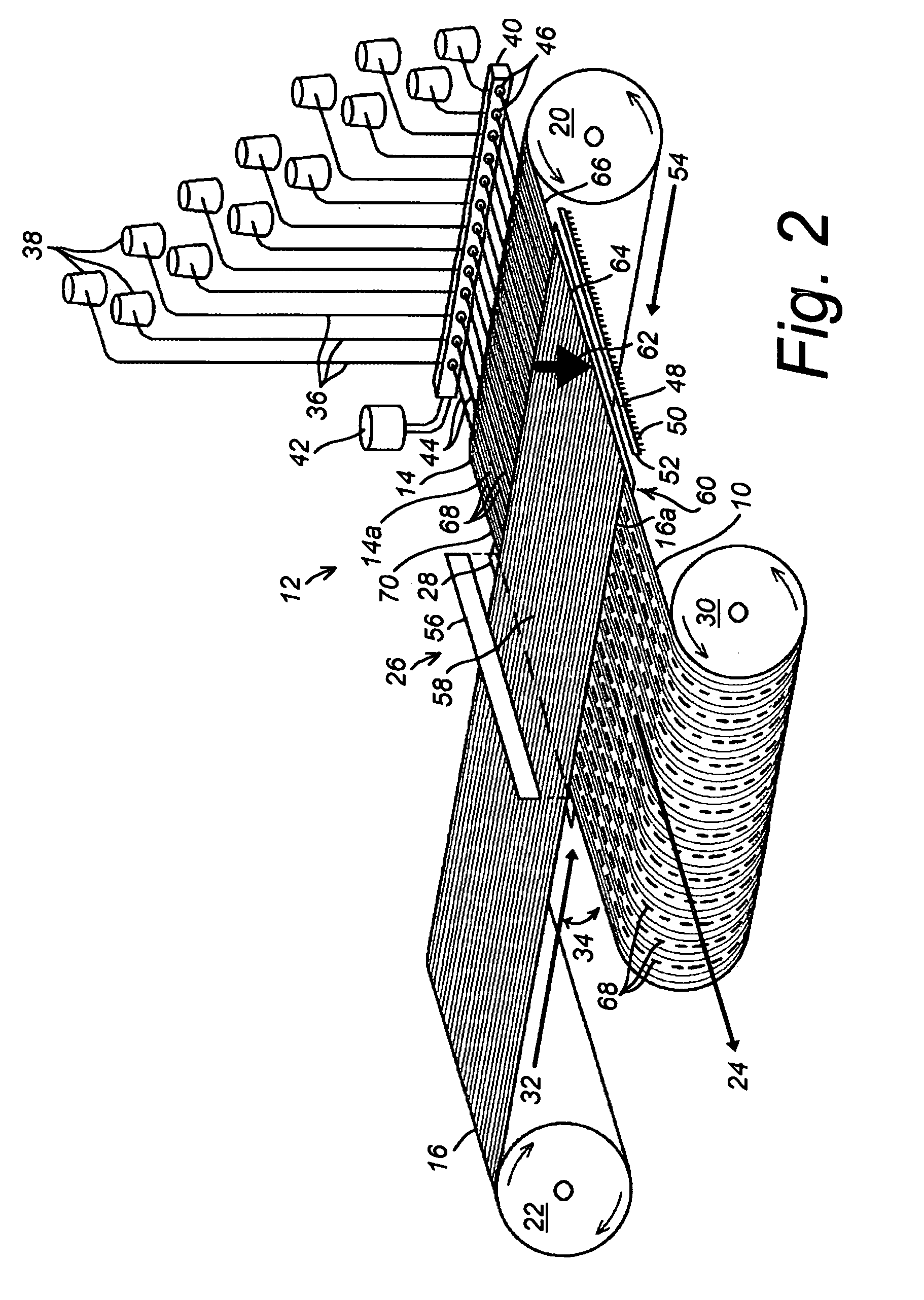

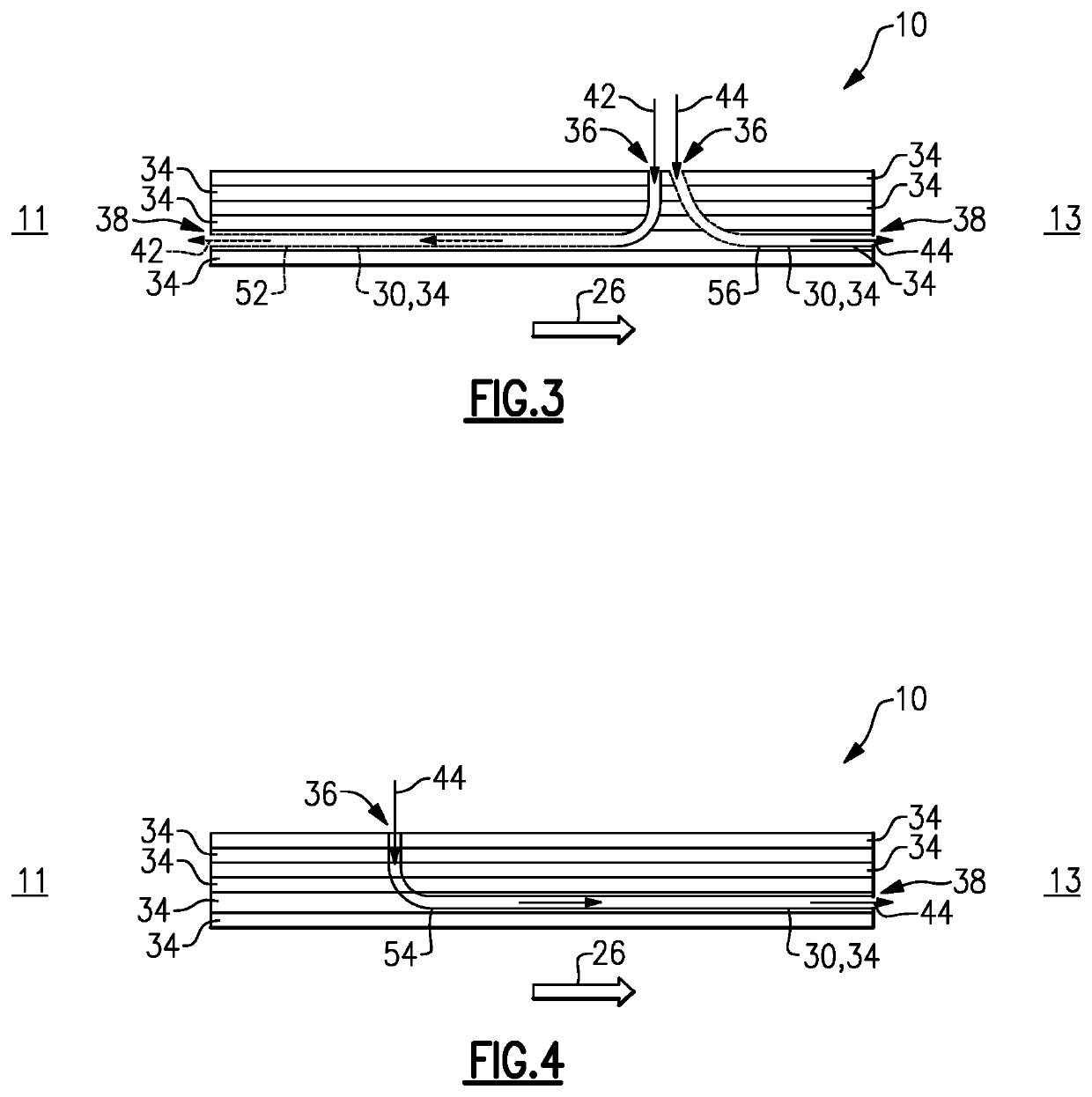

Continuous cross-plied material and method of manufacturing same

A novel cross-plied material is formed of portions of a ply of a ballistic-resistant structure composed of unidirectionally-oriented bundles of high strength filaments laminated between opposing thermoplastic films which portions are cross-plied with portions of a continuous ply of a similar ballistic-resistant structure with a plurality of yarns laterally spaced into a linear array corresponding to the width of the continuous ply along the ply direction. Substantially continuous coatings or deposits of a bonding or coupling agent on the yarns cause a plurality of substantially continuous bonding strips to be formed between the continuous ply and the portions of cross-ply, with the bonding strips being laid in a laterally spaced linear array corresponding to the yarns. The bonding strips couple the cross-ply portions with consecutive portions of the continuous ply, whereby the continuous ply and the cross-ply portions are adhered sufficiently to prevent their being pulled apart.

Owner:KRUEGER RONALD G +1

Ceramic matrix composite component including counterflow channels and method of producing

A ceramic matrix composite (CMC) component and method of fabrication including a plurality of counterflow elongated functional features. The CMC component includes a plurality of longitudinally extending ceramic matrix composite plies forming a densified body and a plurality of elongated functional features formed therein the densified body. Each of the plurality of functional features is configured longitudinally extending and in alignment with the plurality of ceramic matrix composite plies. Each of the plurality of elongated functional features includes an inlet configured in cross-ply configuration. The plurality of elongated functional features are configured to provide a flow of fluid from a fluid source to an exterior of the ceramic matrix composite component. The plurality of functional features are configured in alternating flow configuration.

Owner:GENERAL ELECTRIC CO

Composite ballistic resistant laminate

An unconsolidated impact and penetration resistant laminate comprises a plurality of cross-plied sheets, each cross-plied sheet further comprising (i) first and second layers of fibrous or non-fibrous ultra-high molecular weight polyethylene and (ii) first and second layers of thermoplastic adhesive, each adhesive layer having a basis weight of no greater than 5 gsm, wherein(a) the layers of polyethylene and thermoplastic adhesive alternate within the sheet,(b) at least 50 percent of the polyethylene layers are arranged such that the orientation of the first polyethylene layer is offset with respect to the orientation of the second polyethylene layer, and(c) the plurality of cross-plied sheets form a stack that, when subjected to compaction at a pressure of 255 bar and a temperature of 132 degrees C., will not suffer a pressure loss greater than 8 bar within the first two minutes as measured by Test Method B.

Owner:DUPONT SAFETY & CONSTR INC

Heavy duty pneumatic tire

A tire 2 has a belt 14 and a hard rubber layer 16. The belt 14 has a first ply 26, a second ply 28, a third ply 30 and a fourth ply 32. A width W3 of the third ply 30 is smaller than a width W1 of the first ply 26 and a width W2 of the second ply 28, and 75% of a width of a tread. Each of the plies 26, 28, 30, 32 has a steel cord. The first ply 26 and the second ply 28 construct a cross-ply structure. A cord of the third ply 30 is wound spirally. The third ply 30 has what is referred to as a jointless structure. The hard rubber layer 16 is positioned between the first ply 26 and the second ply 28, and outward of the third ply 30 in an axial direction. A complex elastic modulus of the hard rubber layer 16 is equal to or greater than 30 MPa.

Owner:SUMITOMO RUBBER IND LTD

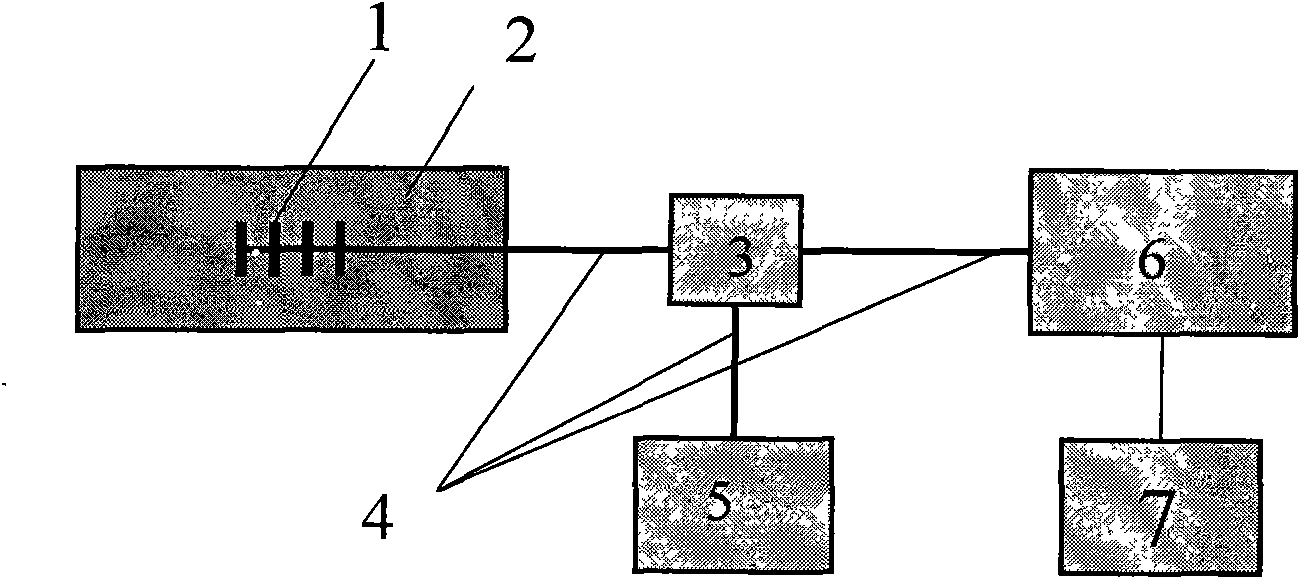

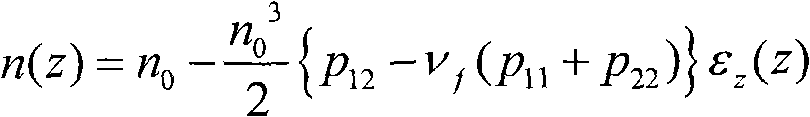

Method for positioning transverse cracks of carbon fiber composite material by using chirp grating

InactiveCN101819160AReal-time detection of transverse cracksSimple methodScattering properties measurementsOptically investigating flaws/contaminationGratingLength wave

The invention discloses a method for positioning transverse cracks of a carbon fiber composite material by using a chirp grating, which comprises the following steps of: (1) manufacturing a carbon fiber composite material cross-ply laminate with the stacking sequence of [0-degree 2 / 90-degree 4 / 0-degree 2], and embedding a chirp grating sensor into a 0-degree layer the carbon fiber composite material cross-ply laminate, wherein the chirp grating sensor is adjacent to a 90-degree layer; (2) under a condition with a constant temperature, using an optical fiber sensing analyzer to monitor a chirp grating reflection spectrum of a carbon fiber composite material test piece in a quasistatic tensile test; and (3) adjusting the length of the chirp grating to be accordant with a bandwidth phase of the chirp grating reflection spectrum before embedding in a coordinate system to ensure that a wavelength position corresponding to a point with decreased light intensity and a grating position corresponding to the wavelength in the chirp grating reflection spectrum are the positions where the transverse cracks are generated in the 90-degre layer of the composite material at that time. The method is simple, has a low cost, and can detect the transverse cracks in the carbon fiber composite material in real time.

Owner:SHENYANG INST OF AERONAUTICAL ENG

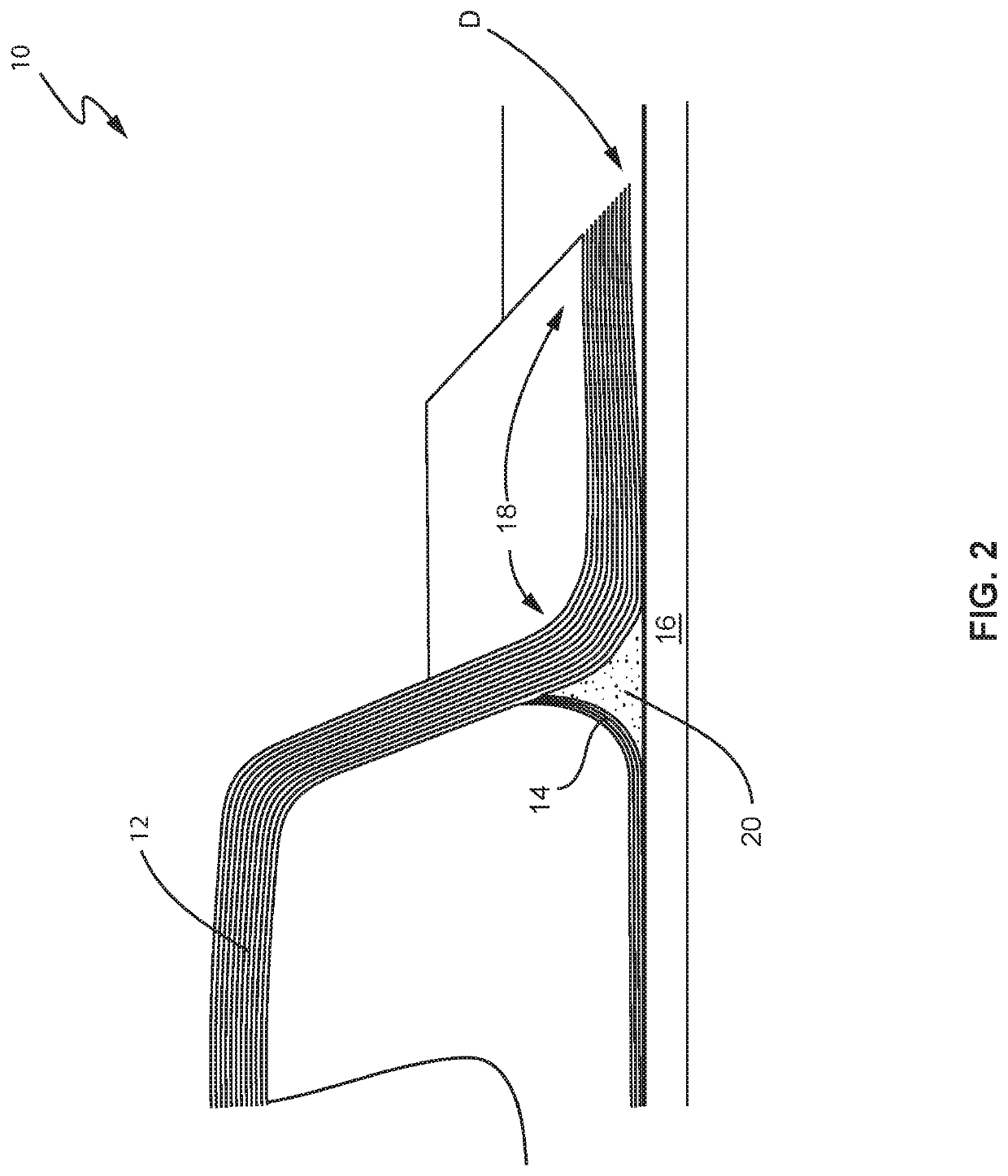

Method for Determining Noodle and Interface Residual Stresses and Properties Under Hygrothermal-Mechanical Loadings

InactiveUS20200173881A1Geometric CADDesign optimisation/simulationCross plyManufacturing engineering

A computer is configured to generate visual representations of a composite filler material, such as a noodle or a crossply laminate, for example, to determine the progressive creation, density, and spacing of a plurality of cracks in the filler material. The composite filler material is disposed at a connection interface between a load-bearing composite structural component, such as a stringer or a spar, for example, and the structural framework of a vehicle on which those structural components are utilized.

Owner:THE BOEING CO

Tire with a radial or cross-ply carcass

InactiveUS9987882B2Compromise performanceReduce movementPneumatic tyre reinforcementsHoopingEngineering

Tire having at least one carcass reinforcement, a tread, a belt reinforcer having a first and a second end and:a reinforcing ply, having a transverse half-width L2, having a reinforcing polymer layer between two layers of coating rubber,at least one hooping ply, surmounting the reinforcing ply, having a transverse half-width L1, and filamentary reinforcing elements, parallel two by two, forming an angle at most equal to 7° with respect to the circumferential direction,the tire having at least one layer of edge uncoupling rubber, positioned at least radially between the hooping ply and the reinforcing ply and positioned at at least one transverse end of the belt reinforcer, the layer of edge uncoupling rubber having a total length between 10 and 40 mm and a thickness between 0.2 and 1.2 mm, having at least one reinforcing ply, and at at least one end of the belt reinforcer, the half-widths L1 and L2 are different, and manifest a difference (L1−L2) between 5 and 10 mm.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

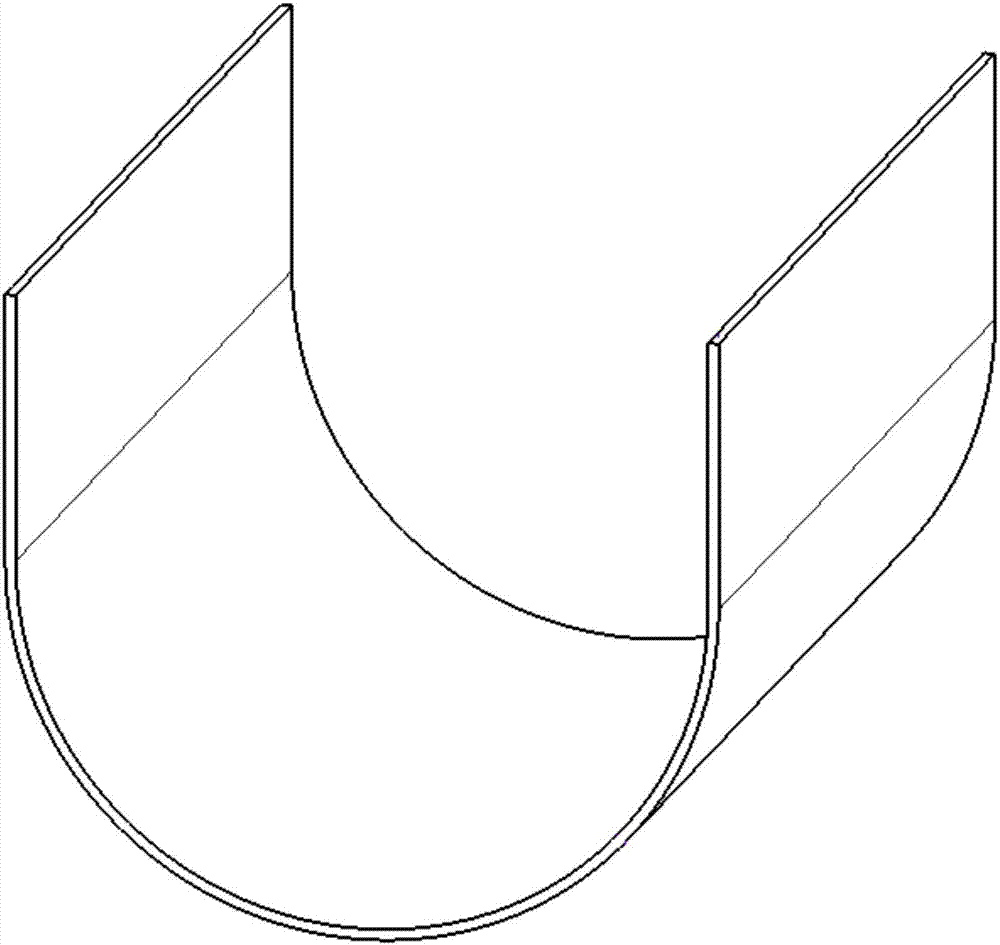

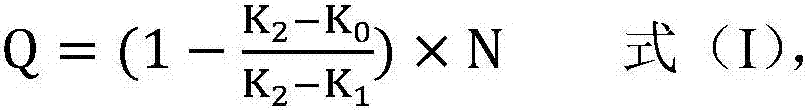

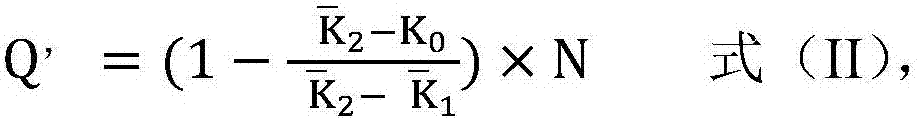

Method for reducing deformation of U-shaped composite part

The invention relates to a method for reducing deformation of a U-shaped composite part. The method comprises the following steps: a, making a continuous fiber sample part according to the layer lay-up design of a target part, and measuring the U-shaped opening dimension K1 of the continuous fiber sample part; b, making a satin fabric sample part after completely replacing the cross-ply layers in the layer lay-up design with satin fabric, and measuring the U-shaped opening dimension K2 of the satin fabric sample part; c, calculating the layer number Q of the satin fabric after correction; and d, making a U-shaped part after correction according to the rules that the number of the cross-ply layers of the satin fabric is Q and the number of the continuous fiber cross-ply layers is N-Q. According to the method for reducing deformation of the U-shaped composite part, the die surface can be obtained without long-time complicated and difficult calculation, making a new die after carrying out additional finite element calculation is not needed, and meanwhile repeated die repairing is also not needed.

Owner:BEIJING AUTOMOTIVE IND CORP +1

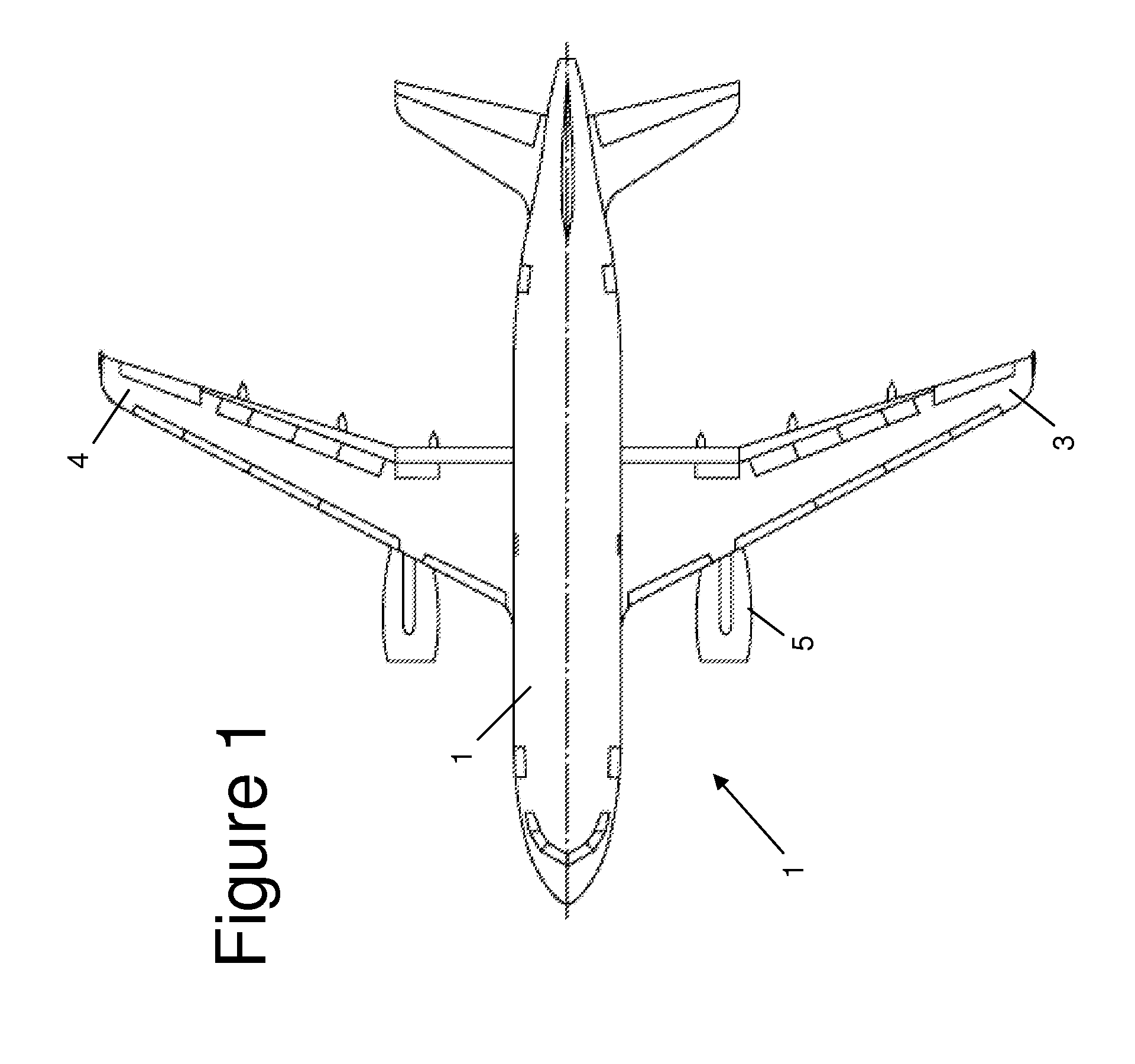

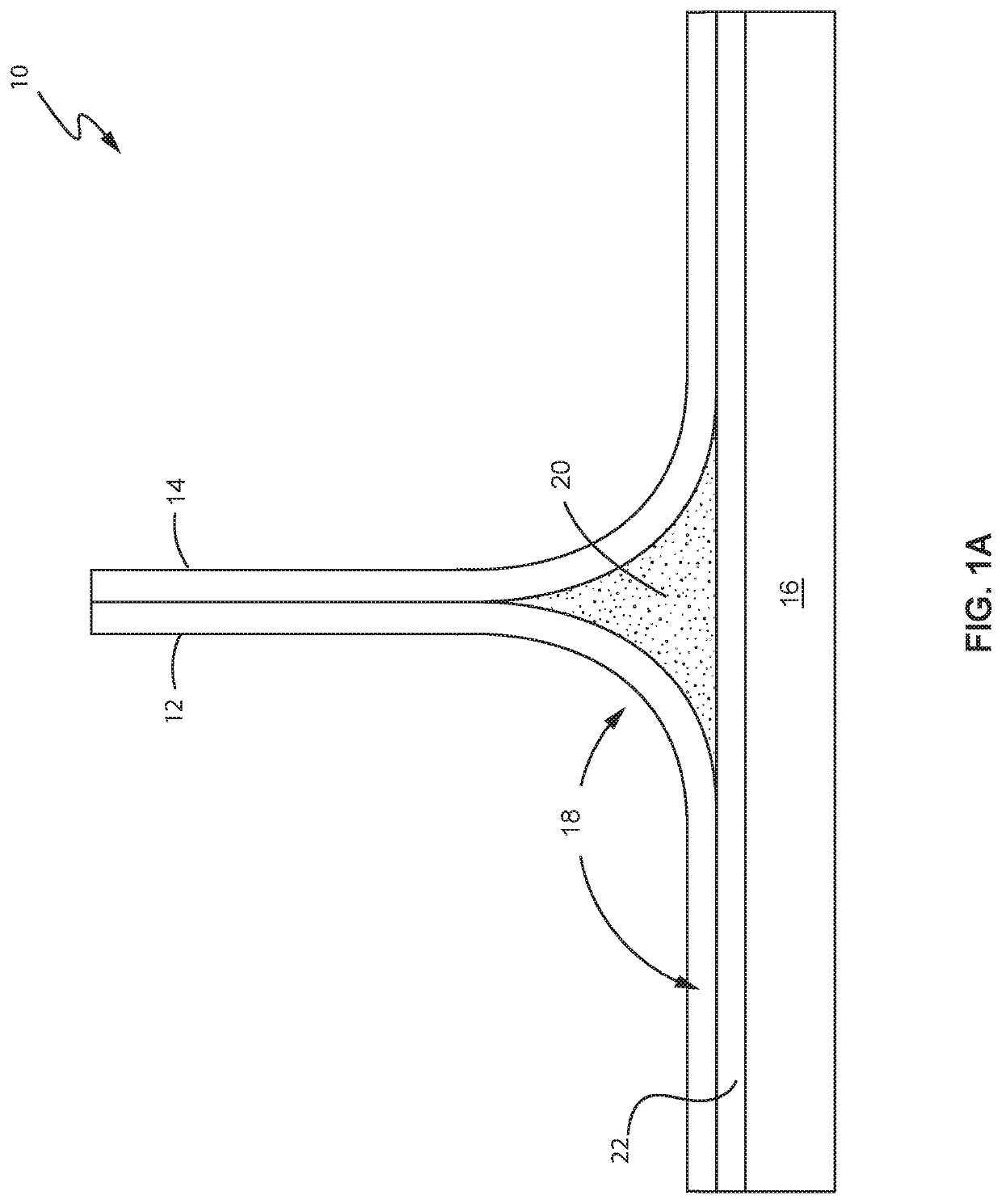

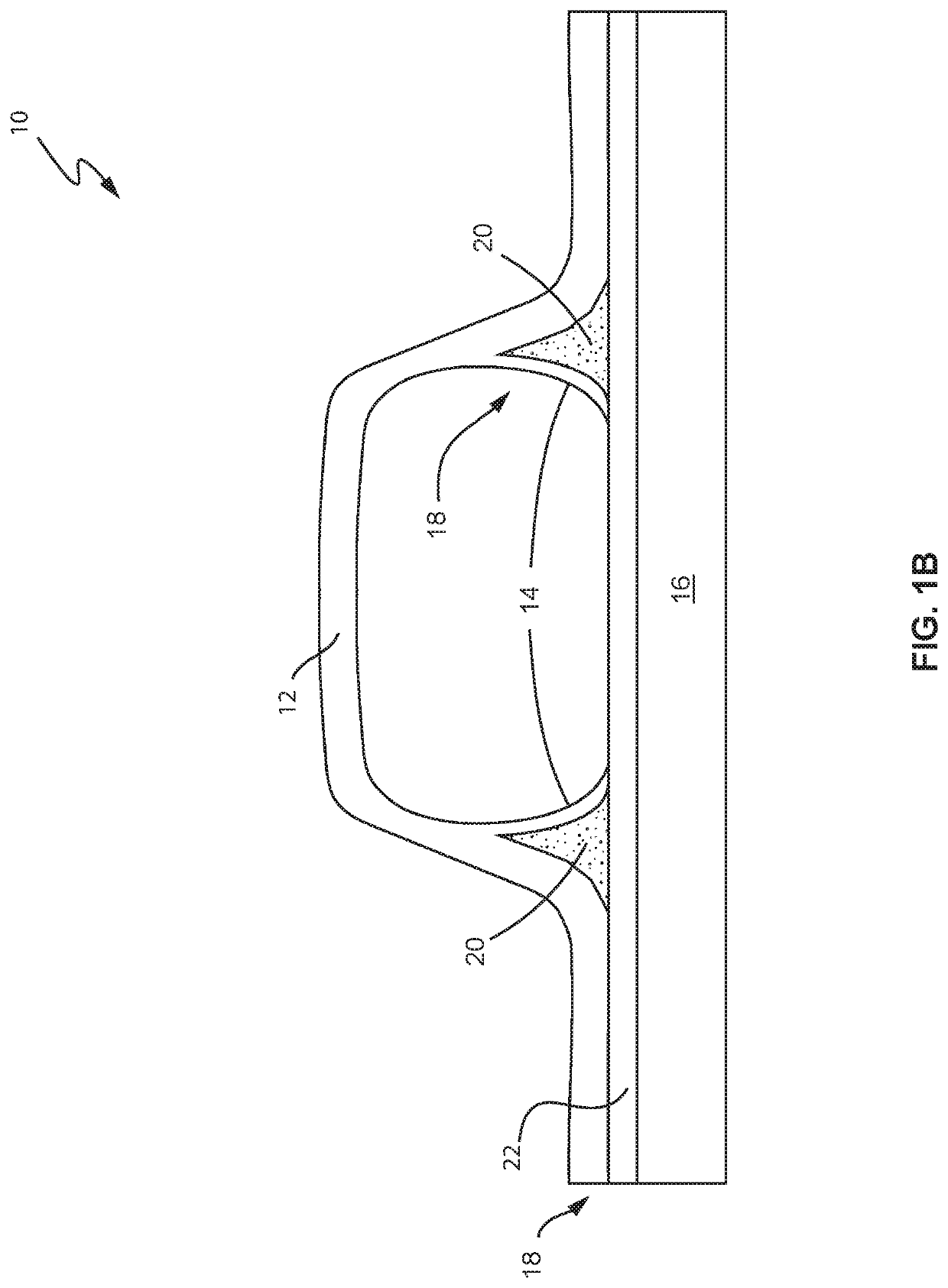

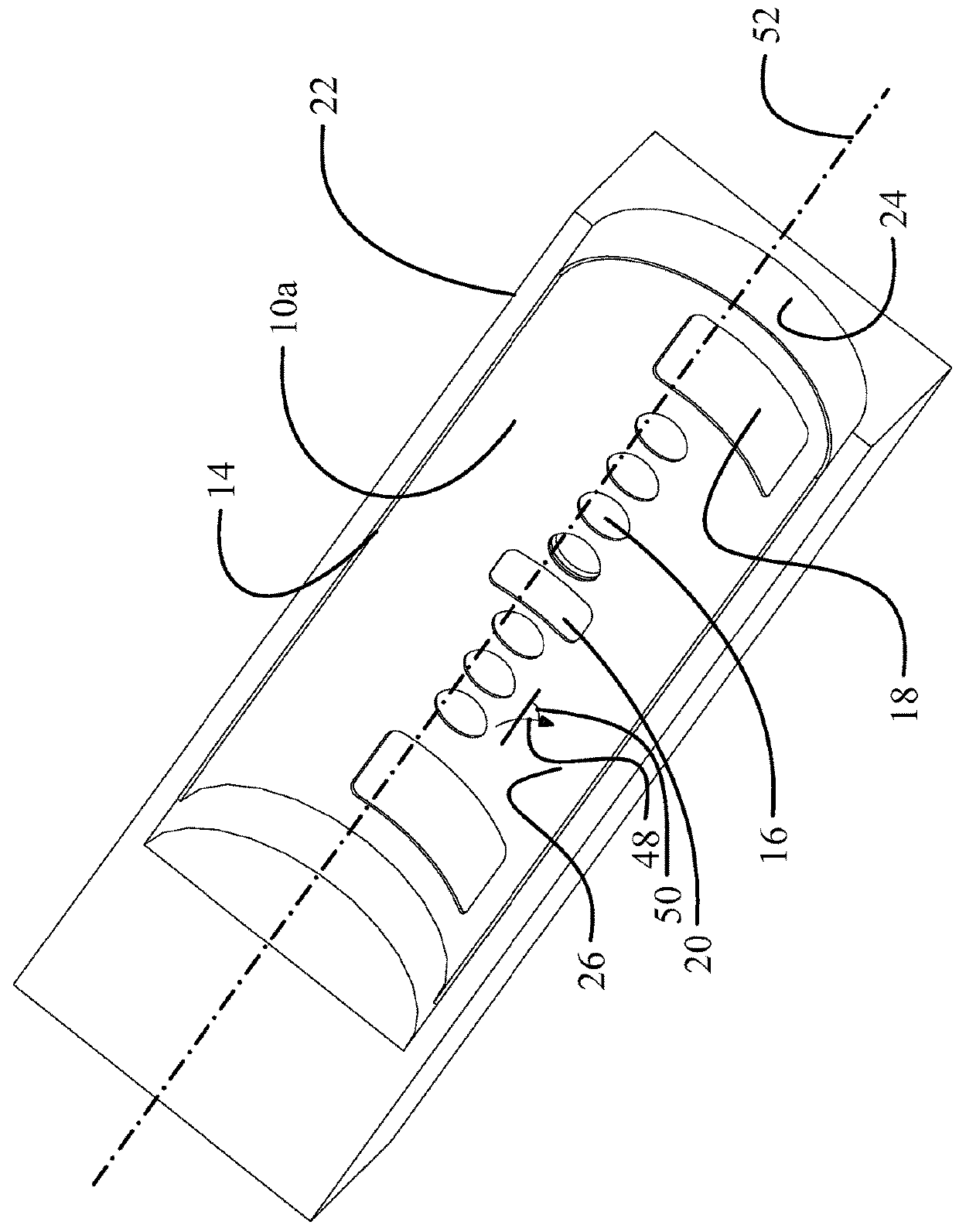

Method and apparatus for fabrication of lattice composite fuselage for commercial aircraft employing steered fiber lay up

InactiveUS20180273206A1Keep the distanceFuselage framesPower plant exhaust arrangementsFiberAviation

A system for fabrication of an aerospace structure incorporates a mold having a surface and at least one unidirectional SFL head adapted to lay down a plurality of collimated tows in a predetermined laminated pattern on the mold surface to produce a fuselage skin. At least one cross plied laminate SFL head is adapted to lay down a cross plied laminate base interface on the fuselage skin to establish a lattice rib shape for each of a plurality of lattice ribs. The cross plied laminate SFL head has a band placement head steerable to avoid structural design features and to maintain spacing from adjacent steered lattice ribs. The unidirectional SFL head is further adapted to lay down a plurality of collimated tows on the base interface of each of the plurality of lattice ribs for a first plurality of unidirectional tow plies in each lattice rib. The unidirectional SFL head has a fiber placement head steerable to match the lattice rib shape to avoid structural design features and to maintain spacing from adjacent steered lattice ribs.

Owner:THE BOEING CO

Ceramic matrix composite component including counterflow channels and method of producing

A ceramic matrix composite (CMC) component and method of fabrication including a plurality of counterflow elongated functional features. The CMC component includes a plurality of longitudinally extending ceramic matrix composite plies forming a densified body and a plurality of elongated functional features formed therein the densified body. Each of the plurality of functional features is configured longitudinally extending and in alignment with the plurality of ceramic matrix composite plies. Each of the plurality of elongated functional features includes an inlet configured in cross-ply configuration. The plurality of elongated functional features are configured to provide a flow of fluid from a fluid source to an exterior of the ceramic matrix composite component. The plurality of functional features are configured in alternating flow configuration.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com