Method for reducing deformation of U-shaped composite part

A composite material and U-shaped technology, which is applied in the field of composite material processing, can solve the problems of reduced surface accuracy, long cycle and high development cost, and achieve the effect of reducing deformation of parts and ensuring surface accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

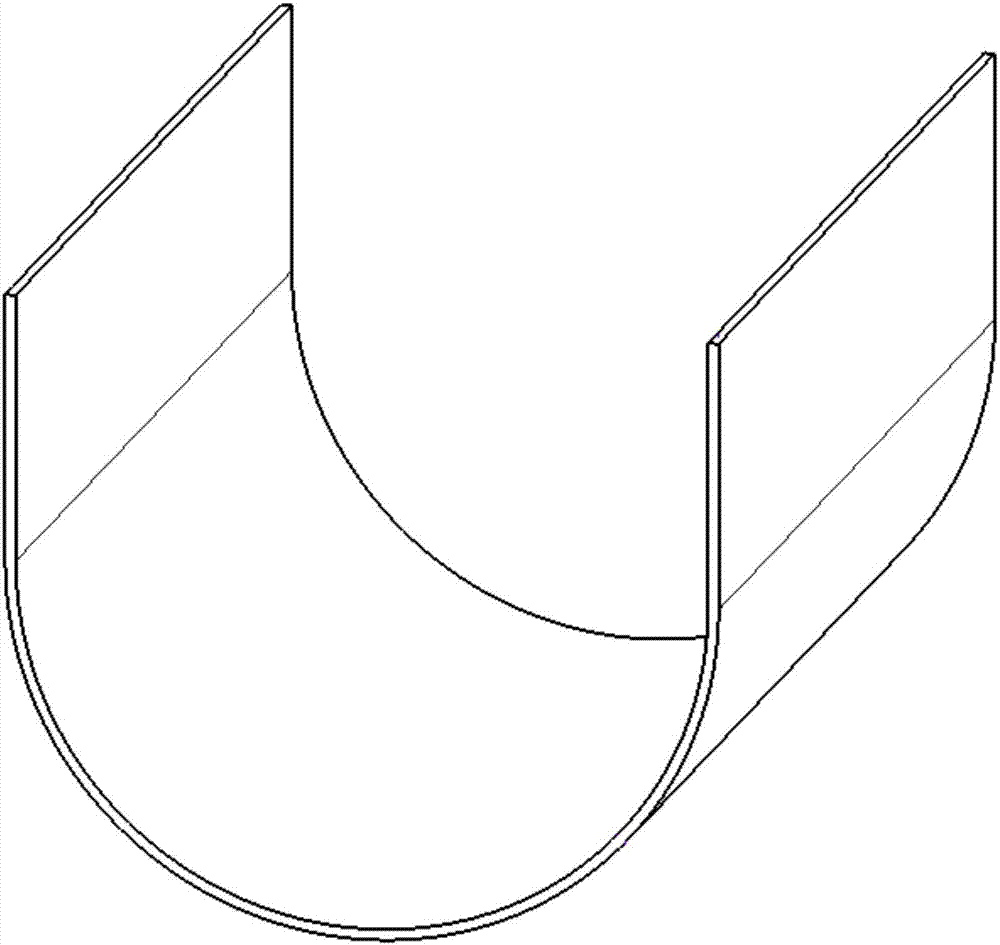

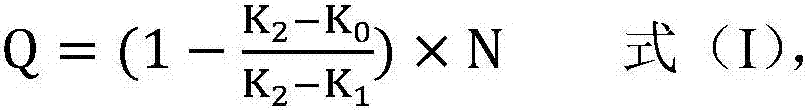

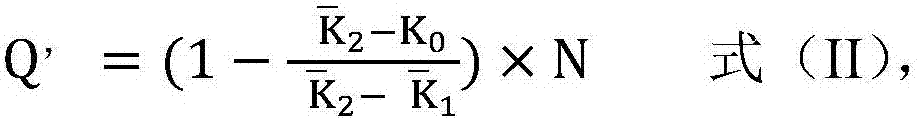

[0057] The U-shaped part that present embodiment makes is as figure 1 shown. The U-shaped opening of the target workpiece requires dimension K 0 for First, use T300-3K unidirectional epoxy prepreg (purchased from Shandong Guangwei Company, made of Toray Company T300 continuous carbon fiber), according to [0° 2 / 90° / 0° / +45° / -45° / 0° 2 / 90° / 0°] s The original lay-up design is placed in a metal counter-mold, molded under a pressure of 15MPa, and the curing temperature is about 120°C to produce a continuous fiber sample. Use a vernier caliper with an accuracy of 0.02mm to measure the U-shaped opening of the continuous fiber sample Size K 1 It is 195.98mm. Then replace all the orthogonal plies in the original ply design with 8 / 3 satin prepreg (purchased from Shandong Guangwei Company), that is, according to [0° / 90° 缎纹 / 0° / +45° / -45° / 0° / 90° 缎纹 / 0°] s The fiber is laid and the side of the satin fabric with less bending is facing the inside of the U-shaped structure. The satin...

Embodiment 2

[0059] The U-shaped part that present embodiment makes is as figure 1 shown. The U-shaped opening of the target workpiece requires dimension K 0 for First, use T300-3K unidirectional epoxy prepreg (purchased from Shandong Guangwei Company, made of Toray Company T300 continuous carbon fiber), according to [0° 2 / (90° / 0°) 3 / +45° / -45° / (0° / 90°) 2 / 0°] sThe original lay-up design was placed in a metal counter-mold, molded under a pressure of 15MPa, and the curing temperature was about 120°C to produce a continuous fiber sample, and the U-shaped opening of the continuous fiber sample was measured with a vernier caliper with an accuracy of 0.02mm Size K 1 1 It is 291.90mm. Then replace all the orthogonal plies in the original ply design with 8 / 3 satin prepreg (purchased from Shandong Weihai Guangwei Company), that is, according to [0° / 90° 缎纹3 / 0° / +45° / -45° / 90° 缎纹2 / 0°] s The fiber is laid and the side of the satin fabric with less bending is facing the inside of the U-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com