Concrete autolysis chemical sulfate corrosion resistance system in water environment

A sulfate-resistant concrete technology, applied in the field of concrete engineering, can solve problems such as limited repair effect, failure to prevent sulfate diffusion, and difficulty in anti-corrosion coating construction, and achieve the effect of slow release of sulfate-resistant corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

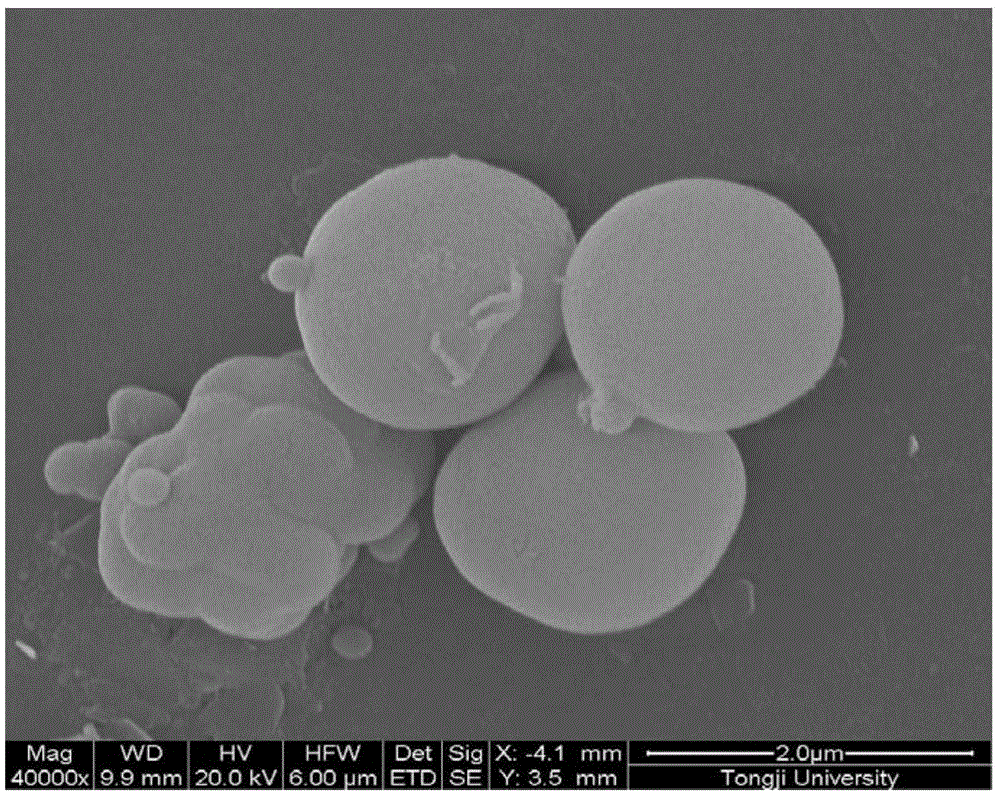

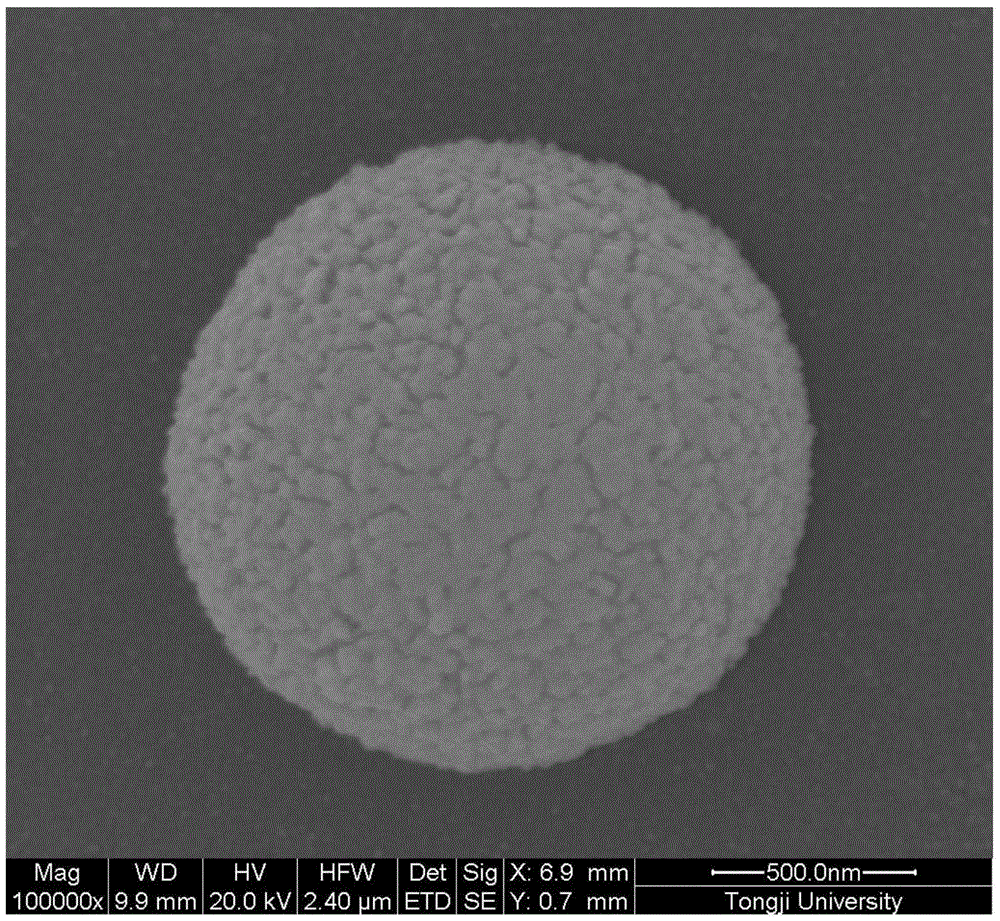

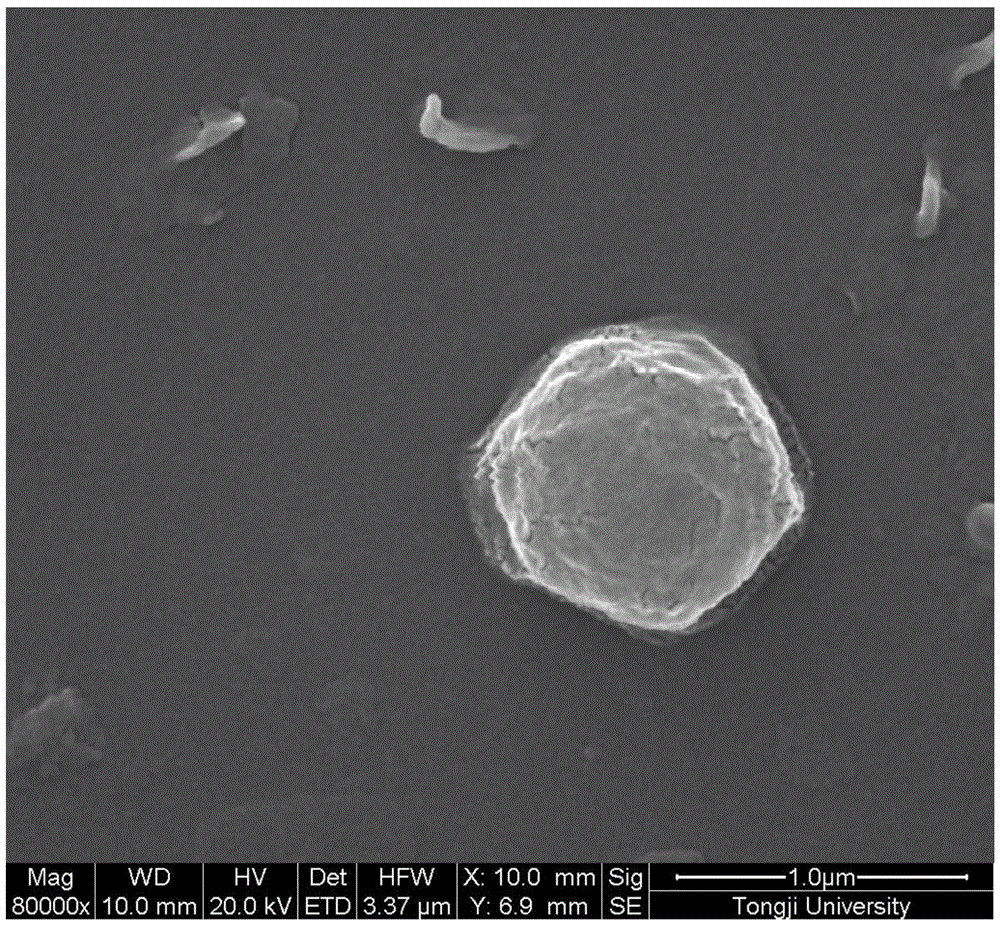

[0081] A concrete self-dissolving chemical anti-sulfate corrosion system in a water environment, including a concrete matrix and porous silica microspheres in the concrete matrix. Dissolvable protective film. The porous silica microspheres are spherical, with a particle size of 1.5-2 μm and a specific surface area of about 60.06m2 / g, the average pore diameter is 32.17nm. Restorative agent is Ba(NO 3 ) 2 , The material of the self-dissolving protective film is polyvinylpyrrolidone K30 with a molecular weight of 40,000. The porous silica microsphere accounts for 10% by mass of the cementitious material in the concrete matrix.

[0082] The preparation method of the concrete self-dissolving chemical sulfate corrosion resistance system under the water environment is as follows:

[0083] (1) Preparation of silica microspheres

[0084] Mix 100ml isopropanol (analytical pure) and 90ml deionized water evenly, add 1g hexadecylamine (analytical pure), ultrasonically mix, then add...

Embodiment 2

[0095] This example is basically the same as Example 1, except that the porous silica microspheres in this example have not undergone the step of pore expansion.

Embodiment 3

[0097] A concrete self-dissolving chemical anti-sulfate corrosion system in a water environment, including a concrete matrix and porous silica microspheres in the concrete matrix. Dissolvable protective film. The porous silica microspheres are spherical, with a particle size of 0.5-1 μm and a specific surface area of about 80m 2 / g, the average pore diameter is 20nm. The repair agent is Pb(NO 3 ) 2 , The material of the self-dissolving protective film is polyvinylpyrrolidone K90. The porous silica microsphere accounts for 15% by mass of the cementitious material in the concrete matrix. The concrete self-dissolving chemical sulfate corrosion resistance system prepared in this example can be effective for a long time, and can improve the sulfate corrosion resistance of concrete structures on a large scale, and establish an underground structural concrete that is intelligently resistant to sulfate corrosion system, improve the safety and durability of underground structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com