Intrinsic self-repairing and recyclable polythiourea polymer, and preparation method and application thereof

A technology of polymer and polythiourea, which is applied in the field of intrinsic self-healing and recyclable polythiourea polymer and its preparation, can solve the problems of unfavorable popularization and application, reduce thermal reversible reaction, and high thermal reversible temperature, and achieve Enhanced use stability, wide thermal reversible temperature range, and low thermal reversible temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

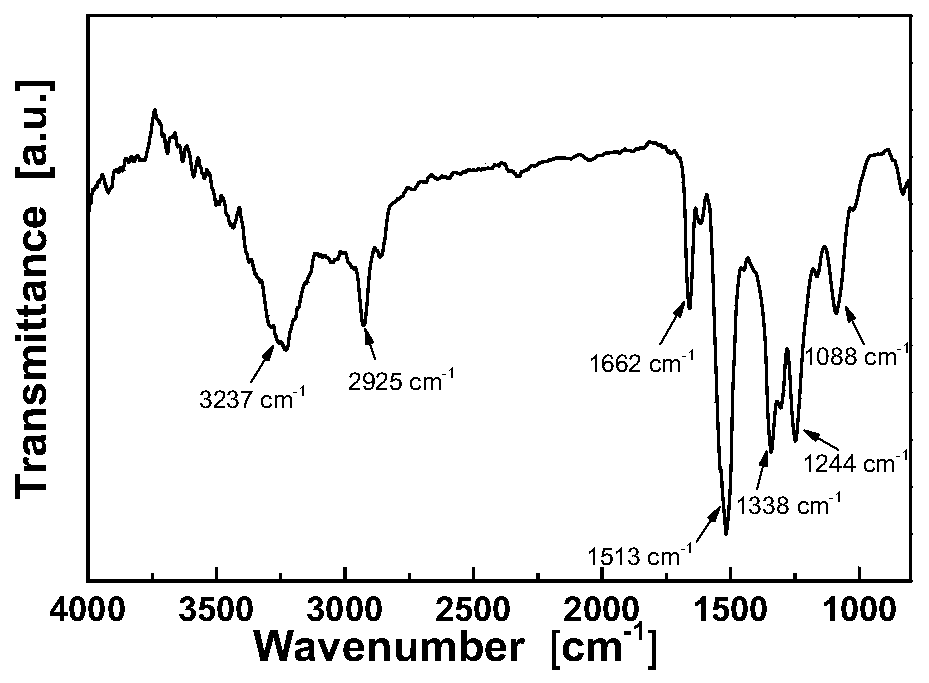

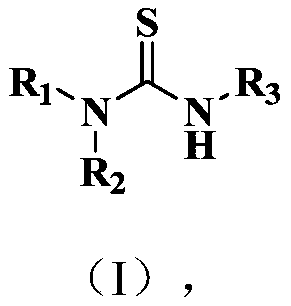

Method used

Image

Examples

Embodiment 1

[0075] This embodiment provides a polythiourea polymer (referred to as cross-linked polythiourea, the same below), and its preparation process is as follows.

[0076] Under nitrogen atmosphere, add 5.0 parts of p-phenylene diisothiocyanate into a 250mL three-necked flask with mechanical stirring, add 100.0 parts of DMF solvent, heat up to 50°C to dissolve p-phenylene diisothiocyanate, Add 1.1 parts of N,N'-diethylethylenediamine and 1.9 parts of 1,2-bis(2-aminoethoxy)ethane, react at 50°C for 16 hours, add 0.1 parts of pentaethylenehexamine to continue the reaction for 8 hours , poured into the mold and continued to cure at 60°C for 16 hours to obtain cross-linked polythiourea. After the material was scratched or broken, the fractured surface was repaired in the air at 35-120°C for 0.5-24 hours, and then it could be repaired . The polymer can recover part of its mechanical strength by crushing-hot pressing or degrading-casting to make a new sample. The results of tensile tes...

Embodiment 2

[0078] This embodiment provides a polythiourea polymer, the preparation process of which is as follows.

[0079] Under nitrogen atmosphere, add 5.0 parts of p-phenylene diisothiocyanate into a 250mL three-necked flask with mechanical stirring, add 100.0 parts of DMF solvent, heat up to 50°C to dissolve p-phenylene diisothiocyanate, Add 1.1 parts of N,N'-diethylethylenediamine and 2.9 parts of diethylene glycol bis(3-aminopropyl) ether, react at 50°C for 16 hours, add 0.1 parts of pentaethylenehexamine to continue the reaction for 8 hours, and pour Continue curing in the mold at 60°C for 16 hours to obtain cross-linked polythiourea. After the material is scratched or fractured, the fractured surface is repaired in air at 35-120°C for 0.5-24 hours, and then it can be repaired. The polymer can recover part of its mechanical strength by crushing-hot pressing or degrading-casting to make a new sample. The results of tensile tests before and after repair or recycling of polymer mat...

Embodiment 3

[0081] This embodiment provides a polythiourea polymer, the preparation process of which is as follows.

[0082] Under nitrogen atmosphere, add 5.0 parts of p-phenylene diisothiocyanate into a 250mL three-necked flask with mechanical stirring, add 100.0 parts of DMF solvent, heat up to 50°C to dissolve p-phenylene diisothiocyanate, Add 1.1 parts of N,N'-diethylethylenediamine and 3.0 parts of polyetheramine PEA230 (the number average molecular weight is 230), react at 50°C for 16 hours, add 0.1 parts of pentaethylenehexamine to continue the reaction for 8 hours, and pour into the mold Continue to cure at 60°C for 16 hours to obtain cross-linked polythiourea. After the material is scratched or fractured, the fractured surface can be repaired by contacting it in the air at 35-120°C for 0.5-24 hours. The polymer can recover part of its mechanical strength by crushing-hot pressing or degrading-casting to make a new sample. The results of tensile tests before and after repair or r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com