Nano-imprinting forming and pressure-print hole-forming method of metal sheet

A technology of metal flakes and metal sheets, which is applied in the direction of material analysis, measuring devices, and instruments using sound waves/ultrasonic waves/infrasonic waves. The effect of improving extrusion strength and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described in detail below in conjunction with specific drawings and embodiments.

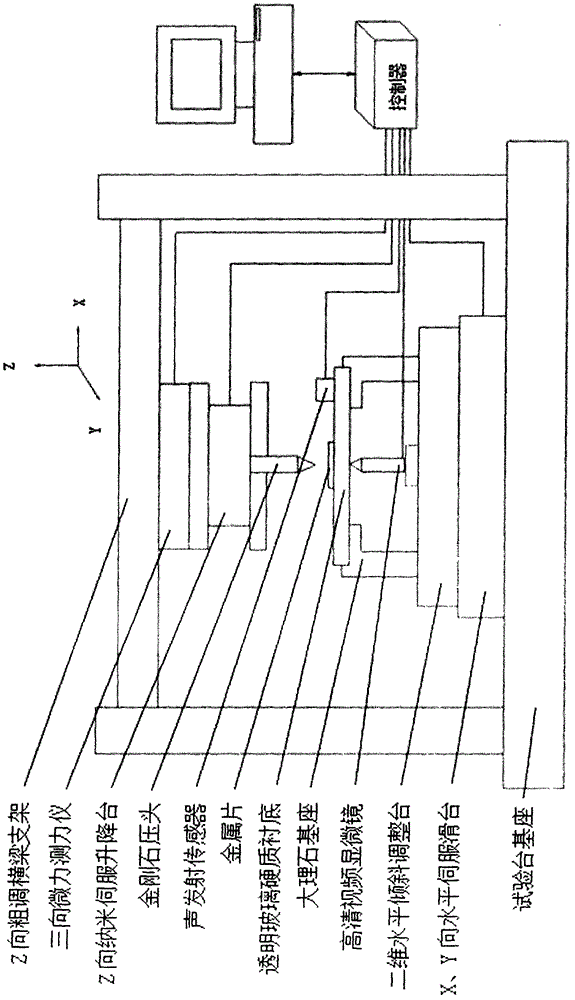

[0019] refer to Figure 1-Figure 2 A method for nano-imprinting and pressing of a metal sheet to form holes, comprising the following steps:

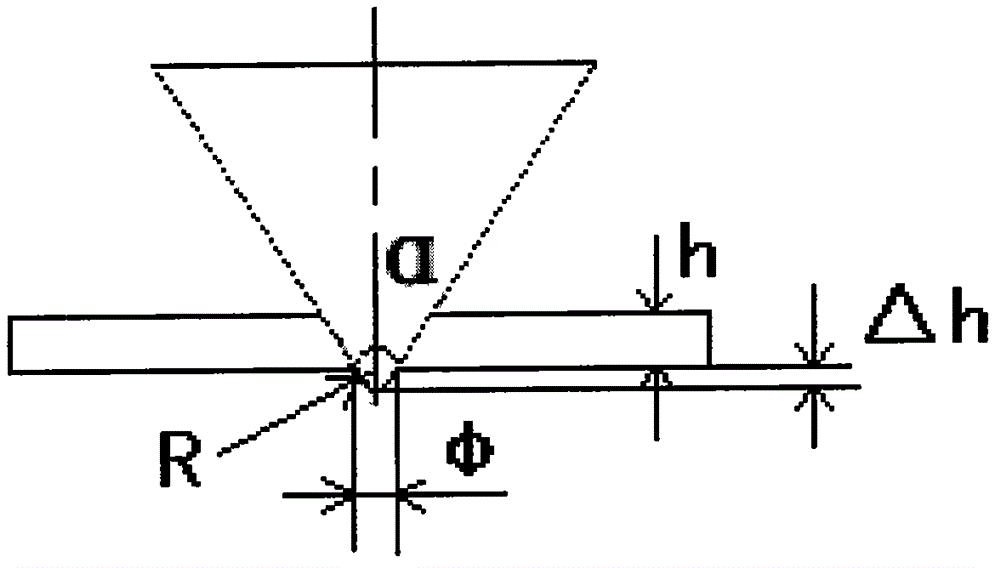

[0020] Step 1: Grinding the cone angle a of the diamond indenter and the radius R of the blunt circle at the tip according to the size index φ of the different forming apertures at the bottom of the metal sheet.

[0021] Step 2: Based on such as figure 1 In the measuring device shown, a thin metal sheet (such as copper sheet) (10*10*0.5mm) is placed, and the downward pressure of the diamond indenter (the radius of the blunt circle at the end is R) is controlled by the Z-direction nano-servo lifting platform. For tool setting, the specific position where the tip of the diamond indenter touches the upper surface of the metal sheet can be accurately judged through the characteristic sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com