Working roller considering both convexity and edge drop control of strip steel and design method for roller shape of working roller

A strip crown, work roll technology, applied in manufacturing tools, metal processing equipment, rolls, etc., can solve the problem of not being suitable for hot rolling, and achieve the effect of reducing the amount of trimming, increasing the yield, and improving the quality of the shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

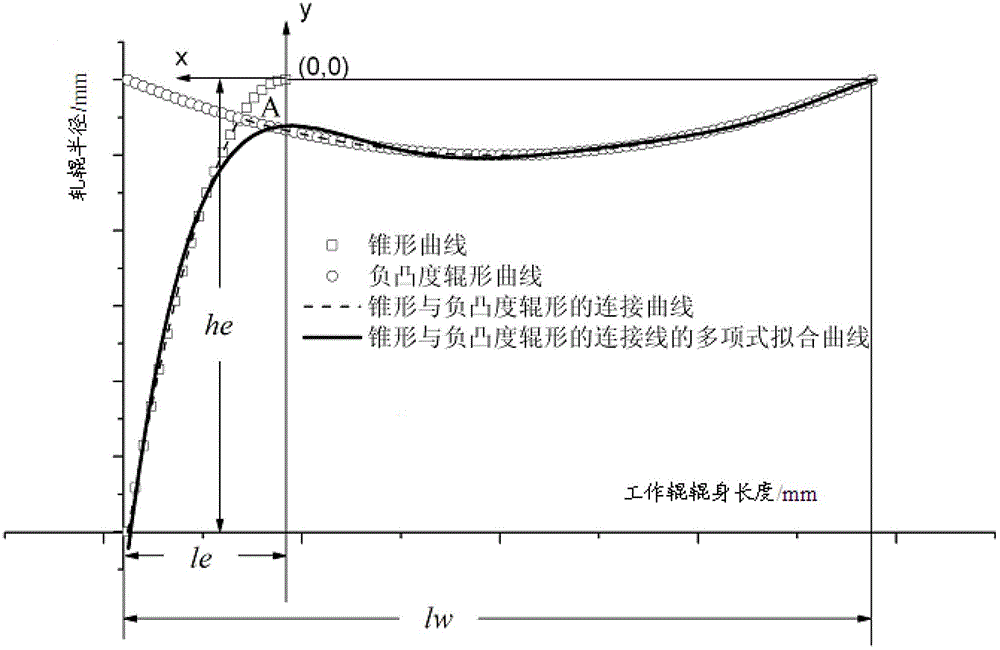

[0086] See attached figure 1 , the solid line is the roll shape curve equation of the work roll that takes into account the strip crown and edge drop control provided by the embodiment of the present invention:

[0087] R(x)=(-3.8142322×10 -19 ) x 6 +(4.3655522×10 -16 ) x 5 +(1.2677177×10 -13 ) x 4 +(-2.1984590×10 -10 ) x 3 +(1.1951196×10 -7 ) x 2 +(1.9948544×10 -5 )x+(-1.0089544×10 -1 ), x∈[0,1880]

[0088] in,

[0089] R(x), work roll body radius difference, mm,

[0090] x, the axial coordinate of the roll body, the origin of the coordinate is at one end of the roll, mm.

[0091] Wherein, the range of the roll shifting stroke of the work rolls may be 0-50 mm.

[0092] Wherein, the range of the roll shifting step length of the work rolls may be 5-10 mm.

[0093] See attached figure 1 According to the embodiment of the present invention, the roll shape design method of the work roll that takes into account both strip crown and edge drop control includes the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com