Control method for strip shape in rolling of cold-rolling strip steel by two-stand temper mill

A technology for shape control and cold-rolled strip, applied in contour control and other directions, and can solve problems such as not being fully satisfied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

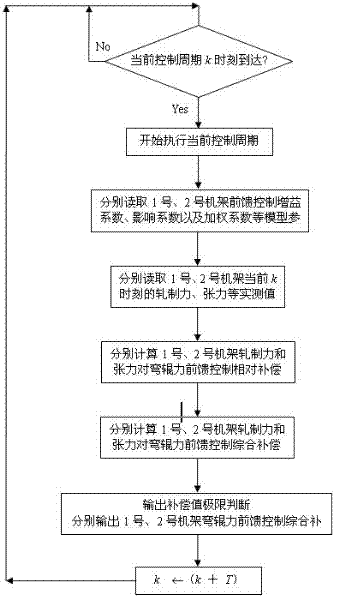

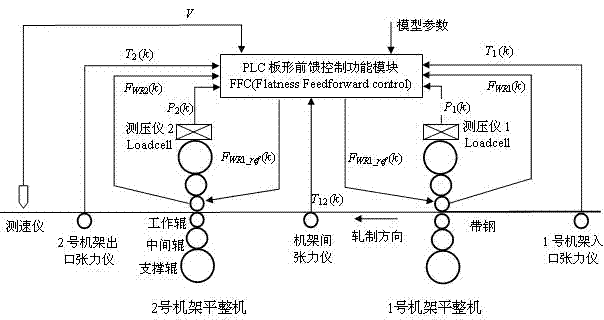

[0190] Taking a two-frame six-roll skin pass mill as an example, the realization process of the flatness feedforward control method of the present invention is described in detail.

[0191] like image 3 Shown, the equipment composition relevant to the present invention in the two-frame leveling machine comprises:

[0192] No. 1 rack inlet tension meter used to detect the tension of the No. 1 rack inlet strip;

[0193] Frame leveling machine No. 1, with upper and lower work rolls, upper and lower intermediate rolls, upper and lower support rolls, used to control the shape of the work roll and intermediate roll bending of the steel plate at the exit of the frame Executing agencies, etc.;

[0194] The No. 1 rack side pressure instrument Loadcell used to detect the rolling force of the No. 1 rack;

[0195] Inter-frame tension meter for detecting strip tension between No. 1 rack and No. 2 rack;

[0196] Frame leveling machine No. 2, with upper and lower work rolls, upper and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com