Fully-automatic flexible pipe filling and tail sealing machine

A tail sealing machine, fully automatic technology, applied in the direction of packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problem of inability to realize hose loading, filling, sealing and tail cutting, low degree of automation, and product quality Poor problems, to achieve the effect of improving stability and heat sealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

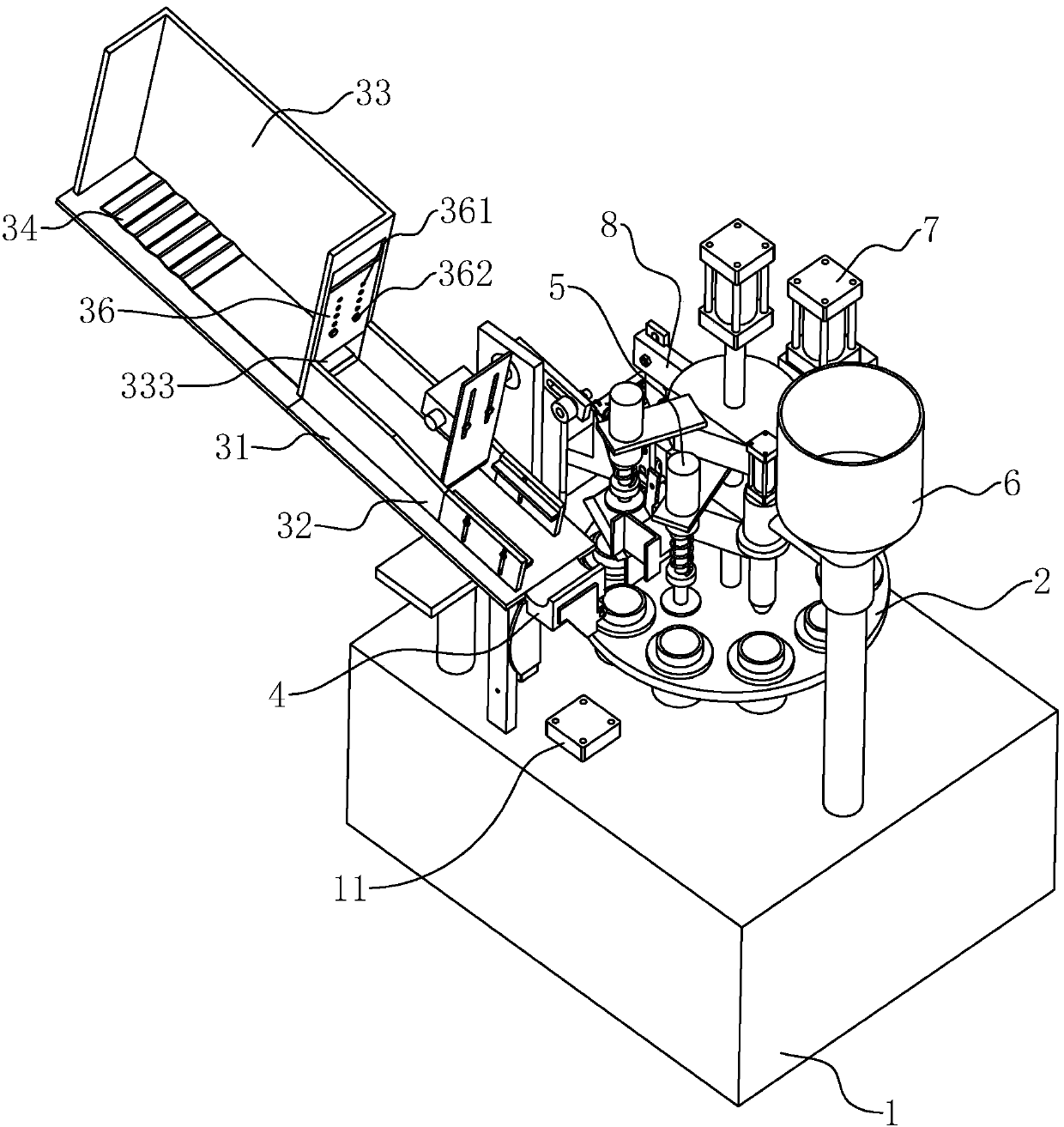

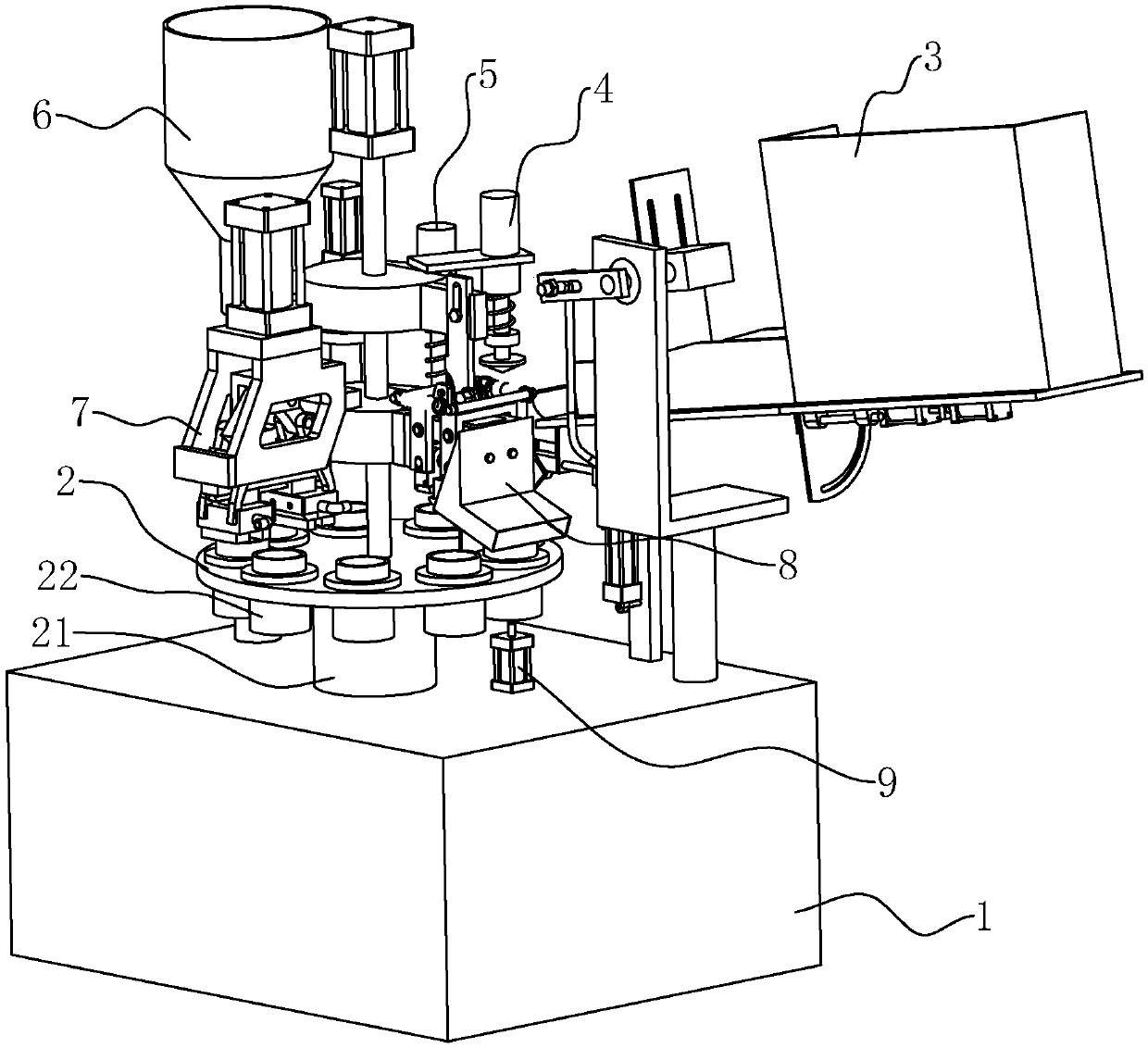

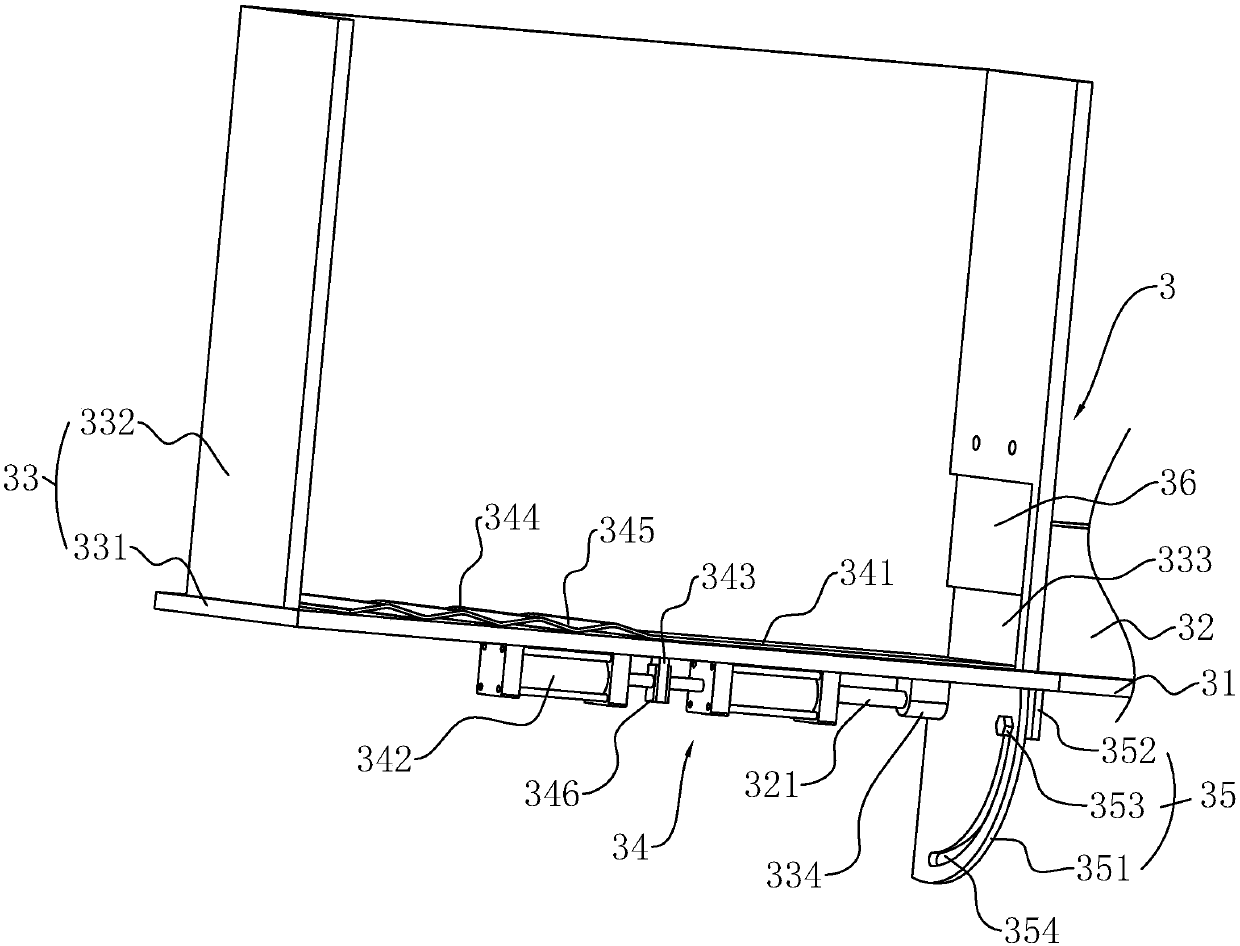

[0044] The automatic hose filling and sealing machine will be further explained with reference to the accompanying drawings.

[0045] A fully automatic hose filling and sealing machine, combined with figure 1 and figure 2 As shown, it includes a frame 1, a turntable 2 arranged on the frame 1, a drive mechanism 21 for driving the turntable 2 to rotate on the frame 1, and a feeding device 3 and an upper tube device 4 arranged on the frame 1 in turn. , tube pressing device 5, filling device 6, clamping heat sealing device 7, tail cutting device 8, tube unloading device 9 and control device 11, control device 11 is connected with feeding device 3, upper tube device 4, tube pressing device 5 respectively , filling device 6, clamping heat sealing device 7, tail cutting device 8, and tube unloading device 9 are electrically connected; the driving mechanism 21 is driven by the motor through gear meshing transmission to drive the turntable 2 to rotate on the frame 1.

[0046] combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com