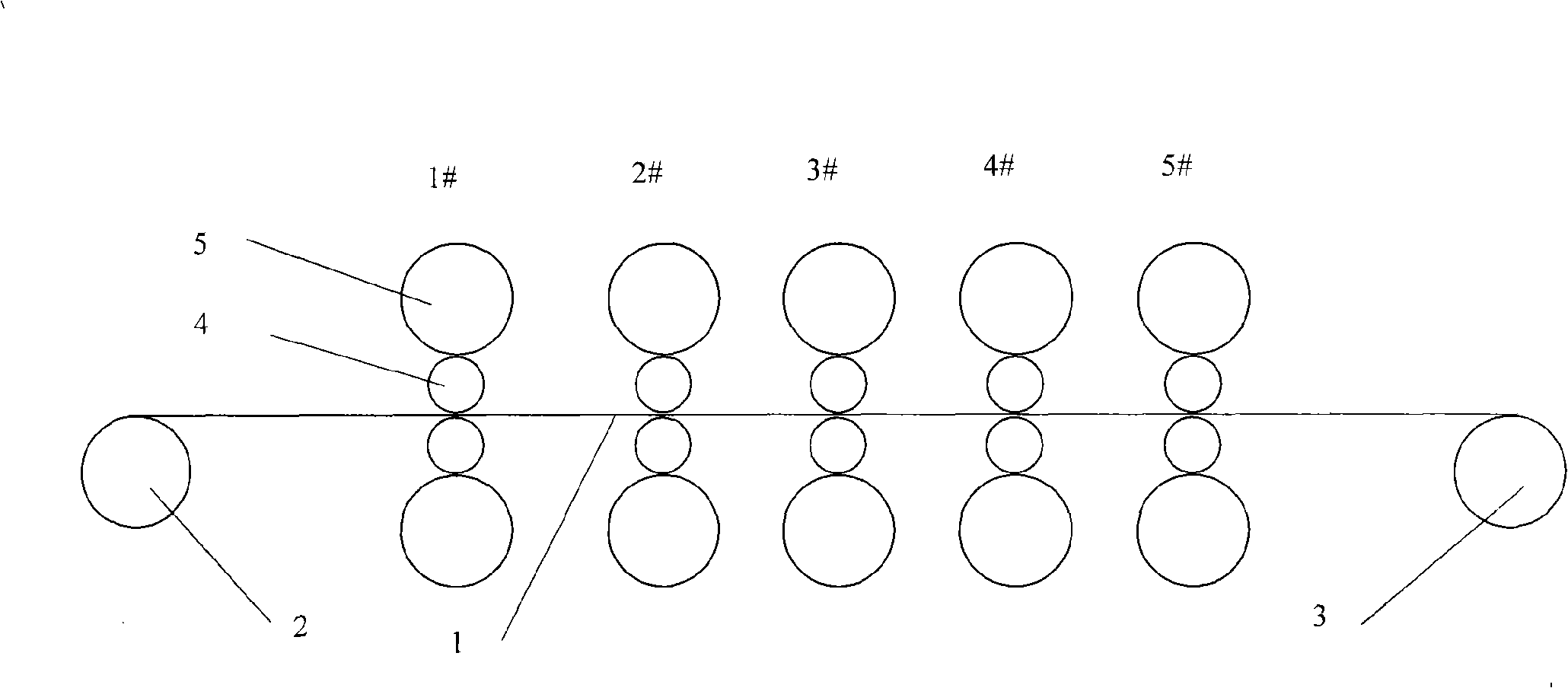

Synthetic setting technology of roll-bending force of five-frame four-roll cold continuous rolling device

A cold tandem rolling unit and five-stand technology, applied in the direction of contour control, digital control, electrical program control, etc., can solve the problems of mutual cancellation, affecting the service life of the bending cylinder, and weakening the bending force control effect, etc. , to achieve the effect of improving the control ability, improving the quality of the plate shape, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

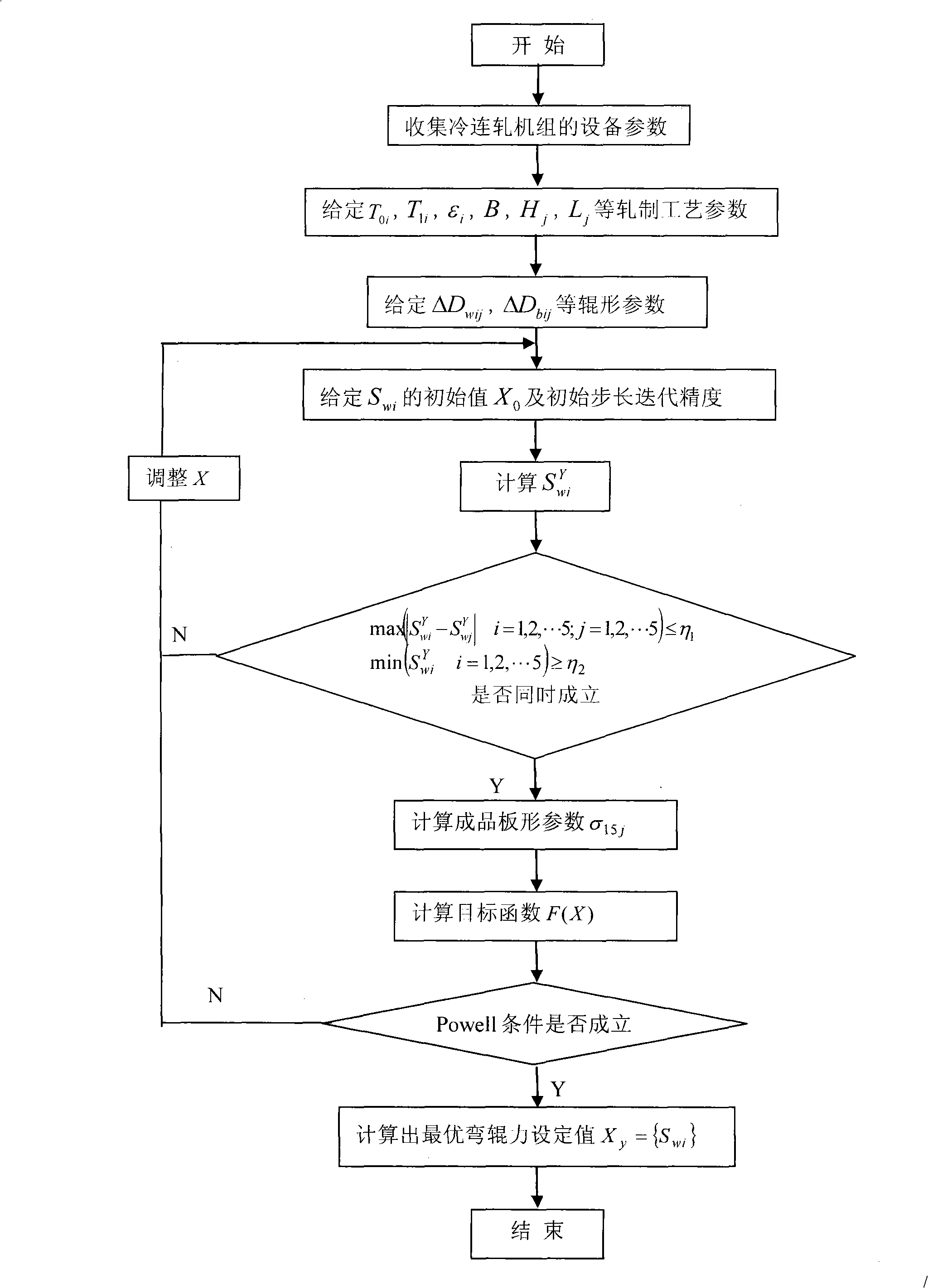

Method used

Image

Examples

no. 1 example

[0026] According to the metal deformation model, it can be known that for a five-stand four-high tandem cold rolling mill, during the rolling process, the exit plate shape of the 1#-5# stand can be represented by the front tension transverse distribution value σ expressed by formula (1) 1ij The function representation of:

[0027] σ 1ij =f 1 (h' ij , h i-1j , σ 1i-1j ,B,T 0i ,T 1i )(1)

[0028] In the formula:

[0029] σ 1ij - The transverse distribution value of the front tension at the strip outlet of the i-th rack. When i=0, σ 10j = L j (where L j Indicates the lateral distribution value of incoming plate shape);

[0030] h' ij - The horizontal distribution value of the strip outlet thickness of the i-th rack. When i=0, h 0j =H j (where H j Indicates the thickness lateral distribution value of the strip incoming material);

[0031] B - the width of the strip;

[0032] T 0i - the average back tension of the i-th rack;

[0033] T 1i - Average front tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com