Roller wear optimization control method for improving quality of band steel

A technology for optimizing control and rolling, applied in the direction of rolling force/roll gap control, general control system, contour control, etc., and can solve problems such as not involving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

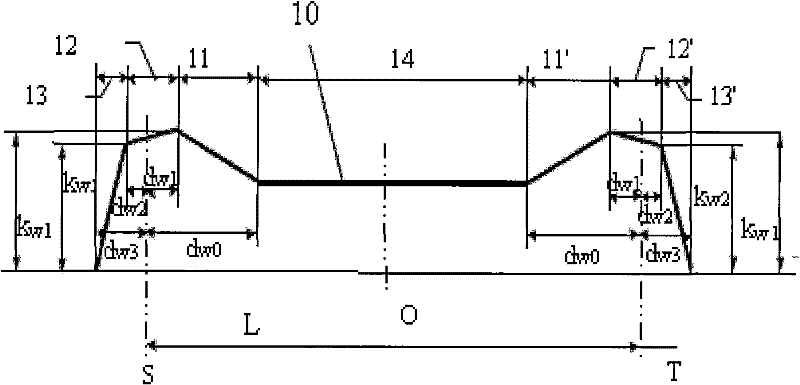

[0065] Firstly, the roll wear calculation model of the hot continuous rolling mill (only calculating the wear amount caused by rolling one coil of strip steel) is explained.

[0066] The friction between the work roll and the strip steel and between the work roll and the backup roll will cause the work roll to wear. Wear change is a slowly accumulating process, and its calculation accuracy has an impact on the setting of the plate crown, the control of the flatness of the plate, and the improvement of the surface quality of the strip.

[0067] The wear is divided into two parts: the steady wear area in the middle and the concentrated wear area at the edge. The main reasons for the increased edge wear are the reduction of edge temperature, the enhancement of the load on the edge area and the three-dimensional flow of the rolled metal.

[0068] Such as figure 1 As shown, according to the different contact positions between the strip and the roll, the roll is divided into seven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com