Model self-adapting sheet shape prediction and control method

A model self-adaptive and predictive control technology, applied in the direction of self-adaptive control, contour control, general control system, etc., can solve the problems affecting the real-time performance of shape adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation methods and processes are given, but the protection scope of the present invention is not limited to the following embodiments.

[0033] This embodiment illustrates the present invention with respect to a six-roll UCM (Universal Crown Mill) mill. This type of mill has work roll bending, intermediate roll bending, intermediate roll shifting, reduction inclination, and partition cooling of the roll surface. Shape adjustment actuator. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

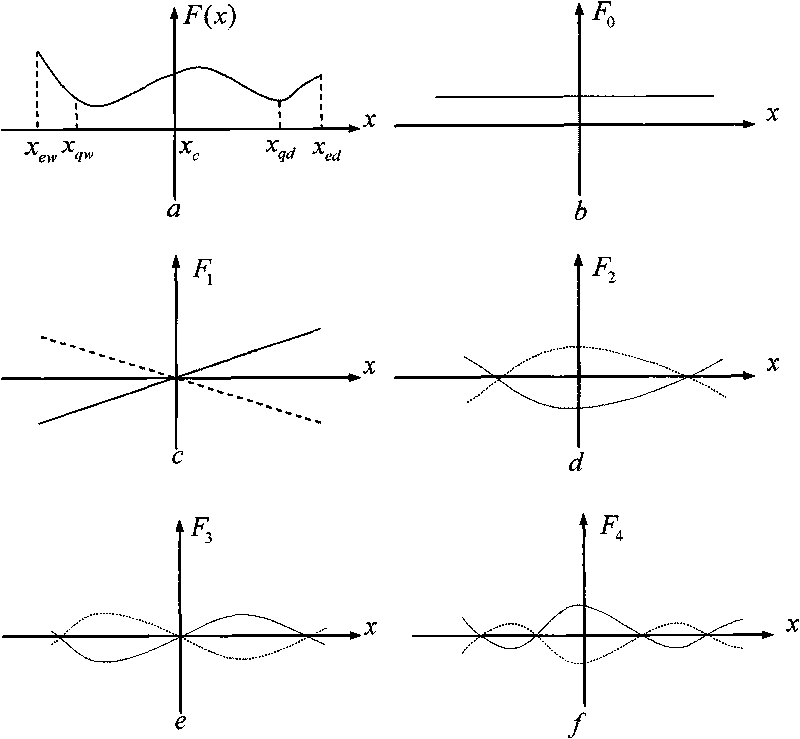

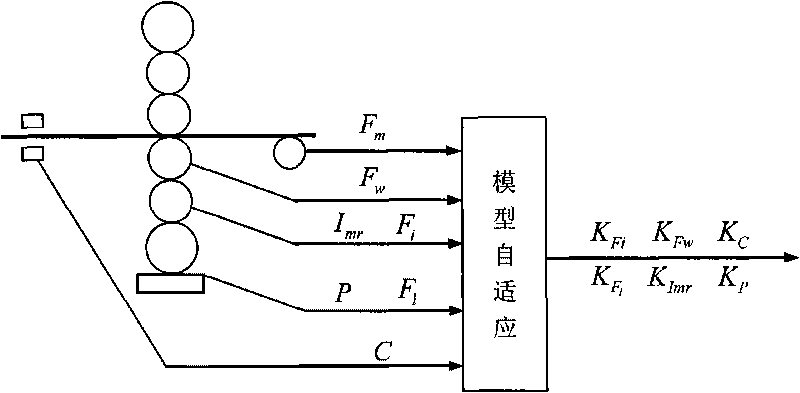

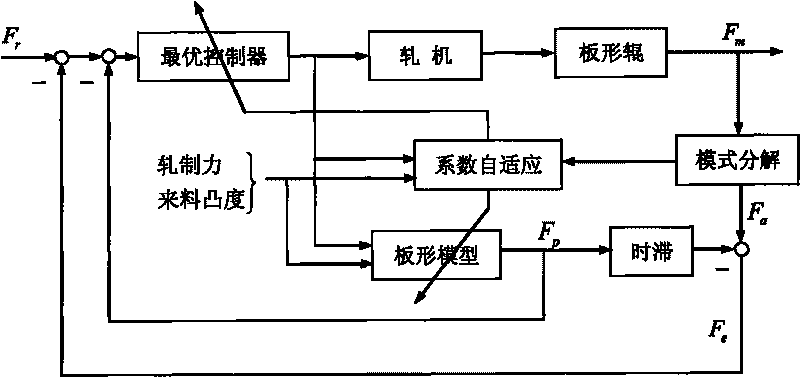

[0034] see image 3 , image 3 It is a block diagram of the shape predictive control structure. A model-adaptive flatness predictive control method, which decomposes the target flatness and the measured flatness according to a simple and practical flatness mode; the coefficient of the flatn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com