Method for setting plate shape and plate convexity off-line prediction of PC rolling mill

A setting method, a technology of strip crown, applied in the direction of contour control, etc., can solve the problems of not considering the rolling characteristics of PC mills, errors, and unsatisfactory strip shape control results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0185] Embodiments of the invention are described below with the aid of the accompanying drawings

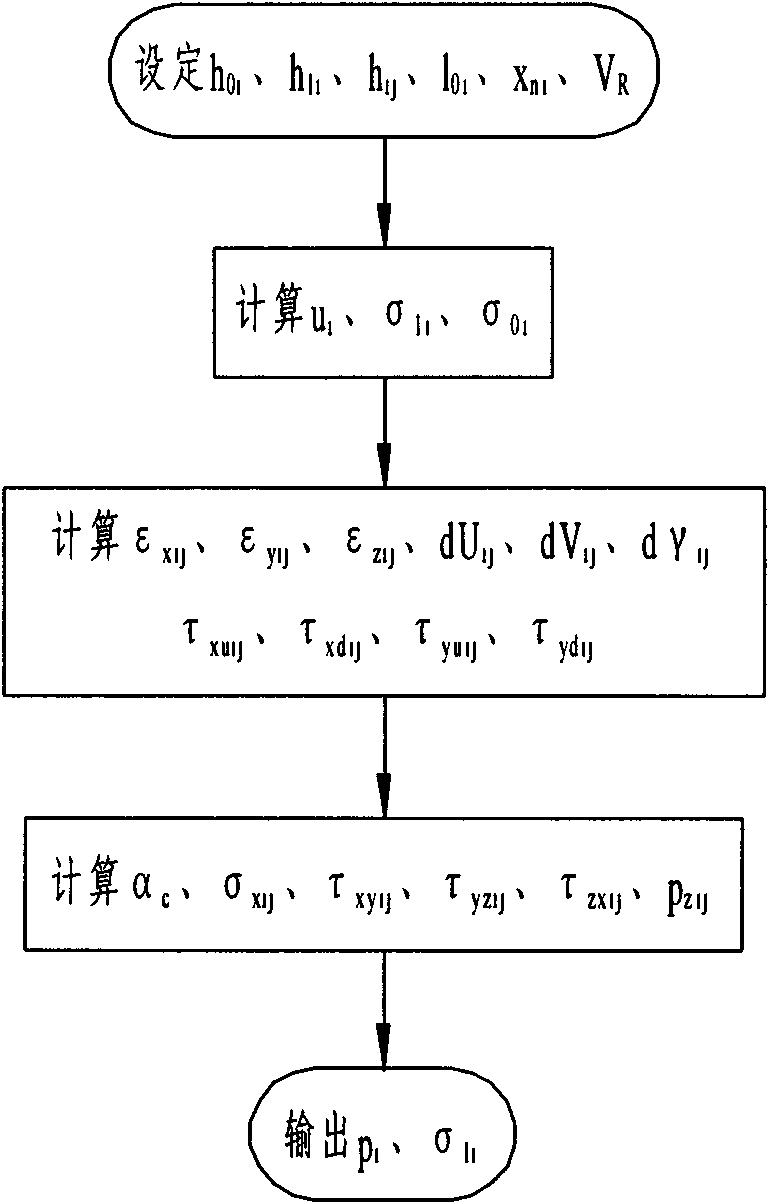

[0186] Figure 10 It is a flow chart of the off-line forecasting and setting process of the PC rolling mill plate crown of the present invention. Taking the on-site rolling parameters of a specific PC mill as an example, the setting and forecasting process and related effects of the intersection angle and roll bending force of a specific steel grade on the third stand of the finishing mill are described. Include the following steps:

[0187] (a) Collect actual PC mill equipment parameters and process parameters:

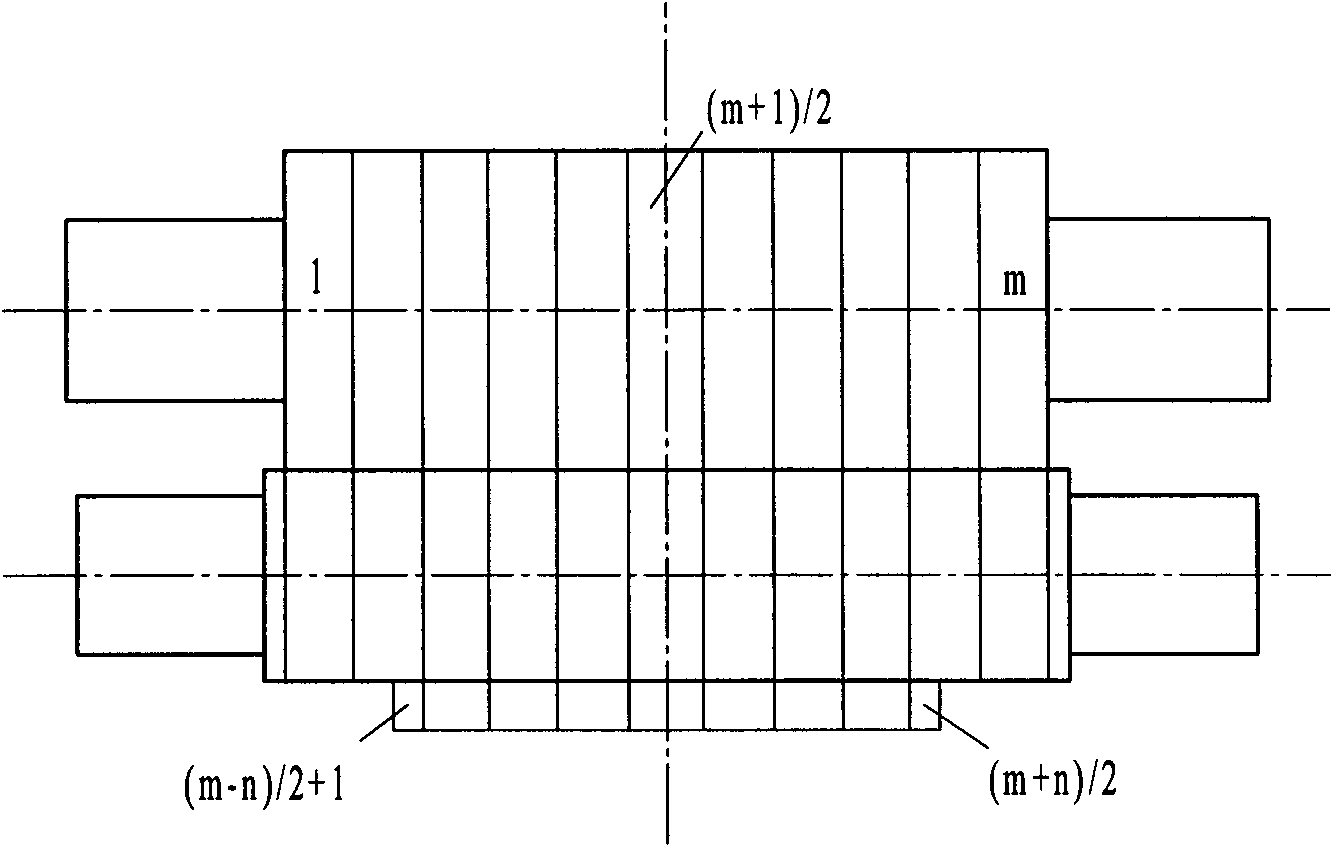

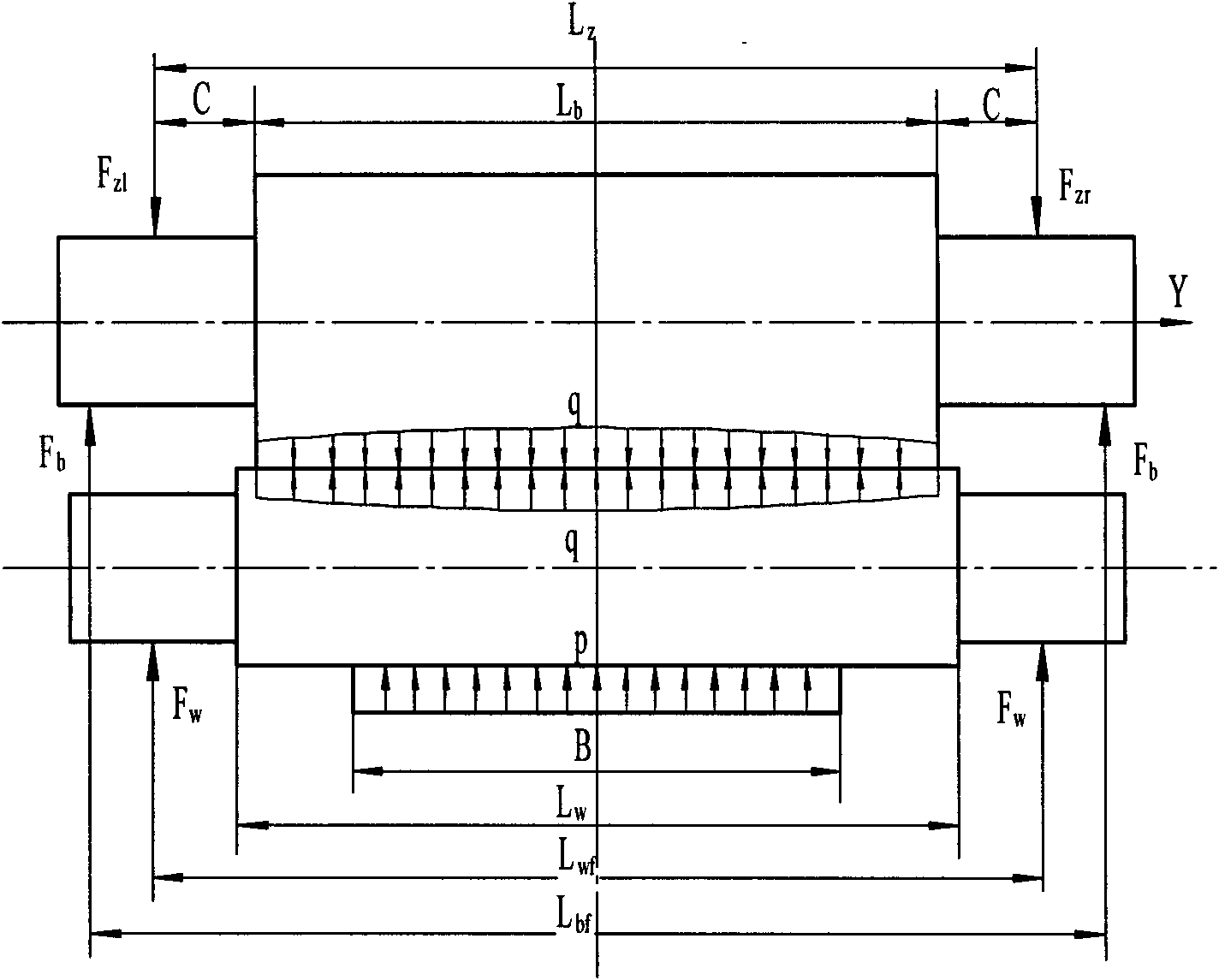

[0188] By adopting the metal three-dimensional plastic model and the roll system elastic deformation model proposed by the present invention, the calculation and analysis of the third stand of a 1880PC hot continuous rolling mill finishing unit is carried out. The back-up roll used has a fulcrum distance of 3080mm, a roll body length of 1860mm, a roll body diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com