Method for comprehensive control of elongation coefficient and plate shape of steel band during even rolling process

A technology of skin-pass rolling and control method, which is applied in the direction of elongation control, rolling mill control device, metal rolling, etc., can solve the problem of inability to take into account the comprehensive control of strip elongation and flat shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

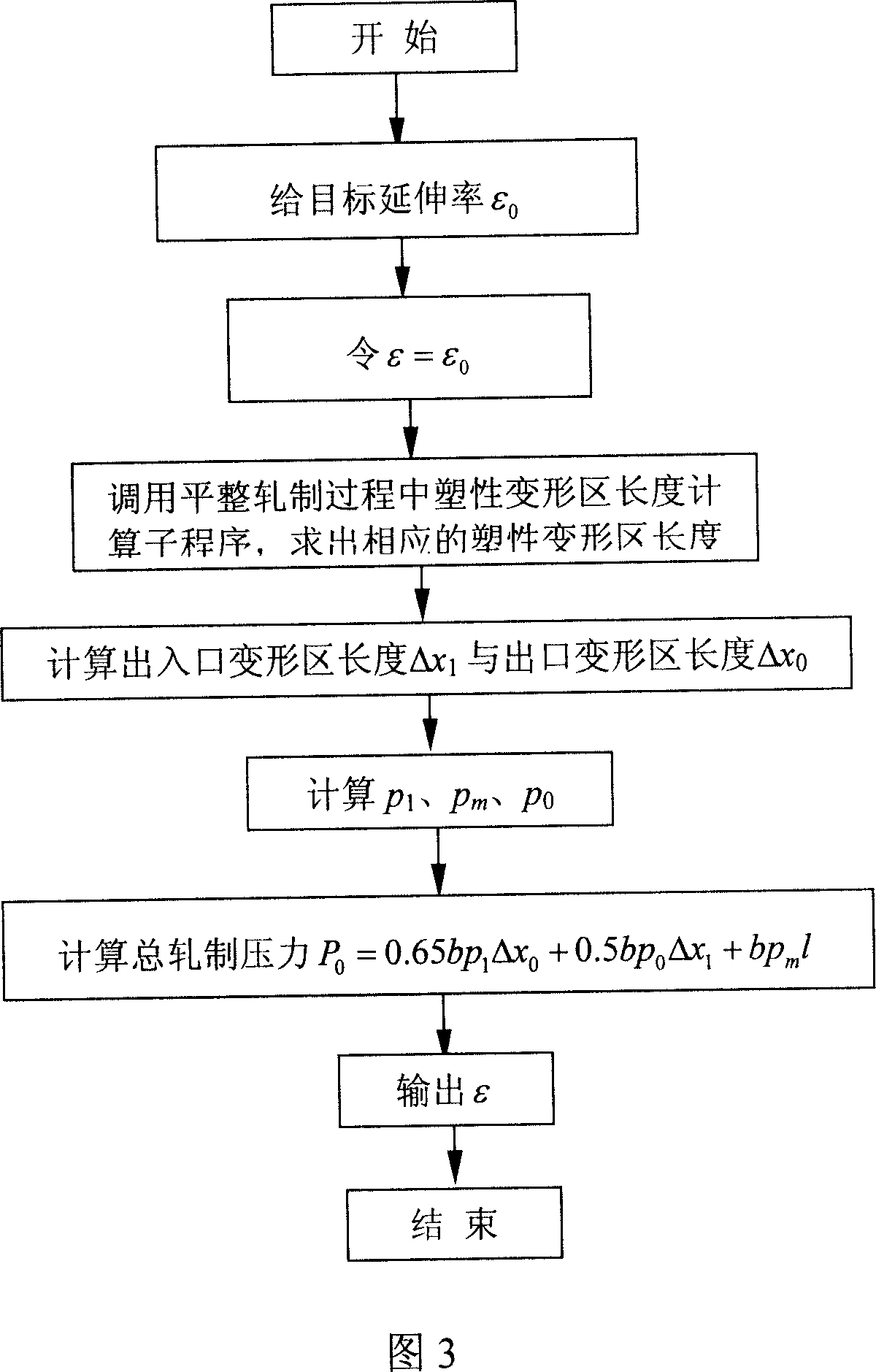

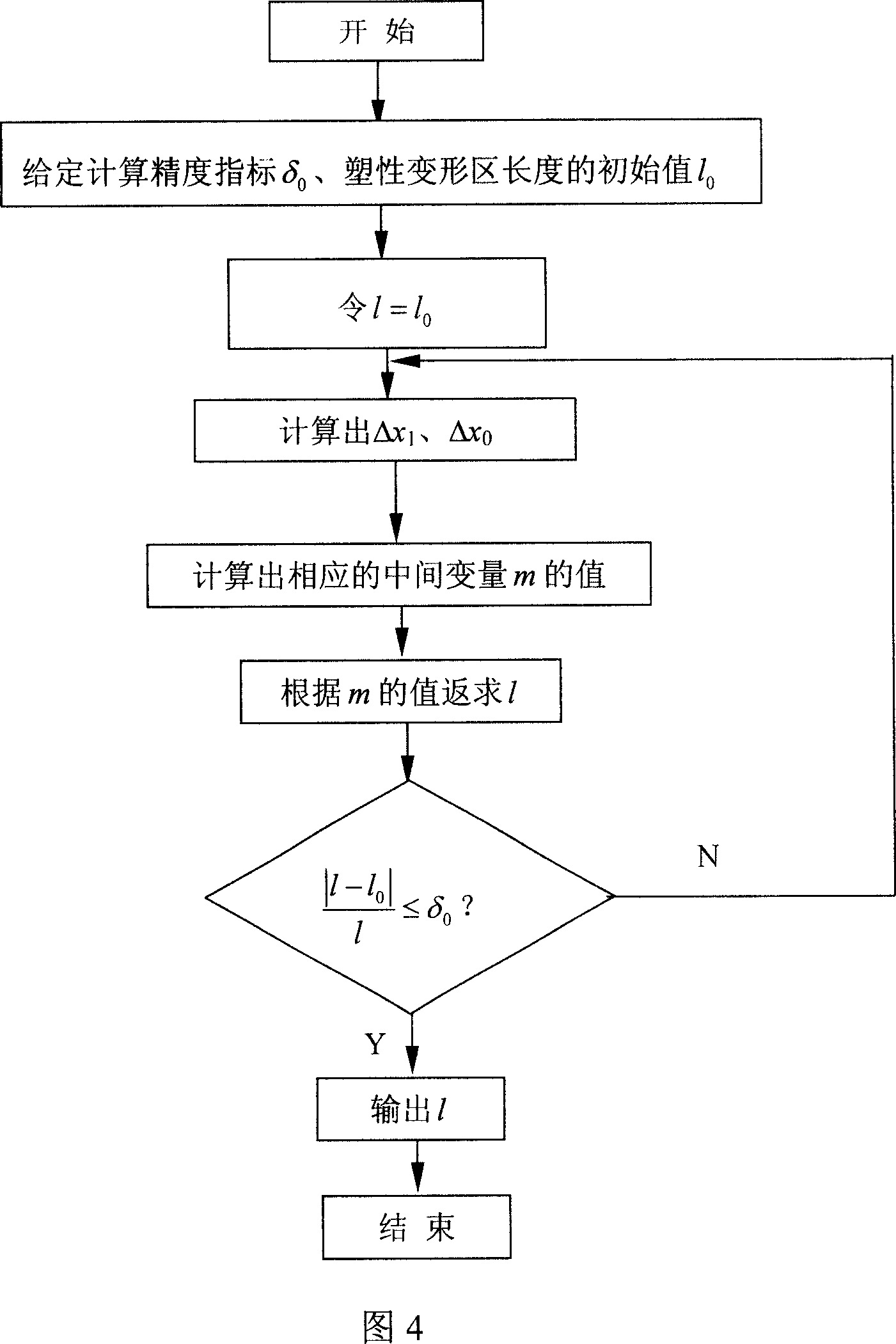

Method used

Image

Examples

no. 1 example

[0143] According to the rolling theory, it can be known that in the process of leveling, if the diameter of the roll is known, and the specifications, steel types and friction conditions of the leveled strip are also determined, the elongation of the strip is the total rolling pressure P 0 , front and rear tension T 1 , T 0 The function of is simply shown in formula (15):

[0144] ε=f 1 (P 0 ,T 1 ,T 0 ) (15)

[0145] From the above formula, as long as the total rolling pressure P 0 , front and rear tension T 1 , T 0 When it is determined, the elongation of the strip is also determined. Obviously, for the same elongation ε, the total rolling pressure P 0 , front and rear tension T 1 , T 0 etc. In theory, there are countless combinations that can meet the requirements, and its value is not unique. In fact, the purpose of flattening is not only to ensure that the finished product meets the mechanical performance index, but also the shape of the plate must be taken in...

no. 2 example

[0160] According to the metal deformation model in rolling theory, the front and rear tension σ of the strip during temper rolling 1i , σ 0i It can be represented by formula (18) and formula (19) respectively:

[0161] σ 1 i = T 1 + E 1 - v 2 [ h i h ( 1 - ϵ ) - H i h ] - - - ( 18 )

[0162] σ 0 i = ...

no. 3 example

[0184] In the actual leveling production, both mechanical properties and appearance quality indicators should be taken into account, and the importance of these factors to user needs can also vary. For this reason, the present invention combines the mechanical performance and appearance quality of strip steel into a unified target for control, and introduces the comprehensive control of strip shape and mechanical performance.

[0185] Control the objective function, as shown in formula (24):

[0186] F ( X ) = α · g 1 ( X ) - 1 ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com