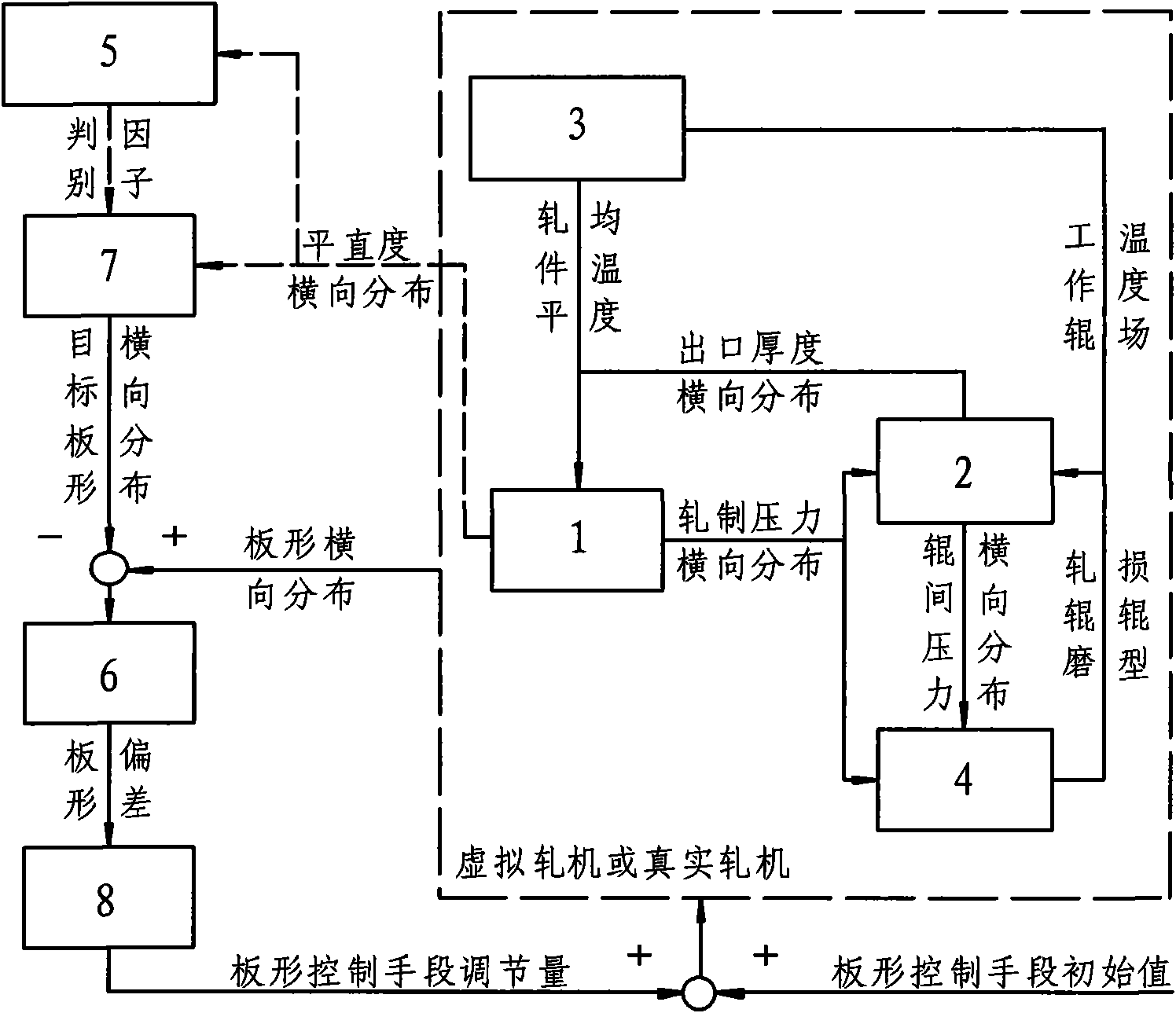

Plate-shape control integrated system and executing method thereof

A shape control and integrated system technology, applied in contour control, electrical program control, program control in sequence/logic controller, etc., can solve difficult shape problems that cannot be obtained, analyzed and solved , did not consider issues such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0168] This example illustrates how to use the present invention to analyze the shape control performance and select the model. Firstly, given the specific machine type, the specific flatness control means that need to be analyzed for flatness control performance are specified. Taking a six-stand full four-high CVC hot tandem rolling mill as an example, the shape control performance of work roll bending force is analyzed.

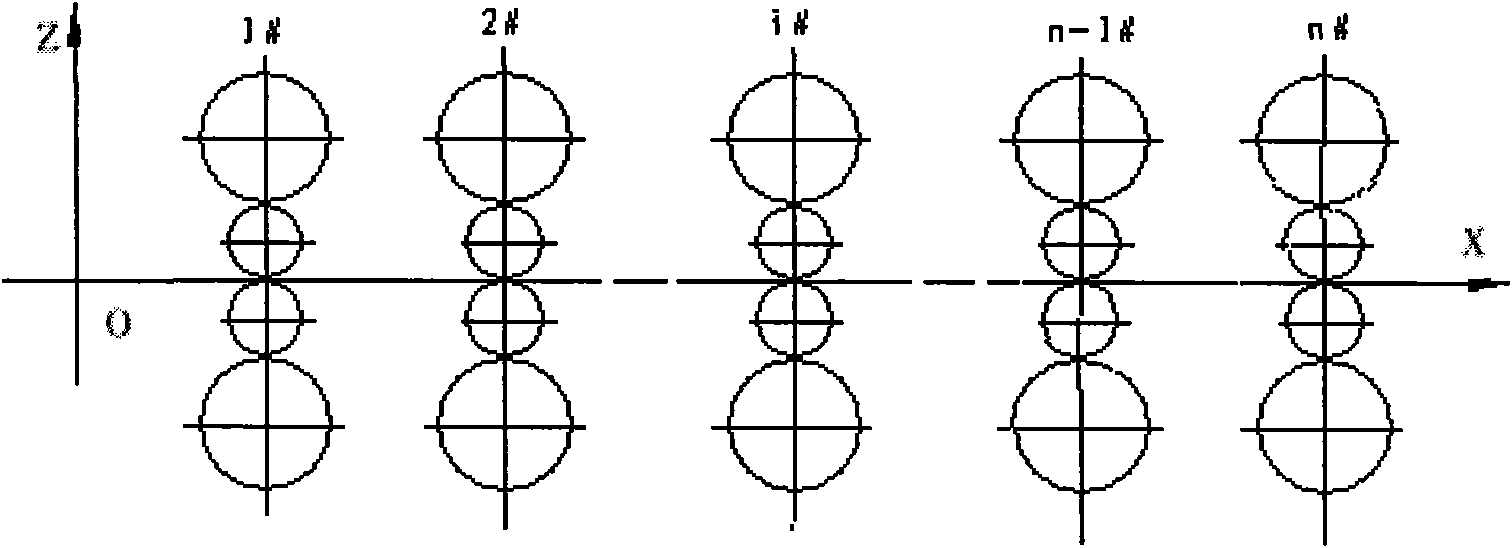

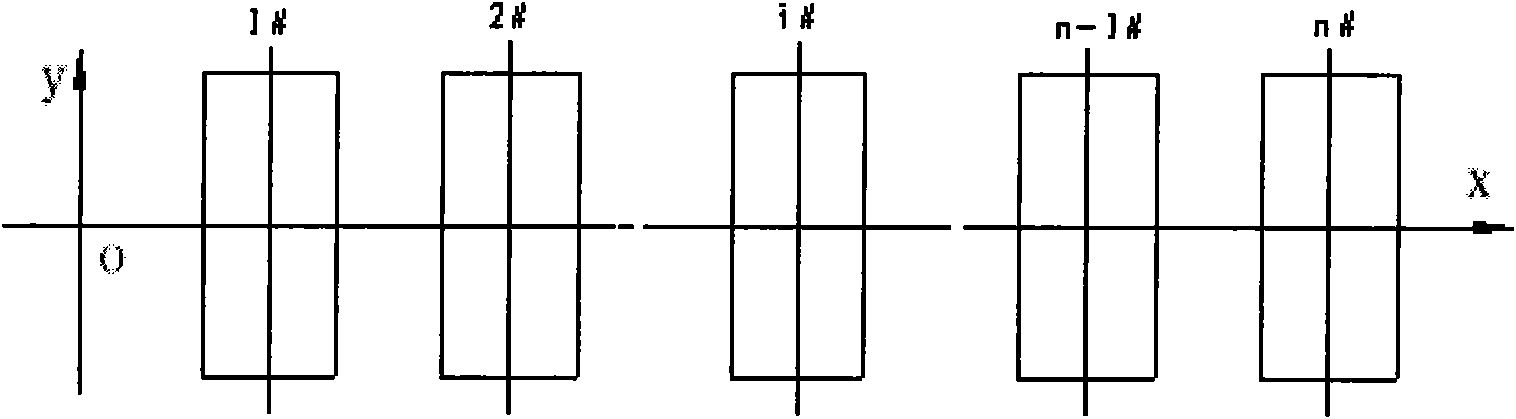

[0169] The 1st step, carry out step 1), establish the continuous rolling mill coordinate system;

[0170] Step 2, execute step 2), after the execution, con1=2, con2 i =2 (i=1~6), con3=2, con4=1;

[0171] Step 3, execute step 3), collect relevant input parameters;

[0172] Step 4, since con1=2, step 4) is automatically skipped, and step 5) is executed to couple the plastic deformation module 1 of the rolled piece and the elastic deformation module 2 of the roll system to obtain the flatness and thickness lateral distribution of the exit of each stand σ ...

no. 2 example

[0177] Taking a six-stand all-ordinary four-high hot continuous rolling mill (without work roll bending function) as an example, it is explained how to use the present invention to carry out back-up rolls with the aim of optimizing the shape of some old rolling mills that lack shape control means. type optimization design. In order to simplify the process management of grinding rollers and improve the efficiency of grinding rollers in general production sites, it is hoped that the supporting rollers of each frame adopt the same roller shape. Therefore, the original grinding roll shape of each frame is uniformly represented by the following formula: C bgi (y)=c 2 (2y / L bi ) 2 +c 4 (2y / L bi ) 4 +c 6 (2y / L bi ) 6 (i=1~6), wherein, C bgi The original grinding roll shape of the support roll of each frame, L bi is the body length of the supporting rollers of each frame, c 2 、c 4 、c 6 Support roll profile characteristic parameters. The goal of roll shape optimization i...

no. 3 example

[0185] Taking a five-stand full UCM tandem cold rolling mill as an example, this example illustrates how to use the present invention to carry out on-line setting control of strip shape. The specific plate shape control parameters that need to be set include the bending force S of the work rolls of 1 to 5 stands 11 j ~S 15 j , The bending force S of the middle roll of 1~5 racks 21 j ~S 25 j 、Roll shifting amount RS of intermediate rolls of 1~5 racks m1 j ~RS m5 j . The specific calculation process is given below:

[0186] The 1st step, carry out step 1), establish the continuous rolling mill coordinate system;

[0187] Step 2, execute step 2), after execution con1=3, con2 i =2 (i=1~6), con3=1, con4=3;

[0188] Step 3, execute step 3), collect relevant input parameters;

[0189] Step 4, perform step 4), calculate the strip temperature field according to the rolled piece and roll temperature field module 3, and calculate the average deformation resistance of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com