High-precision strip shape control prediction method for CVC (continuously variable crown) four-roll cold rolling mill

A technology of shape control and cold rolling mill, applied in metal rolling, profile control, metal rolling, etc., can solve the problem that field control cannot be applied online

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

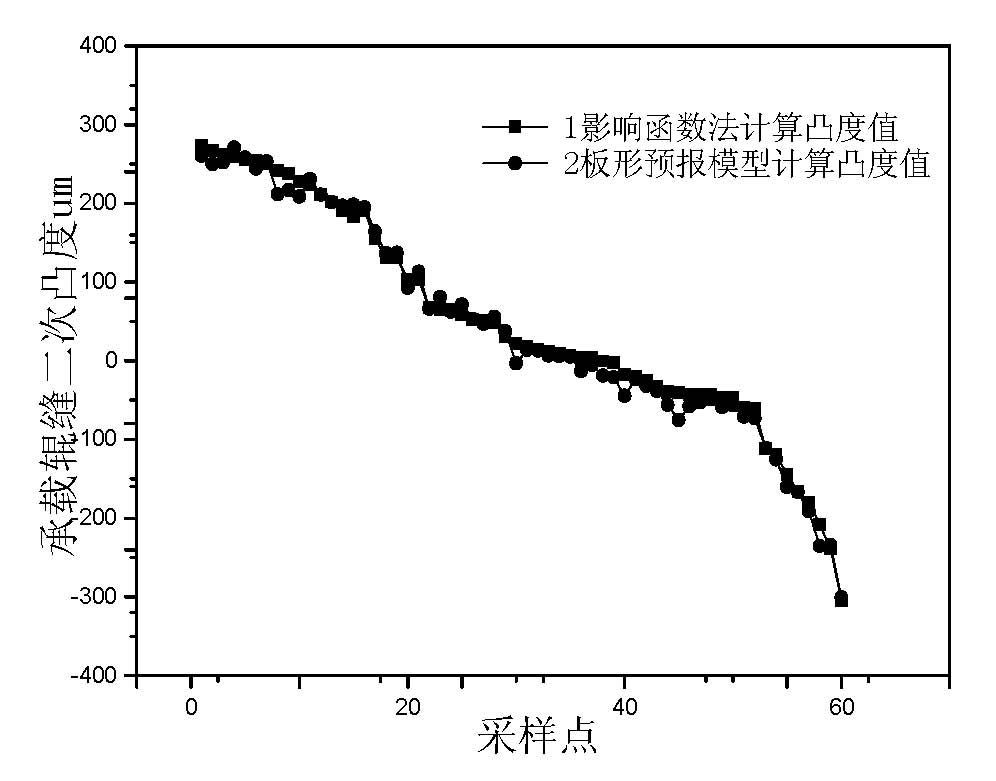

[0083] Now take a CVC four-high rolling mill in a factory as an example. The main equipment parameters are shown in Table 1 and Table 2. A total of 60 working conditions are randomly sampled to calculate the crown of the load-bearing roll gap, and the calculation results of the influence function method are compared with the calculation results of the model. ,Such as image 3 with Figure 5 As shown, the two agree well; it can be seen that it is reasonable to use the established load-bearing roll gap crown model for field shape control.

[0084] Table 1 Work Roll Parameters

[0085] Device parameters

Roll length

Center distance of bending cylinder

Young's modulus

Poisson's ratio

equivalent convexity

400~450mm

1950mm

2850mm

220kN / mm2

0.3

0

[0086] Table 2 Support Roller Parameters

[0087] Device parameters

Roll surface length

Hydraulic cylinder cente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com