Patents

Literature

44results about How to "Add drying function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

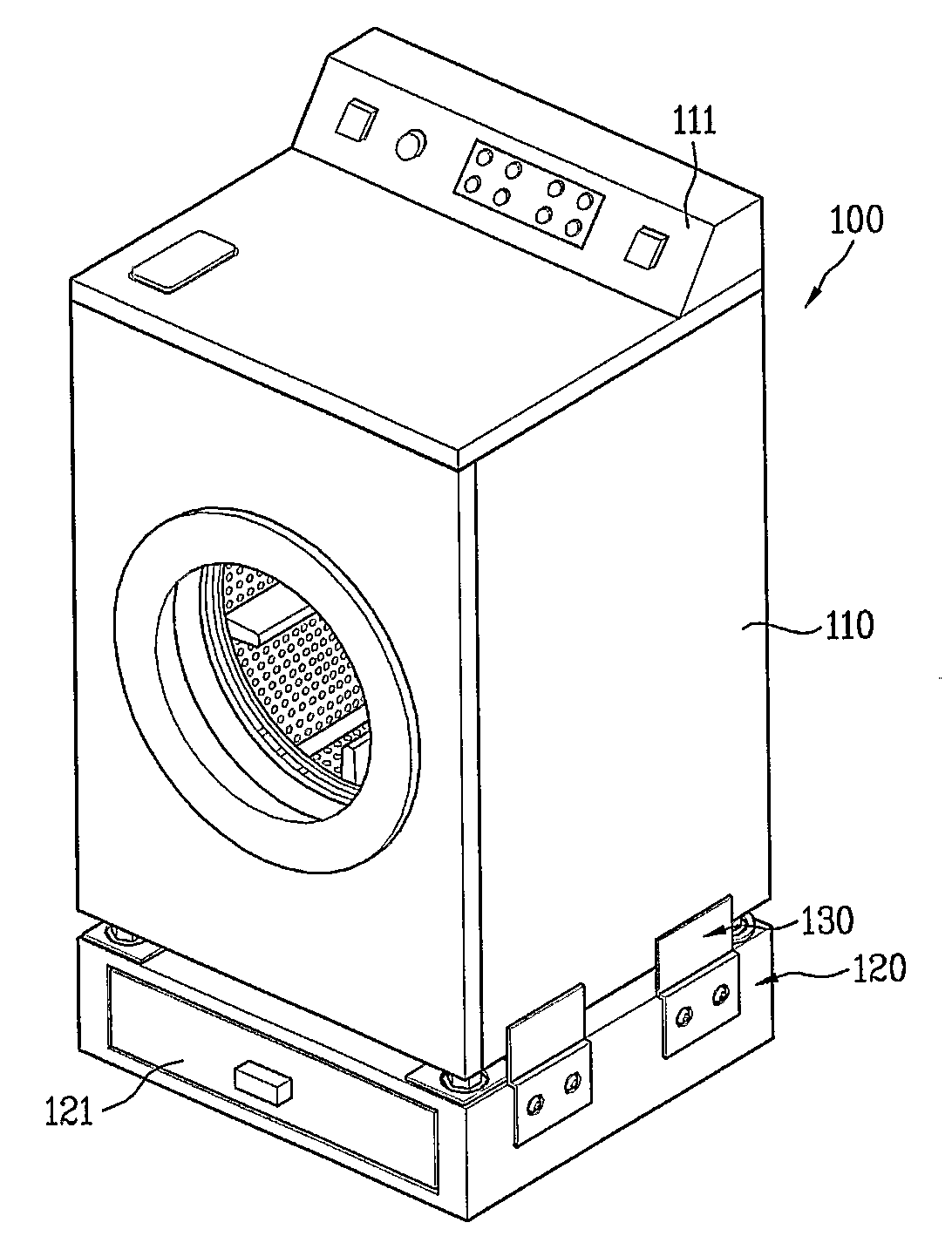

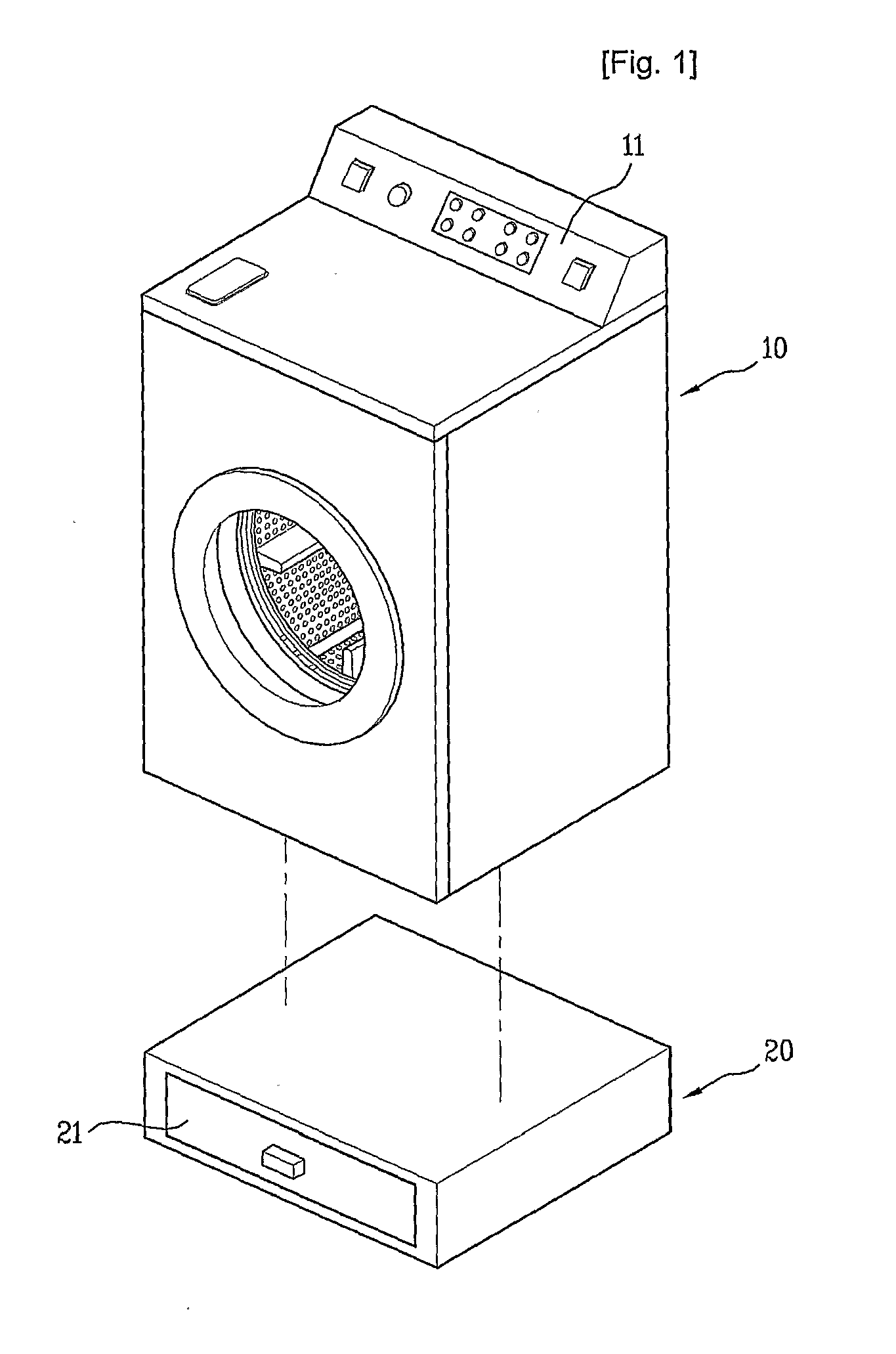

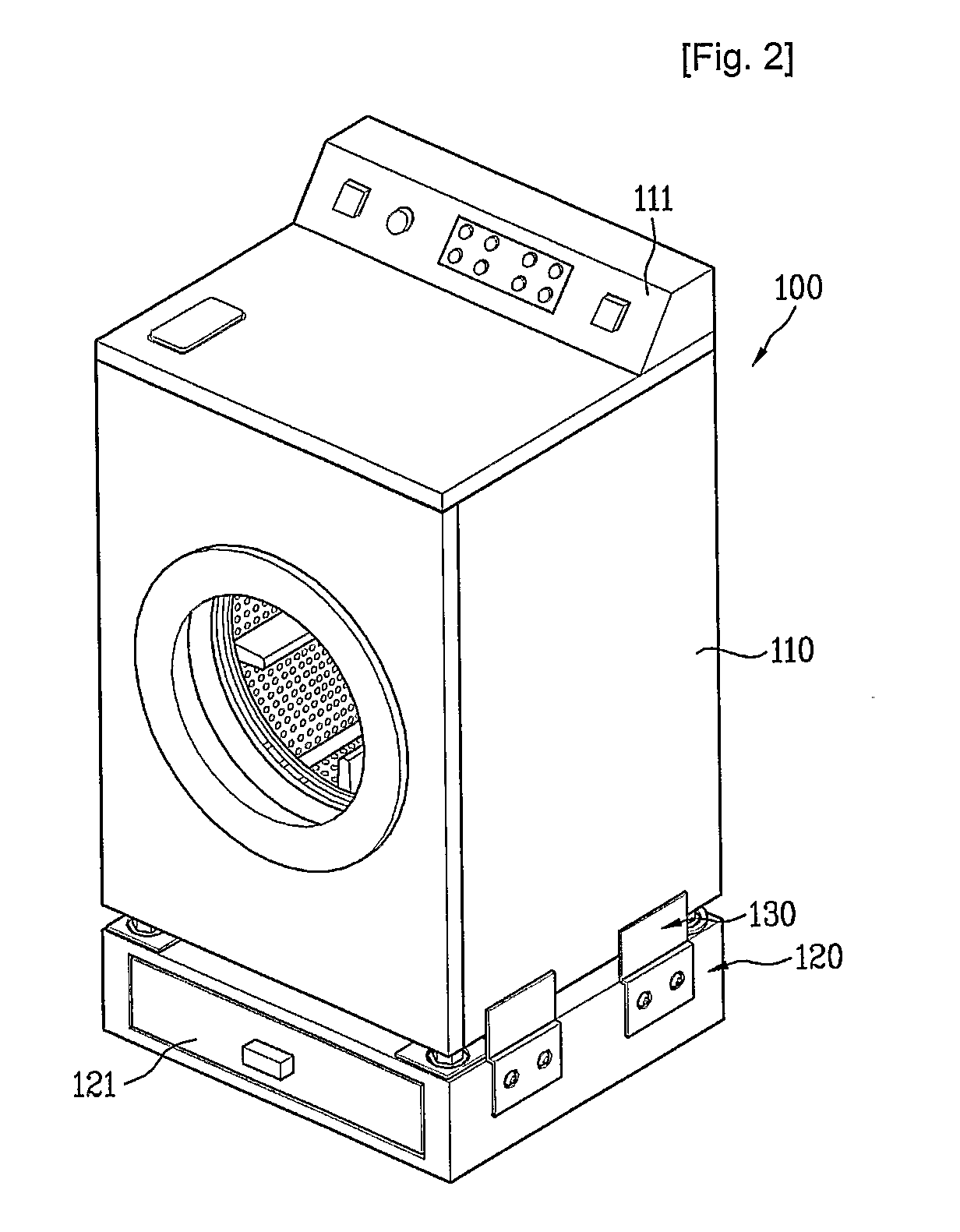

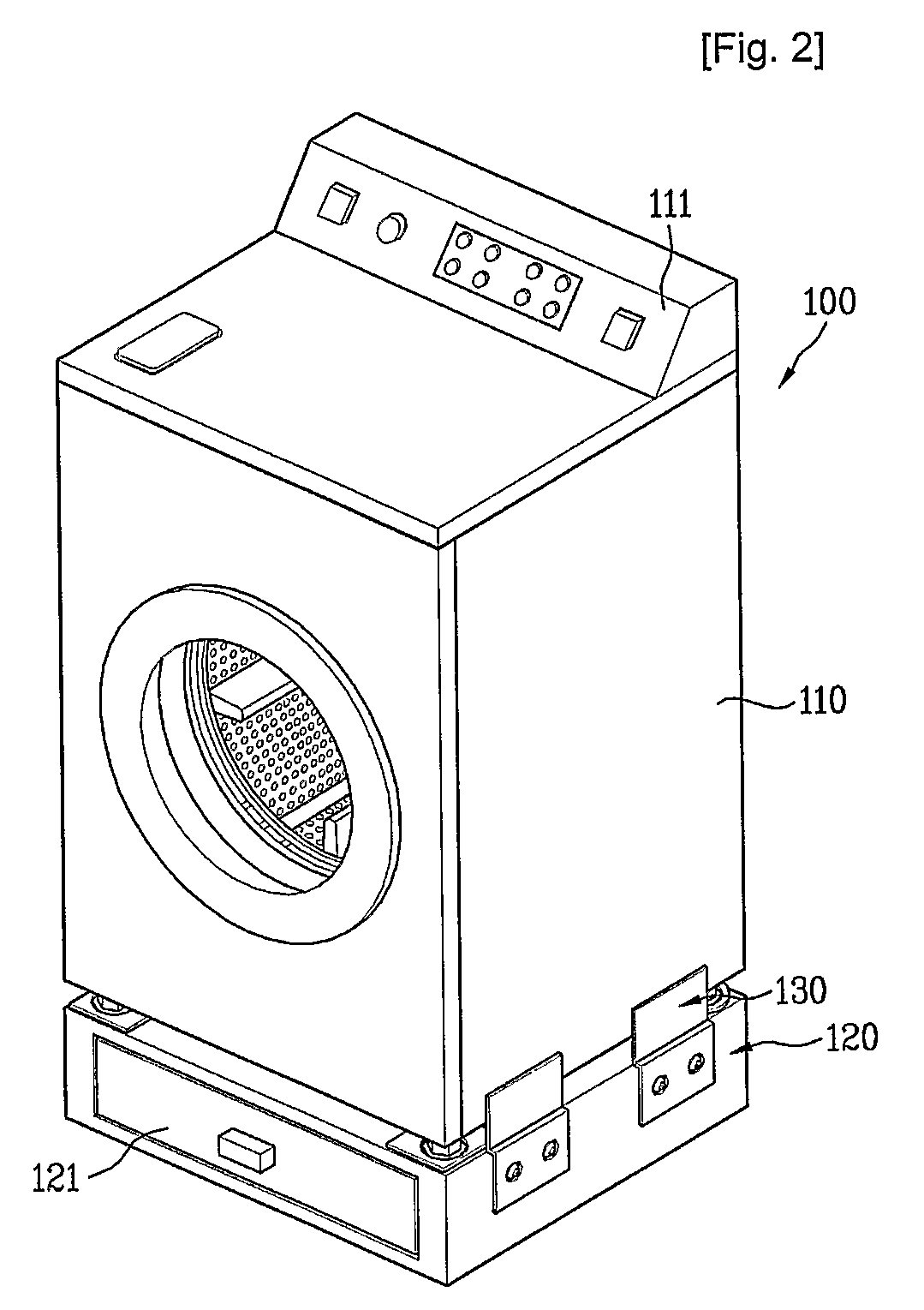

Multiple laundry treating machine

ActiveUS20100011609A1Easy to useSave energyOther washing machinesControl devices for washing apparatusLaundryBiomedical engineering

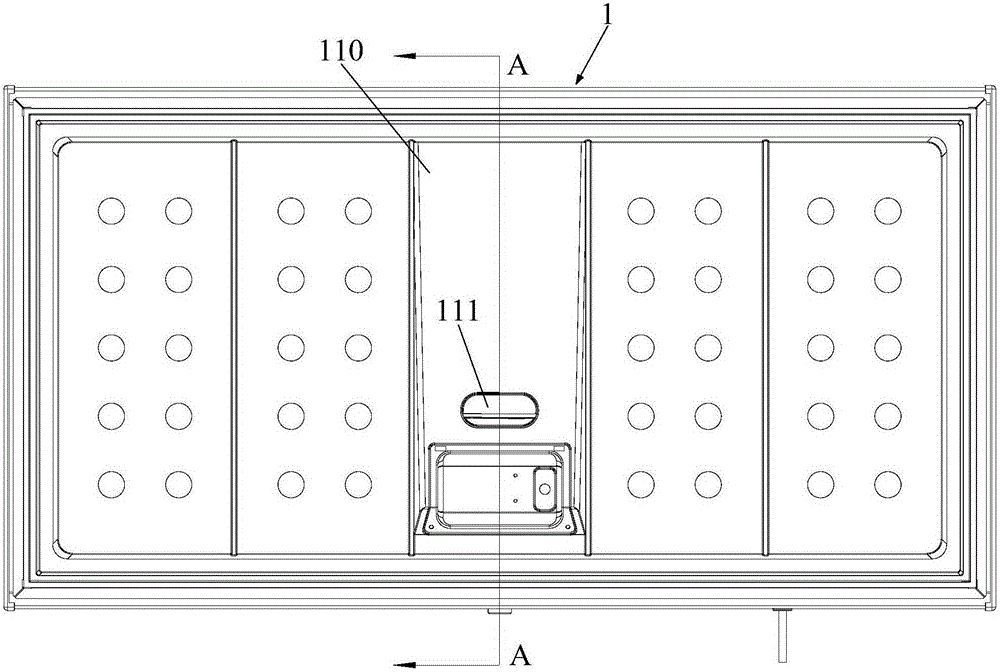

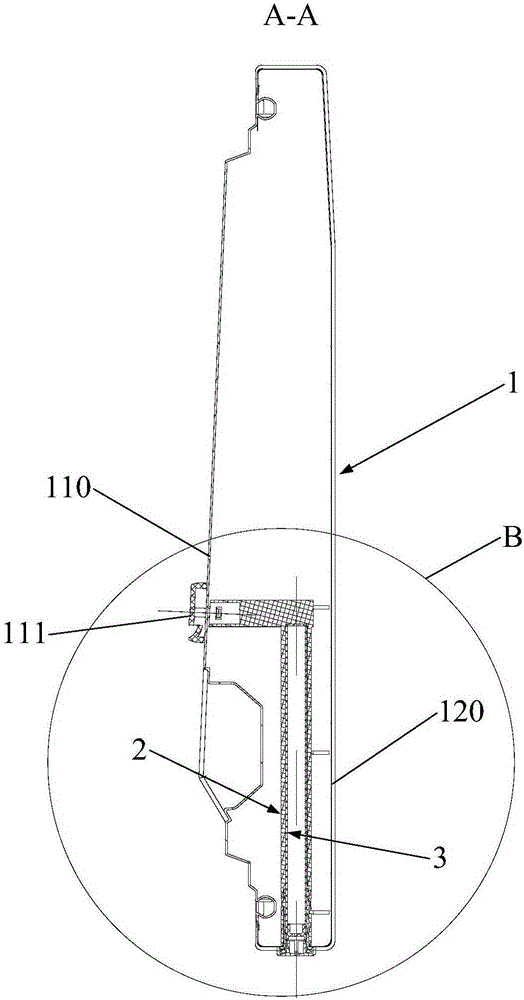

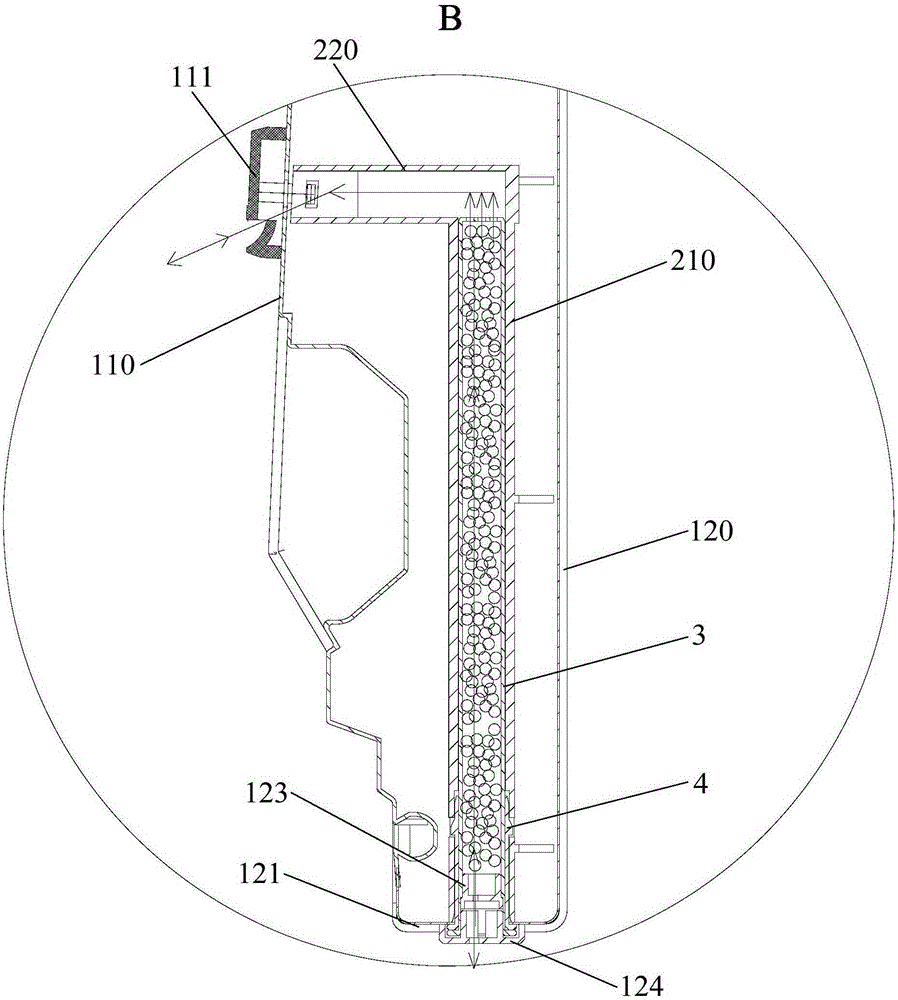

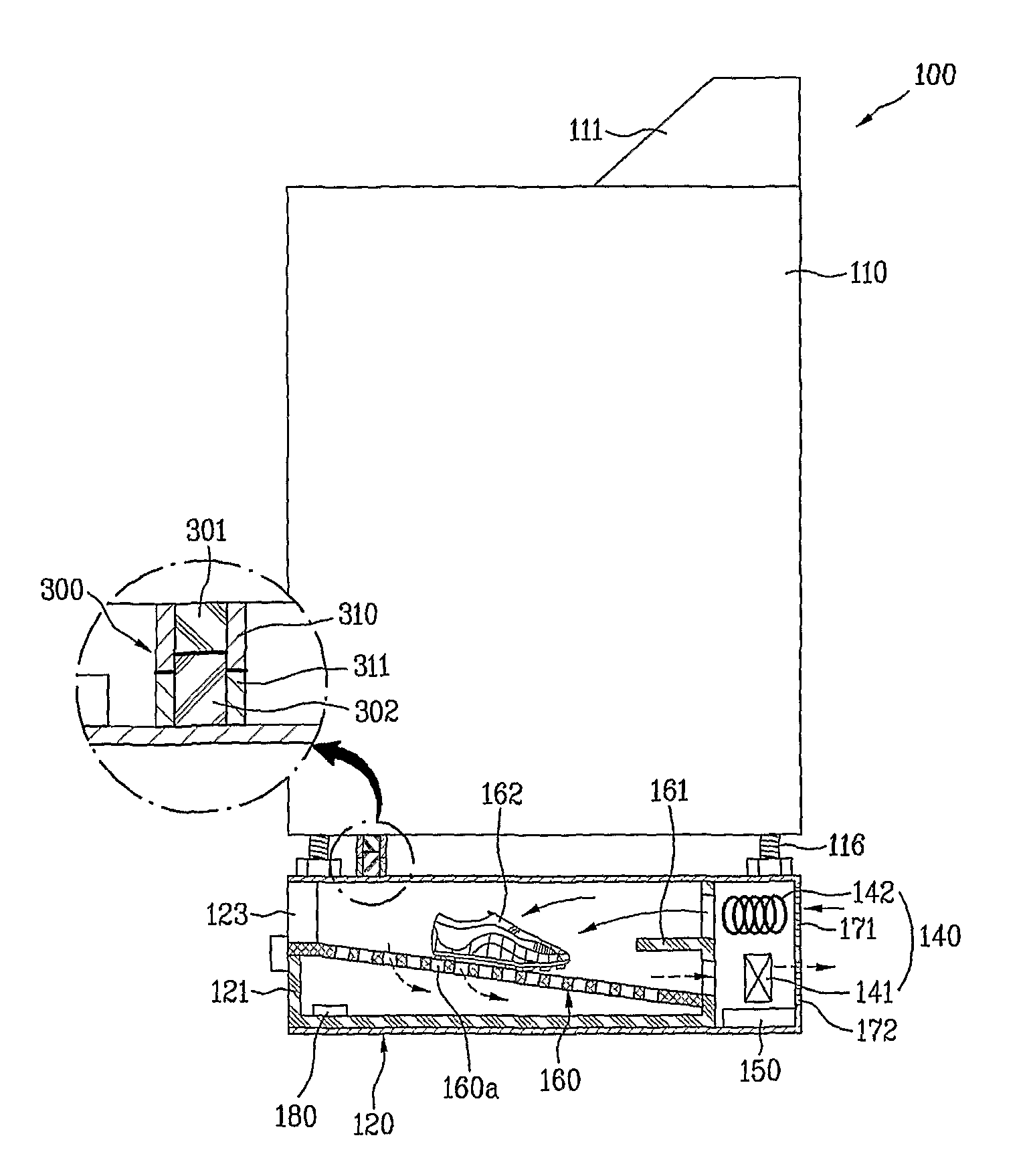

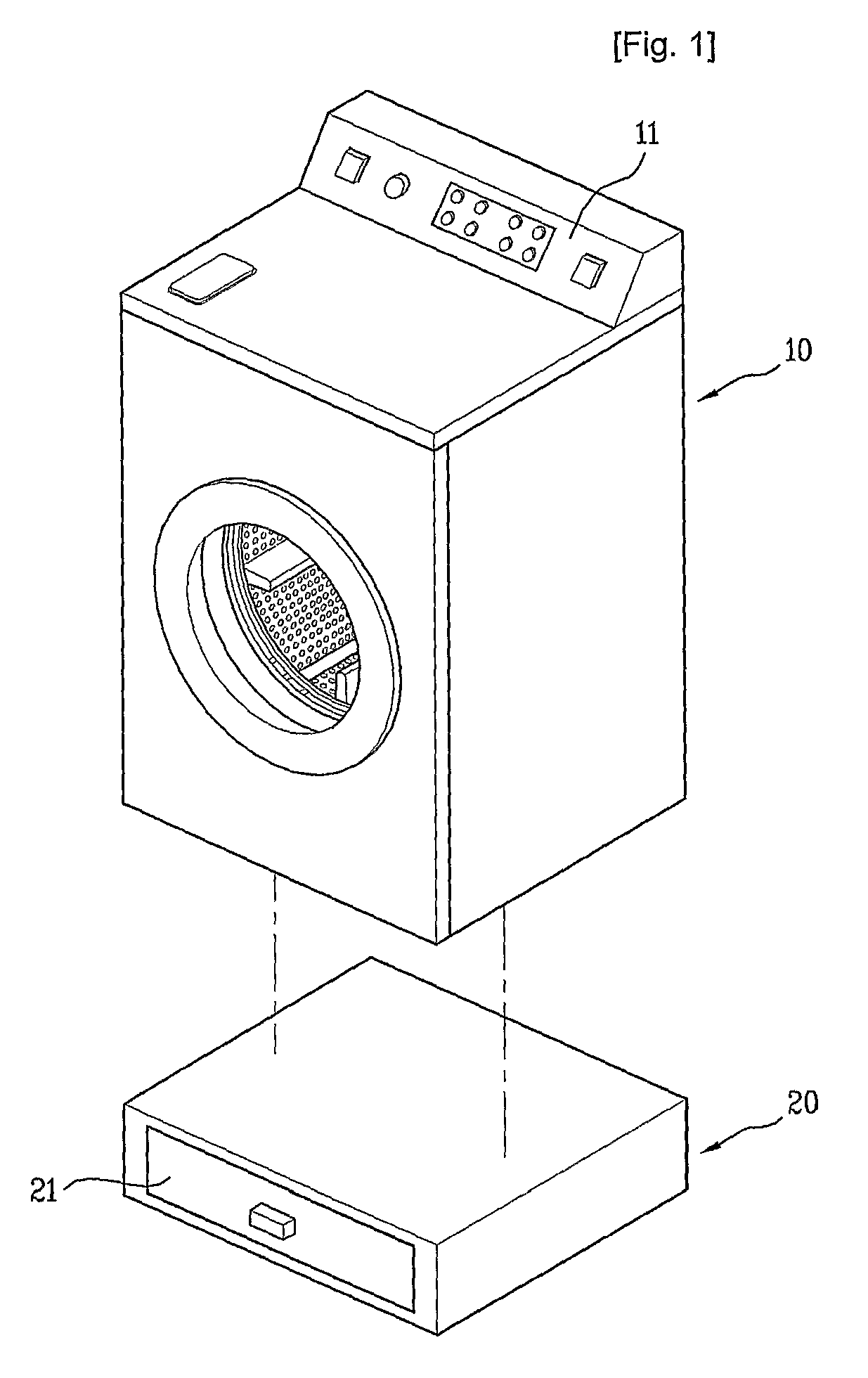

A multiple laundry treating machine, in which an auxiliary laundry treating device (120) is coupled to a general laundry treating device (110), is disclosed. The multiple laundry treating machine includes a main laundry treating device (110) for washing or drying laundry contained in an interior of the main laundry treating device (110), an auxiliary laundry treating device (120) arranged at one side of the main laundry treating device (110), the auxiliary laundry treating device (120) having a volume and a height respectively smaller than a volume and a height of the main laundry treating device (110), and having a laundry container (121) formed in an interior of the auxiliary laundry treating device (120), and a connecting unit (300) for connecting the main and auxiliary laundry treating devices (110, 120), to enable communication or control operations between the main and auxiliary laundry treating devices (110, 120). In accordance with the multiple laundry treating machine, it is possible to achieve a convenience in use and to save energy because a small amount of clothes or shoes can be dried by the auxiliary laundry treating device (120), without driving a laundry treating device (120) having a relatively-large capacity.

Owner:LG ELECTRONICS INC

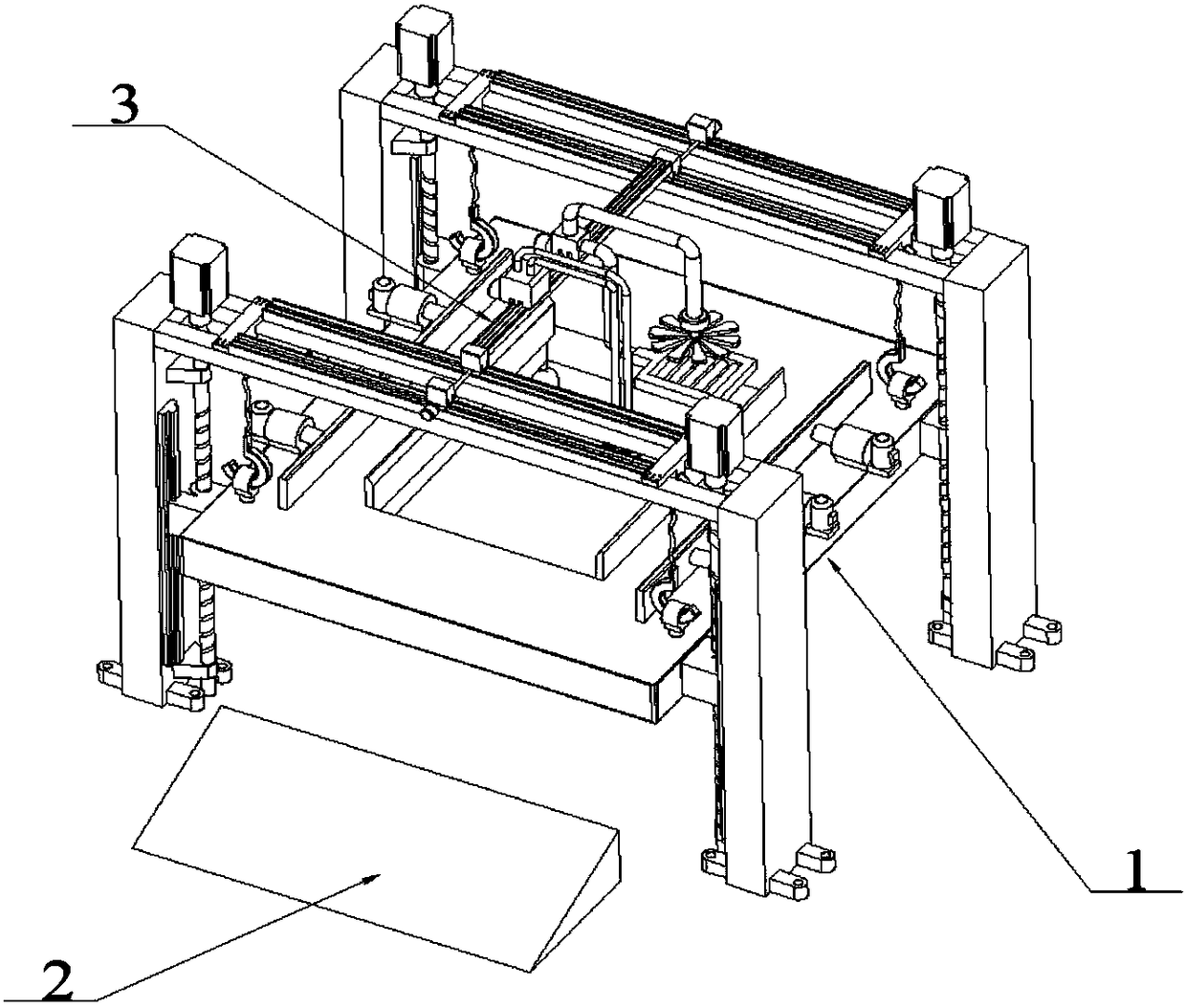

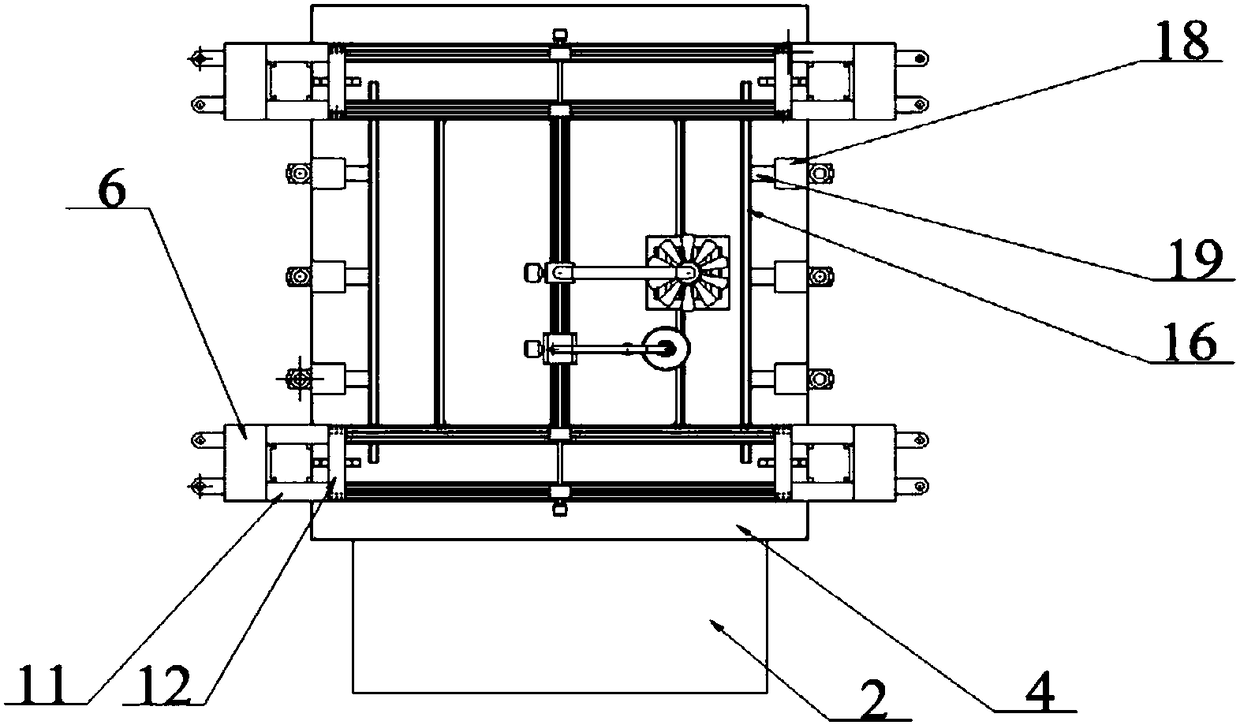

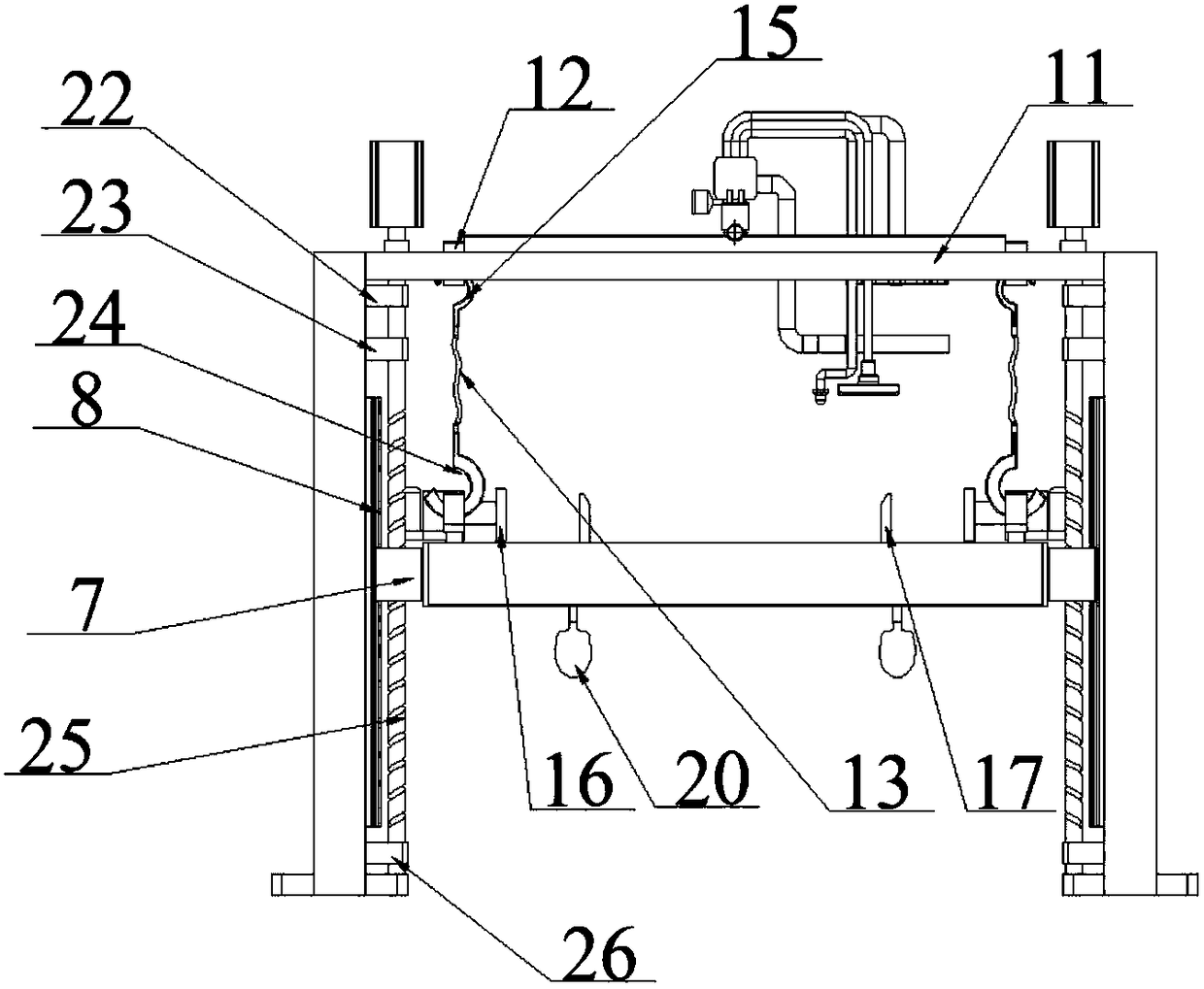

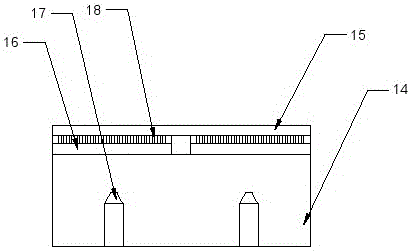

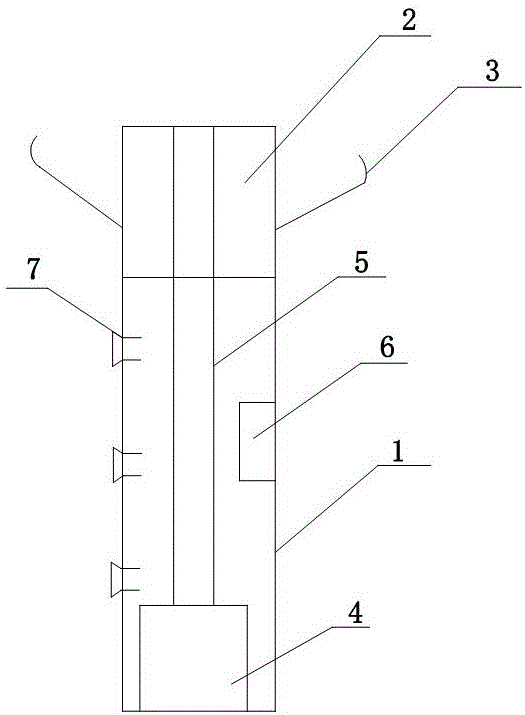

Automobile overhauling and washing hoist

PendingCN108439255AImprove stabilityAvoid breakingLifting framesCleaning using liquidsWater sprayMechanical engineering

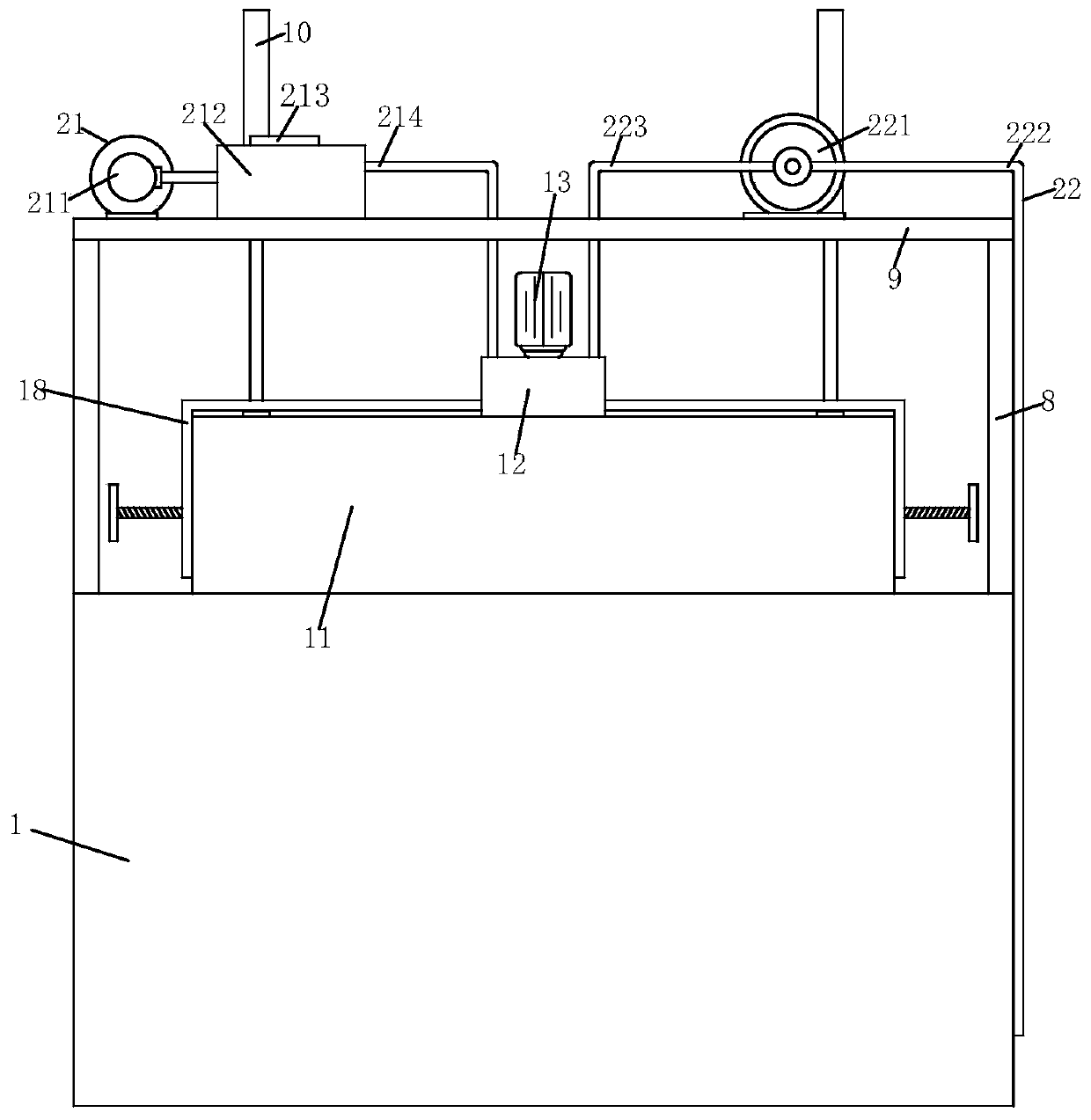

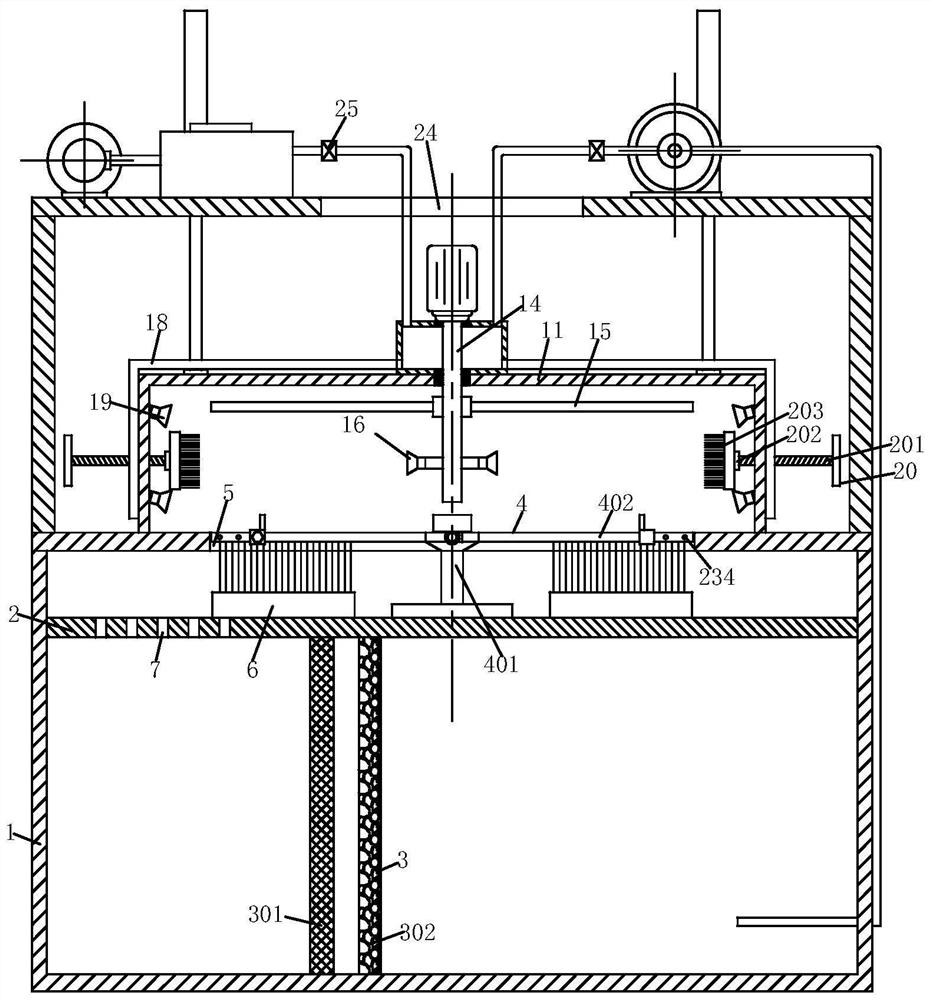

The invention discloses an automobile overhauling and washing hoist and belongs to the field of automobile overhauling and washing equipment. The automobile overhauling and washing hoist comprises a lifting device and a sliding device. The lifting device comprises a frame and a moving mechanism, wherein the frame is composed of four stand columns and two cross beams, and the middle of a lifting platform is further provided with a notch for overhauling a vehicle. The sliding device is provided with a cleaning device, and the cleaning device is installed on the upper part of the frame through asliding mechanism. The sliding device comprises a transverse sliding mechanism and a transverse sliding mechanism. The cleaning device comprises a water spraying mechanism and an air drying mechanism.The water spraying mechanism is installed on an auxiliary sliding trolley I, and the air drying mechanism is installed on an auxiliary sliding trolley II. The automobile overhauling and washing hoisthas the main applications that the full-functionality service can be provided, the facility can complete several jobs, it does not need to purchase multiple devices, the cost is saved, washing is flexible, drying is rapid, and operation is easy.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

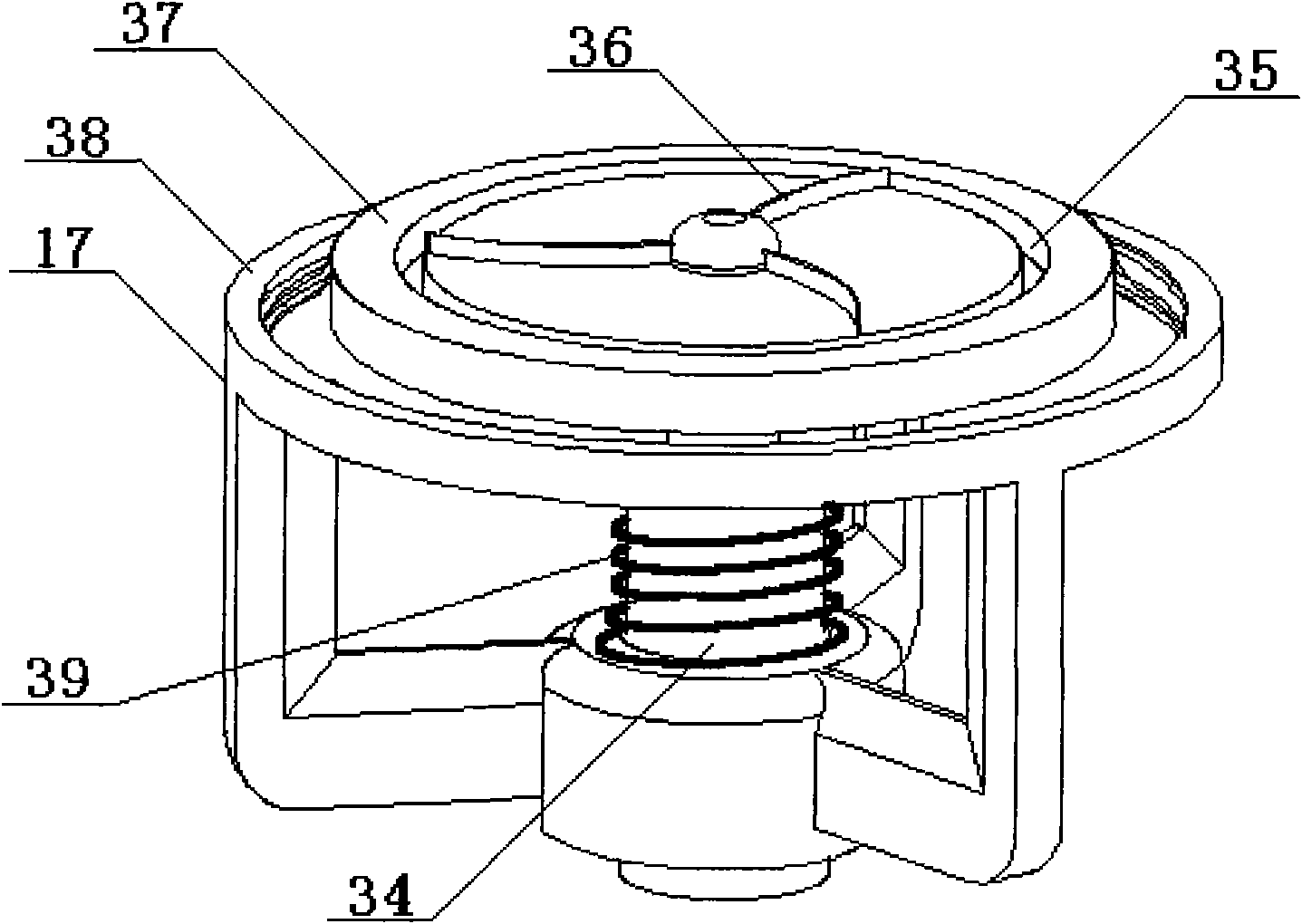

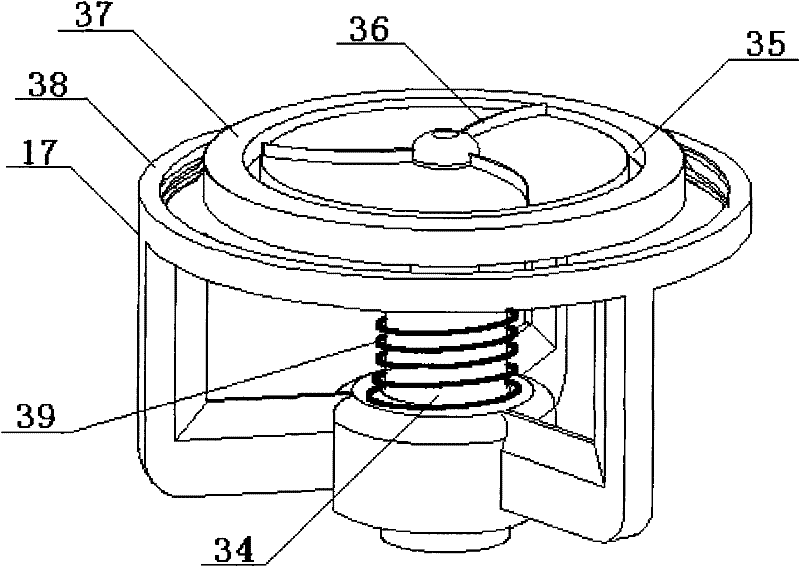

Turntable type quantitative discharging device

The invention discloses a turntable type quantitative discharging device, which comprises a storage bin. The turntable type quantitative discharging device is characterized in that the storage bin is a barrel with a circular upper part and a conical lower part, the lower edge of the lower conical part of the barrel is fixedly connected with a discharging pipe provided with a serrated bottom edge, and the outer side of the discharging pipe is fixedly provided with a bin bottom flange plate with external threads. The turntable type quantitative discharging device also comprises a cylinder which supports a supporting point outside of the storage bin so that the storage bin can rotate; a turntable assembly which is connected with the threads of the bin bottom flange plate through threads and comprises a three-claw turntable seat, a turntable arranged in the middle of the turntable seat and a rotating beam barrel; a collecting tank which is arranged below the turntable assembly and is a barrel with an upper circular part and a lower conical part; a driving host which is arranged in the middle upper part of the collecting tank; and a weighing scale which is arranged in the middle upper part of the collecting tank. The device has the advantages of simple structure, stable discharge and easy use and cleaning, can realize the smooth, accurate, rapid and automatic quantitative discharging of trace raw materials, and is applicable to the mixing and production with multiple types of powdered and particular trace raw materials and high weighing precision.

Owner:广西南宁市真唯特自动化设备有限公司

Cleaning and drying device for medical instruments

InactiveCN108080311AReduce workloadImprove work efficiencyDrying gas arrangementsCleaning using toolsEngineeringMedical treatment

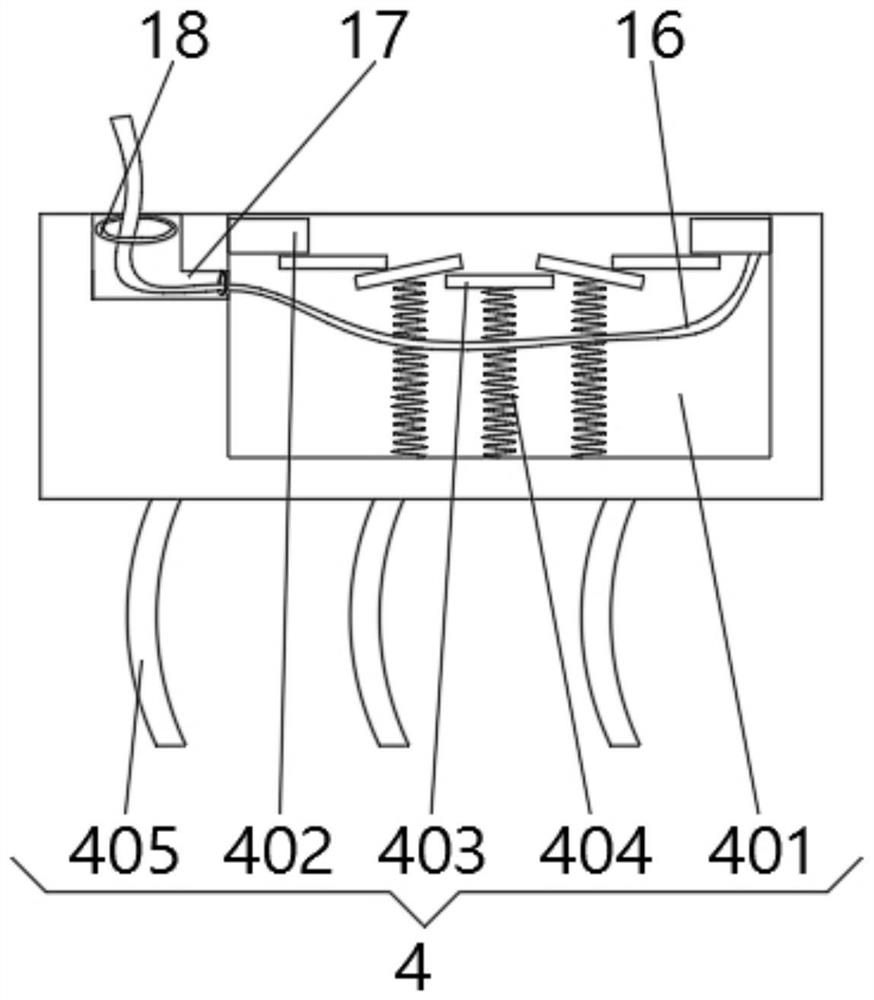

The invention discloses a cleaning and drying device for medical instruments. The cleaning and drying device comprises a fixing box, wherein buffering devices are fixedly connected to two sides of thebottom part of the inner wall of the fixing box, and a cleaning box is fixedly connected to the top parts of the buffering devices; protecting devices are fixedly connected to two sides of the top part of the cleaning box, and one sides of the protecting devices are fixedly connected to the fixing box; the top part of the inner wall of the fixing box is fixedly connected to a shaking device through a supporting frame, the top part of the shaking device is in sliding connection with the top part of the inner wall of the fixing box, and the bottom part of the shaking device is fixedly connectedto the cleaning box; and the top part of the inner wall of the cleaning box is fixedly connected with first motors through supports. The invention relates to the technical field of medical instruments. According to the cleaning and drying device for the medical instruments, the problem that an existing medical cleaning is low in cleaning speed due to manually cleaning is solved, the work load ofpeople is relieved, the cleaning effect is improved, the working efficiency of the people is improved, and the functions of a medical cleaning device are increased.

Owner:赵国苗

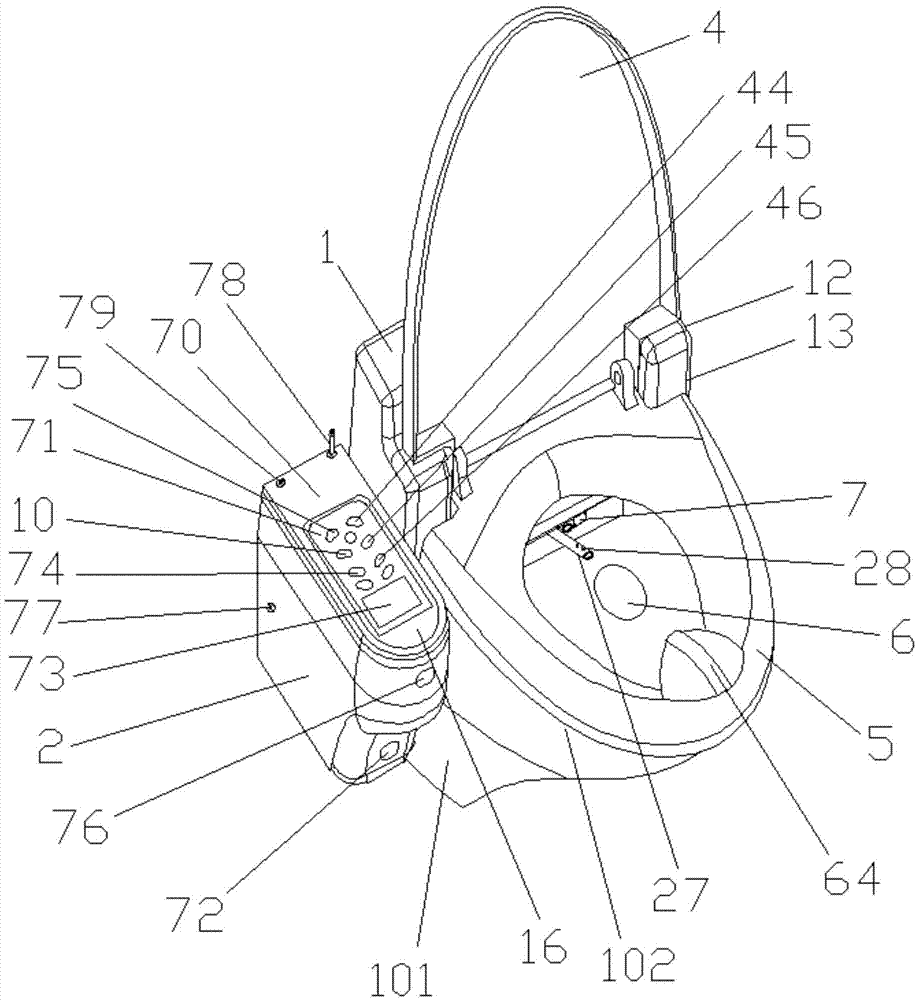

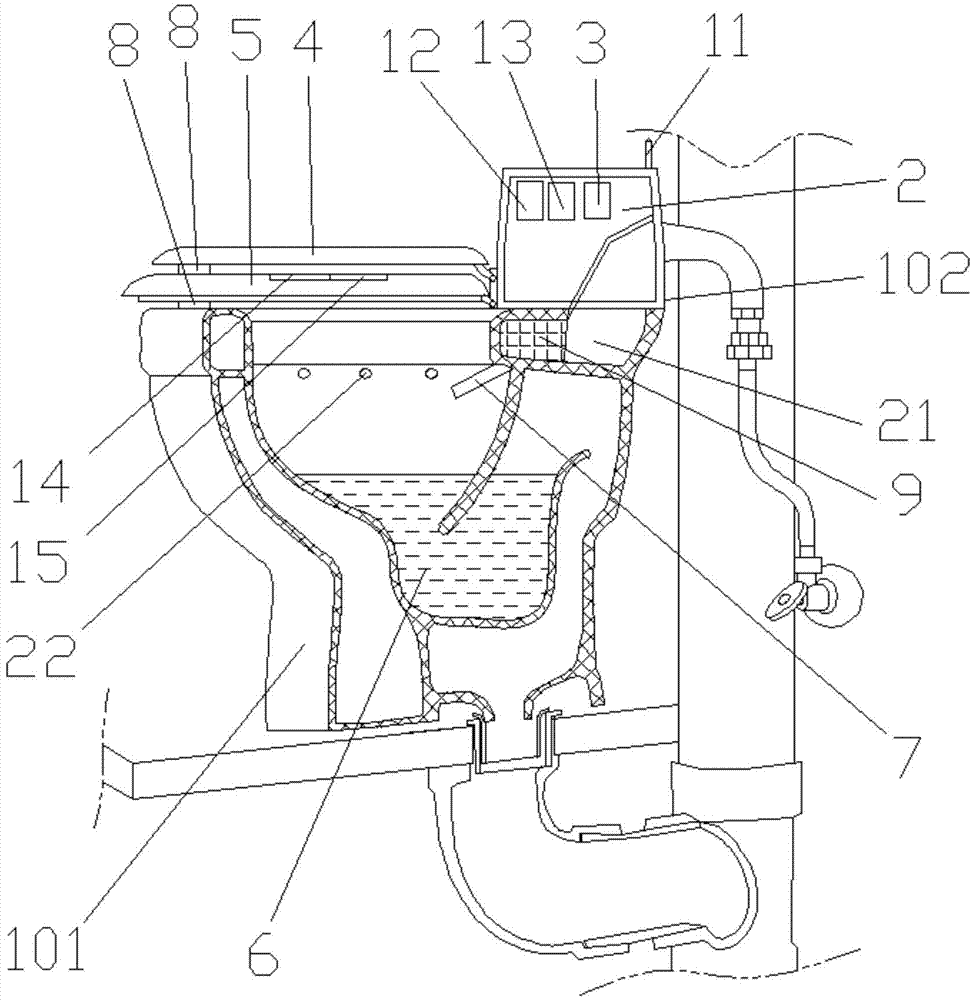

Intelligent health monitoring toilet

ActiveCN104727413AImprove intelligenceImprove deodorization functionWater closetsFlushing devicesEngineeringPhysical examination

The invention discloses an intelligent health monitoring toilet. The intelligent health monitoring toilet comprises a toilet seat body and an intelligent toilet cover body. The intelligent toilet cover body comprises a main water storing tank, an intelligent control tank, a control device, an overturning toilet cover and an overturning toilet ring. The overlapping position of the intelligent control tank and the overturning toilet ring is provided with an air blowing and sucking circulation system. The air blowing and sucking circulation system comprises an air blowing pipeline, an air sucking pipeline and an air pumping device. The position of the air sucking pipeline is opposite to the position of the air blowing pipeline. The side of the intelligent toilet cover body is provided with a physical examination handle. The physical examination handle is provided with a physical examination sensor and a manual control input device. The physical examination sensor can detect the heartbeat, the blood pressure, the height, the weight and the special sick body smell of a human body. According to the intelligent health monitoring toilet, user information and body data can be collected, a user real-time body health condition is analyzed and fed back through a dedicated data analyzing system, and a nursing or curing suggestion is provided. The intelligent health monitoring toilet has the advantages of being simple in device, low in cost, and free of update. The intelligent health monitoring toilet is a health tip for a user.

Owner:SUZHOU LUZHIYAO TECH

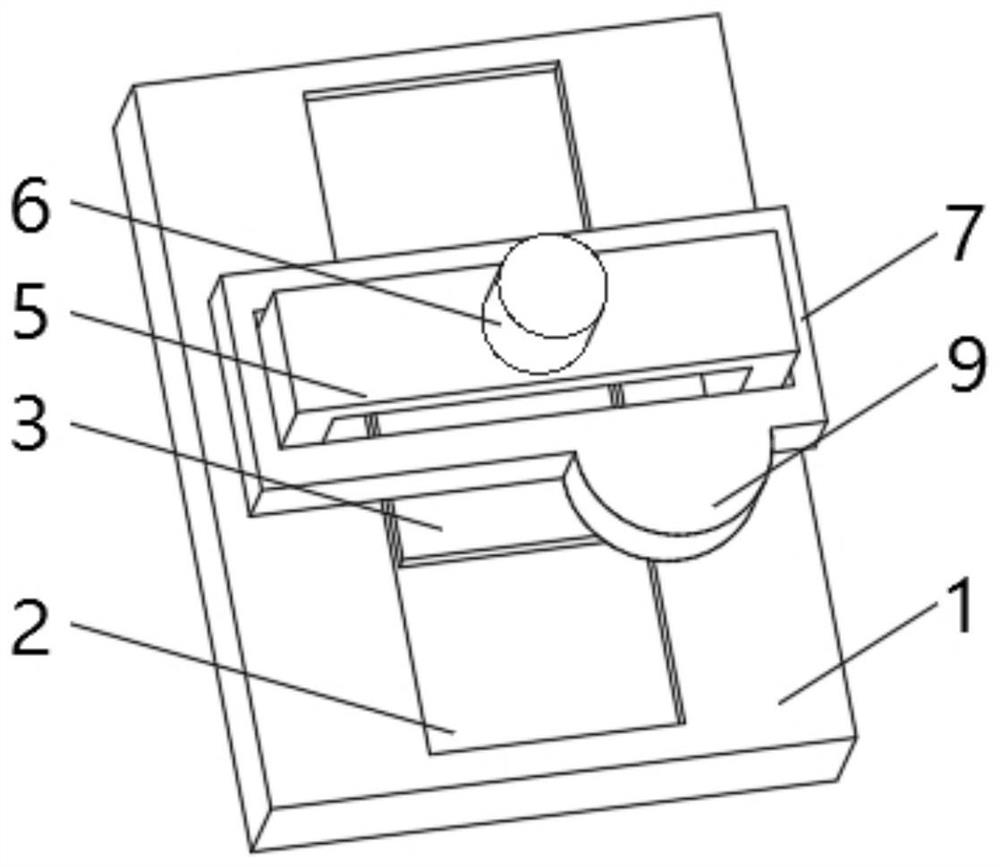

Flat pressing apparatus used for lithium battery

ActiveCN107293762AIncrease productivityQuality improvementPrimary cell manufactureNon-aqueous electrolyte cellsCouplingEngineering

The invention discloses a flat pressing apparatus used for a lithium battery. The flat pressing apparatus comprises a fixed box; the top of the inner wall of the fixed box is fixedly connected with a first motor through a supporting plate; the output shaft of the first motor is fixedly connected with a first belt wheel through a coupling; the surface of the first belt wheel is in transmission connection with a second belt wheel through a belt; a threaded rod runs through the middle part of the second belt wheel; movable blocks are in threaded connection with the two ends of the surface of the threaded rod respectively; fixed blocks are fixedly connected with the bottoms of the movable blocks; the surfaces of the fixed blocks are rotationally connected with rotary rods through movable parts; and one ends, far from the fixed blocks, of the rotary rods are rotationally connected with a fixed base through the movable parts. The flat pressing apparatus used for the lithium battery relates to the technical field of the lithium battery, and solves the problem that the existing flat pressing apparatus used for the lithium battery cannot perform good extrusion and forming and the problem of low flat pressing speed of the lithium battery; and by adoption of the flat pressing apparatus, the production efficiency of the lithium battery is improved, the flat pressing quality of the lithium battery is improved, and rapid and effective production of the lithium battery is ensured.

Owner:江苏芯界新能源科技有限公司

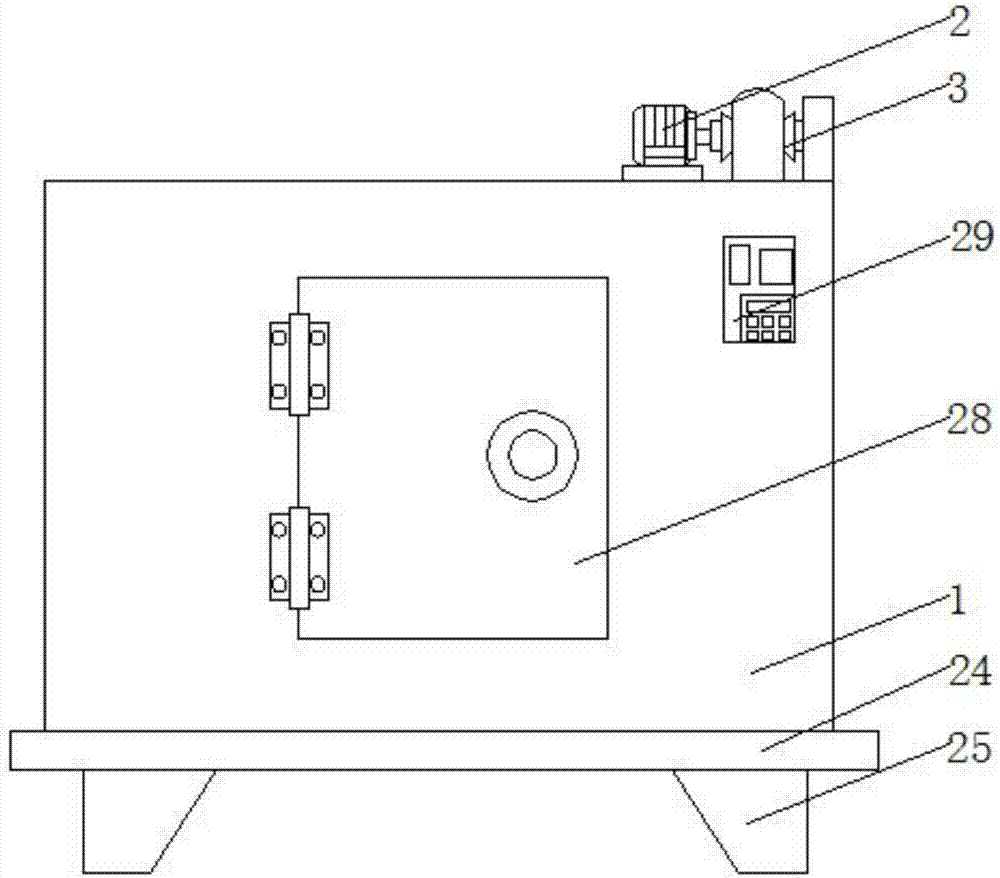

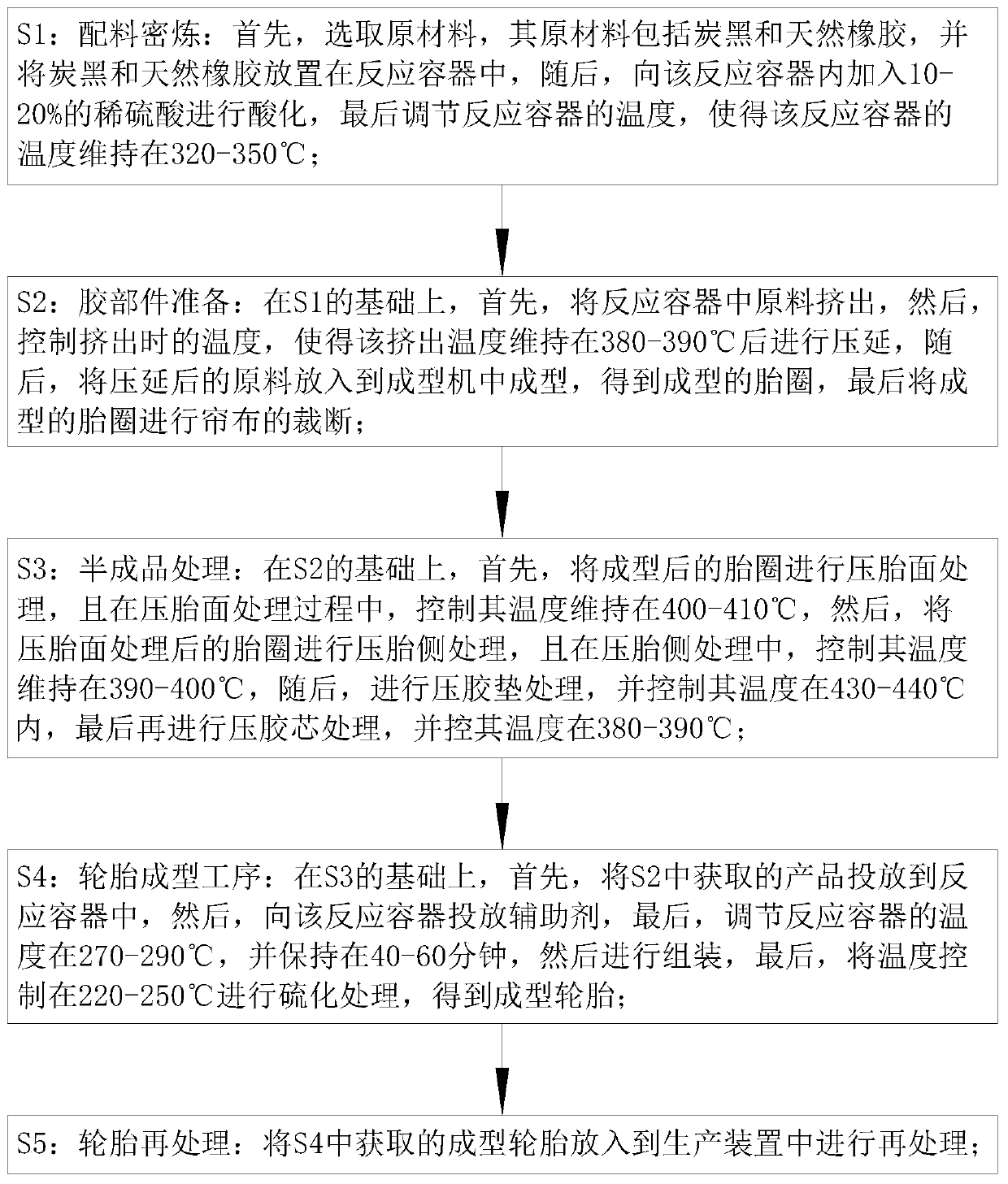

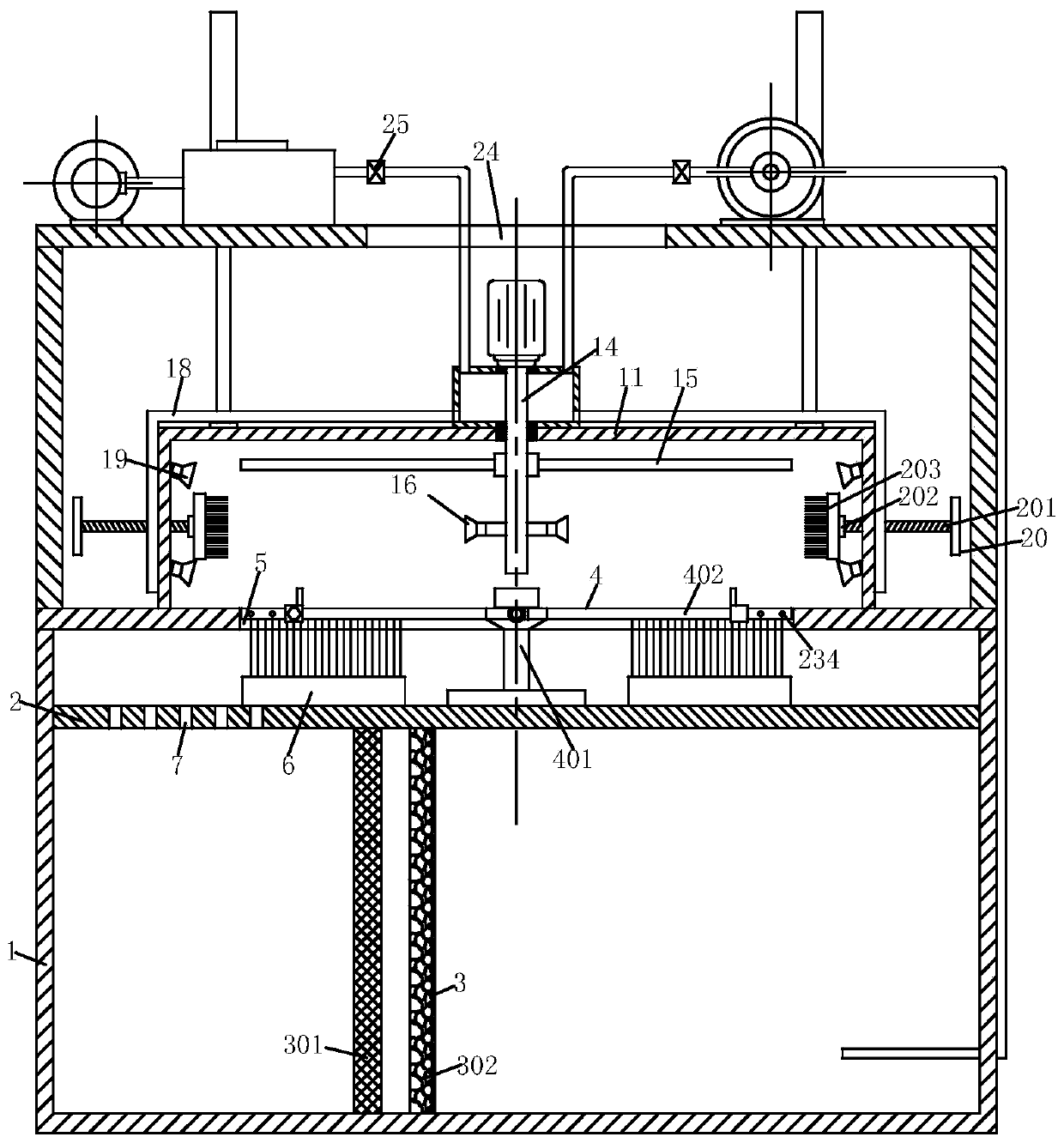

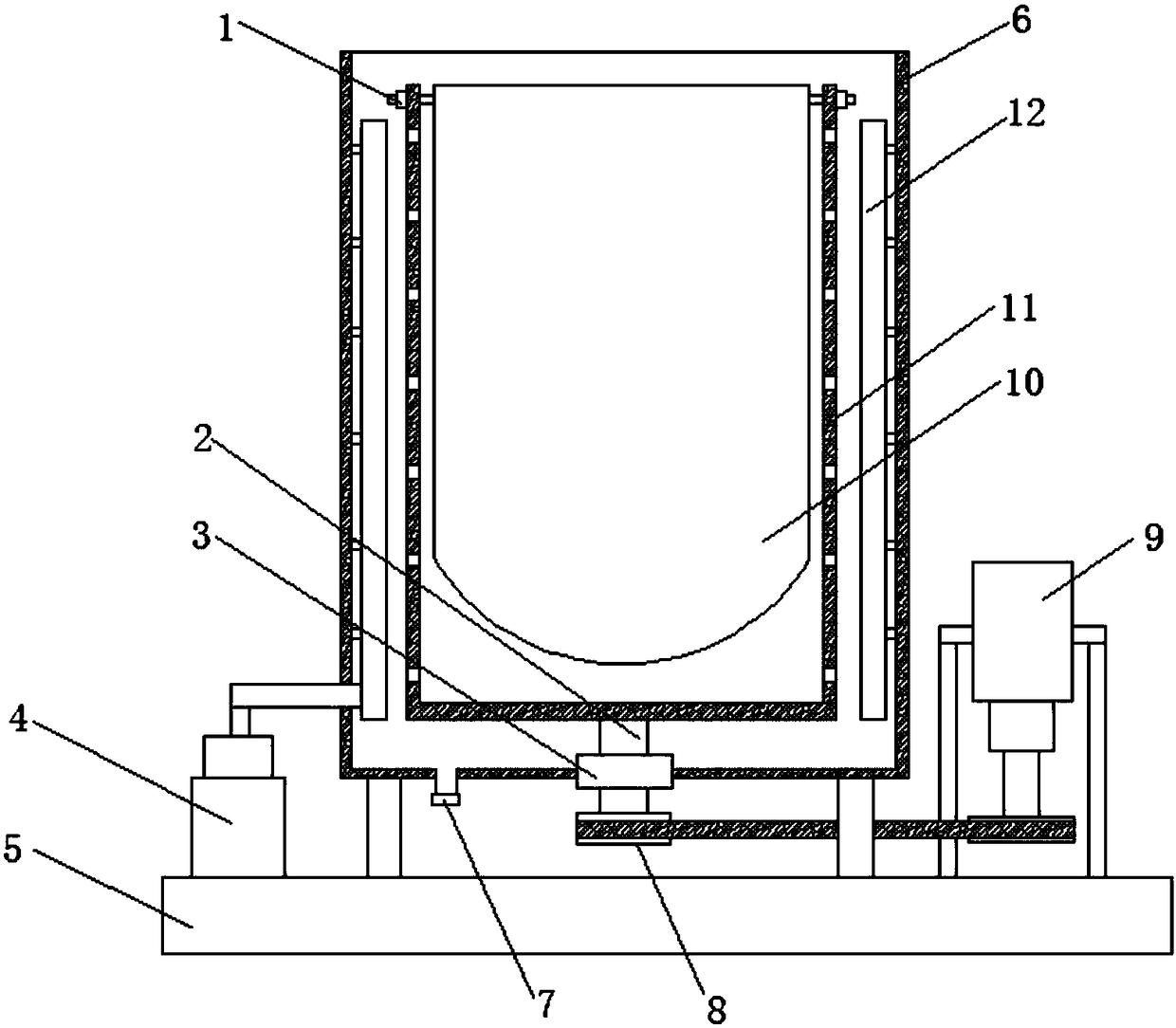

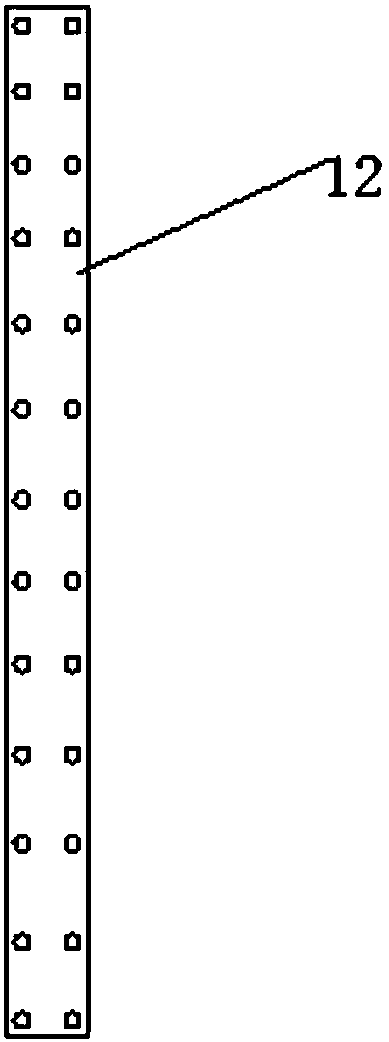

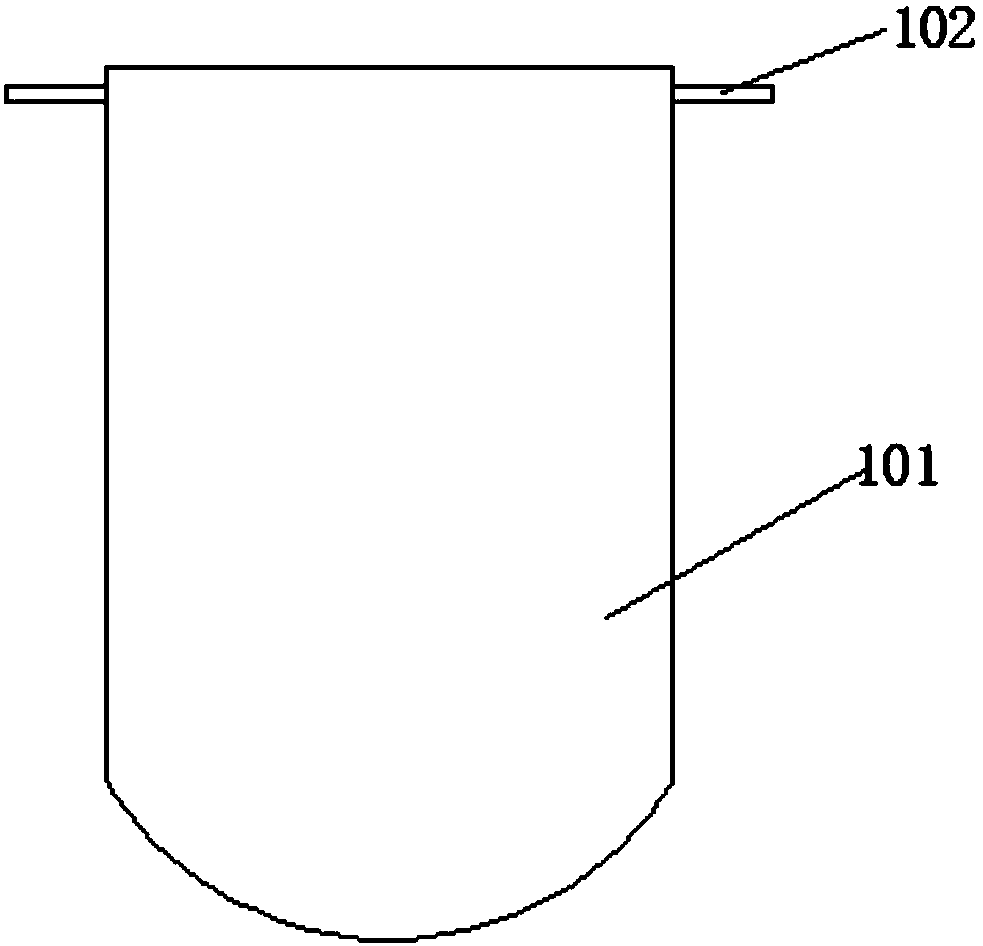

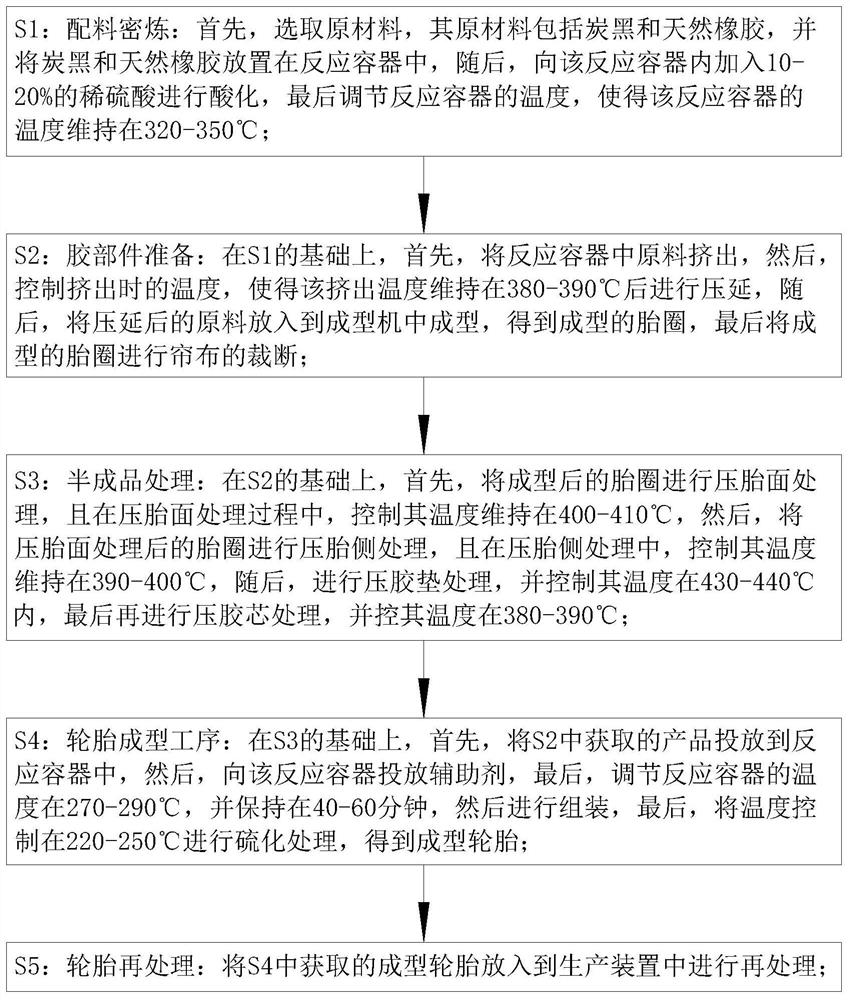

Tire production process

ActiveCN110341221APrevent splashClean working environmentDrying gas arrangementsTyresWater resourcesEngineering

The invention relates to the field of tire production, in particular to a tire production process. A production device adopted by the process comprises a water tank, a partition plate is transverselyand fixedly arranged at the position, close to the middle, of the inner wall of the water tank, a filter mechanism is longitudinally and fixedly arranged between the position, close to the middle, ofthe lower surface of the partition plate and the inner wall of the lower side of the water tank, a placement mechanism is fixedly arranged at the position, close to the middle, of the upper surface ofthe partition plate, a round hole is formed in the position, corresponding to the placement mechanism, of the upper side wall of the water tank, and first brushes are fixedly arranged on the positions, on the left side and the right side of the placement mechanism, of the upper surface of the partition plate. According to the tire production process, a cleaning part is arranged on the inner wallof a round cover, the round cover is used for blocking water sprayed out during cleaning, and splashing of water is avoided; meanwhile, the water tank can be used for recycling water resources, watercan be recycled after being filtered, so that more energy is saved; the inner wall and the outer surface of a tire are cleaned at the same time through first spray heads, second spray heads and cleaning mechanisms, so that the cleaning efficiency is higher; and in addition, the tire can be dried, and thus the practicability is high.

Owner:江西岳大轮胎有限公司

Ventilated frost reduction device, door body and freezer with door body

InactiveCN105157321AReduce the amount of frostingReduce energy consumptionLighting and heating apparatusDefrostingMolecular sieveFrost

The invention provides a ventilated frost reduction device, a door body and a freezer. The freezer comprises the door body. The ventilated frost reduction device comprises an embedded piece and a molecular sieve assembly. The embedded piece is arranged in the door body and has a first end and a second end; the first end and the second end are communicated; and when the door body is closed, the first end is communicated with the external environment, and the second end is communicated with the interior of the freezer. The molecular sieve assembly is detachably assembled in the embedded piece and used for ventilation and gas filtration. The door body is provided with the ventilated frost reduction device, and the freezer comprises the door body. The ventilated frost reduction device is easy to install in production, productivity can be improved, a filter substance and a drying agent can be replaced, and the excellent performance of the freezer can be kept all the time.

Owner:HEFEI HUALING CO LTD +1

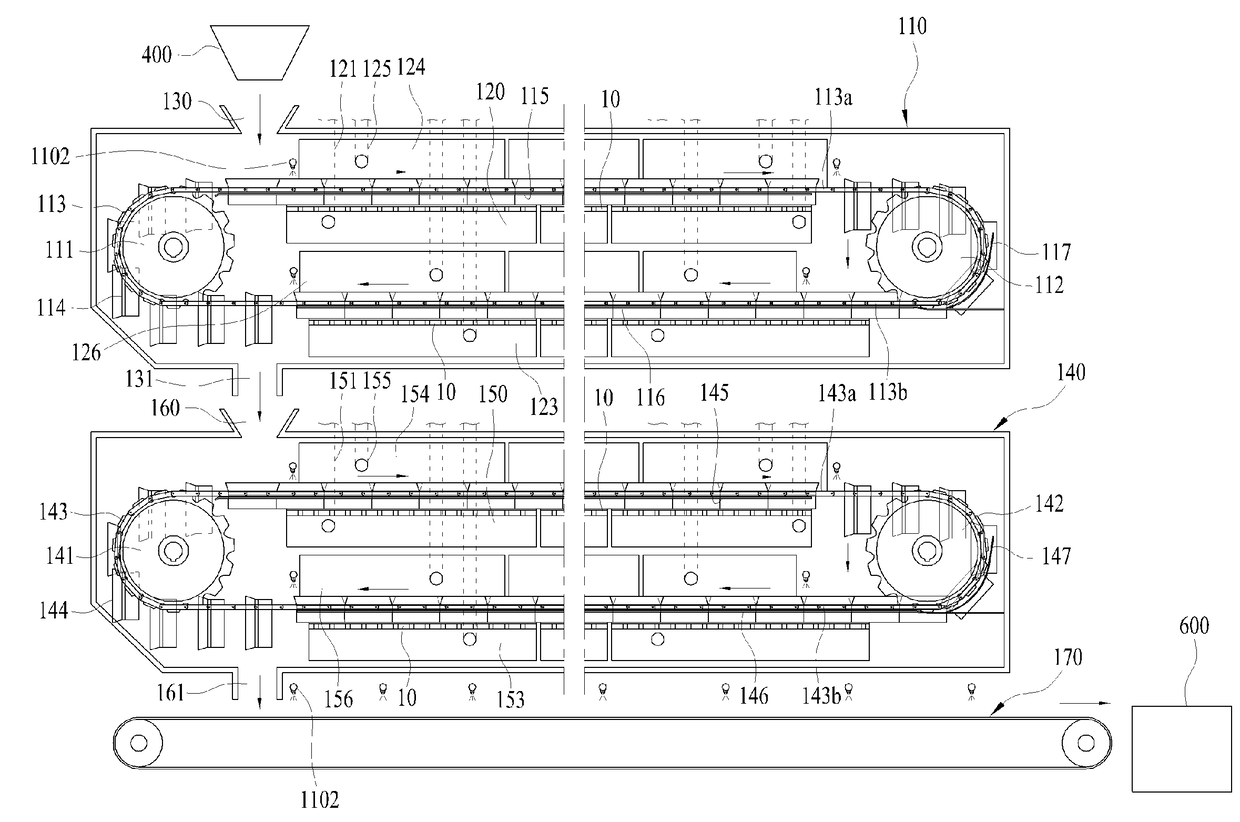

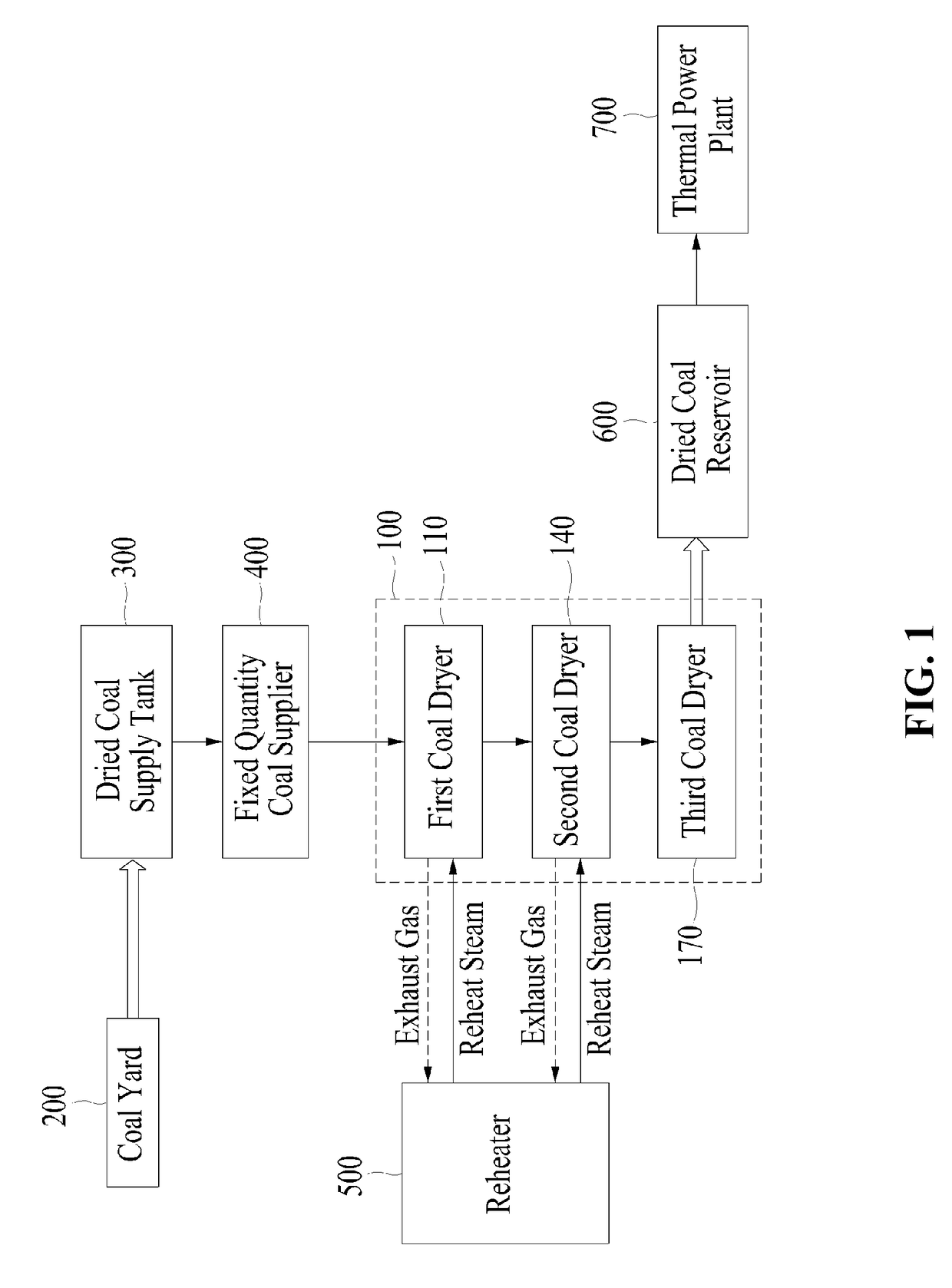

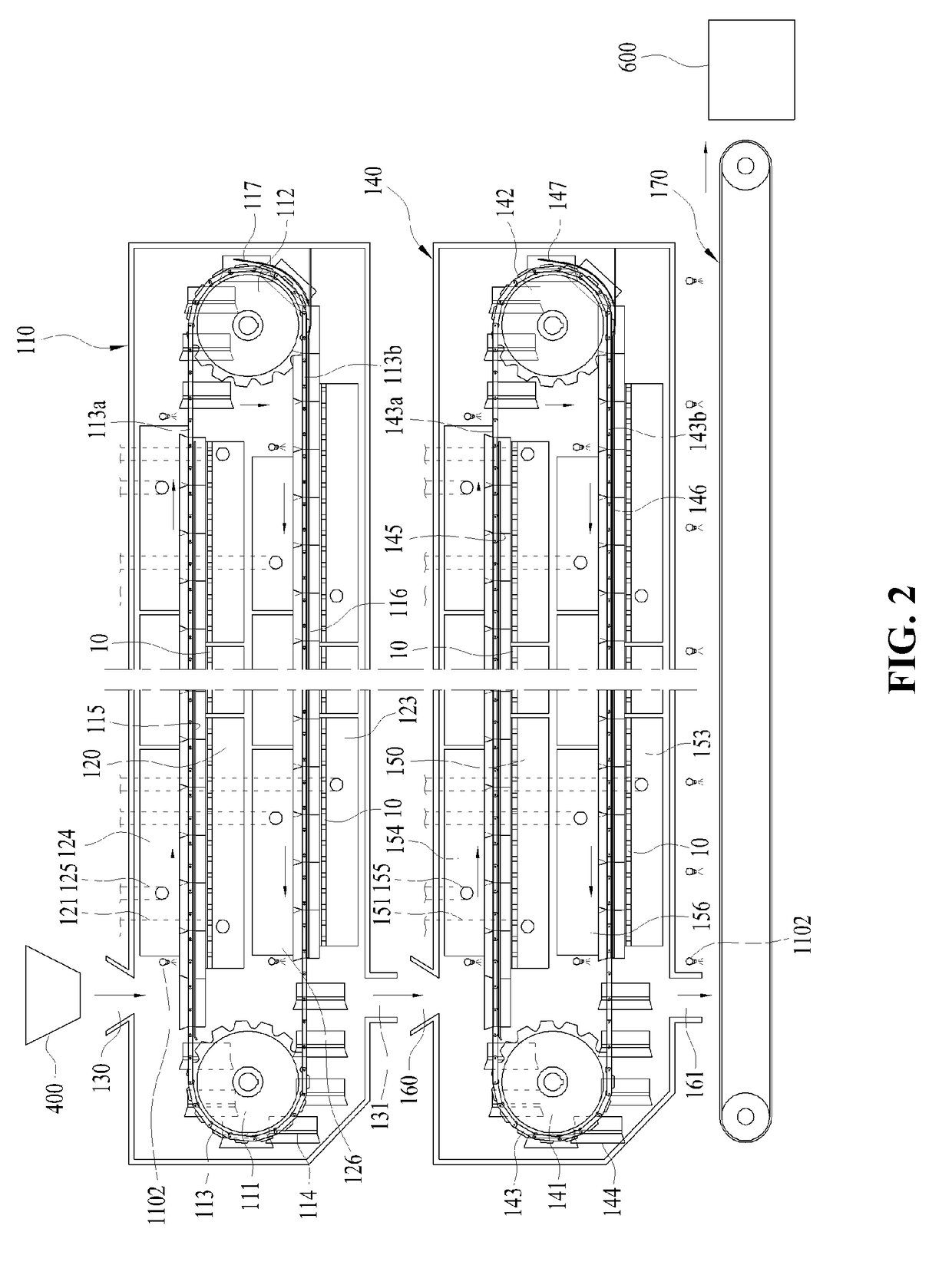

Apparatus for preventing spontaneous ignition of transferred coal in apparatus for drying coal using reheat steam

InactiveUS20170145315A1Maximize useMinimize occurrenceDrying solid materials with heatCoke ovensFour-way valveNitrogen

The present invention relates to an apparatus for preventing, in a multi-stage dryer for drying coal using reheat steam, spontaneous ignition caused by oxidation of coal when coal is transferred to the multi-stage dryer from a fixed quantity coal supplier by way of a pulverizer. The present invention relates to an apparatus for drying coal using reheat steam, the apparatus being configured so that coal which has been dried primarily in a first coal dryer is inputted into a second coal dryer and thus is secondarily dried, wherein reheat steam generated from a reheater is supplied through a reheat steam supply pipe; a nitrogen supplier supplies nitrogen through a nitrogen supply pipe; saturated steam generated from a saturated steam generator is supplied through a saturated steam supply pipe; the reheat steam supply pipe, the nitrogen supplier, and the saturated steam supply pipe are connected to a 4-way valve; and the 4-way valve supplies nitrogen and saturated steam, or nitrogen or saturated steam, along with reheat steam, to first to fourth steam chambers through the steam supply pipe, and injects steam into coal which is transferred to a first transfer plate and a second transfer plate so that spontaneous ignition of coal is prevented in the course of drying and transferring coal.

Owner:HANKOOK TECH

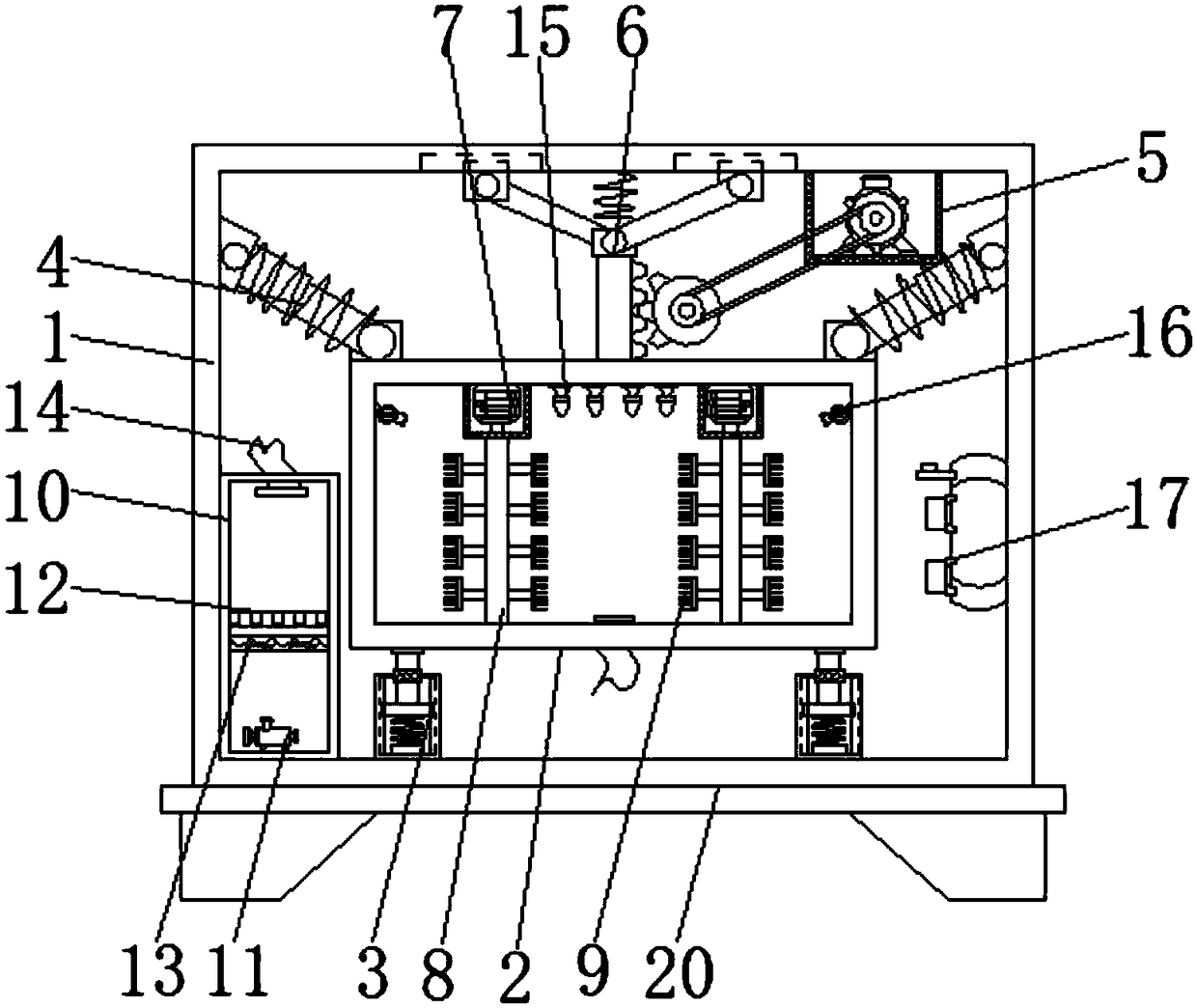

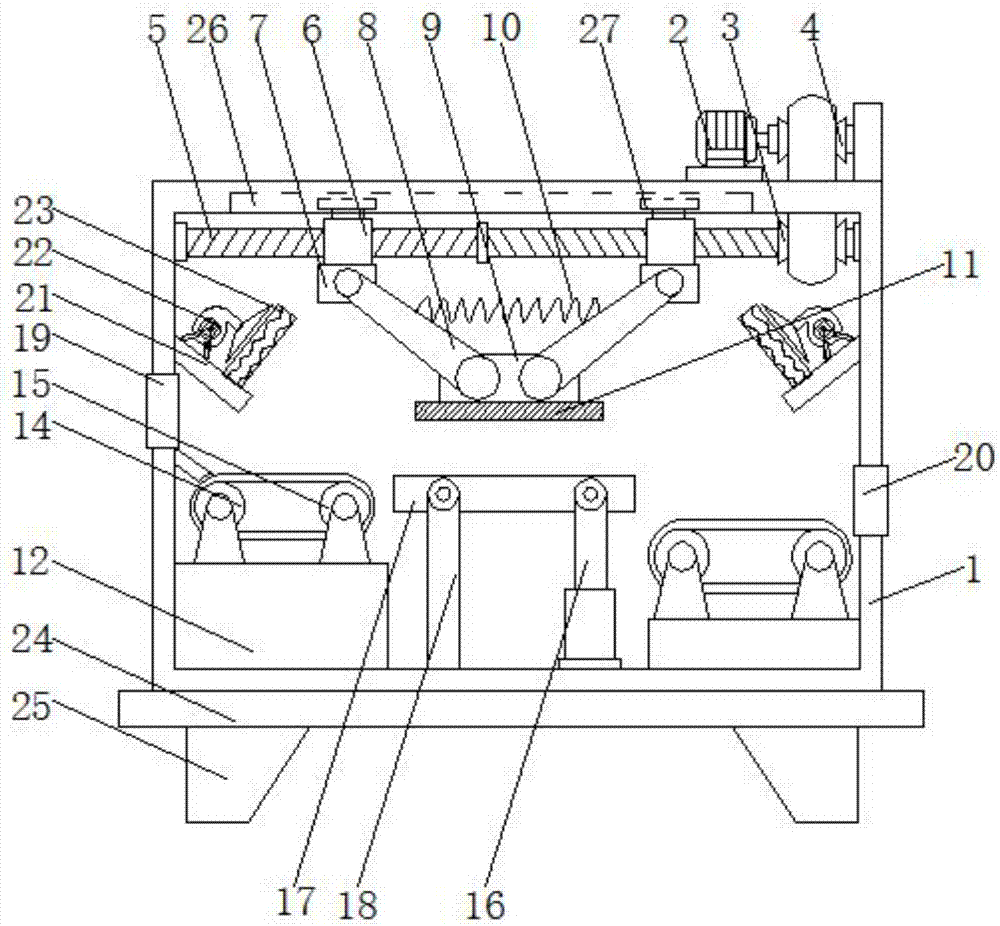

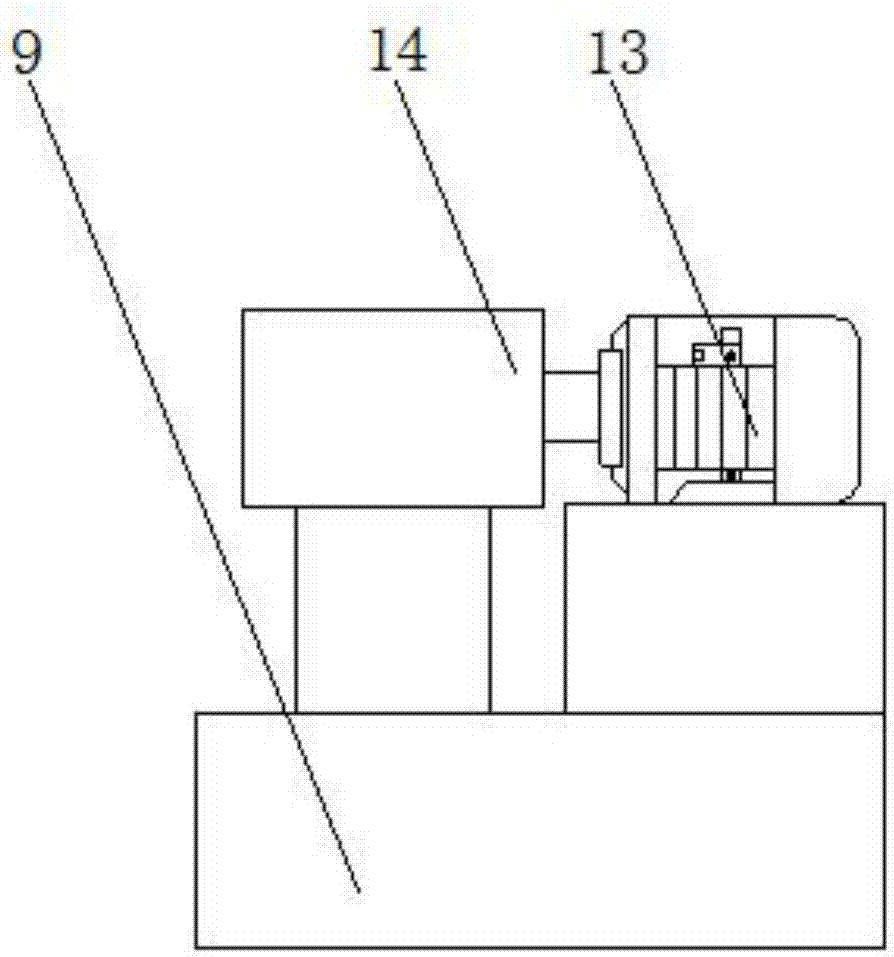

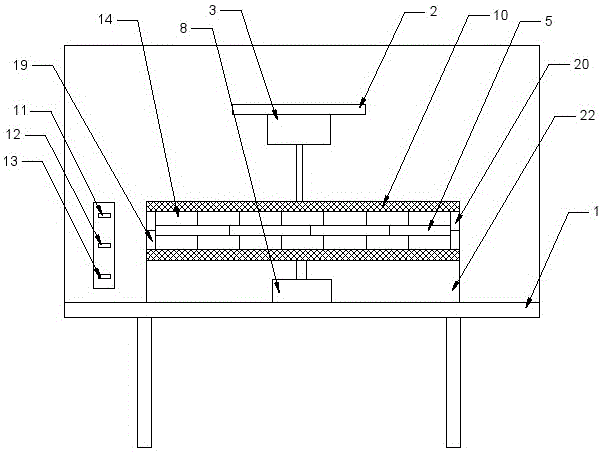

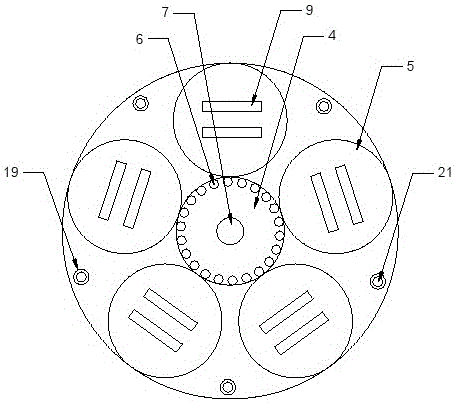

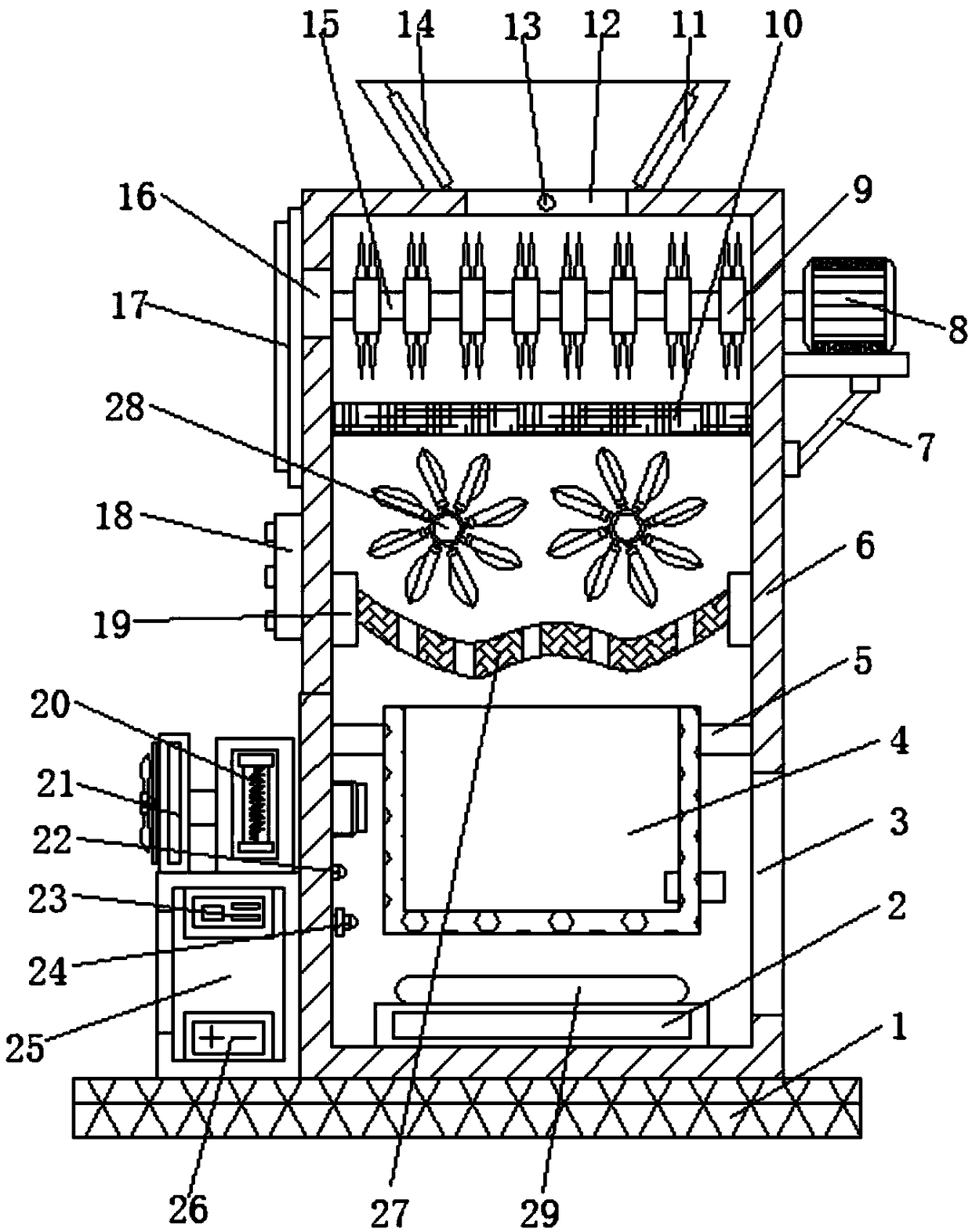

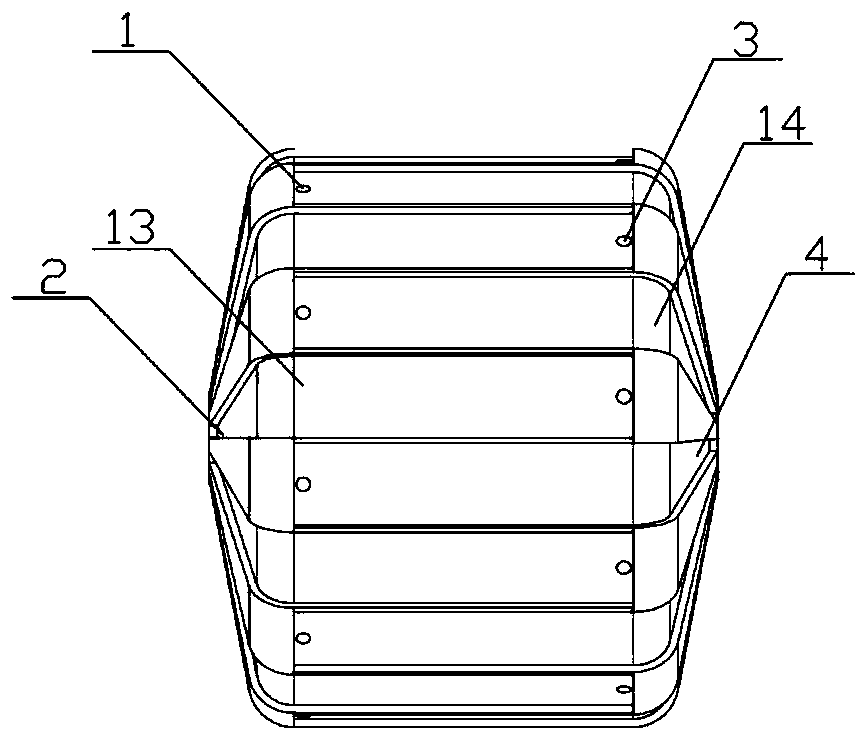

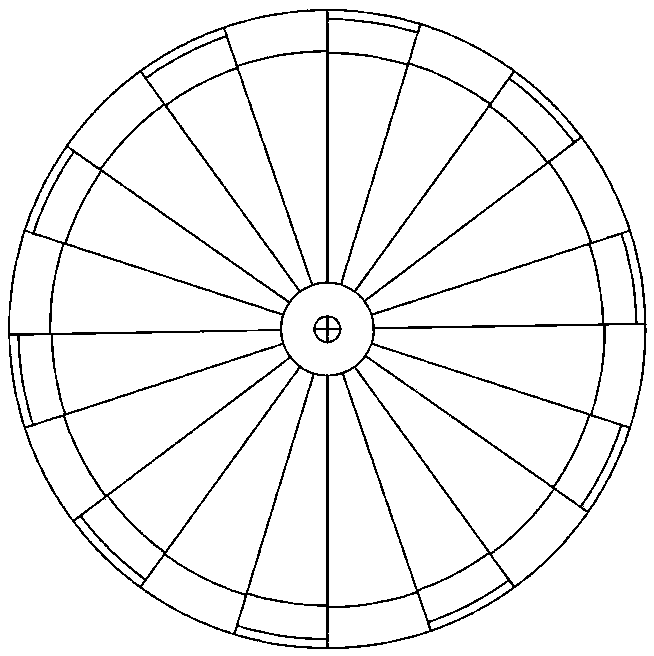

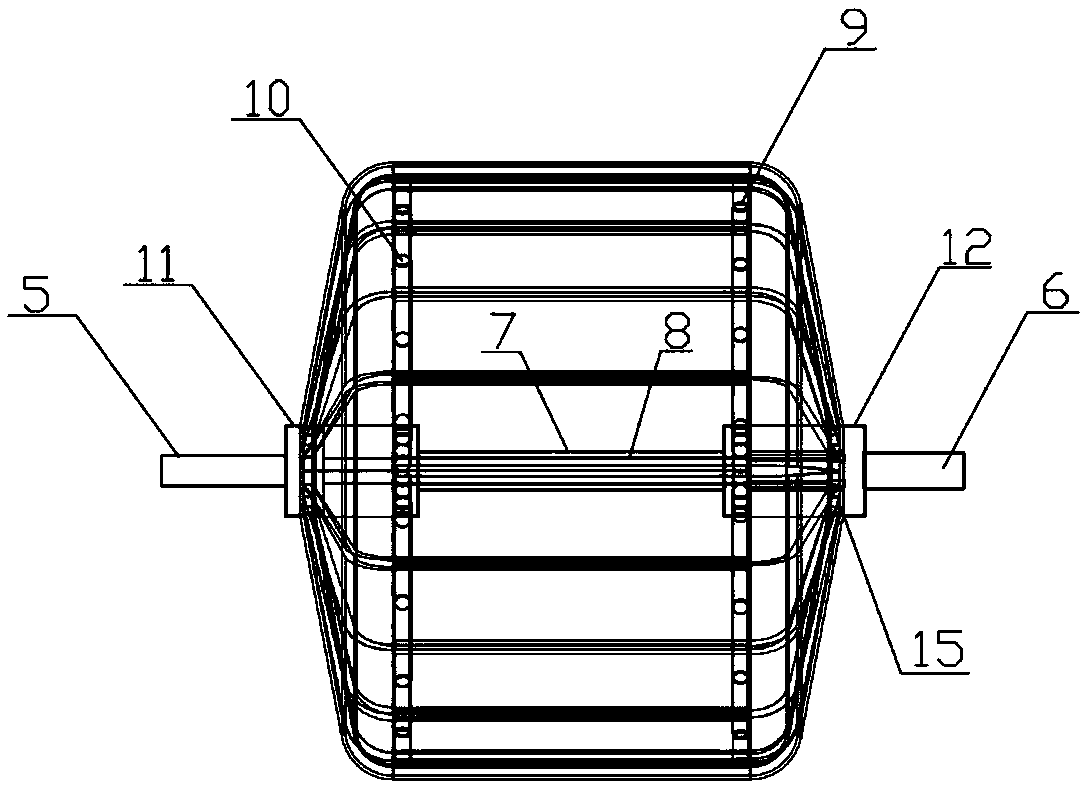

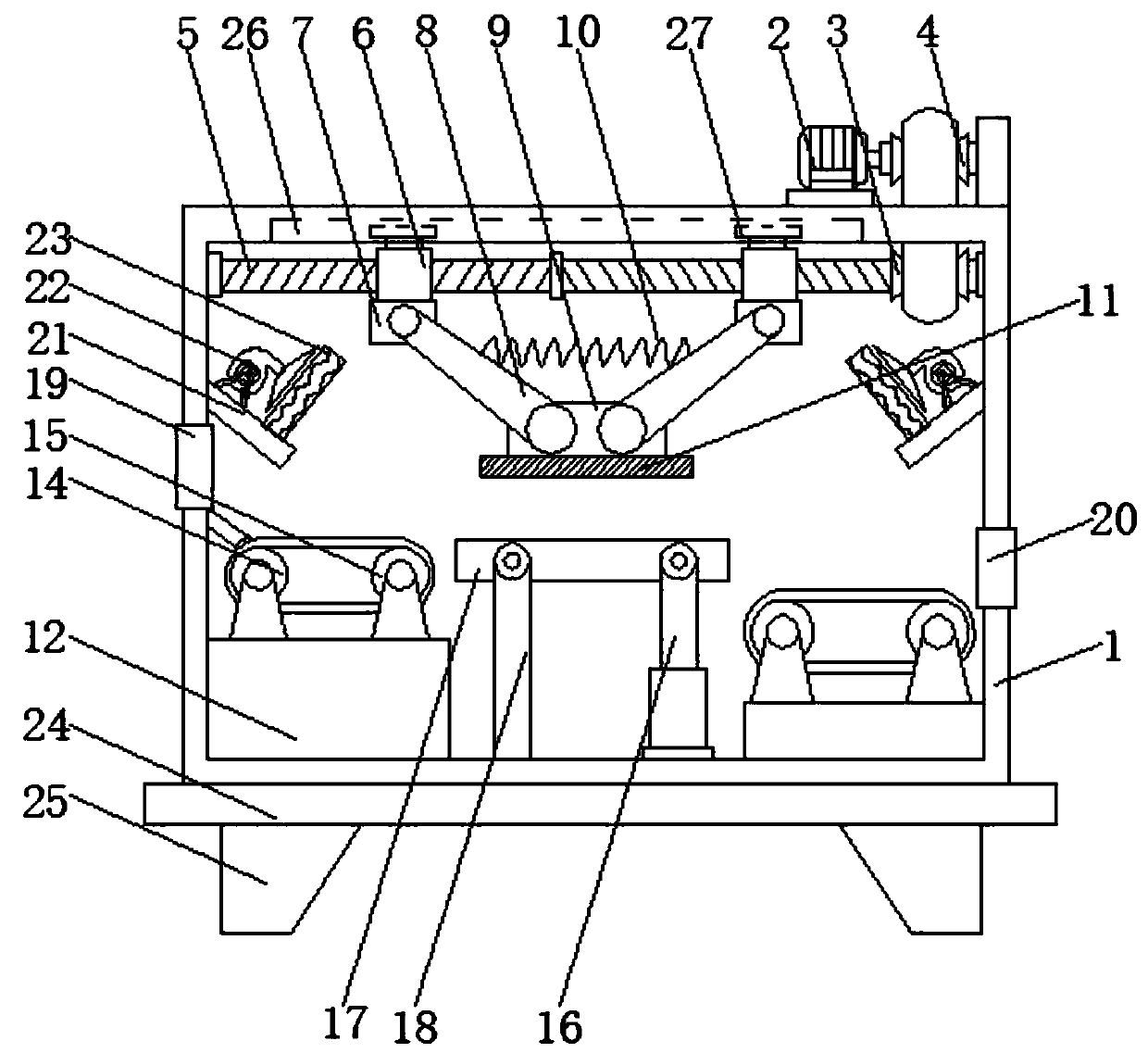

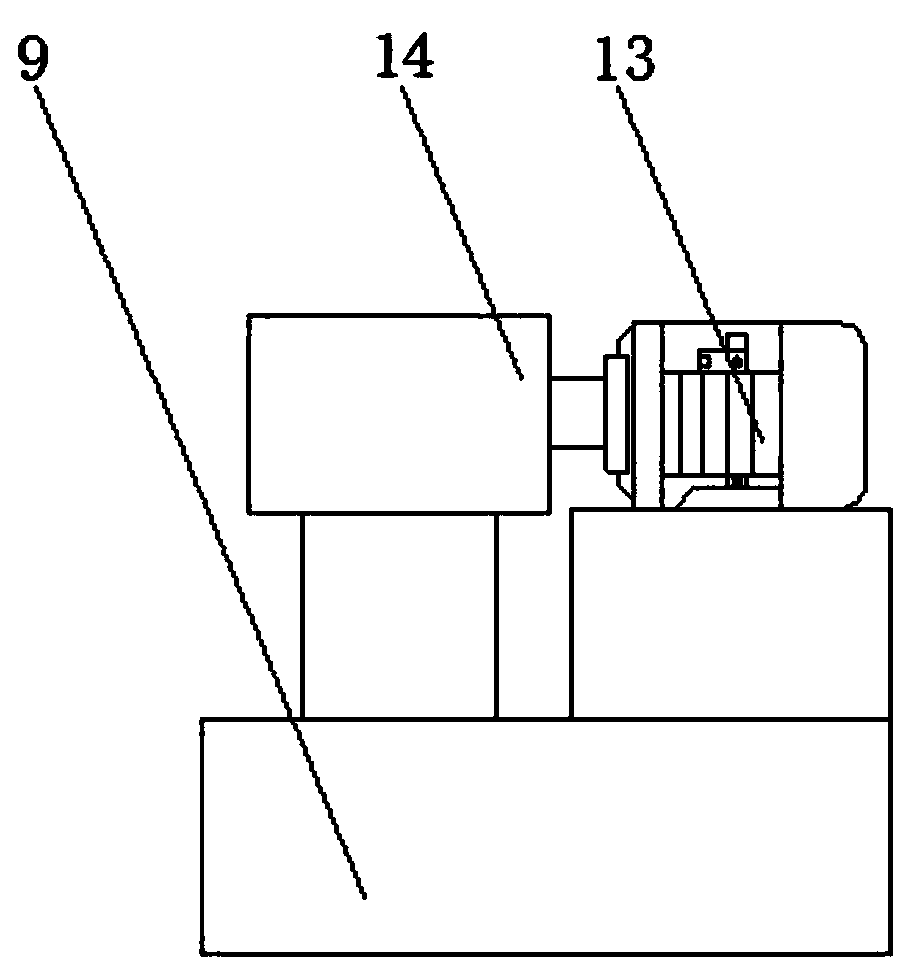

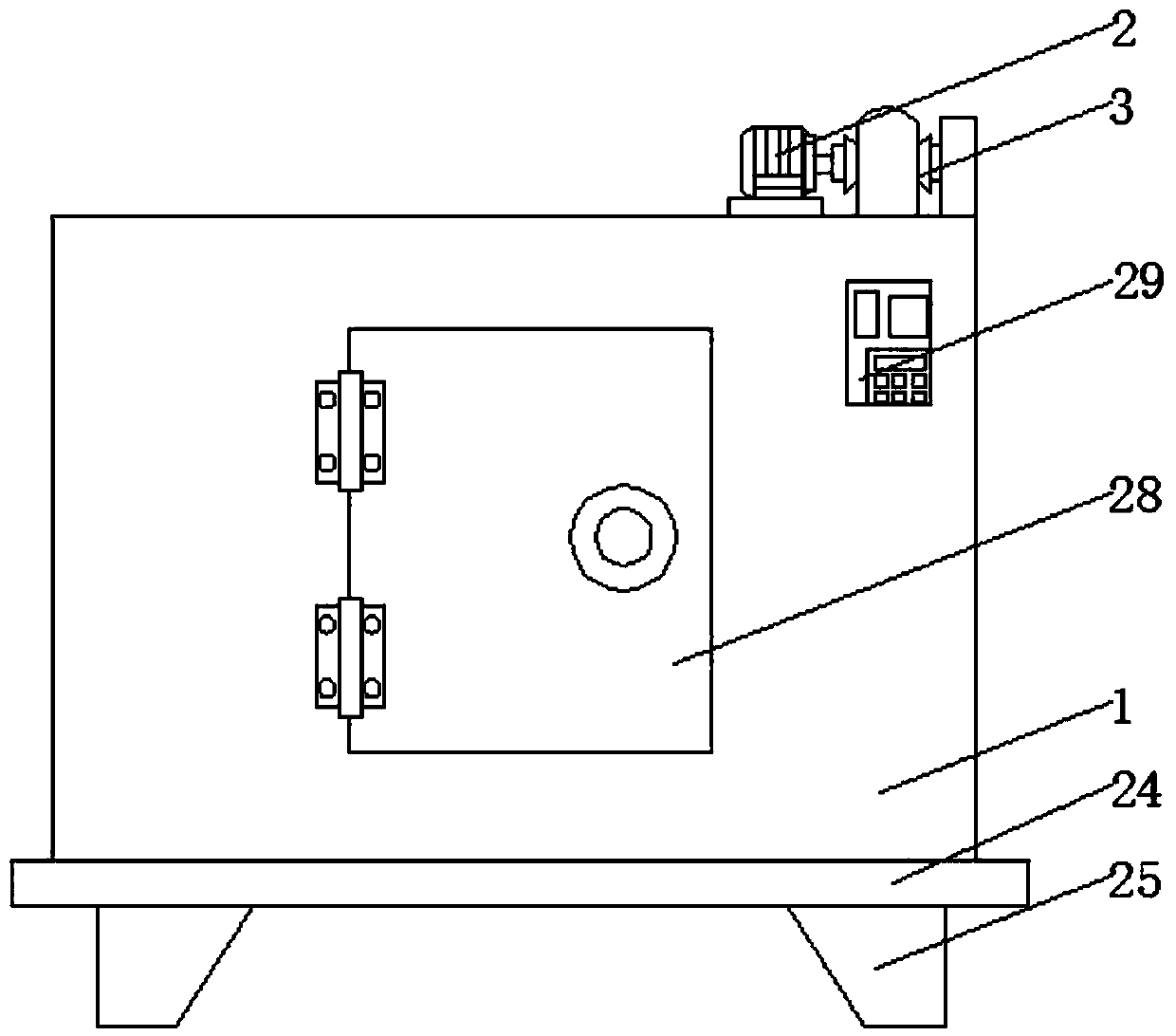

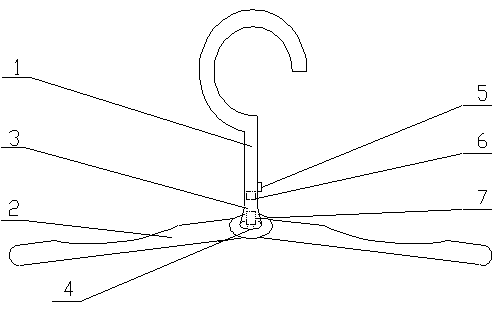

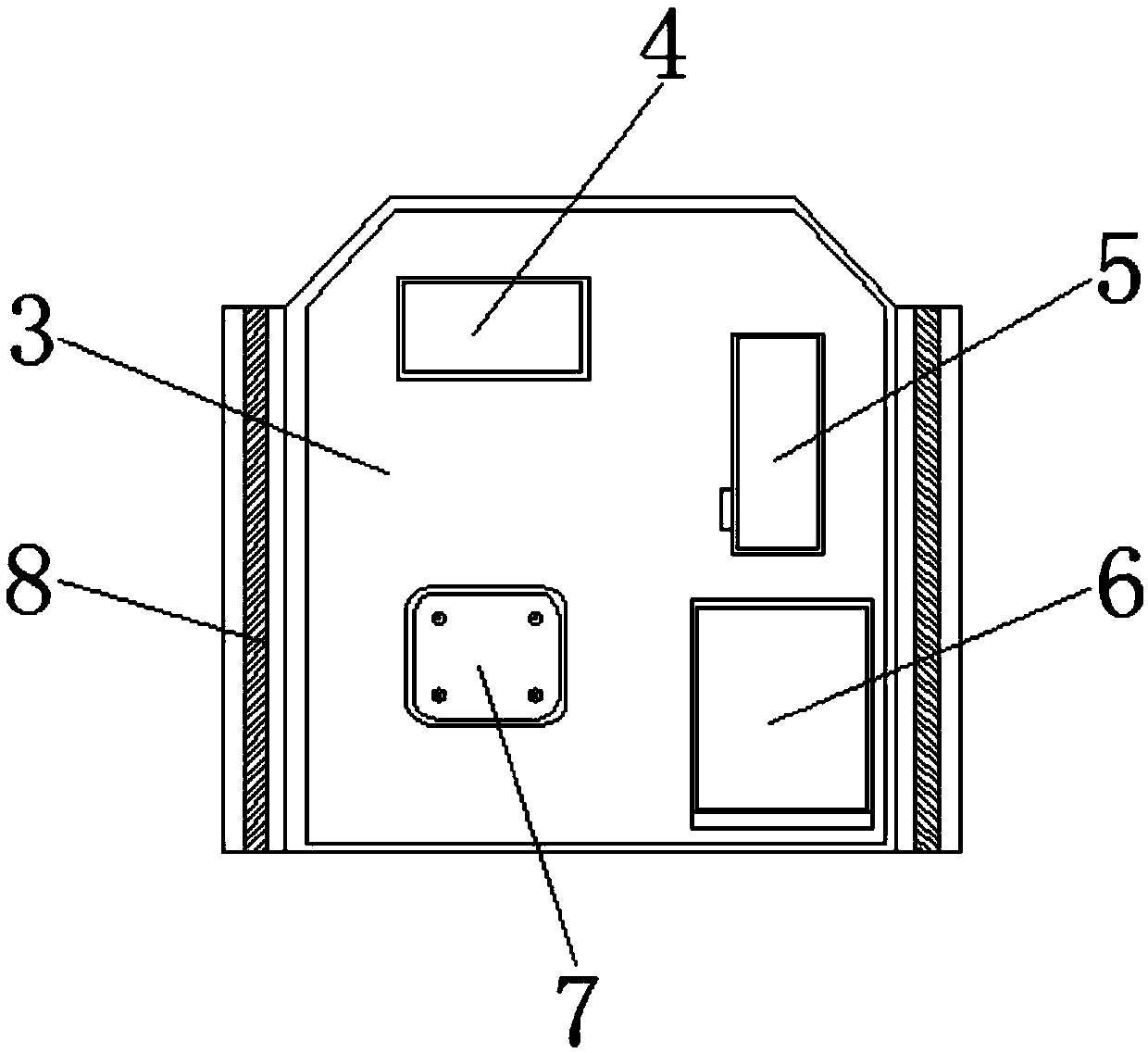

Machining device for thermal insulation plate

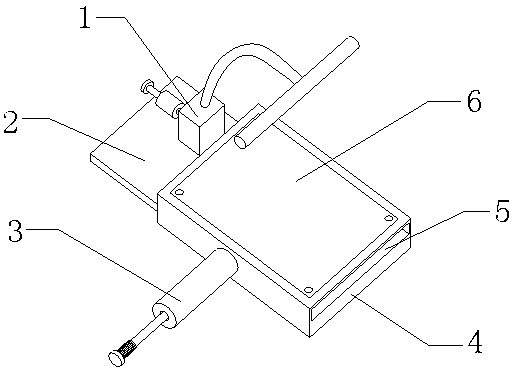

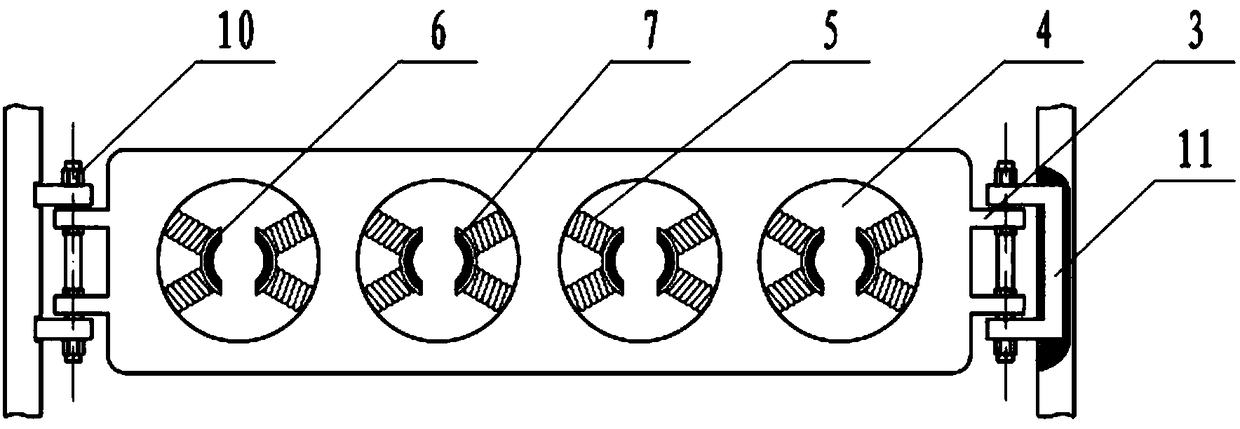

ActiveCN106271922AAdd cleaning functionAdd drying functionGrinding machine componentsCleaning using toolsThermal insulationElectric machinery

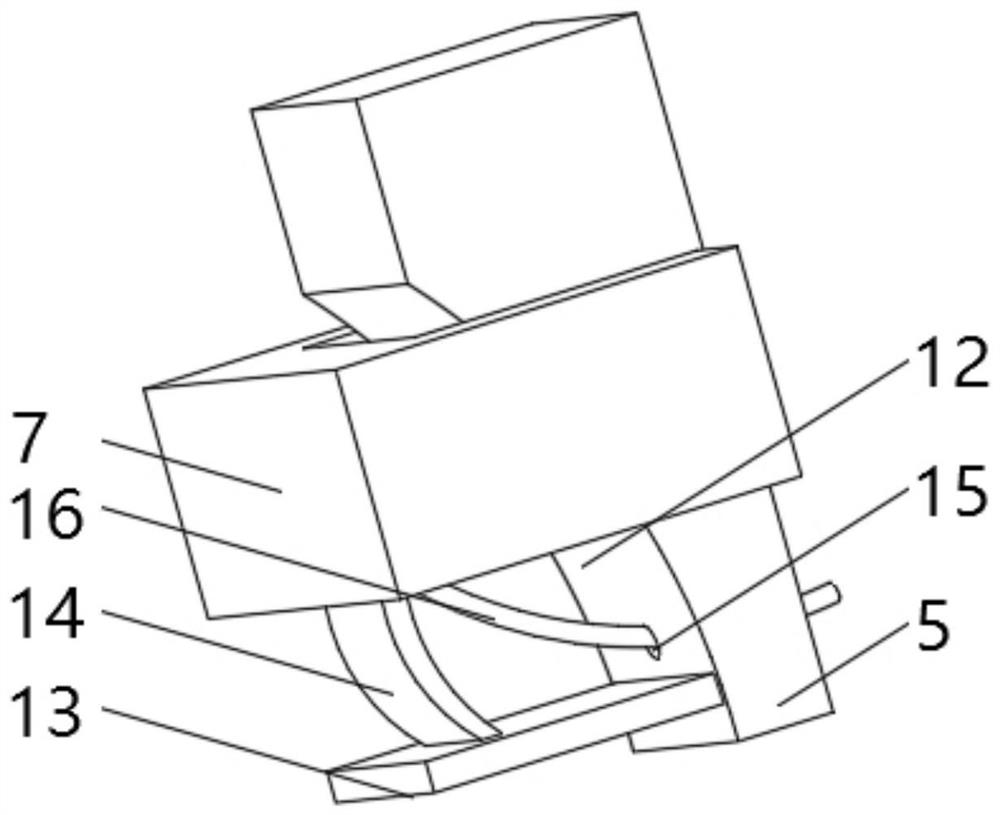

The invention discloses a machining device for a thermal insulation plate. The machining device comprises a machine base and a machining mechanism; the machining mechanism is arranged in the middle of the machine base and comprises a bracket and two grinding mechanisms oppositely arranged in the vertical direction; an air cylinder is arranged on the bracket and fixedly connected with the upper grinding mechanism; the lower grinding mechanism is provided with a rotating mechanism and a limiting mechanism; the rotating mechanism comprises a rotating disc and a plurality of gears; a plurality of limiting rollers are arranged on the rotating disc in the circumferential direction at equal intervals; a rotating shaft is fixedly connected to the bottom of the rotating disc and penetrates through the lower grinding mechanism; a motor is arranged at the end, away from the rotating disc, of the rotating shaft; each gear is provided with a plurality of limiting holes for placing the thermal insulation plate; each grinding mechanism comprises a round filtering screen, a first switch, a second switch and a third switch; a grinding block is arranged on each crossing joint of the filtering screens; and fan blades and water guns are arranged in the grinding blocks. According to the scheme, the problems that traditional machining devices for thermal insulation plates cannot be cleaned and dried are solved.

Owner:徐州宏巨机械制造有限公司

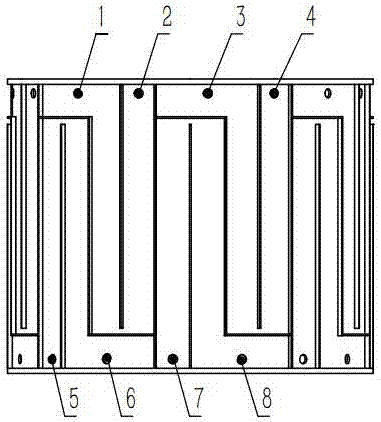

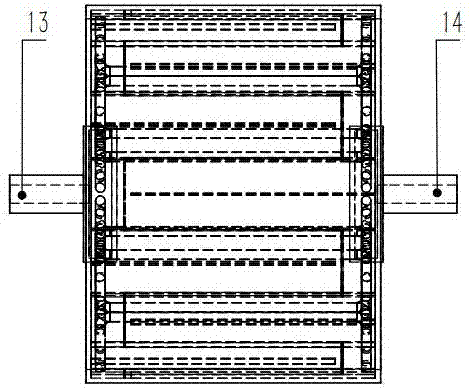

Maze crossed type conduction oil drying cylinder with two-side oil supply

Provided is a conduction oil drying cylinder for drying paper pulp. The whole cylinder adopts welded steel, wherein maze type conduction oil cavities are distributed on the cylindrical surface of the conduction oil drying cylinder in a crossed mode, and an oil inlet and an oil outlet connected with the conduction oil cavities are connected with the left side and the right side of each conduction oil cavity; the inner structure of each conduction oil cavity comprises 32 conduction oil cavity channels and 32 metal hoses, and each two channels are communicated through a welded baffle; a baffle is welded at the tail ends of the first conduction oil cavity and the second conduction oil cavity, a baffle is welded at the beginning ends of the third conduction oil cavity and the fourth conduction oil cavity, the rule of the baffles is executed after the 32nd conduction oil cavity is executed; conduction oil flows in from the right end of the conduction oil cavities, turns, and enters the second channel to flow reversely when about to reach the bottom of the cylinder; when flowing to the end of the second conduction oil cavity, the conduction oil turns again by 90 degrees to flow out from the end of the third conduction oil cavity, and part of the conduction oil flows to the beginning end of the fourth conduction oil cavity. Through the above structure, hot oil passes through two adjacent conduction oil cavities so as to complete heat exchange fully and transfer more energy, and the temperature difference of the surfaces of the cylinder filled with the hot oil is smaller, and can be reduced to within 0.5 DEG C.

Owner:QILU UNIV OF TECH +1

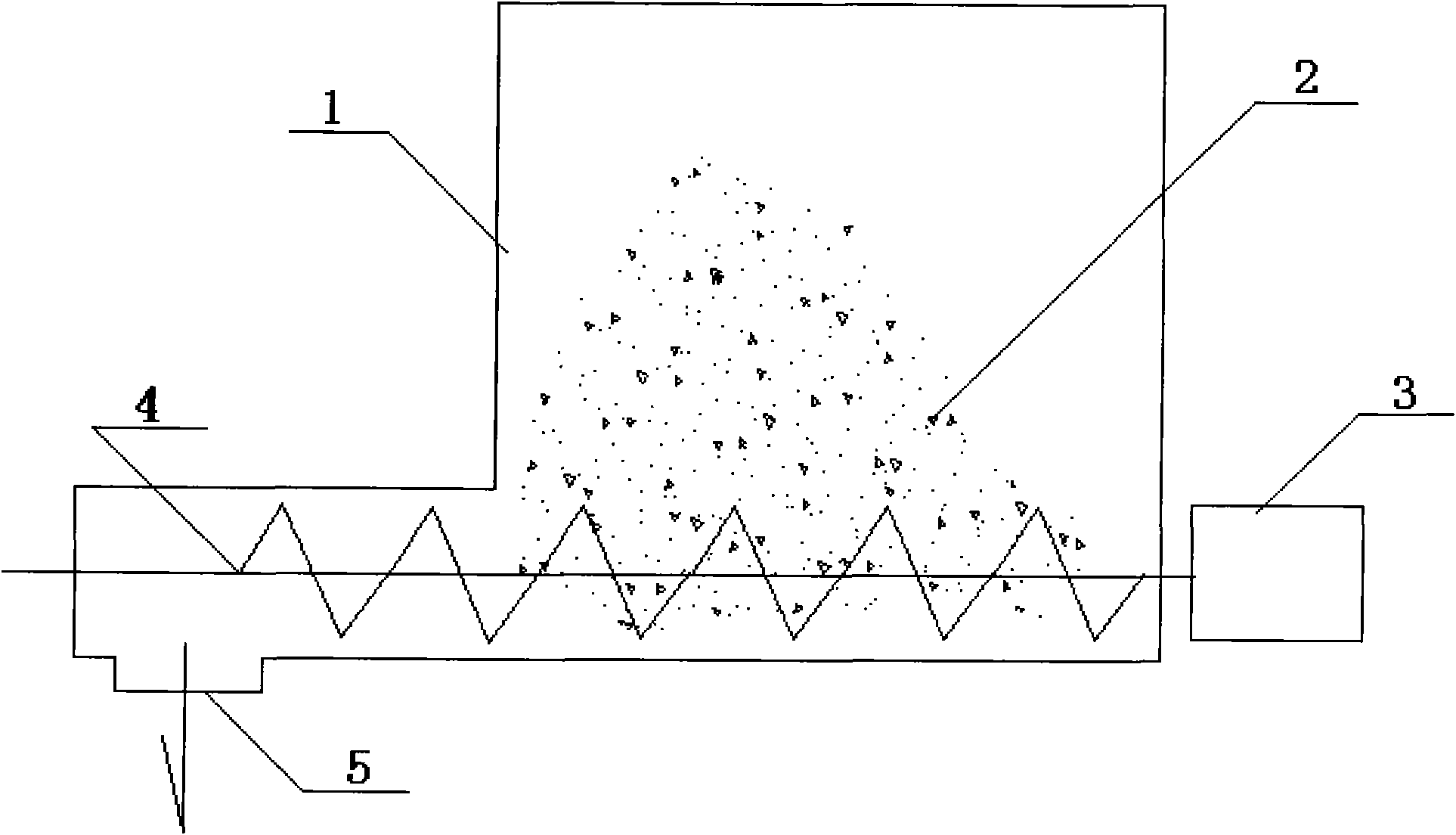

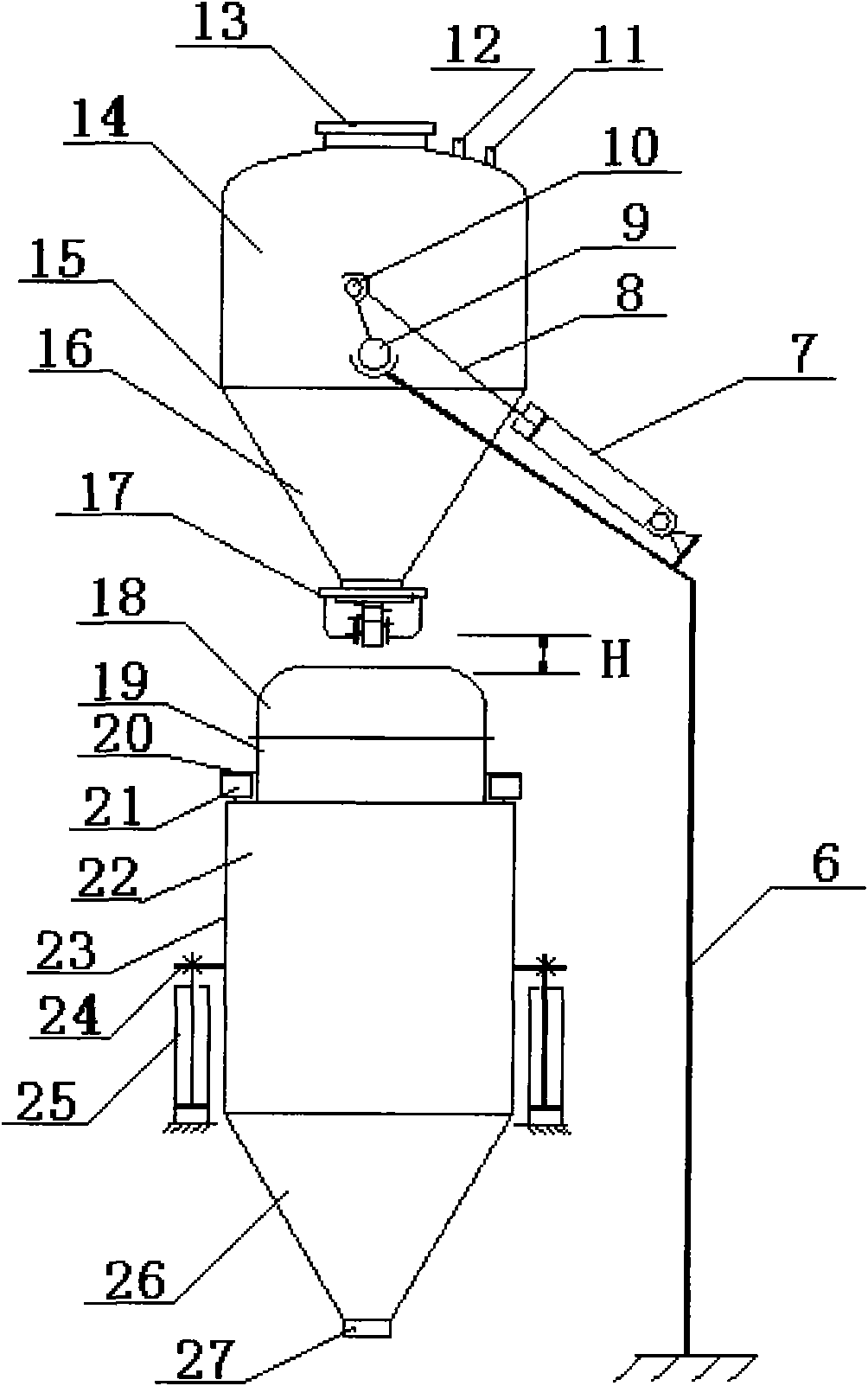

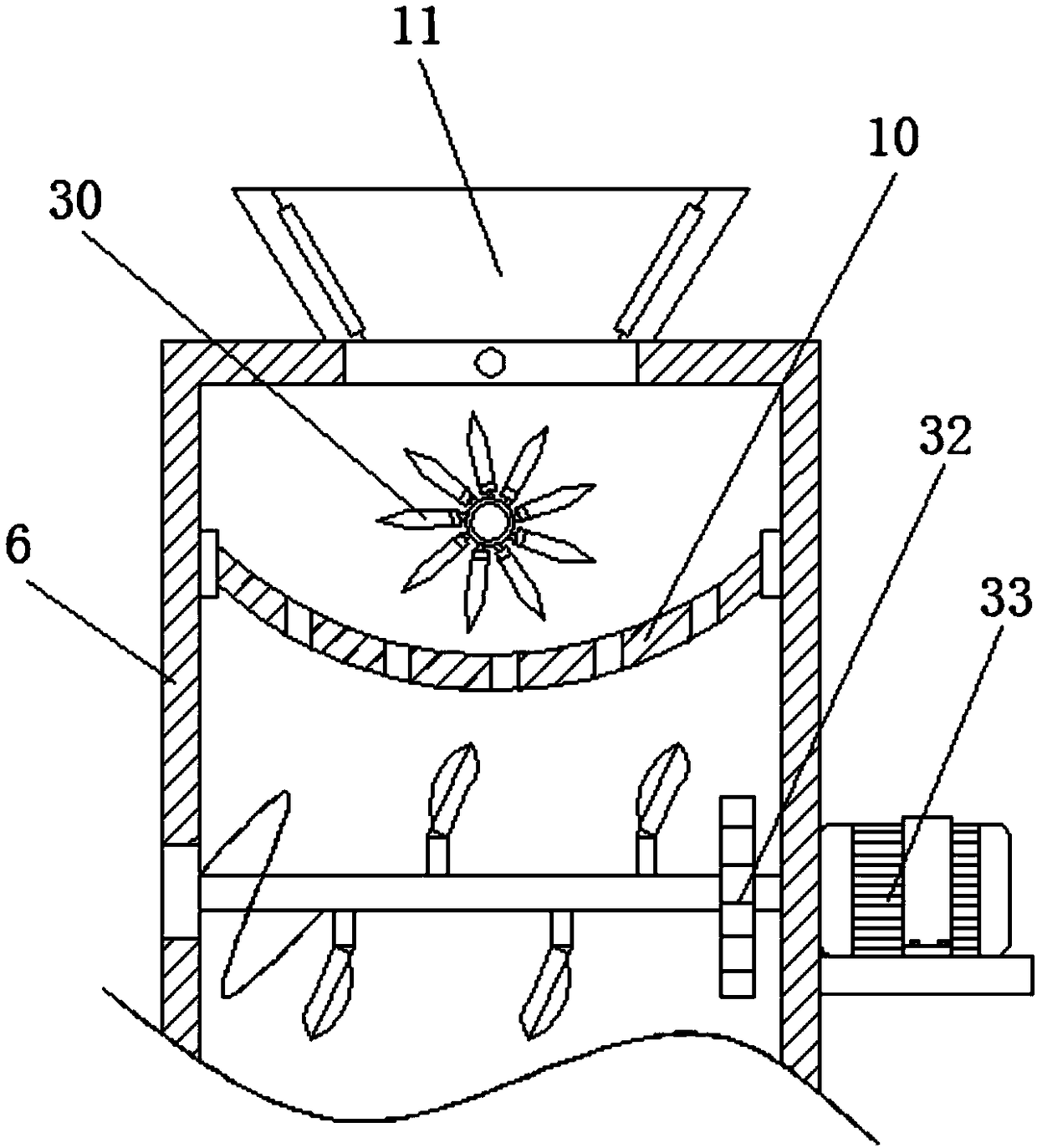

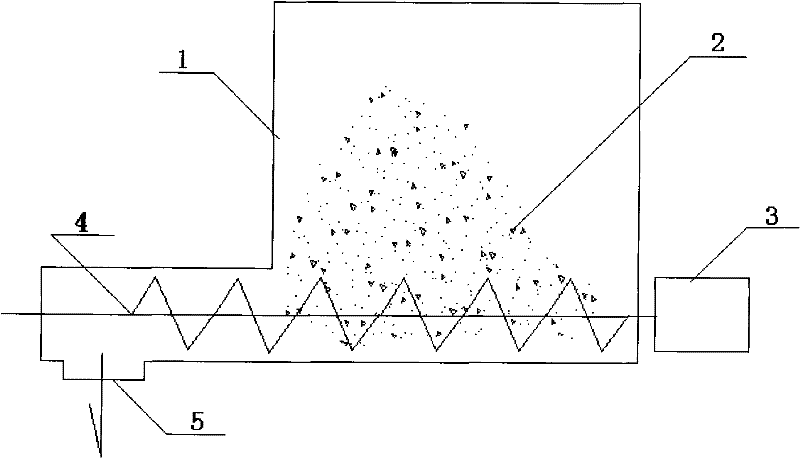

Agricultural and sideline product processing pulverizing device with drying function

The invention belongs to the technical field of agricultural and sideline product processing equipment, and particularly relates to an agricultural and sideline product processing pulverizing device with a drying function. To solve the problems that the design structure is simple, functions are single, no drying device is arranged, and the pulverizing efficiency is low, the following scheme is provided at present, a bottom plate is included, a pulverizing box is fixed to the outer wall of the top of the bottom plate through bolts, a drying machine is fixed to the inner wall of the bottom of the pulverizing box through bolts, and a heating pipe distributed in a concentric-square-shaped manner is fixed to the outer wall of the top of the drying machine through bolts, first connecting blocksare fixed to the inner wall of one side of the pulverizing box through bolts, and an uncovered drying net box is fixed to the outer walls of one sides of the first connecting blocks through bolts. Theagricultural and sideline product processing pulverizing device is abundant in structure, diverse in function and capable of detecting the temperature and humidity; the drying functions are increased, diversity of the device functions is improved, heating drying and hot air drying can be conducted, and the device drying manners are increased; and the device is heated evenly, and the drying effectis improved.

Owner:ANHUI YONSENT PHARMA

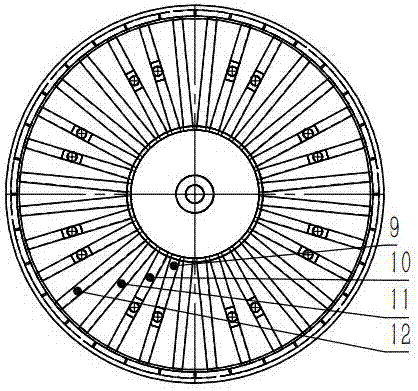

Double-inlet and double-outlet conduction oil drying cylinder

PendingCN109056404AAdd drying functionDryer sectionHeating arrangementPapermakingTemperature difference

The invention relates to the field of papermaking, and belongs to drying equipment. A double-inlet and double-outlet conduction oil drying cylinder comprises an inner cylinder of a cylinder body, an outer cylinder of the cylinder body, oil guiding cavities, an oil inlet main shaft, an oil outlet main shaft, outlet metal pipes, a transmission side shaft head and an operation side shaft head. The entire drying cylinder is made from a steel material, provided with 20 oil guiding cavity passages and 20 metal pipes, every two adjacent passages are partitioned through a welding partition plate, andthe tail ends of a first axial oil guiding cavity and second axial oil guiding cavity are closed; conduction oil flows into the right end of the first axial oil guiding cavity and flows out from the left end of the first axial oil guiding cavity and flows into the left end of the second axial oil guiding cavity and flows out from the right end of the second axial oil guiding cavity respectively, and the first axial oil guiding cavity and the second axial oil guiding cavity are provided with 10 inlets and 10 outlets respectively. The 20 inlets of the oil guiding cavities are directly connectedwith the passages, and the 20 outlets are communicated with the inner cylinder of the cylinder body and the oil outlet main shaft through the metal pipes. The double-inlet and double-outlet conductionoil drying cylinder has the advantages that the conduction oil convectively flows in the dying cylinder, so that the surface temperature of the drying cylinder is distributed more evenly, the temperature difference is reduced, and the quality of paper is improved.

Owner:QILU UNIV OF TECH +1

Hat and coat stand with drying and dust removing functions

InactiveCN106037412AOmni-directional dryingAll-round dust removalApparel holdersEngineeringBase function

The invention discloses a coat rack with the function of drying and dust removal, which comprises a cylinder, a top column is placed on the upper end of the column, and at least two support frames are arranged on the side wall of the top column. A rotating motor is arranged in the column, and a longitudinal rotating shaft is connected to the rotating motor, and the upper end of the rotating shaft extends into the top column, and the rotating shaft can drive the top column to rotate, and the column is also provided with As for the heater, at least three fans arranged vertically and uniformly are arranged on the side wall of the cylinder. On the basis of retaining the basic function of hanging clothes, the present invention adds the functions of drying and dust removal, so that the functionality of the coat rack is greatly enriched, and it also brings great convenience to people.

Owner:NANJING QUNYE HARDWARE PROD

A flat pressing device for lithium battery

ActiveCN107293762BIncrease productivityQuality improvementPrimary cell manufactureNon-aqueous electrolyte cellsCouplingElectric machine

The invention discloses a flat pressing apparatus used for a lithium battery. The flat pressing apparatus comprises a fixed box; the top of the inner wall of the fixed box is fixedly connected with a first motor through a supporting plate; the output shaft of the first motor is fixedly connected with a first belt wheel through a coupling; the surface of the first belt wheel is in transmission connection with a second belt wheel through a belt; a threaded rod runs through the middle part of the second belt wheel; movable blocks are in threaded connection with the two ends of the surface of the threaded rod respectively; fixed blocks are fixedly connected with the bottoms of the movable blocks; the surfaces of the fixed blocks are rotationally connected with rotary rods through movable parts; and one ends, far from the fixed blocks, of the rotary rods are rotationally connected with a fixed base through the movable parts. The flat pressing apparatus used for the lithium battery relates to the technical field of the lithium battery, and solves the problem that the existing flat pressing apparatus used for the lithium battery cannot perform good extrusion and forming and the problem of low flat pressing speed of the lithium battery; and by adoption of the flat pressing apparatus, the production efficiency of the lithium battery is improved, the flat pressing quality of the lithium battery is improved, and rapid and effective production of the lithium battery is ensured.

Owner:江苏芯界新能源科技有限公司

Metal material laser cutting device

PendingCN112809201AWith ambient temperature detection functionTimely reminder warningLaser beam welding apparatusMetallic materialsWorking environment

The invention discloses a metal material laser cutting device which comprises a cutting table. A rail groove is formed in the top of the cutting table; a supporting plate is slidably connected to the bottom of the inner side of the rail groove; a deformation device is installed at the top of the supporting plate; a supporting frame is installed at the position, above the rail groove, of the top of the cutting table; a laser device is installed at the top of the supporting frame, penetrates through the supporting frame and extends to the position below the supporting frame; and the supporting frame is sleeved with a detection frame. The metal material laser cutting device provided by the invention relates to the technical field of laser cutting equipment. According to the metal material laser cutting device, the purpose of increasing the environment temperature detection function is achieved, reminding and warning can be conducted in time when the environment temperature is excessively influenced by work of laser cutting equipment, the drying function is increased, the influence of air humidity in the work environment on the cutting effect can be relieved, the energy-saving effect is improved, and the use cost of the laser cutting equipment can be reduced.

Owner:王远彬

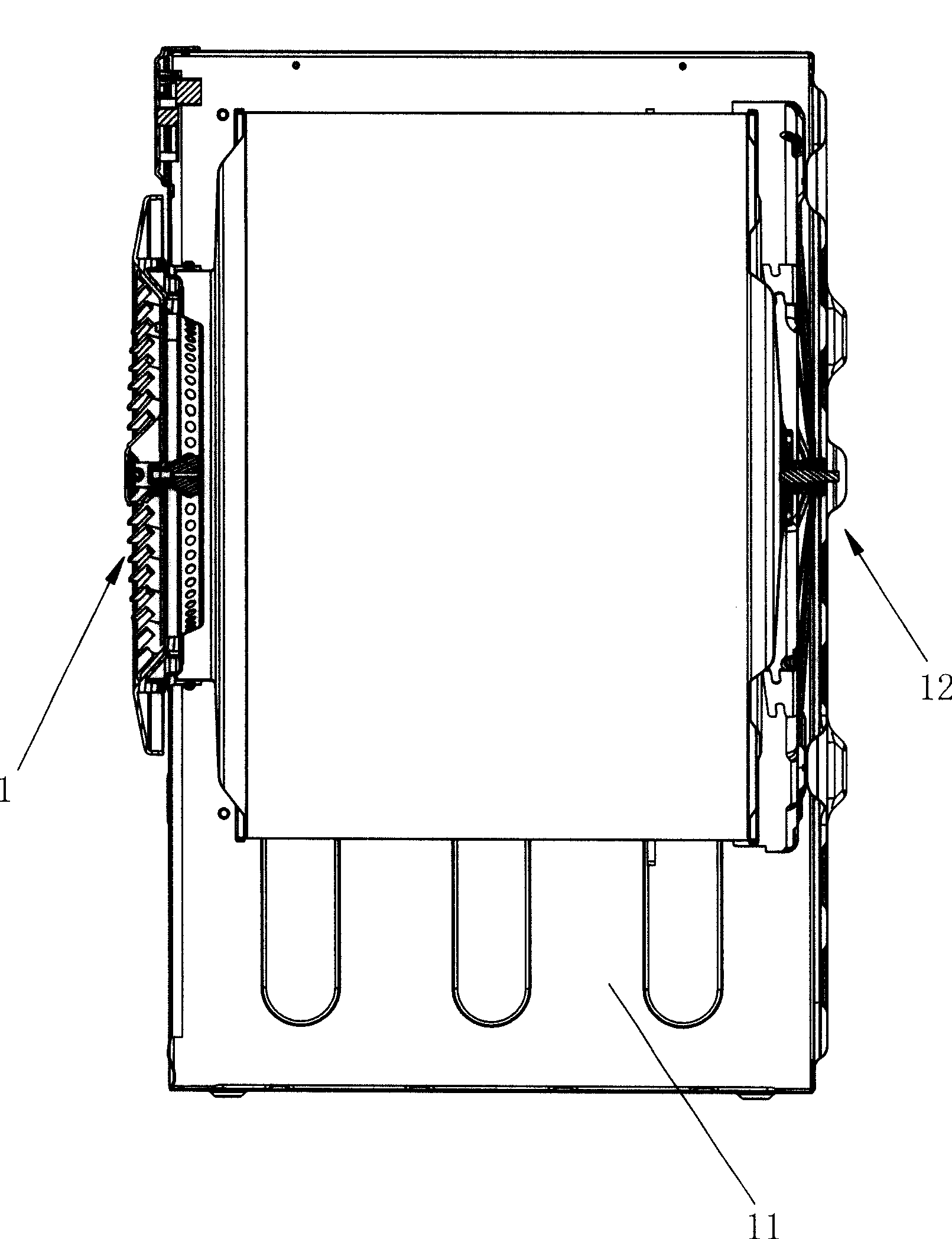

Multiple laundry treating machine

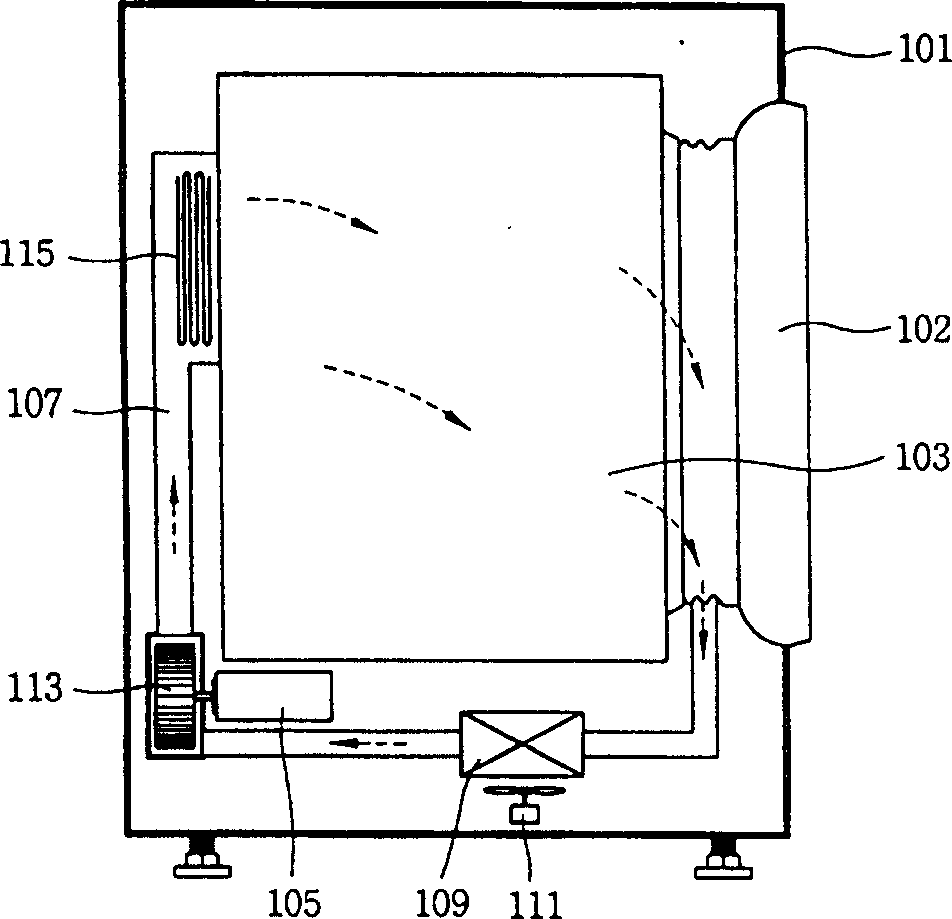

ActiveUS8312638B2Easy to useSave energyOther washing machinesControl devices for washing apparatusLaundryBiomedical engineering

A multiple laundry treating machine, in which an auxiliary laundry treating device (120) is coupled to a general laundry treating device (110), is disclosed. The multiple laundry treating machine includes a main laundry treating device (110) for washing or drying laundry contained in an interior of the main laundry treating device (110), an auxiliary laundry treating device (120) arranged at one side of the main laundry treating device (110), the auxiliary laundry treating device (120) having a volume and a height respectively smaller than a volume and a height of the main laundry treating device (110), and having a laundry container (121) formed in an interior of the auxiliary laundry treating device (120), and a connecting unit (300) for connecting the main and auxiliary laundry treating devices (110, 120), to enable communication or control operations between the main and auxiliary laundry treating devices (110, 120). In accordance with the multiple laundry treating machine, it is possible to achieve a convenience in use and to save energy because a small amount of clothes or shoes can be dried by the auxiliary laundry treating device (120), without driving a laundry treating device (120) having a relatively-large capacity.

Owner:LG ELECTRONICS INC

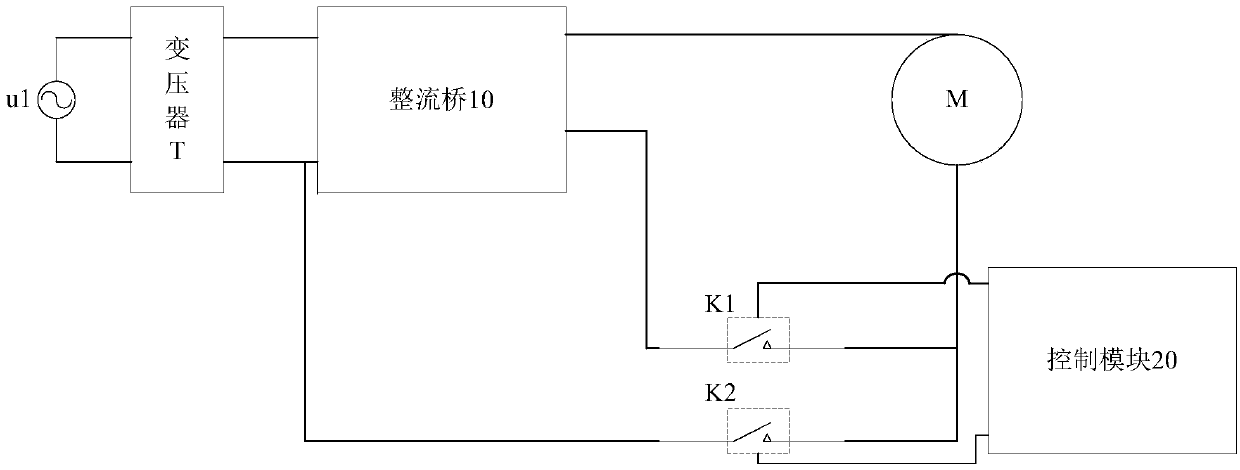

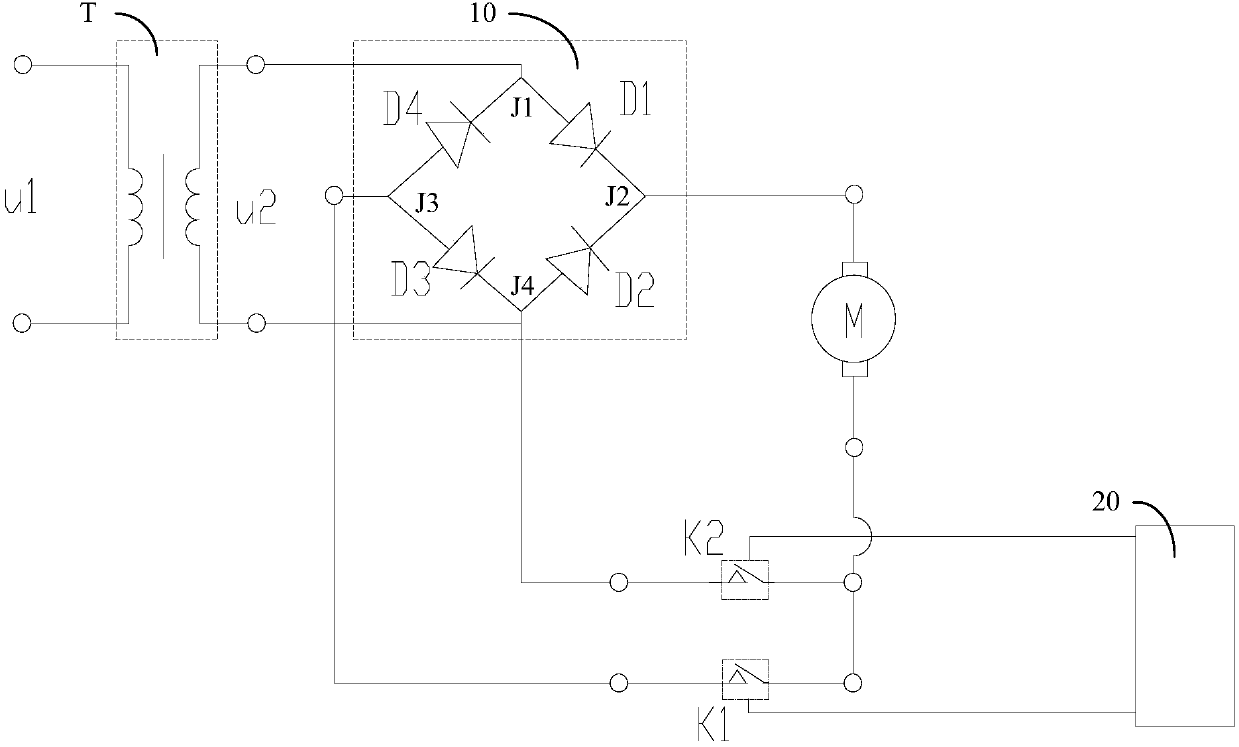

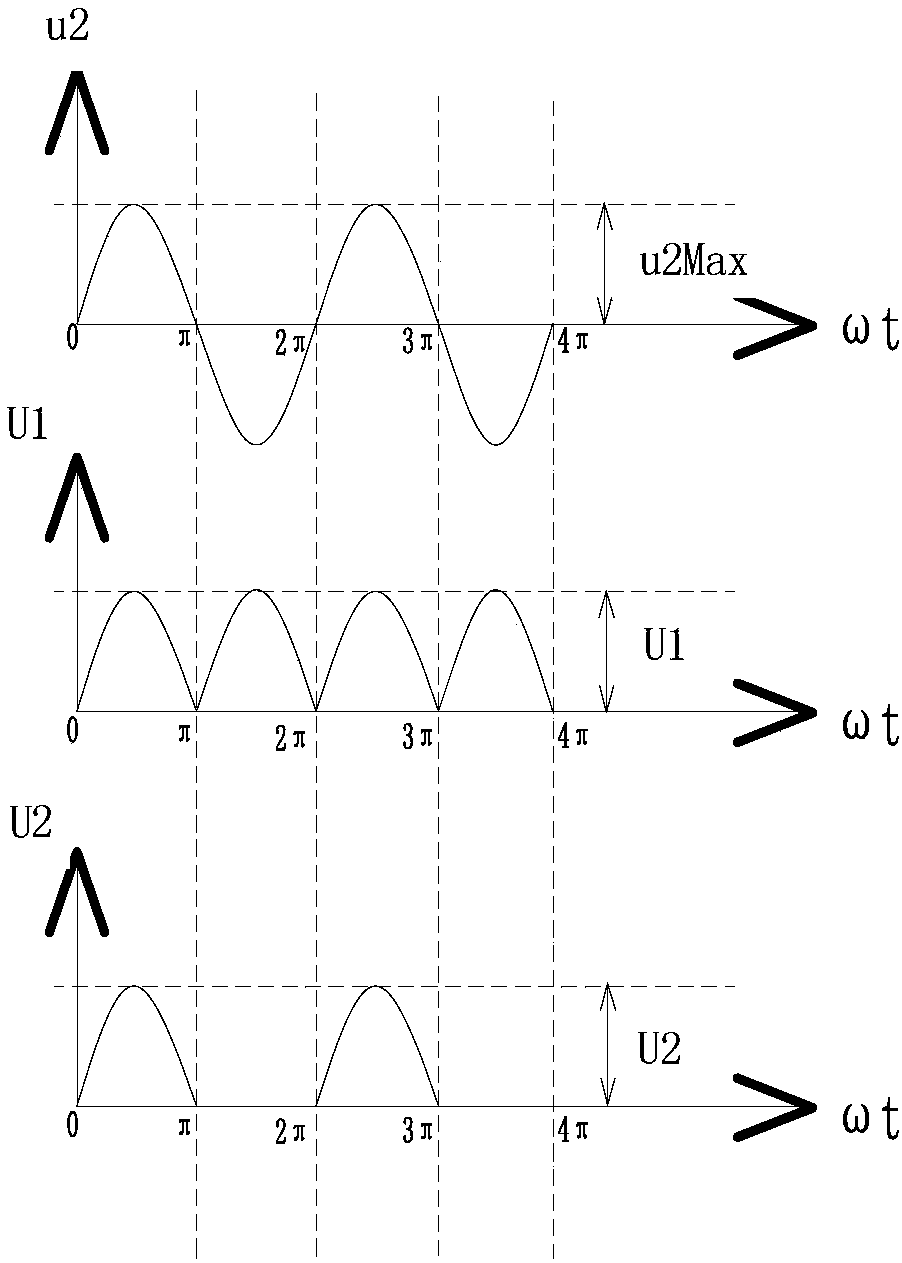

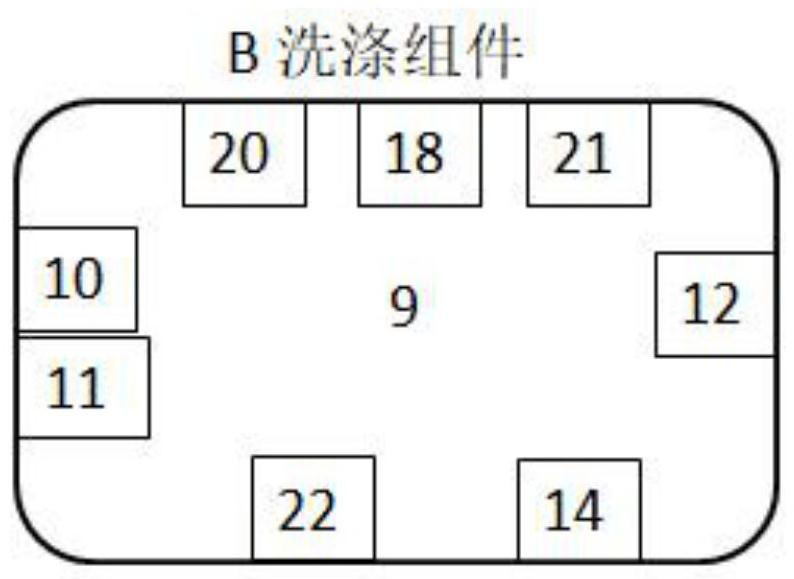

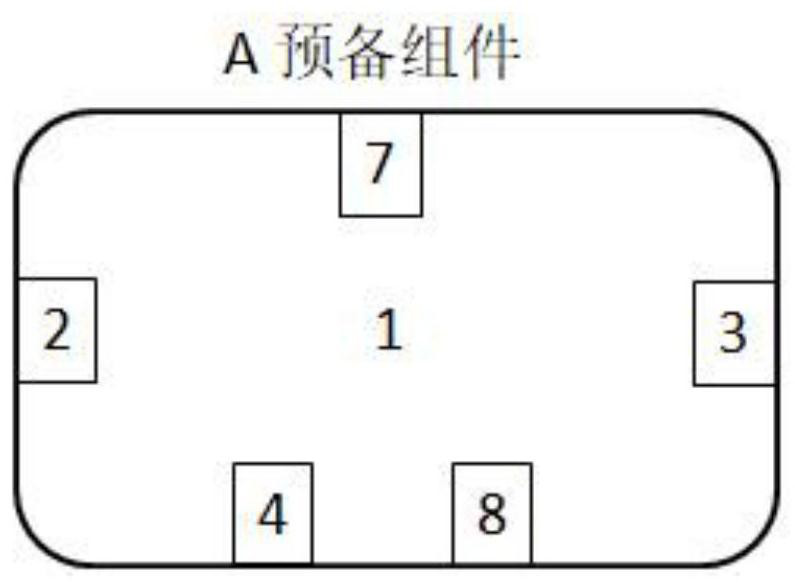

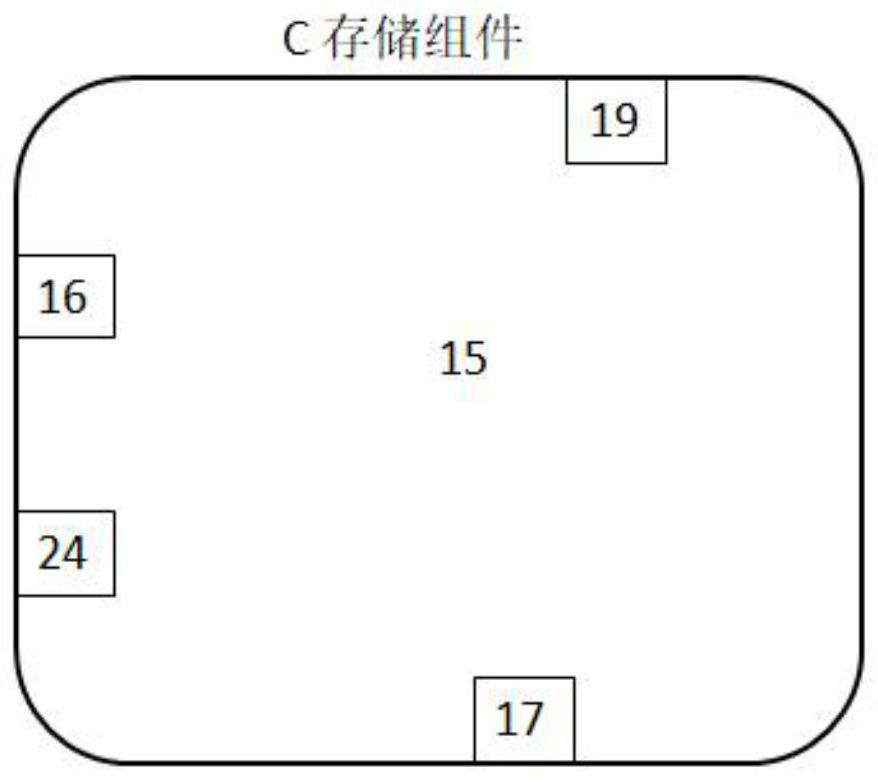

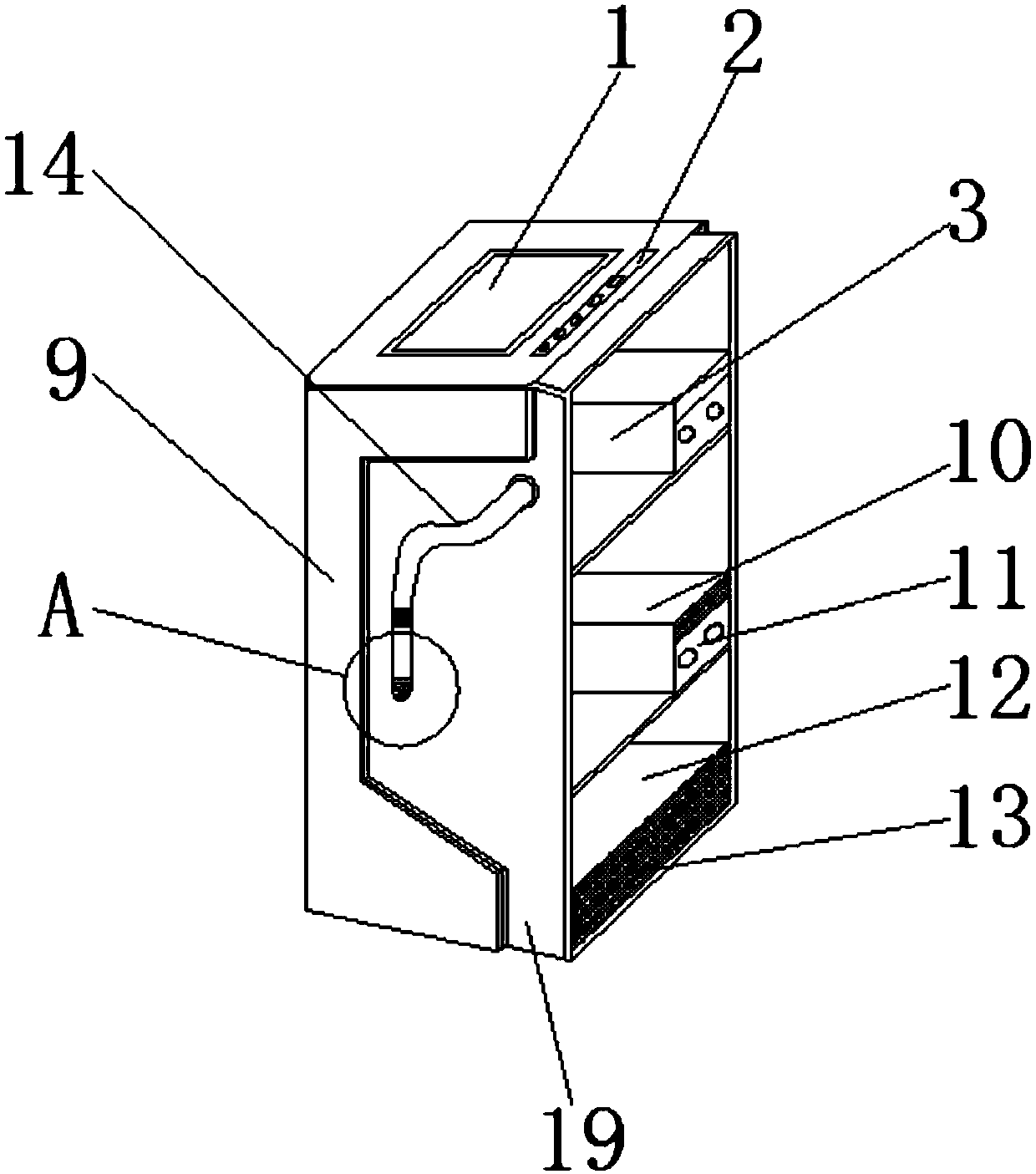

Dish washing machine and control circuit thereof

InactiveCN107911052AReduce noiseControl the amount of washing waterTableware washing/rinsing machine detailsField or armature current controlRectifier diodesEngineering

The invention discloses a dish washing machine and a control circuit thereof. The control circuit comprises a washing pump direct current motor for the dish washing machine; a transformer for performing step-down conversion on inputted first alternating current to output second alternating current; a rectifier bridge, wherein a first input end of the rectifier bridge is connected with one end of asecondary winding of the transformer; a first output end of the rectifier bridge is connected with one end of the direct current motor; a second input end of the rectifier bridge is connected with the other end of the secondary winding of the transformer and is connected to the other end of the direct current motor through a second controllable switch; a second output end of the rectifier bridgeis connected to the other end of the direct current motor through a first controllable switch; and the rectifier bridge is used for performing rectifying conversion on the second alternating current so as to output the direct current and supply the direct current to the direct current motor; and a control module used for controlling the first controllable switch and the second controllable switch,so that the direct current motor can operate at a first rotating speed and a second rotating speed respectively, and the double-speed washing of the dish washing machine is realized, thus the noise of the dish washing machine is reduced, and meanwhile the loading space of the dish washing machine is improved.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD +1

PCB (Printed Circuit Board) printing bearing jig

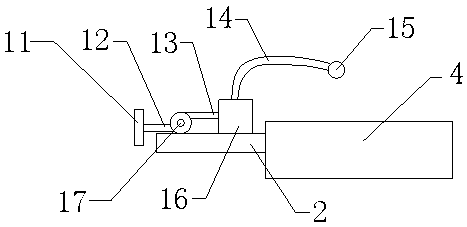

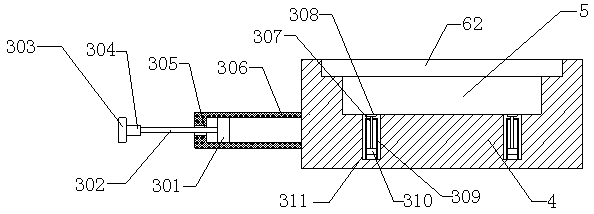

InactiveCN107809851AImprove efficiencyEasy to useConductive pattern formationPistonPrinted circuit board

The invention provides a PCB (Printed Circuit Board) printing bearing jig. The PCB printing bearing jig comprises an air inlet pipe, a gooseneck pipe, an air distribution pipe, a heating tank, a piston one, a threaded rod, a round hole, ejector rods, rubber discs and pistons II, wherein the heating tank is arranged at the right side of the upper end surface of a placement plate, the right end of the air inlet pipe is connected with a draught fan, the air distribution pipe is arranged at the upper side of a box body, and the left end of the gooseneck pipe is connected with the heating tank, sothat through the design, a drying function of the PCB printing bearing jig is added, and the purpose of quickly drying a PCB by the PCB printing bearing jig can be realized; the piston I is arranged in an air cylinder, a push-pull board is arranged on the left end of the threaded rod, the round holes are formed in the left end surface of the air cylinder, the pistons II are arranged in a cylinder,and the upper ends of the ejector rods are fixed to middle positions of the lower end surfaces of the rubber discs, so that through the design, the purpose of fixing the PCB by utilizing air pressureis realized. The PCB printing bearing jig provided by the invention is convenient to use, wide in application range, good in stability and high in reliability.

Owner:中山市标致电子科技有限公司

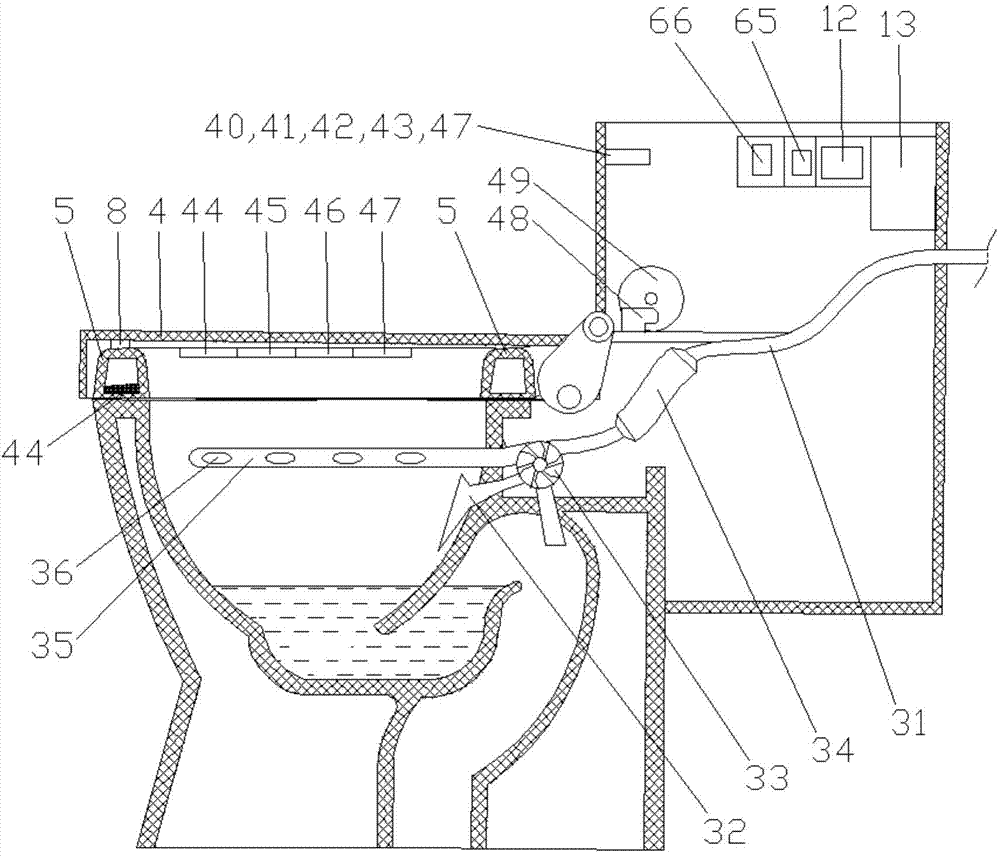

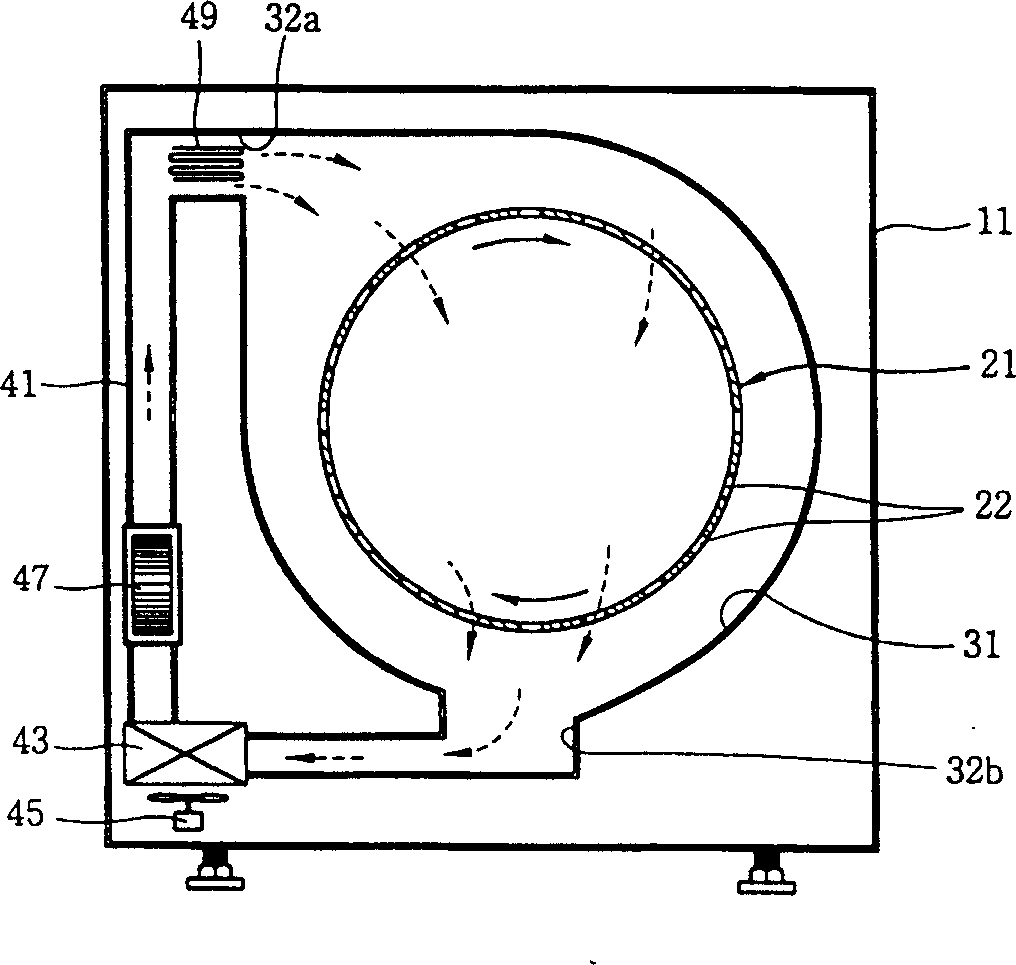

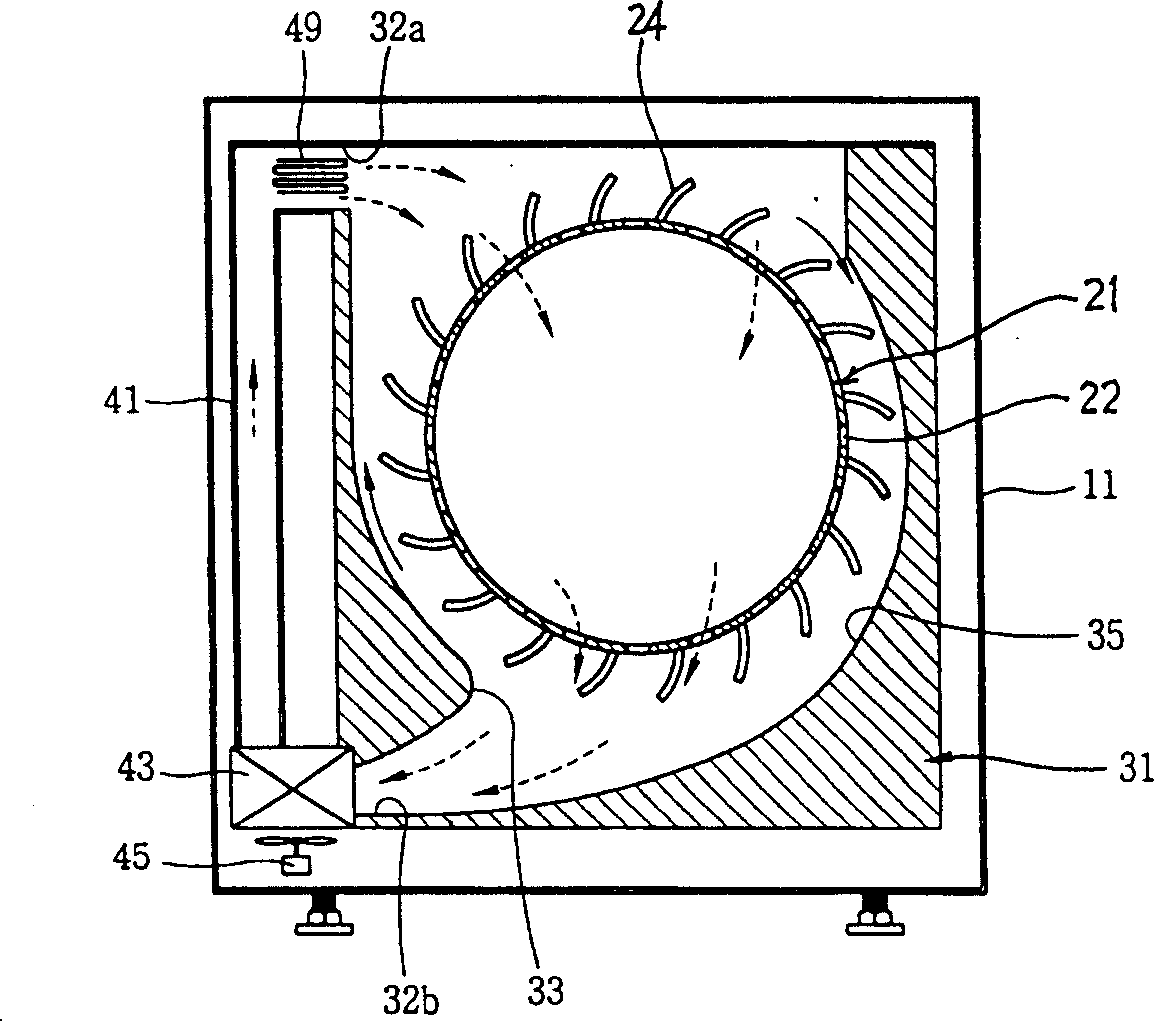

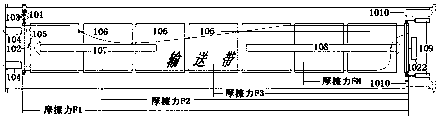

Air flowing transversely type drum dryer

The transversely flowing cylindrical stoving machine has the structure including casing to form inside holding space; rotating cylinder for holding clothing to be dried, capable of rotating horizontally and with ventilating ports set for air to flow transversely; air flow channel set inside the casing for air to flow axially and transversely around the rotating cylinder; and blower to ensure air flow along the air flow channel. By means of the said structure, air can flow transversely in axial direction of the cylinder to raise the stoving effect.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

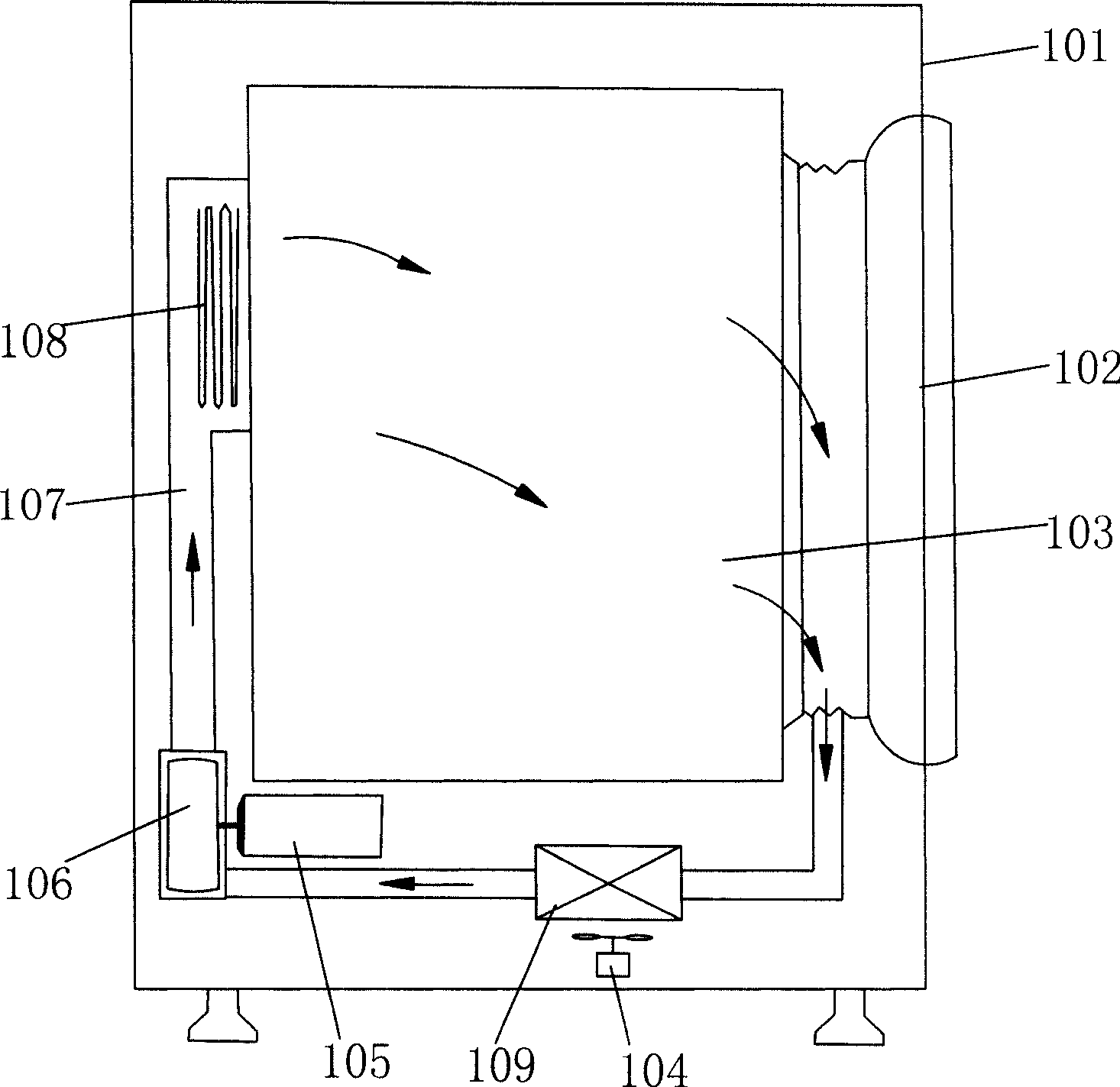

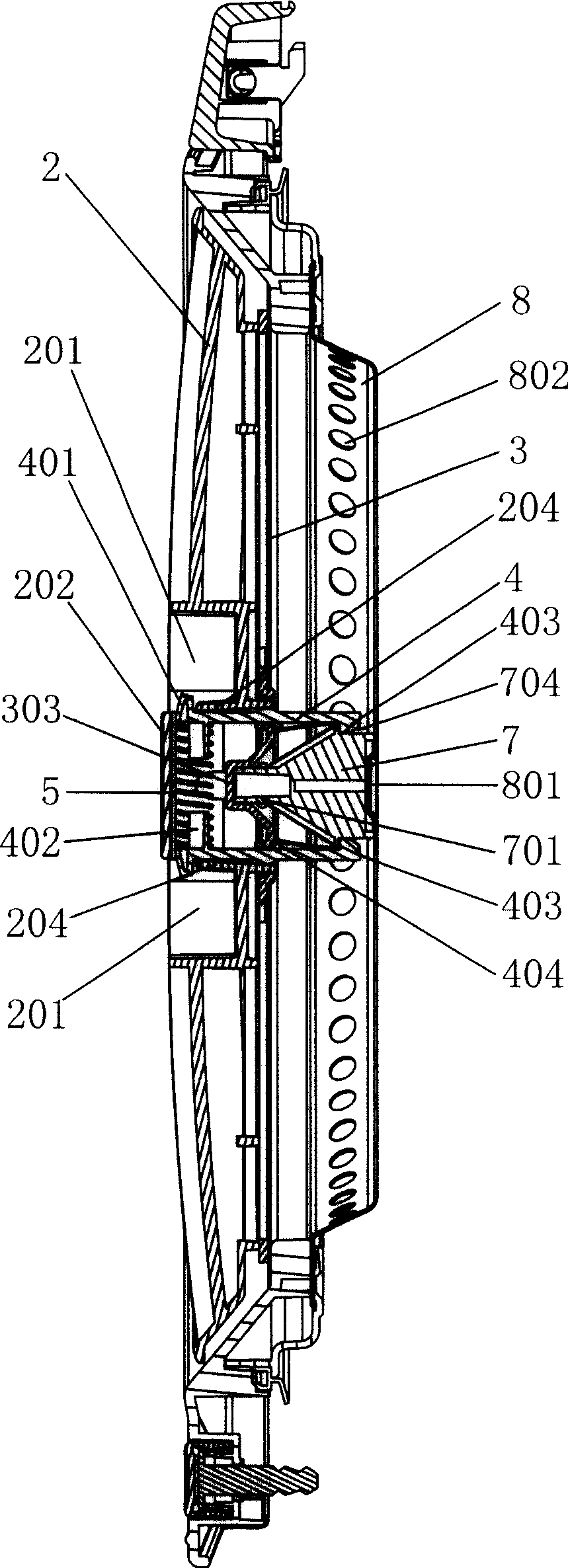

Clothes dryer door structure with air outlet device

ActiveCN101096816BEasy to cleanEasy maintenanceTextiles and paperLaundry driersMechanical engineeringEngineering

The invention discloses a clothes dryer door structure with air outlet device, which is characterized by the following: comprising door body, air outlet device and fastening holder three sections; setting the door body as door out frame, door inner frame and air outlet plate three sections; fixing the air outlet plate between the door out frame and the door inner frame with screw; fixing the fastening holder at the center position of the air outlet plate with screw; setting the air outlet device as air outlet grid, screen, fastening clamp and spring four sections; assembling the fastening clamp, spring and screen in together; mutual-corresponding the screen and the air outlet grid; assembling on the air outlet grid through inserting block on the screw and fastening clamp; fastening the air outlet device on the fastening holder through claw of the fastening clamp; connecting the door body and the air outlet device together; making the air outlet device rotate out the door; changing airoutlet direction from the air outlet grid through rotating air outlet device to twice use hot air. The air outlet device of this invention arranges on the door of the clothes dryer, which possesses good effect to improve drying function.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

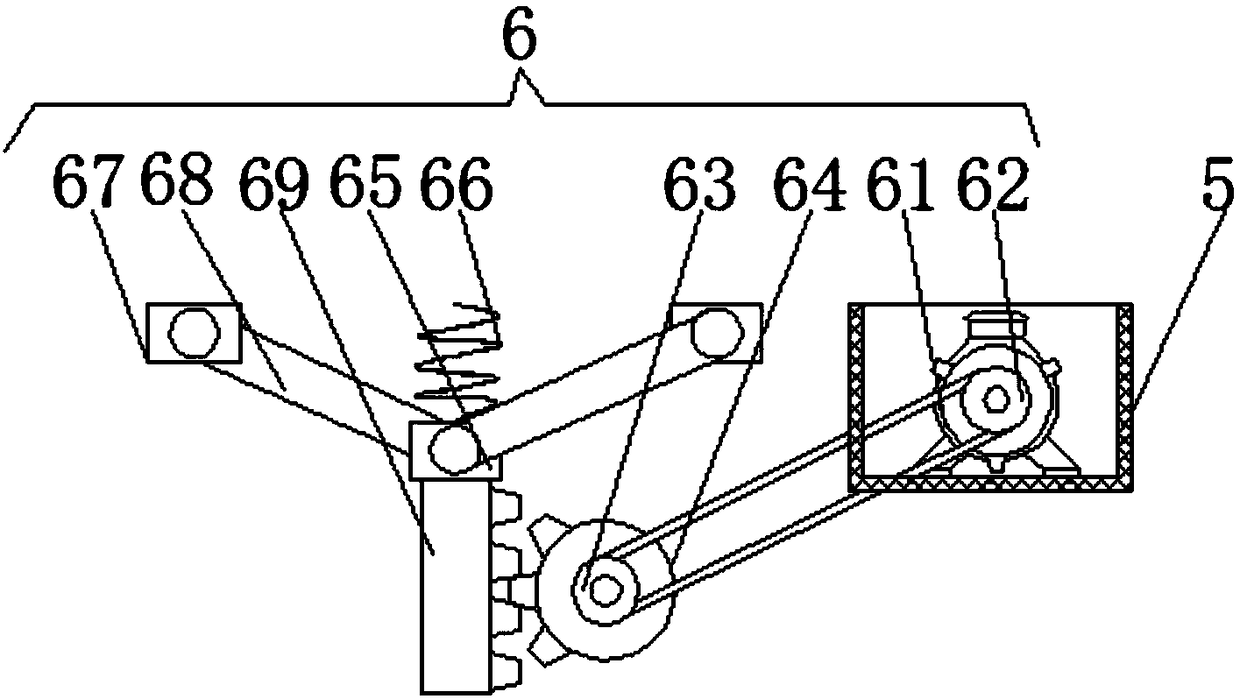

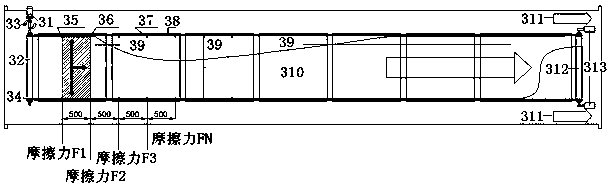

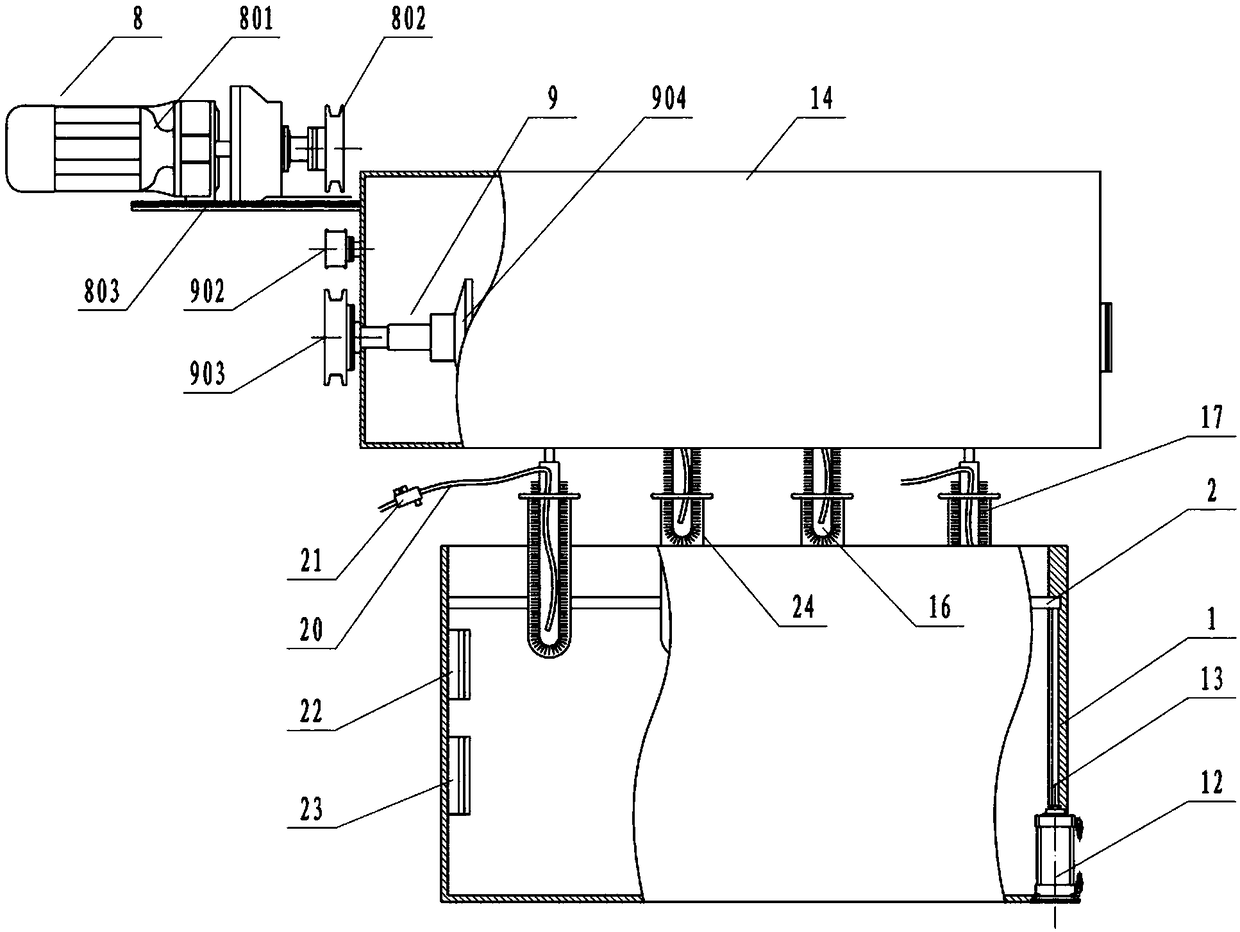

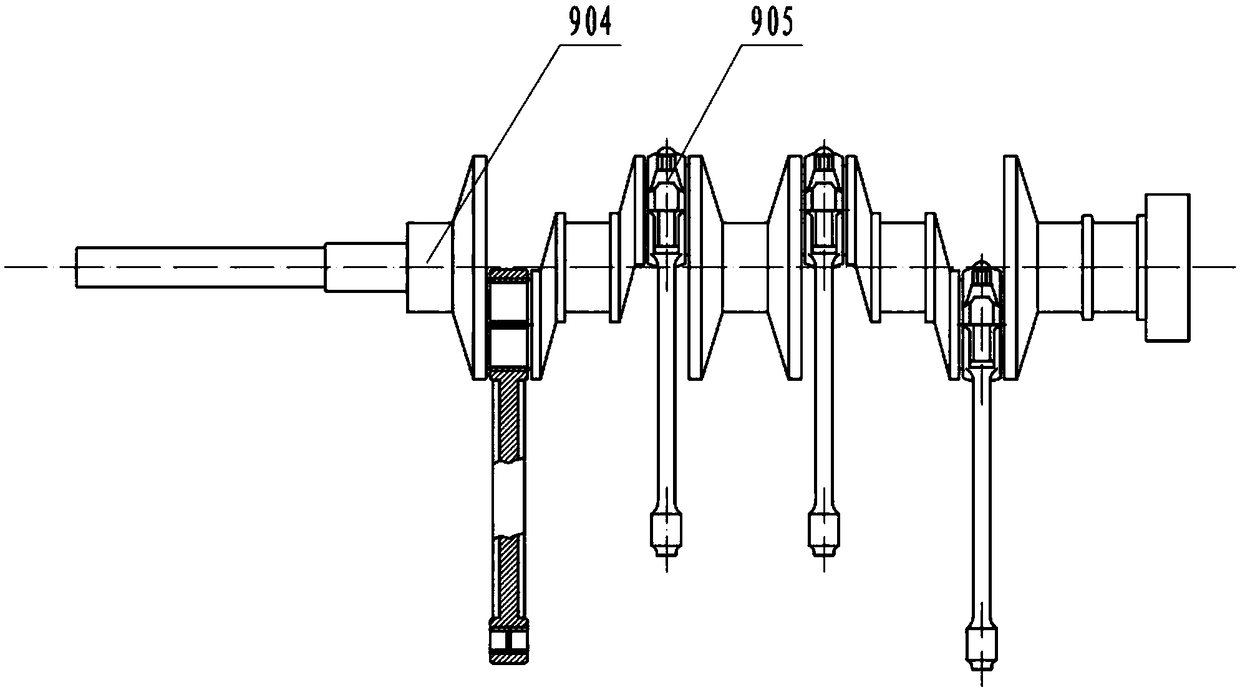

A vacuum belt dryer

ActiveCN107356081BAdd drying functionControl lateral irregular movementDrying machines with progressive movementsDrying solid materialsMotor driveDrive shaft

The invention discloses a vacuum belt drying machine. The vacuum belt drying machine comprises a left cabin door, a solid material feeding cabin, a left isolation air brake, a liquid extract feeding cabin, an adjusting cabin, a main engine cabin, a powder material discharging cabin, a right isolation air brake, a solid material discharging cabin and a right cabin door which are sequentially connected from left to right. A two-way chain-type drive unit comprises a motor, a driving shaft, sprocket wheels, conveyer belt connecting holes, conveyer belt staple bolts, chain connection plates, a chain, a plurality of heating plates, a conveyer belt, a driven shaft and cylinders. The motor drives the driving shaft to rotate; the sprocket wheels are arranged on the driving shaft; the sprocket wheels and the chain form an inlay transmission structure; the conveyer belt connecting holes are arranged in the conveyer belt, the chain connection plates are arranged between the chain and the conveyer belt, the conveyer belt staple bolts traverse the conveyer belt connecting holes and connect the chain, the chain connection plates and the conveyer belt together; the plurality of heating plates are arranged on the conveyer belt; and the driven shaft is connected with the cylinders, and the chain is connected between the driving shaft and the driven shaft.

Owner:温兄控股集团股份有限公司

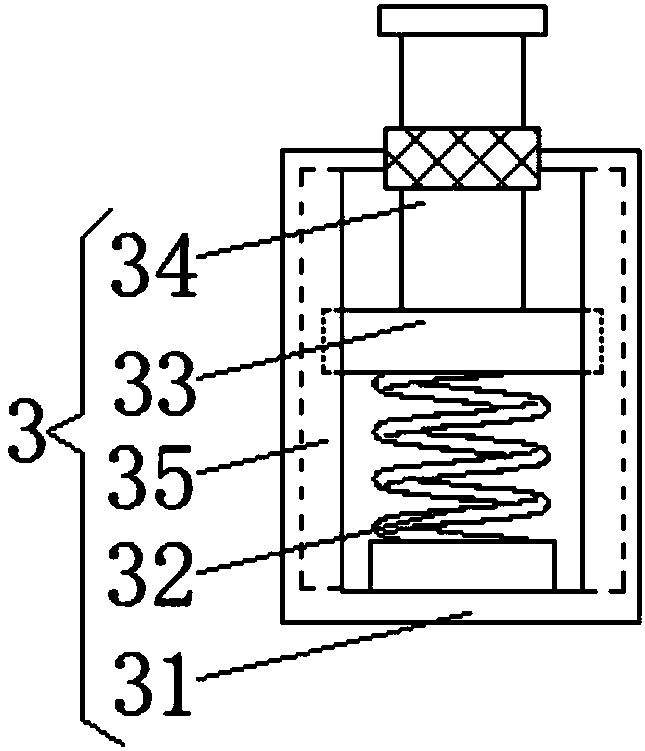

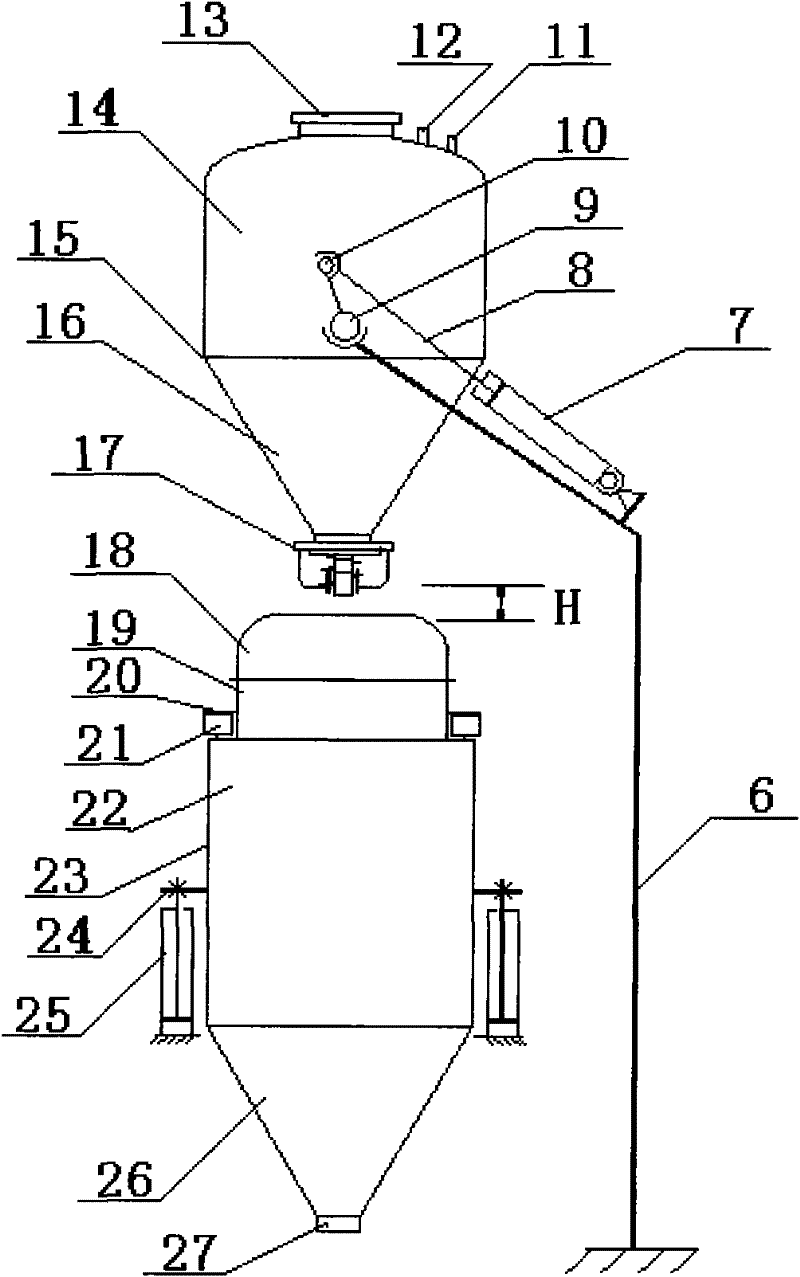

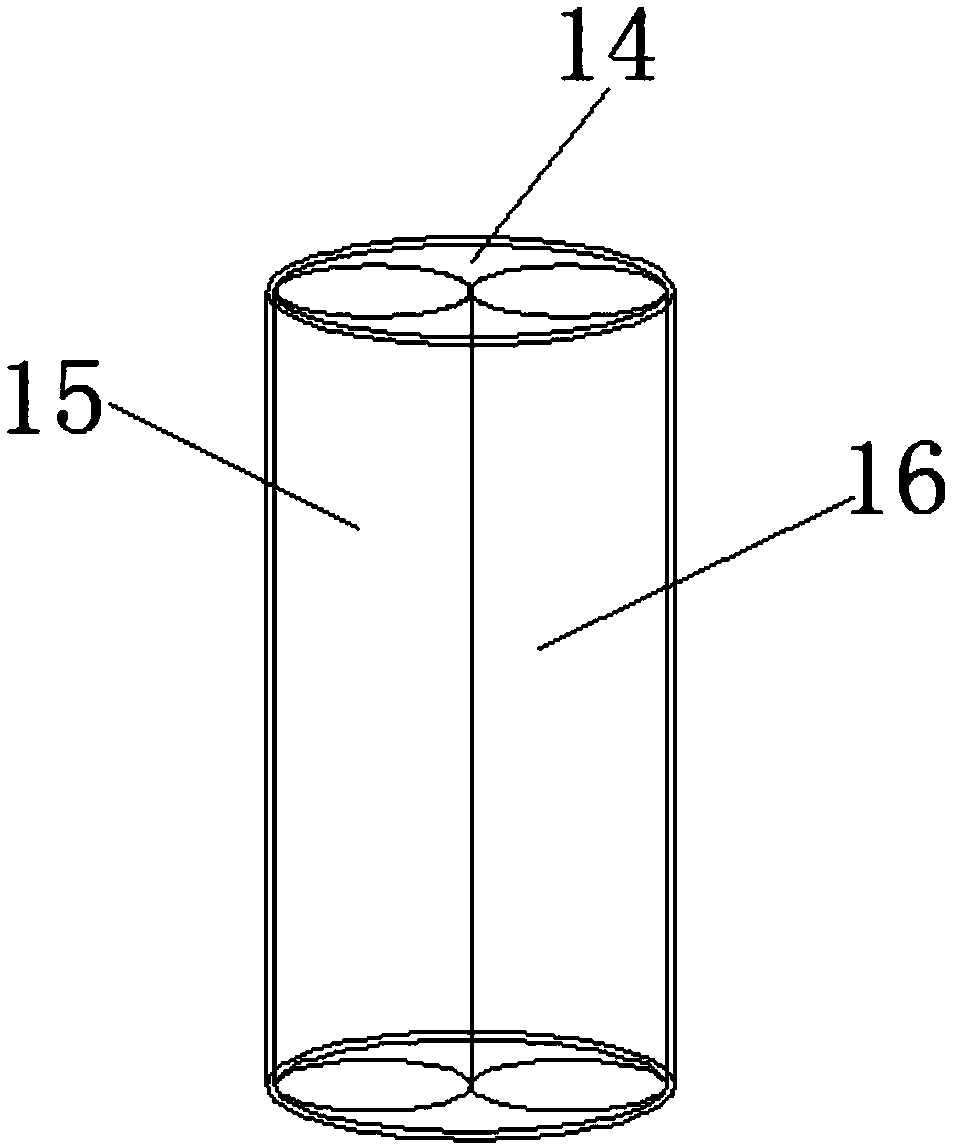

Dual sludge dewatering environmental protection equipment with drying function

InactiveCN108623122AAdd drying functionDries out quicklySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningEngineeringSludge dewatering

The invention discloses dual sludge dewatering environmental protection equipment with a drying function. The dual sludge dewatering environmental protection equipment with the drying function comprises a cylindrical drum, wherein through holes are formed in the side wall of the cylindrical drum; the cylindrical drum is hollowed; a sludge accommodating device is arranged in the inner cavity of thecylindrical drum; the sludge accommodating device comprises a cloth bag and tying ropes; the tying ropes are sewn at the edge of an opening of the bag; the tying ropes are tied to fixing rings; the fixing rings are welded to the outer side wall of the cylindrical drum; a rotating shaft is fixed to the bottom of the cylindrical drum through screws; the rotating shaft is sleeved with a bearing; thebearing is fixed to the bottom of a shell through a bearing base; one end, away from the cylindrical drum, of the rotating shaft runs through the side wall of the bottom end of the shell, stretches out of the shell and is connected with a belt pulley. The dual sludge dewatering environmental protection equipment with the drying function is equipped with a drying mechanism and a dewatering mechanism, and through the coordination of the drying mechanism and the dewatering mechanism, sludge can be dried quickly; the dual sludge dewatering environmental protection equipment with the drying function is simple in structure, ingenious in design, low in cost, convenient to use and easy to popularize widely.

Owner:天津鼎格科技有限公司

A tire production process

ActiveCN110341221BPrevent splashClean working environmentDrying gas arrangementsTyresStructural engineeringWater spray

Owner:江西岳大轮胎有限公司

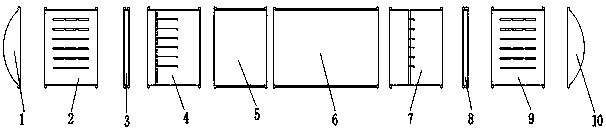

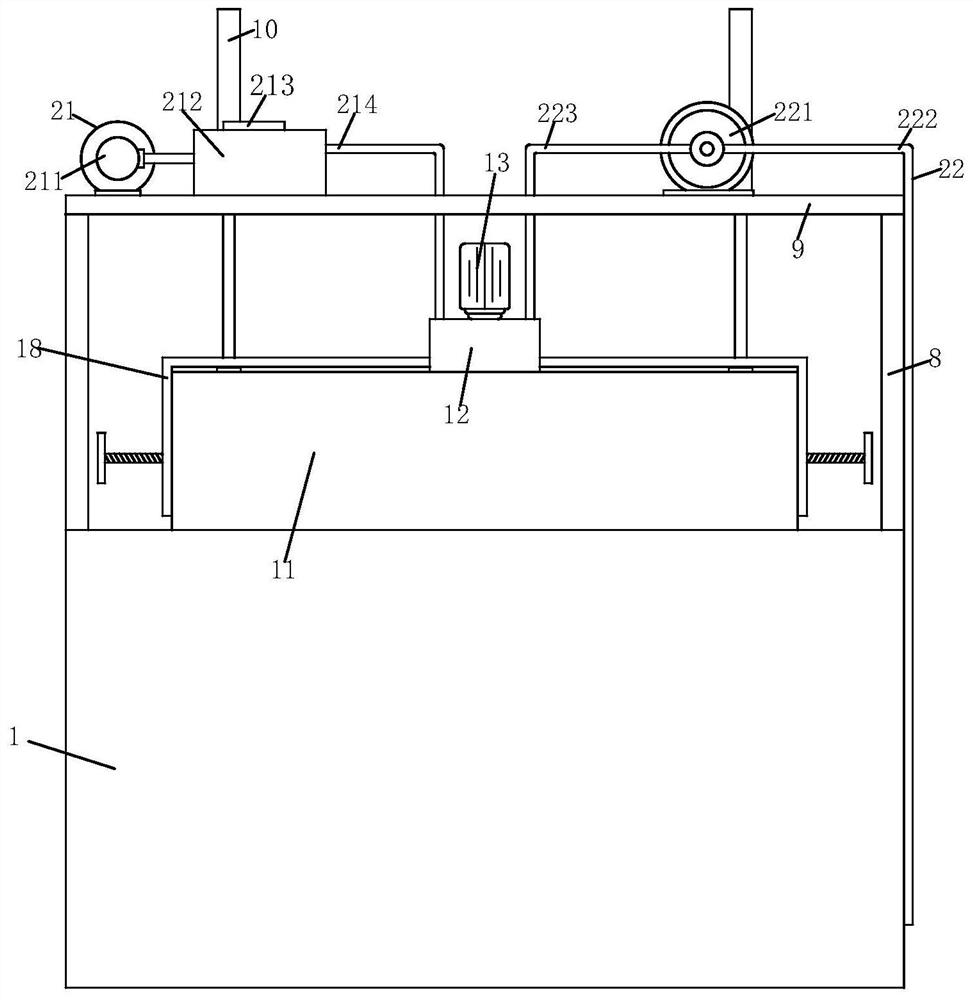

Rotary clothes hanger

The invention relates to a rotary clothes hanger, which includes a hook, a clothes hanger body (2) with a ring arranged in the center, and a hook connection end (1) for connecting the hook with the clothes hanger body (2). The hook connection end (1) is provided with a rotating device (3), which includes a switch (5), a power supply (6) and a rotating unit (7) connected in series sequentially, wherein the rotating unit (7) is connected with the clothes hanger body (2), and the switch (5) is arranged on the outer wall of the hook connection end (1). The inventive rotary clothes hanger provided with the rotating device is simple to operate, can realize uniform sunlight irradiation on clothes, makes full use of light energy to save electric power, speeds up drying, and can also achieve sun-drying sterilization effects to therefore convenience life of people.

Owner:WUXI INST OF COMMERCE

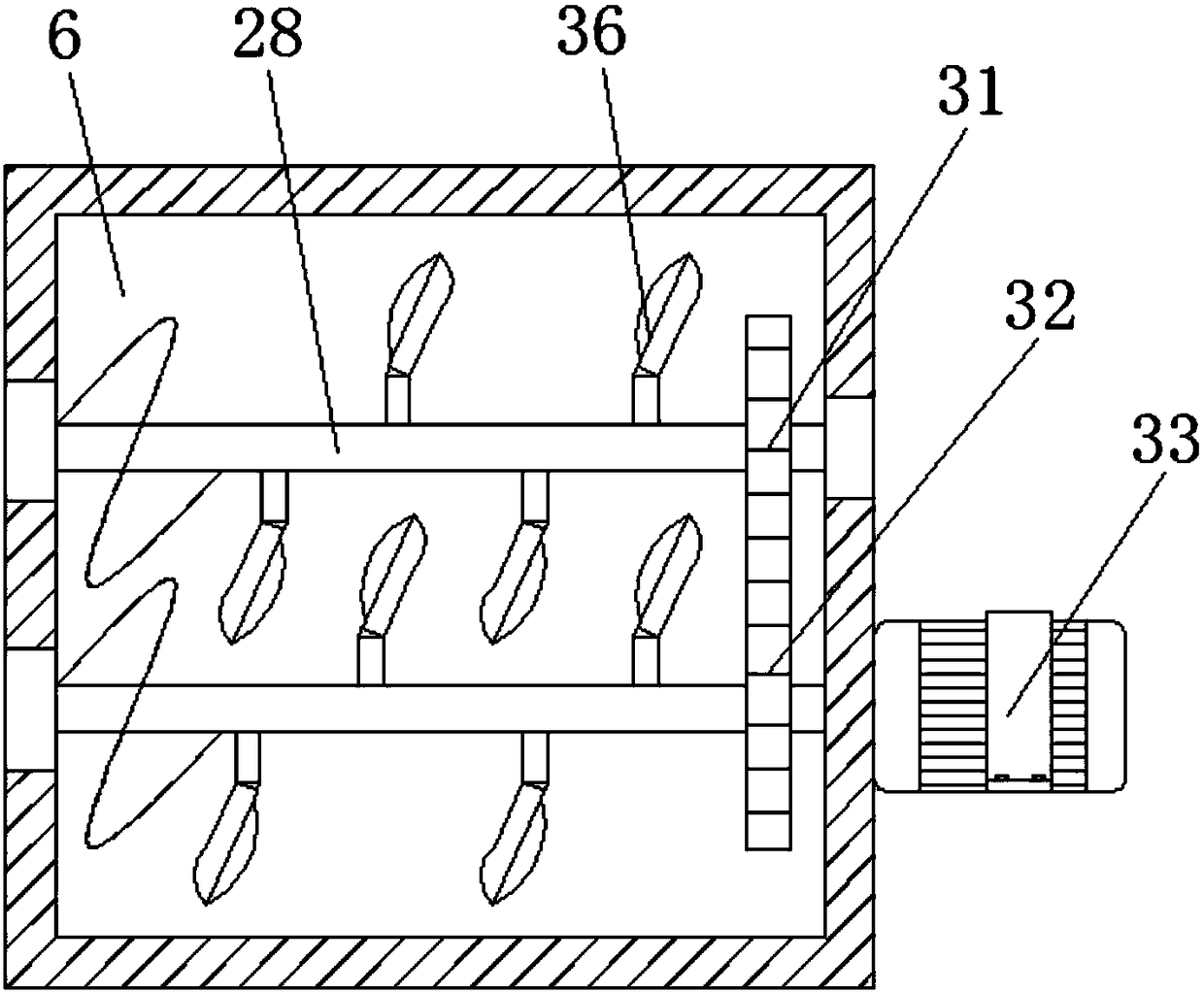

A test tube automatic cleaning device

ActiveCN106890834BImprove accuracySave human effortHollow article cleaningRadiationAutomatic test equipmentBristle

Disclosed is an automatic cleaning device for test tubes and belongs to the technical field of automatic cleaning equipment. The automatic cleaning device is characterized in that a top rod on a top lift cylinder is connected with a slider; multiple installation holes are arranged in a moving plate side by side, clamping pieces are arranged in the installation holes, and each clamping piece is connected with the inner edge of each installation hole through a spring; a cabinet is arranged above a cleaning groove, a drive device is fixed on the side face of the cabinet, the drive device is connected with the slide II through a transmission device, the slider is connected with a push bar, bristles are arranged in the push bar, and the push bar is coincided with the axis of the installation holes. The automatic cleaning device has the advantages that the test tubes are cleaned automatically, sterilization and drying functions are added on the basis of the existing technology, and accuracy of detection results is favorably improved.

Owner:东营中达石油设备有限公司

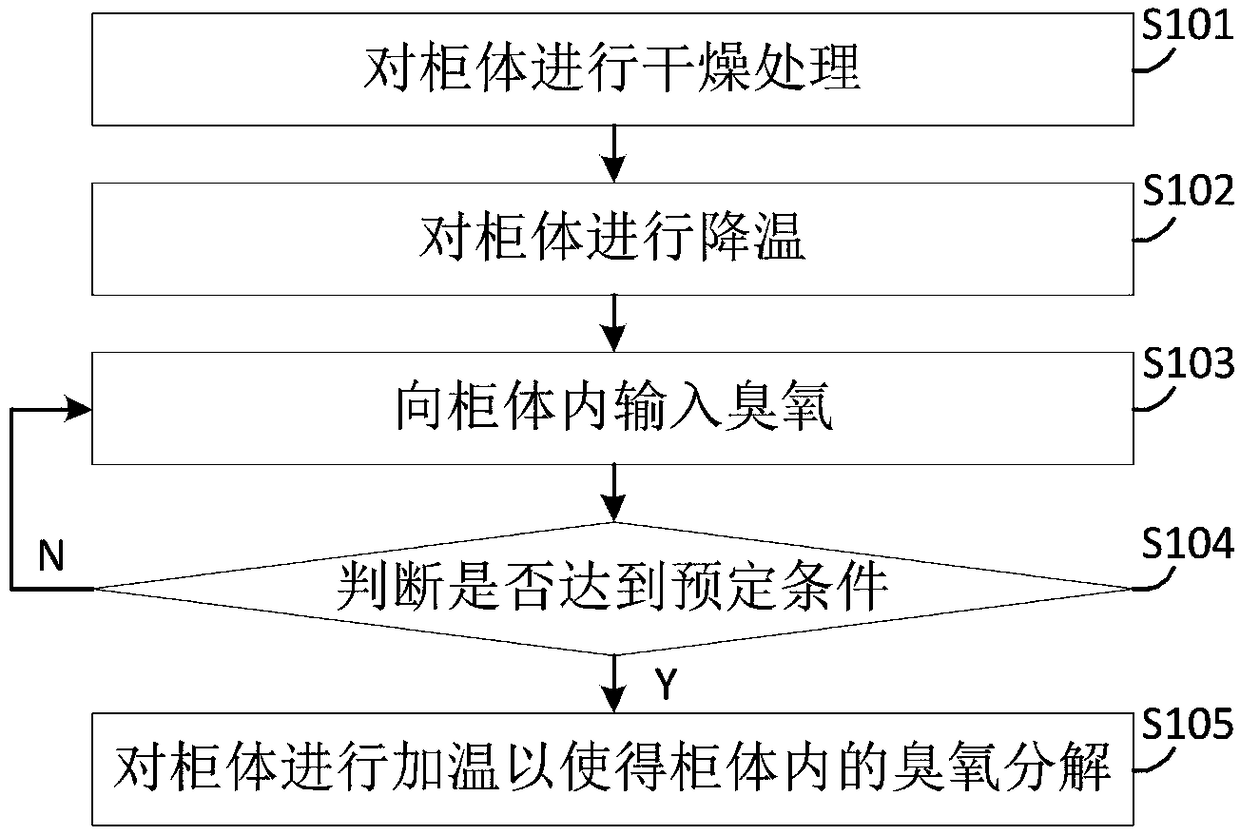

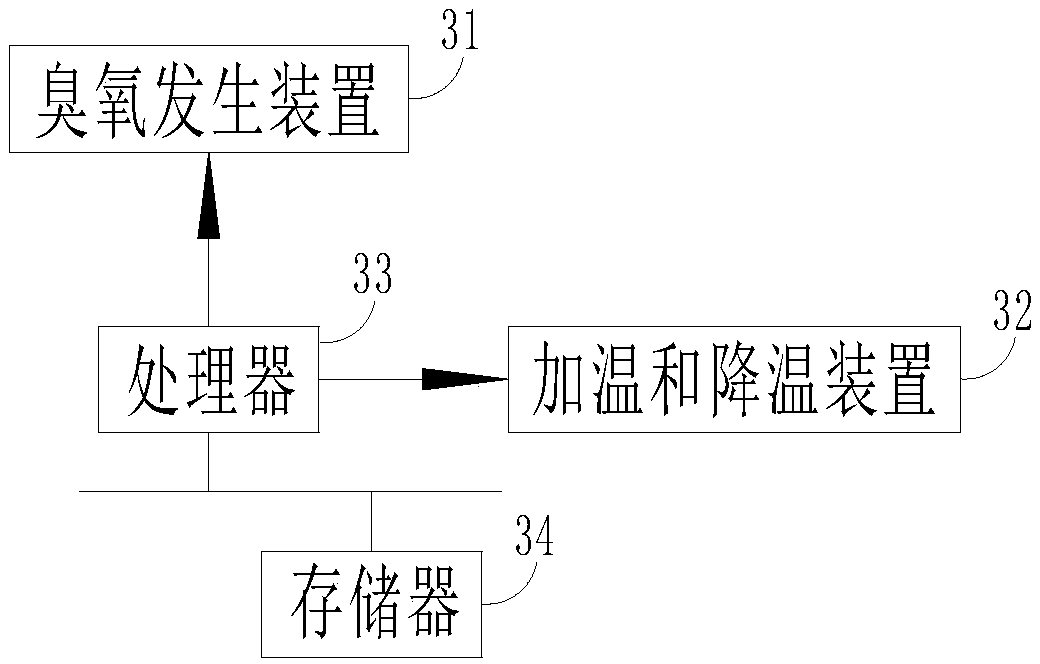

Method for disinfecting cabinet and clothes dryer

InactiveCN109172850AGuaranteed sterilization effectPrevent overflowLavatory sanitoryTextiles and paperUltravioletEnvironmental engineering

The invention discloses a method for disinfecting a cabinet and a clothes dryer. The method comprises the following steps: inputting ozone into a cabinet; and heating the cabinet to decompose the ozone in the cabinet when a preset condition is achieved. According to the method for disinfecting a cabinet and a clothes dryer, clothes and other objects in a cabinet can be sterilized and disinfected by utilizing ozone since ozone is input into the cabinet, and the problem that an existing clothes dryer does not have a sterilizing function. Ozone has an intense smell and can be easily identified bypeople, so that ozone can be applied to household disinfection and sterilization, and has the safety remarkably higher than that of ultraviolet ray which is colorless and odorless.

Owner:GREE ELECTRIC APPLIANCES INC

Turntable quantitative discharge device

The invention discloses a turntable-type quantitative discharge device, which includes a storage bin, which is characterized in that: the storage bin is a cylindrical body with an upper circle and a lower cone, and the bottom edge of the lower cone body is fixedly connected with a sawtooth Shaped discharge pipe, on the outside of the discharge pipe is fixed a warehouse bottom flange with threads outside; it also includes: a cylinder that rotates the storage bin through the fulcrum support located outside the storage bin; through The thread is threadedly connected with the flange at the bottom of the silo, and includes a three-jaw turntable seat, a turntable set in the middle of the turntable seat, and a turntable assembly of a rotating shaft barrel; the set of upper circular and lower cone barrels is set under the turntable assembly. A feed tank; a drive host at the middle and upper part of the collecting tank; a weight scale at the middle and upper part of the collecting tank. The device has simple structure, stable output, and is easy to use and clean. It can smoothly, accurately, quickly and automatically quantitatively discharge the trace raw materials. It is suitable for batching production requirements with many types of powder and granular trace raw materials and high weighing accuracy.

Owner:广西南宁市真唯特自动化设备有限公司

Full-automatic foot massage control method and device

PendingCN113616095AGood for healthAchieve cleaningBathsDouchesPhysical medicine and rehabilitationMassage

The invention provides a full-automatic foot massage control method and device, and the device comprises a second barrel body which is used for washing feet or rinsing; a third barrel body used for storing water discharged from the second barrel body; and a waste water conveying part which is arranged between the second barrel body and the third barrel body and is used for controlling water in the second barrel body to be discharged to the third barrel body. The control method comprises the following steps that S1, water is injected into the second barrel body, and when the water level and the water temperature in the second barrel body reach set parameters, the feet are cleaned and massaged; and S2, after cleaning is completed, water in the second barrel body is drained into a third barrel body to be stored. According to the full-automatic foot massage control method and device, the foot washing and foot bath functions are integrated, the foot washing, rinsing and drying functions can be achieved, meanwhile, the actions such as lifting up and squatting are not needed, water inflow and water drainage are facilitated, and it is convenient for the old, pregnant women, wounded persons, patients and other weak people to use the the full-automatic massage bath control device.

Owner:北京必和易达知识产权咨询中心(有限合伙)

Ozone therapeutic apparatus for gynecology department

InactiveCN107789183AImprove treatment comfortExtended service lifeBathing devicesOzone generatorTherapeutic Devices

The invention discloses an ozone treatment instrument for gynecology, which comprises a main body of the ozone treatment instrument. An operation display screen is arranged on the top of the main body of the ozone treatment instrument, and an operation panel of the treatment instrument is connected to the side wall of the operation display screen. There is a first layer of therapeutic apparatus, the bottom side wall of the first layer of therapeutic apparatus is fixed with an ozone generator, a transformer is installed on the right side wall of the ozone generator, and a heater is arranged on the front side wall of the transformer, and the left side of the heater is A power supply is installed on the wall, and a slide rail is fixed on the left side of the power supply. The bottom of the first layer of the therapeutic apparatus is provided with a second layer of therapeutic apparatus, and a dryer is installed inside the second layer of the therapeutic apparatus. The bottom of the dryer is provided with a therapeutic apparatus. The third layer of the instrument has a water tank installed inside the third layer of the therapeutic instrument, and the bottom of the water tank is fixed with a therapeutic instrument base. The gynecological ozone therapy device adopts dual treatment methods of washing and fumigation, and at the same time uses a dryer to keep the treatment area dry, improving the patient's treatment comfort.

Owner:耿俐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com