Maze crossed type conduction oil drying cylinder with two-side oil supply

A heat transfer oil, labyrinth technology, used in textiles and papermaking, papermaking machines, dryers, etc., can solve problems such as differences in the degree of drying of paper, achieve uniform flow, improve transfer efficiency, and improve the effect of drying function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further description will be made below in conjunction with the accompanying drawings and specific embodiments.

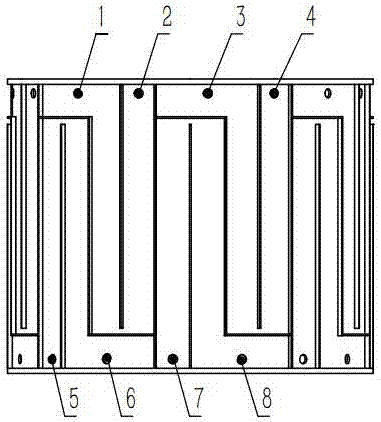

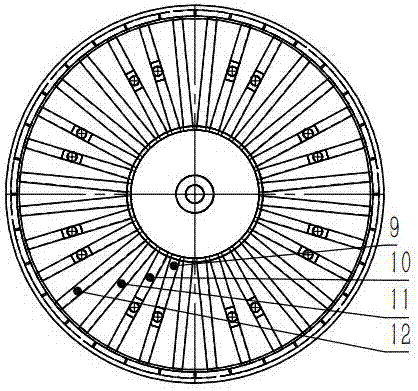

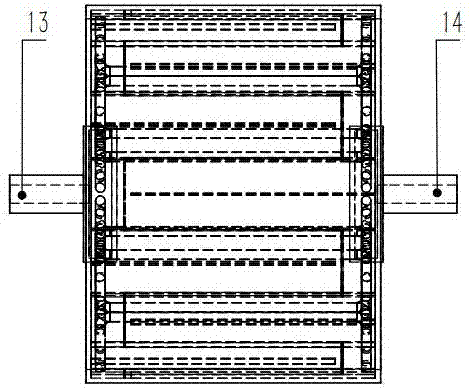

[0016] The present invention as figure 1 , 2 , 3, and 4 are a kind of pulp drying heat conduction oil cylinder for papermaking, which has a new type of heat conduction oil cylinder with double-sided inflow and a labyrinth channel for the oil guide chamber. and some metal hoses for description of the implementation.

[0017] image 3 As shown, hot oil flows in from the shaft head on the inlet side of 13. With the rotation of the hot oil cylinder and the continuous storage of hot oil in the shaft head, the hot oil gradually accumulates. After reaching a certain level, the hot oil begins to flow out, and the hot oil inside the shaft head is continuously increased. , until the air in the shaft head and the oil guide chamber is completely exhausted.

[0018] figure 2 As shown, the hot oil inside the shaft head flows out of the shaft head on the inlet side an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com