A test tube automatic cleaning device

An automatic cleaning and test tube technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, irradiation, etc., can solve the problems of poor cleaning efficiency, low cleaning efficiency, and inability to clean, so as to improve work efficiency, improve accuracy, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

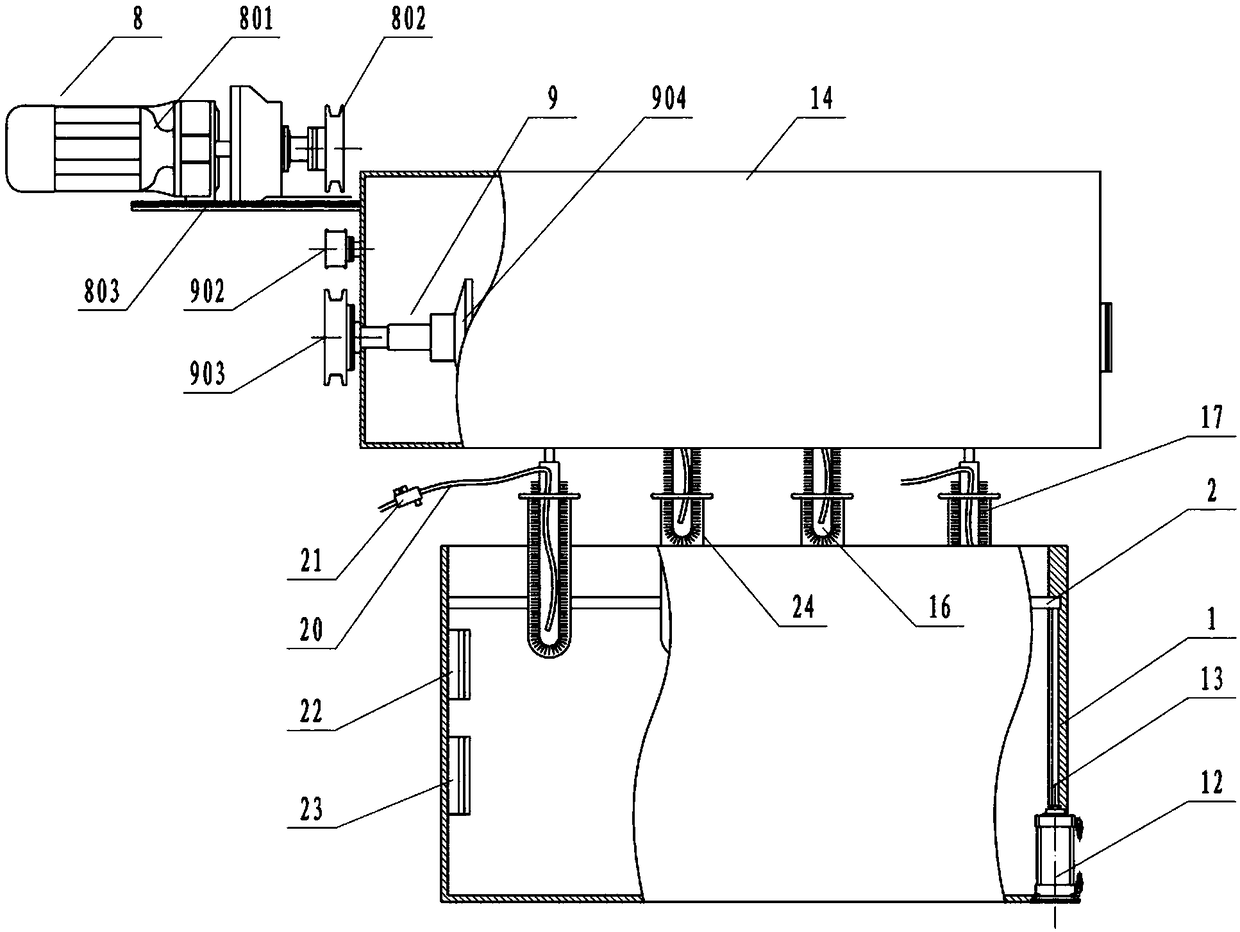

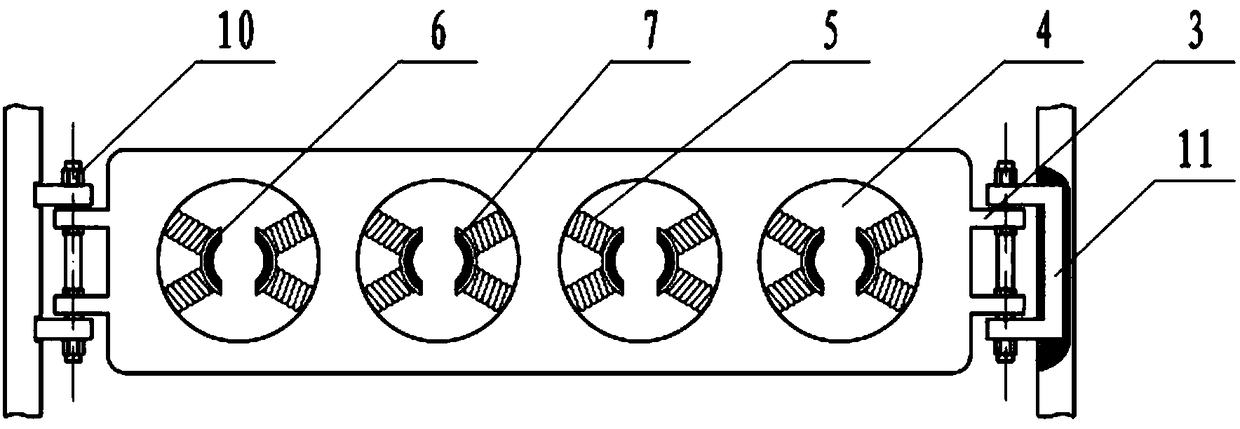

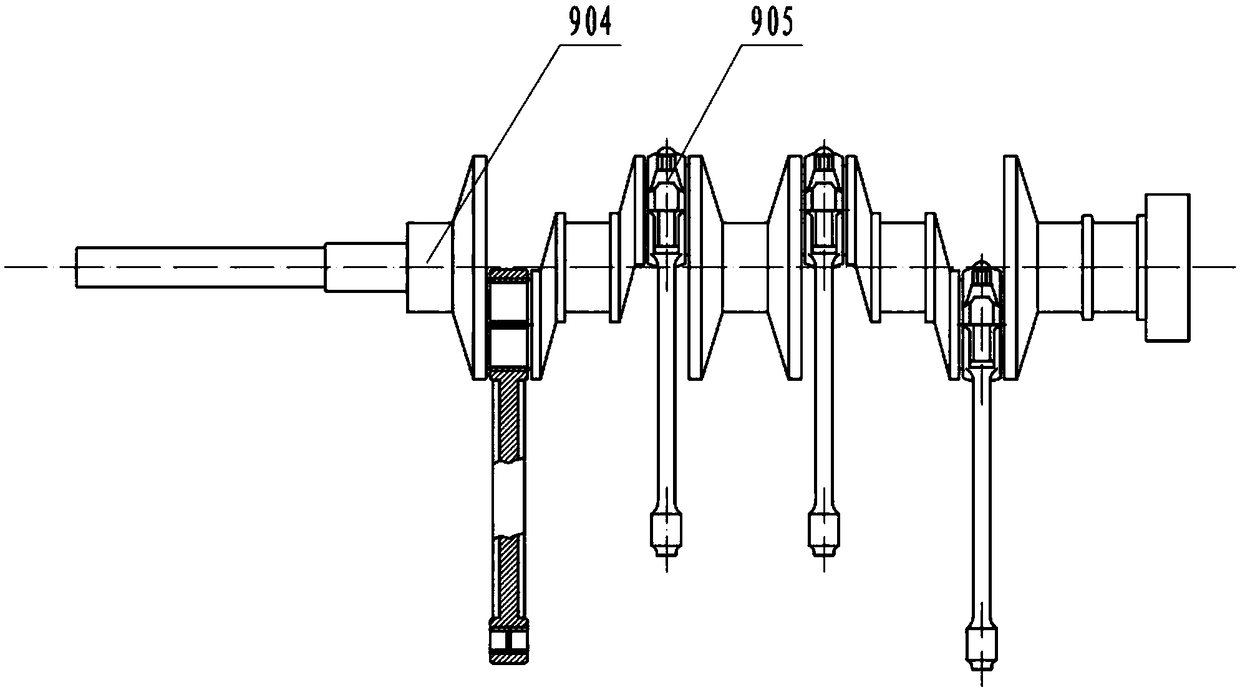

[0019] The present invention is realized through the following technical solutions:

[0020] A test tube automatic cleaning device, including cleaning tank 1, moving plate 2, lifting lug 3, installation hole 4, spring 5, clip 6, rubber pad 7, connecting rod 10, slider I11, jacking cylinder 12, ejector rod 13. Driving device 8, transmission device 9, casing 14, slider II15, push rod 16 and bristles 17, characterized in that: the moving plate 2 is set inside the cleaning tank 1, and the two sides of the moving plate 2 are set There are lugs 3, and the lugs 3 are connected to the slider I11 through the connecting rod 10. The slider I11 is "U" shaped, and the slider I11 is arranged inside the side wall of the cleaning tank 1. The slider I11 The movable plate 2 can be driven to move up and down in the side wall, and a jacking cylinder 12 is arranged below the slider I11, and the ejector rod 13 on the jacking cylinder 12 is connected with the slider I11; A plurality of spaced mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com