A vacuum belt dryer

A vacuum belt drying and chain technology, applied in progressive dryers, dryers, dry goods handling, etc., can solve the problems of heating plate length limitation, long stroke, short service life of conveyor belts, etc. Pull load, improve service life, and expand the effect of drying function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

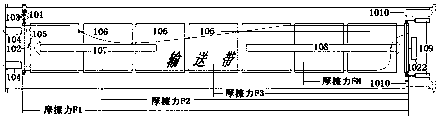

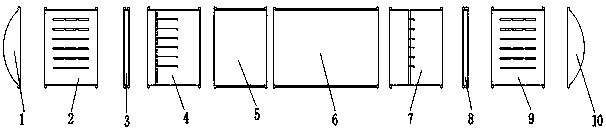

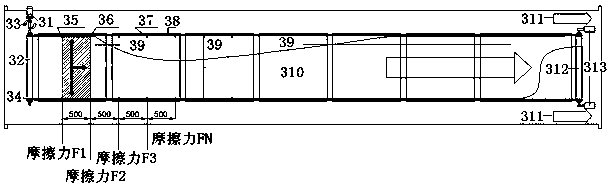

[0028] Such as Figure 2 to Figure 5 As shown, the vacuum belt dryer of the present invention includes a left hatch 1, a solid material feeding cabin 2, a left isolation airlock 3, a liquid extract feeding cabin 4, and an adjustment cabin connected in sequence from left to right 5. The main engine cabin 6, the powder material discharge cabin 7, the right isolation airlock 8, the solid material discharge cabin 9 and the right hatch door 10, also include a two-way chain drive device, and the two-way chain drive device includes a motor 31, drive shaft 32, sprocket wheel 34, conveyor belt connecting hole 35, conveyor belt staple 36, chain connecting plate 37, chain 38, multiple heating plates 39, conveyor belt 310, driven shaft 312 and cylinder 313, the described The output shaft of the motor 31 is connected with the drive shaft 32, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com