Dual sludge dewatering environmental protection equipment with drying function

A sludge dehydration and environmental protection equipment technology, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, sludge treatment, etc., can solve secondary pollution of water bodies and atmosphere, waste of manpower, material and financial resources , troublesome operation and other problems, to achieve the effect of simple structure, low cost and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

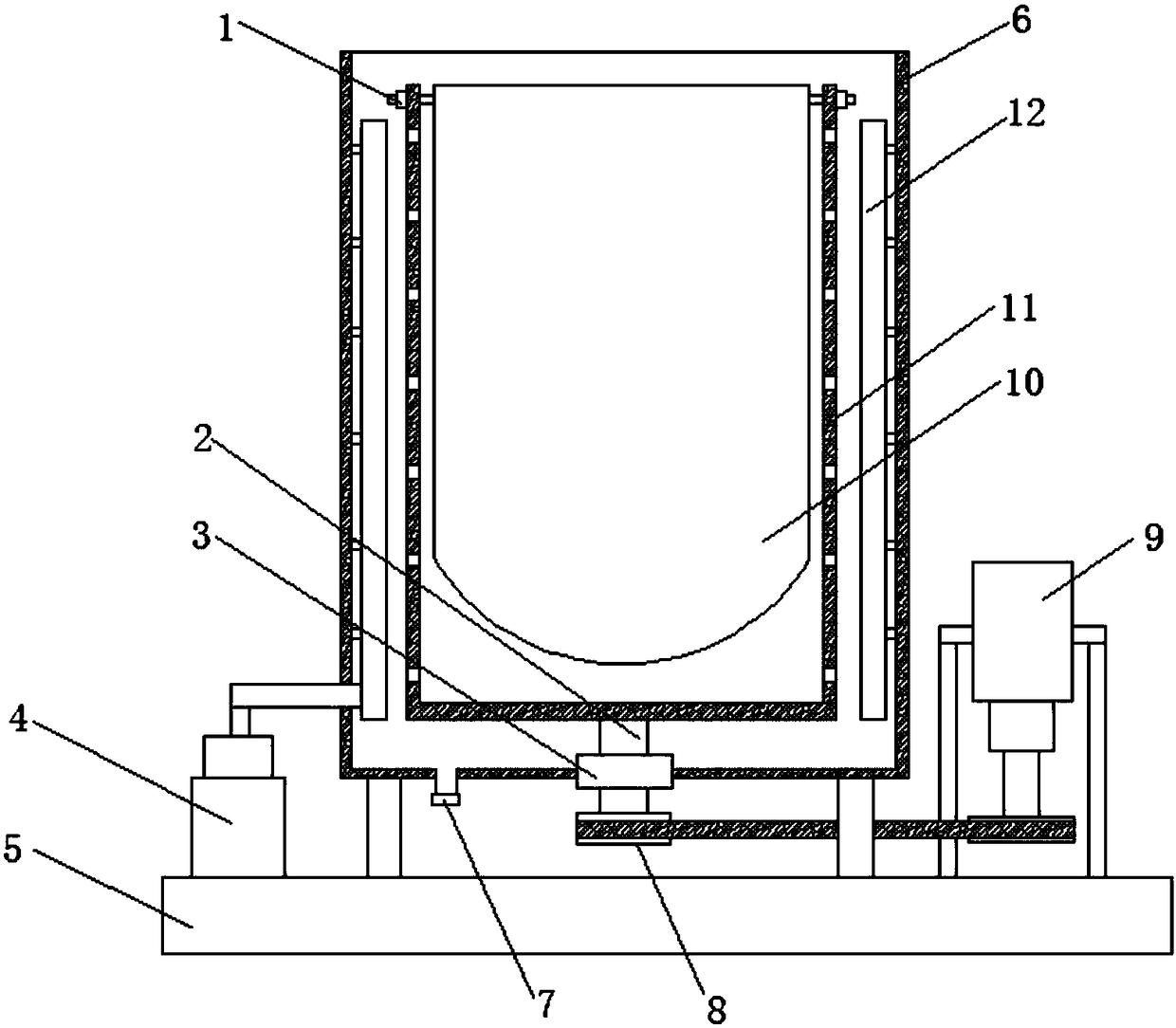

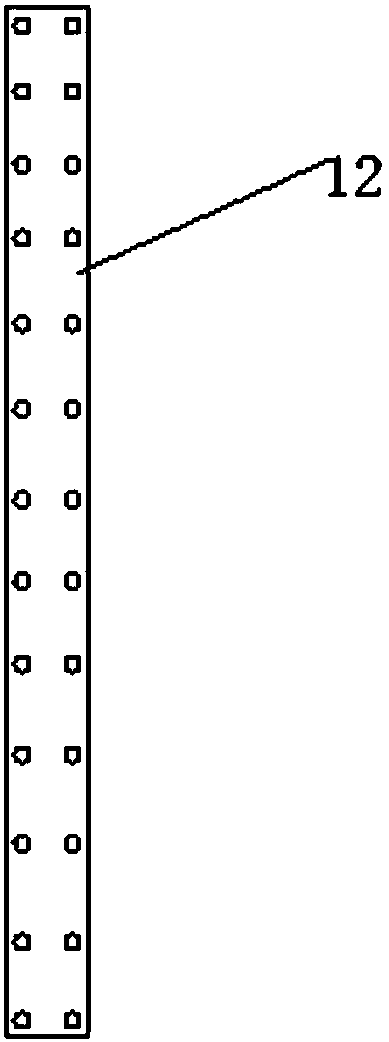

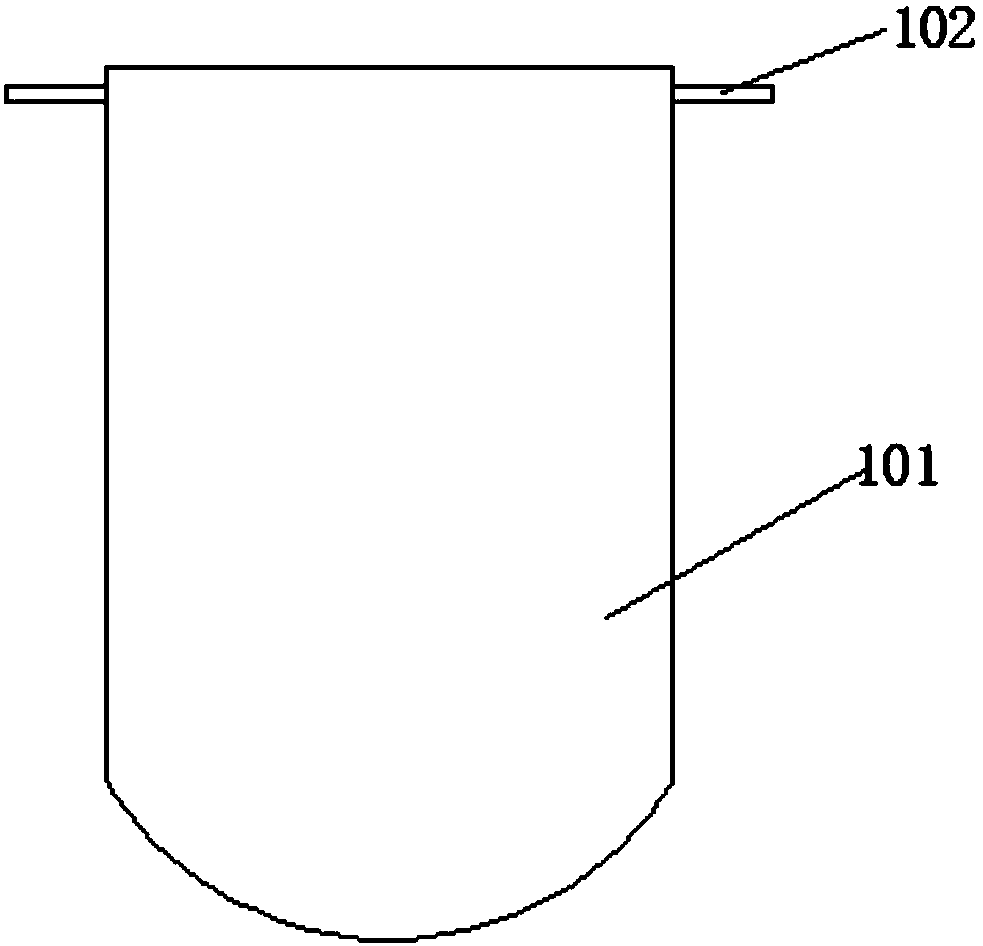

[0019] refer to Figure 1-3 , double sludge dehydration environmental protection equipment with drying function, including a cylinder 11, a through hole is opened on the side wall of the cylinder 11, the cylinder 11 is hollowed out, and the inner cavity of the cylinder 11 is provided with a sludge holding device 10 , the sludge holding device 10 includes a cloth bag 101 and a bolting rope 102, wherein the bolting rope 102 is seamed at the edge of the bag opening, the bolting rope 102 is bolted to the fixing ring 1, and the fixing ring 1 is welded to the cylinder 11 On the outer side wall of the cylinder 11, the bottom of the cylinder 11 is fixed with a rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com