Air flowing transversely type drum dryer

A drum dryer and cross-flow technology, which is applied in household dryers, washing devices, textiles and papermaking, etc., can solve the problems of general products without structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

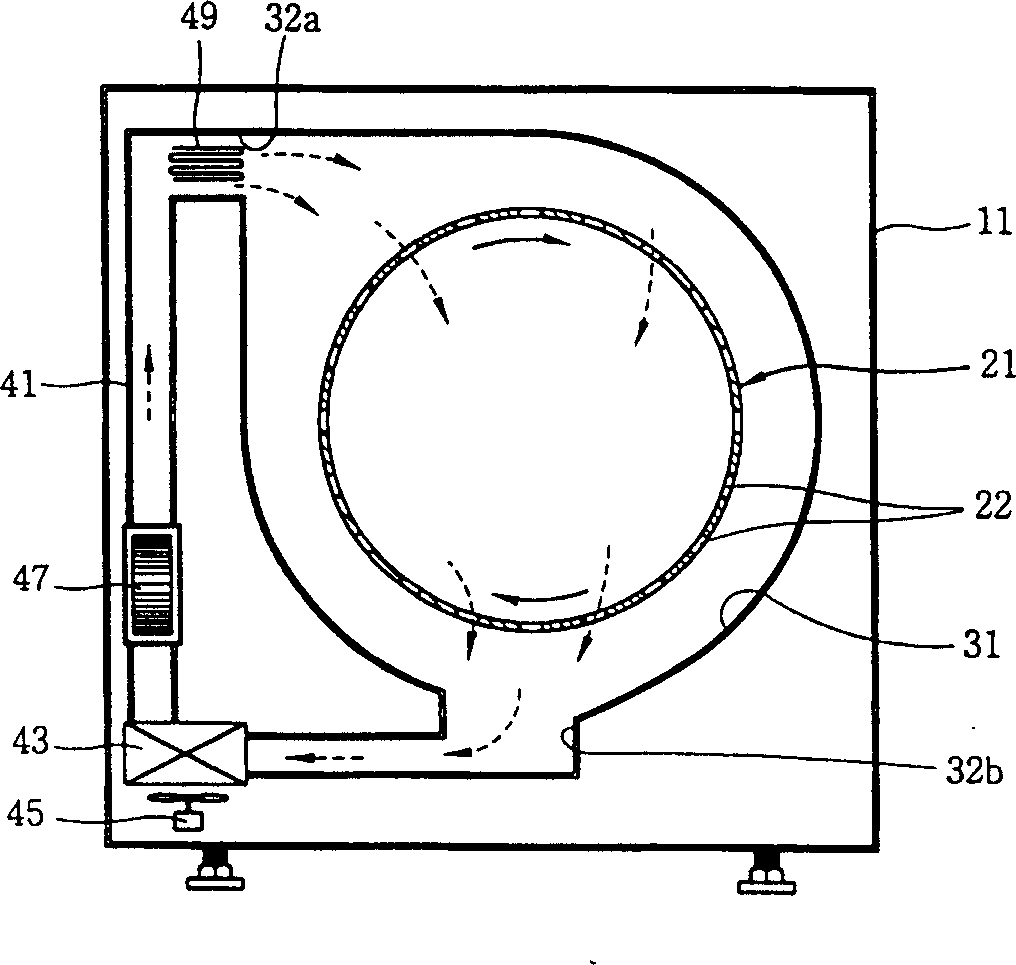

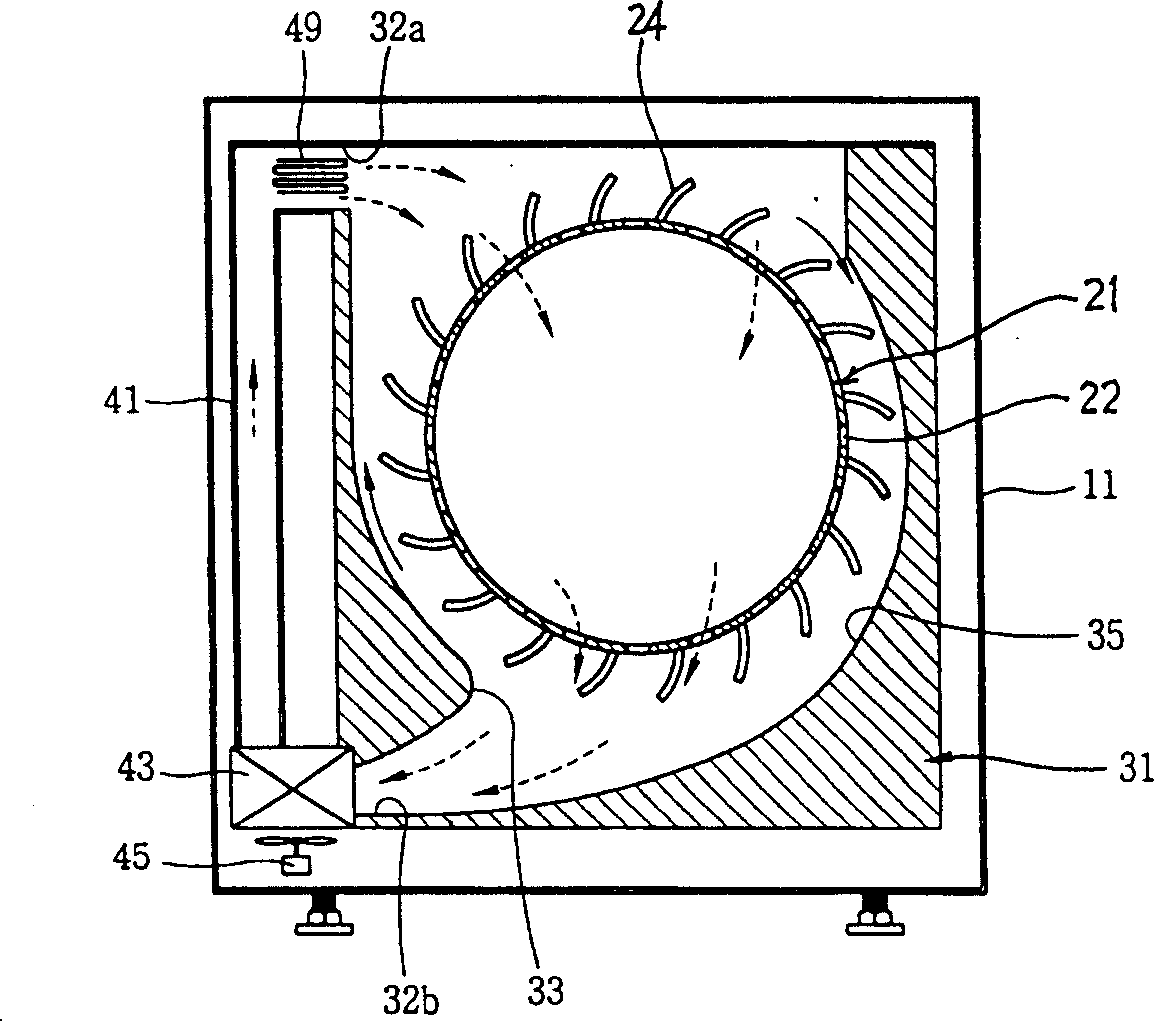

[0059] The specific implementation, structure, features and functions of the cross-flow tumble dryer proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

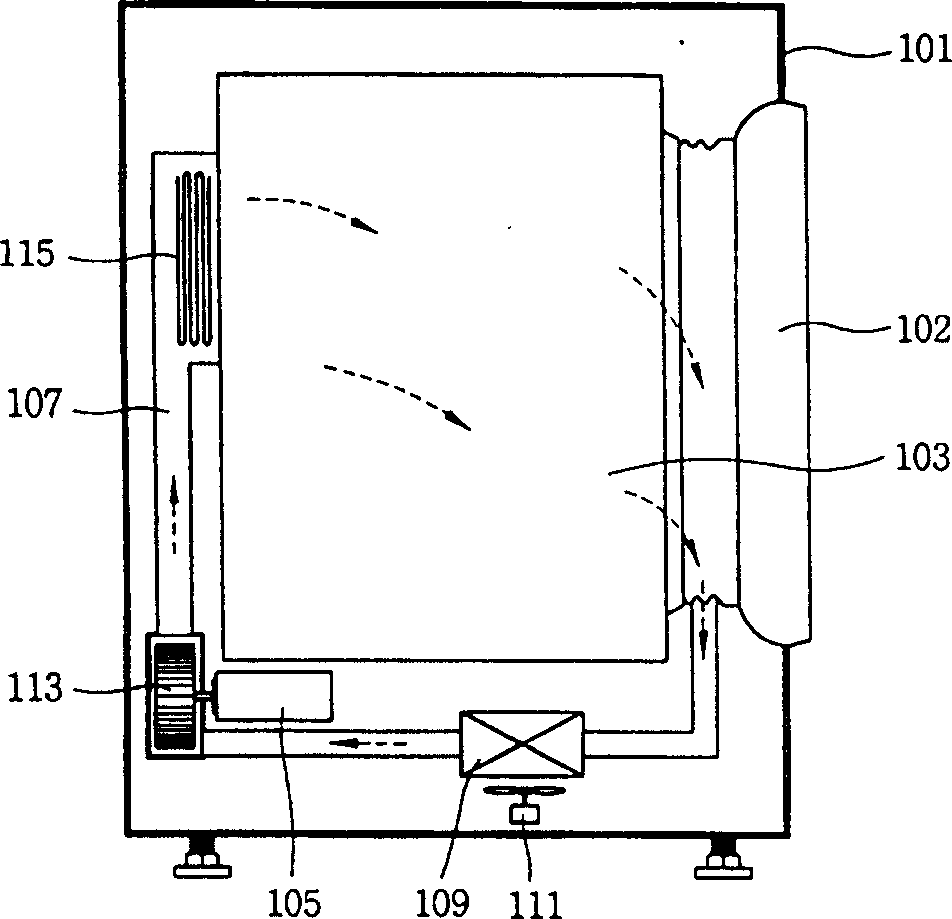

[0060] see figure 2 Shown is a schematic longitudinal section view of the first embodiment of the cross-flow tumble dryer of the present invention. The cross-flow drum dryer of the present invention mainly includes the following parts: a casing 11 with a storage space is formed inside; a number of air vents are provided, so that the air can flow laterally on the circumferential surface relative to the axial direction, and in the casing 11. The interior is installed in a substantially horizontal direction, and the rotating drum 21 that can rotate around the rotating shaft; around the rotating drum 21; the air circulation part 31 that makes the air circulate horizontally relative to the axial direction of the rotating drum 21; o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com