Double-inlet and double-outlet conduction oil drying cylinder

A double-input, double-outlet, heat-conducting oil technology, applied in drying, drying machines, heating devices, etc., can solve problems such as intricate metal hoses, complicated manufacturing processes, and unbalanced cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further description will be made below in conjunction with the accompanying drawings and specific embodiments.

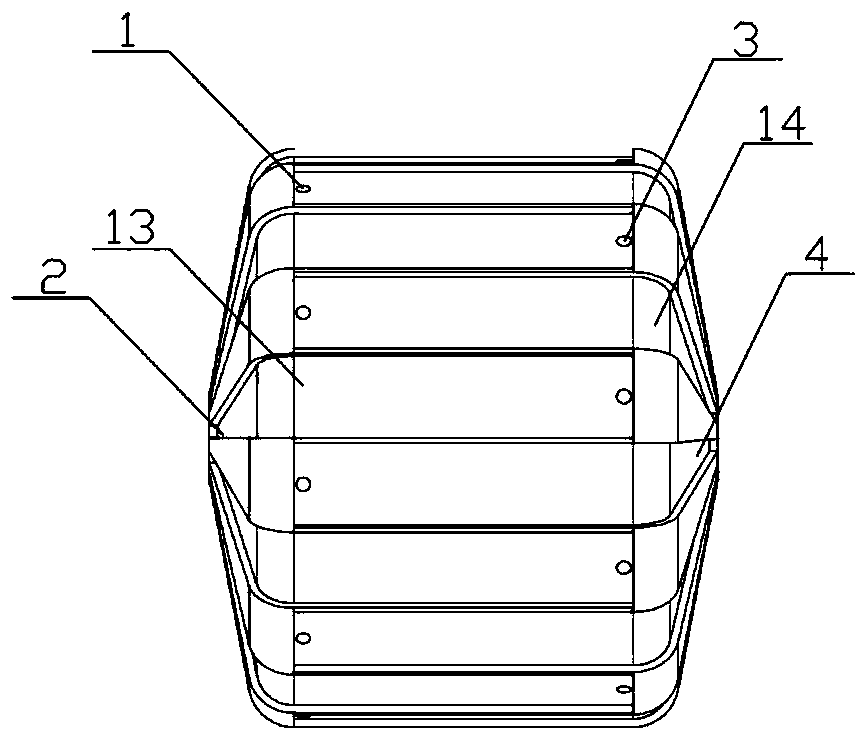

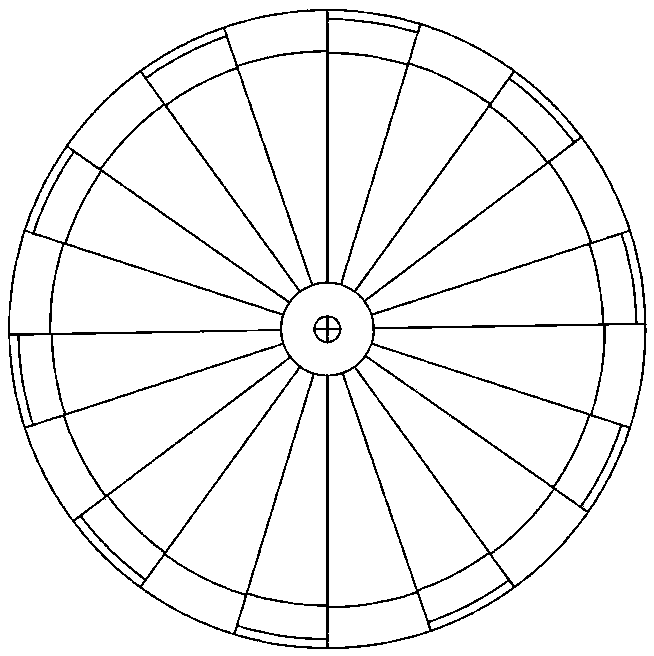

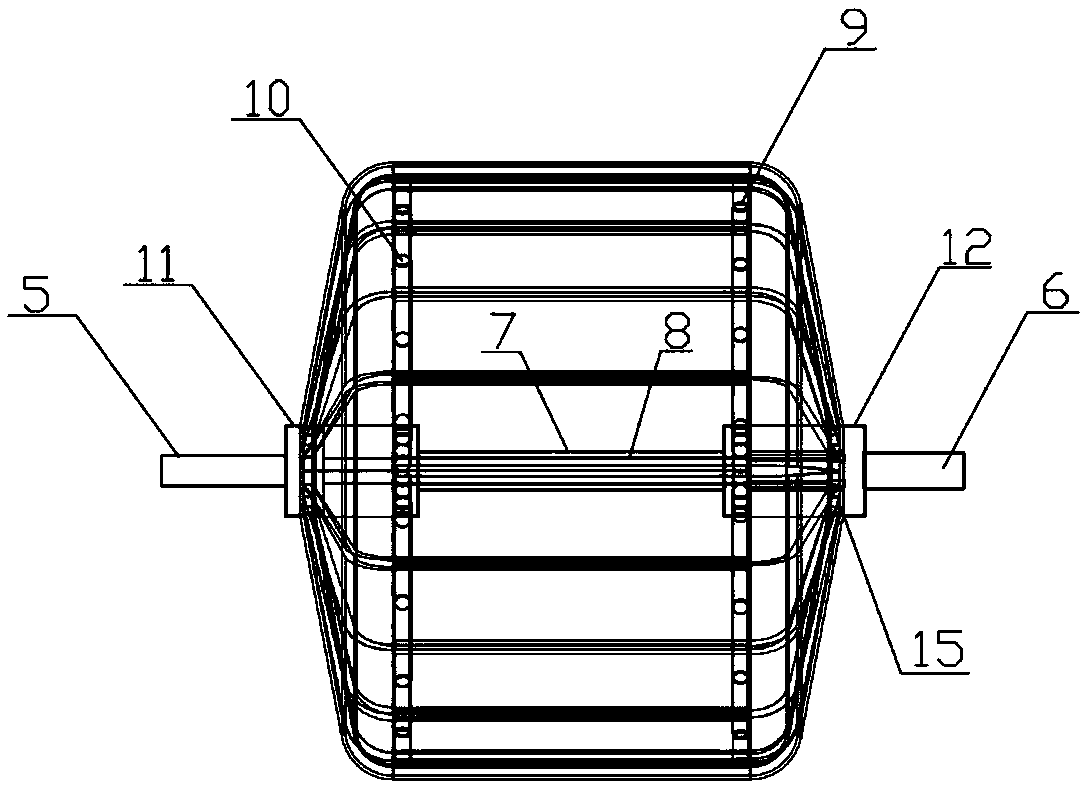

[0016] The present invention as figure 1 , as shown in 2, 3, and 4, is a pulp drying heat transfer oil cylinder for papermaking, which has a new type of heat transfer oil cylinder with double-sided inflow and double-side outflow. The 8 oil inlet main shaft connected to the 11 oil inlet groove and the 15 oil inlet groove connected to the right end of the 8 oil inlet spindle, and then the 11 oil inlet groove and the 15 oil inlet groove respectively flow into the first axial oil guide cavity of 13 and the second axial guide chamber of 14 The oil chamber realizes convective flow, and flows in and out from the 10 first radial oil outlet metal pipe at the left end of the 13 first axial oil guide chamber and the 9 second radial oil outlet metal pipe at the end of the 14 second axial oil guide chamber The main shaft with 8 oil outlets connected with the metal pipe f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com