PCB (Printed Circuit Board) printing bearing jig

A PCB board and fixture technology, applied in the field of PCB board printing bearing fixtures, can solve the problems of increased printing time, easy damage to PCB boards, waste of resources, etc., and achieves the effect of wide application, convenient use and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

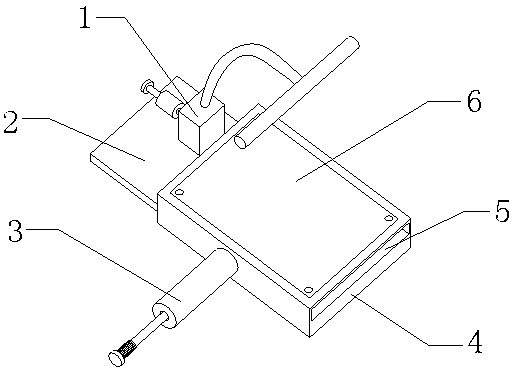

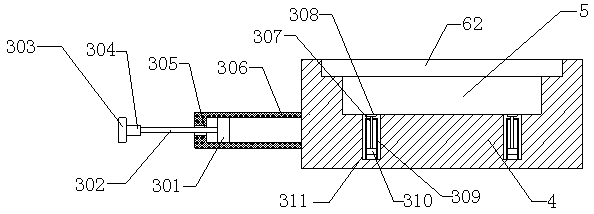

[0025] see Figure 1-Figure 4 , the present invention provides a technical solution: a PCB board printing bearing jig, including a device main body, a quick drying mechanism 1, an air pressure fixing mechanism 3, and a disassembly and assembly mechanism 6. The device main body includes a placement board 2, a box body 4 and a square Groove 5, place plate 2 is installed on box body 4 left end faces, square groove 5 offers on box body 4 right end faces.

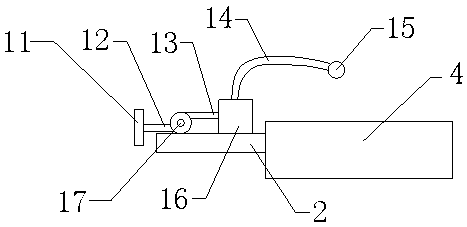

[0026] The fast drying mechanism 1 includes a wide mouth mask 11, an air intake pipe 12, an air delivery pipe 13, a gooseneck pipe 14, an air distribution pipe 15, a heating box 16 and a fan 17, and the fan 17 is installed on the left side of the upper end surface of the placement plate 2, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com