A tire production process

A production process and tire technology, applied in the field of tire production, can solve the problems of increasing production costs and equipment costs, unable to recycle water resources, consuming a lot of time and manpower, etc., to increase the drying function, avoid splashing, and cleaning. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

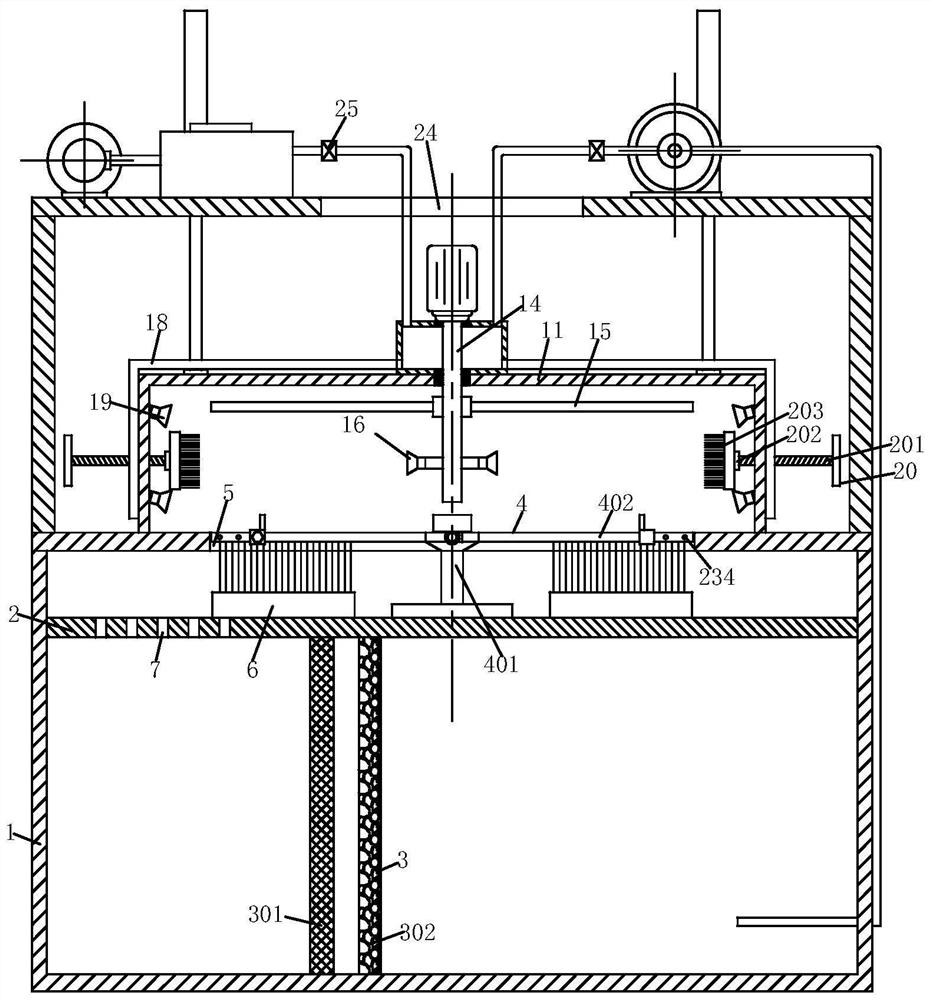

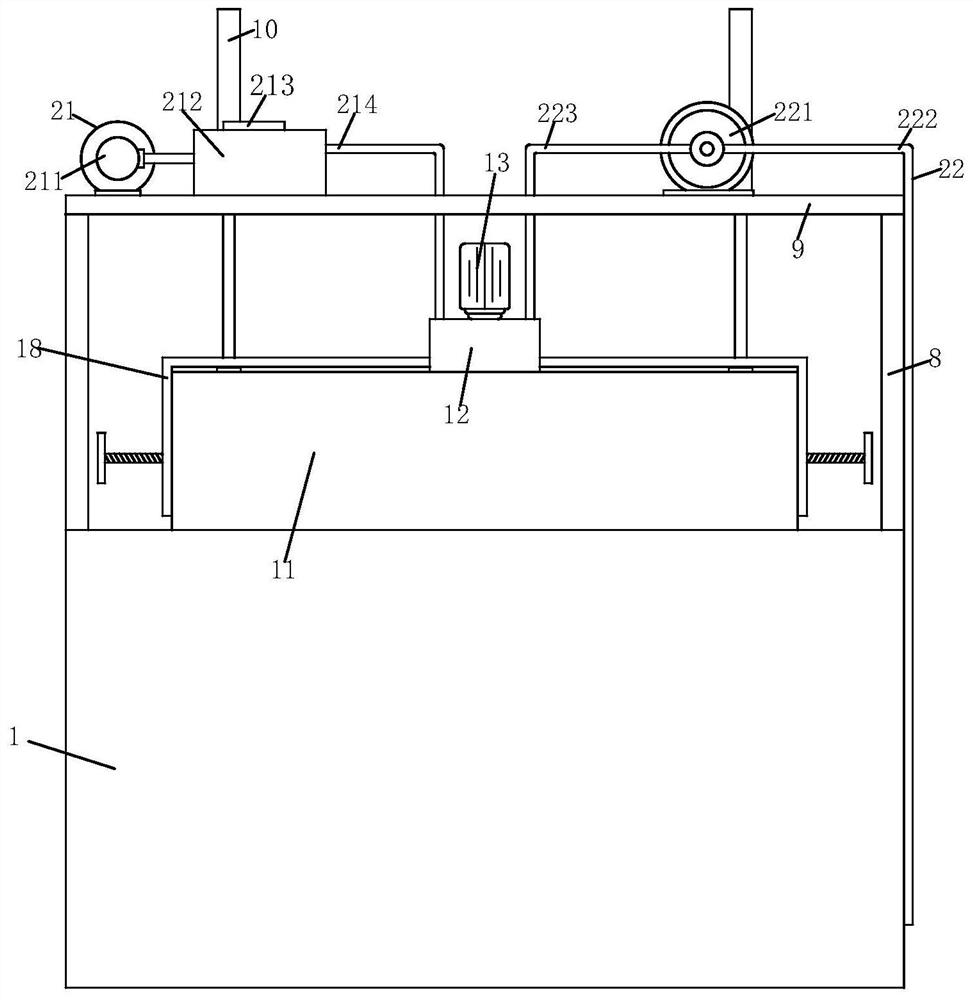

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

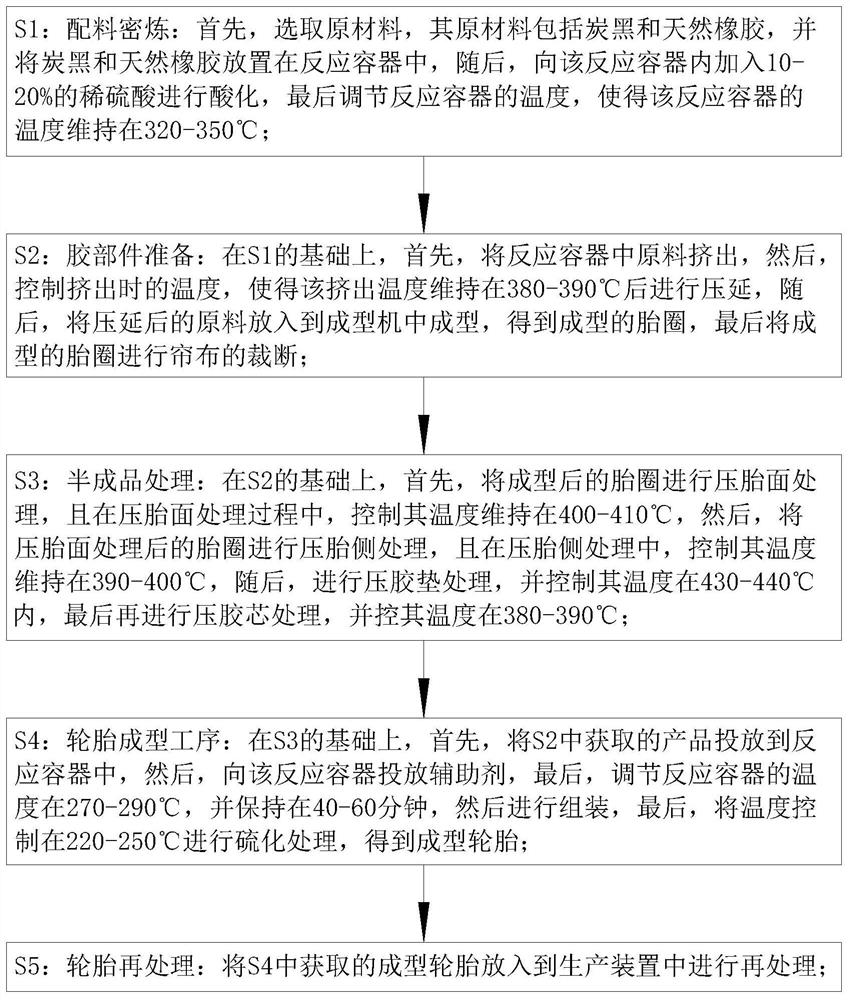

[0034] like Figure 1-Figure 6 Shown, a kind of tire production technique of the present invention, this technique comprises the following steps:

[0035] S1: Mixing ingredients: First, select raw materials, including carbon black and natural rubber, and place carbon black and natural rubber in a reaction vessel, then add 10-20% dilute sulfuric acid into the reaction vessel for acidification , and finally adjust the temperature of the reaction vessel so that the temperature of the reaction vessel is maintained at 320-350°C;

[0036] S2: Rubber parts preparation: On the basis of S1, firstly, extrude the raw materials in the reaction vessel, then control the temperature during extrusion so that the extrusion temperature is maintained at 380-390°C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com