High-entropy alloy welding wire for welding titanium/low-carbon steel in TIG (Tungsten Inert Gas) mode and application

A technology of high-entropy alloy and low-carbon steel, applied in the direction of welding/welding/cutting articles, welding/cutting medium/material, welding medium, etc., can solve the problems of low joint strength and cracking, and achieve good adaptability and welding process Simple, high-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

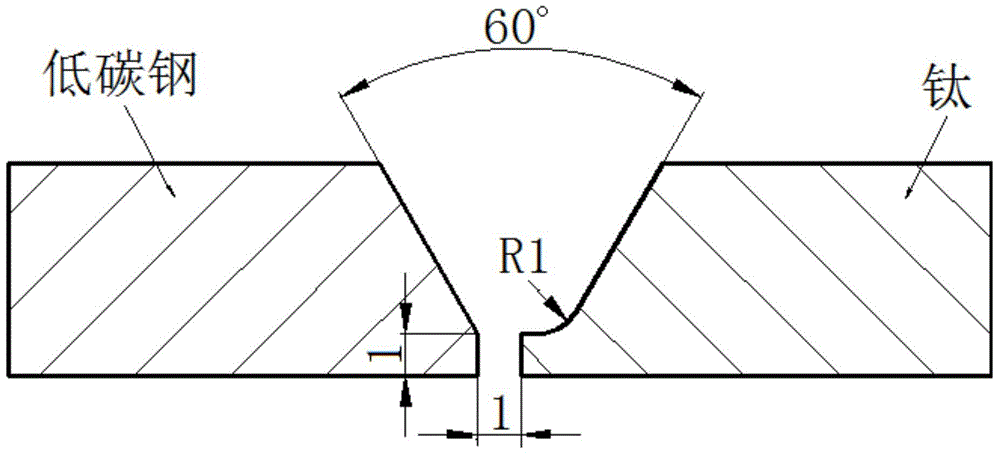

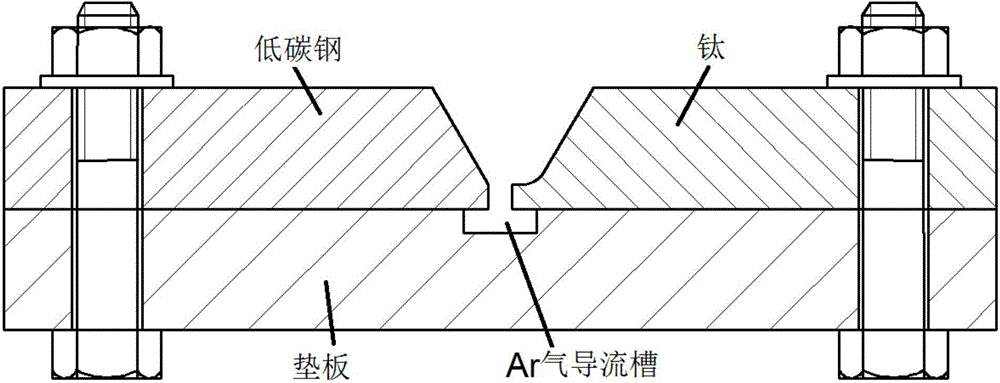

Method used

Image

Examples

Embodiment 1

[0031] According to the total atomic percentage of 100%, the content of each component is selected according to the data of Ti being 5%, Fe being 7%, Ni being 28%, Cu being 25%, and V being 35%, and the diameter of 1.2mm Ti5Fe7Ni28Cu25V35 high-entropy alloy wire. Apply TIG welding to weld 5mm thick TC4 titanium and Q235 low carbon steel. The welding process is as above. 80A, welding speed 50mm / min, Ar gas hysteresis 4s.

[0032] The test found that the weld metal fusion of the obtained joint is good, there is no crack in the fusion zone, the weld structure shows a gradient layered distribution from the center to the fusion line of the base metal on both sides, and the phase structure is composed of a single fcc and bcc, and the welded joint is obtained The tensile strength is 170Mpa.

Embodiment 2

[0034] According to the total atomic percentage of 100%, the content of each component is selected according to the data of Ti being 5%, Fe being 10%, Ni being 27%, Cu being 28%, and V being 30%. 1.4mm Ti5Fe10Ni27Cu28V30 high-entropy alloy welding wire. TIG welding is used to weld TA2 titanium and R20 steel with a thickness of 5mm. The welding process is as described above. The specific welding process parameters are: preheat the base metal to 200°C before welding, the Ar gas flow rate is 10L / min, and the welding current is 75A. Welding speed 55mm / min, Ar gas lag 3s.

[0035] The test found that the welded joint is full, the base metal is not damaged, the weld metal has good fusion, no cracks in the fusion zone, and the structure near the fusion line is dense equiaxed crystals, which then grow in the form of dendrites toward the center of the weld. The phase structure is composed of Composed of single fcc and bcc, the tensile strength of the welded joint is 200Mpa.

Embodiment 3

[0037] According to the total atomic percentage of 100%, the content of each component is selected according to the data of Ti being 5%, Fe being 15%, Ni being 25%, Cu being 23%, and V being 32%. 1.2mm Ti5Fe15Ni25Cu23V32 high-entropy alloy welding wire. TIG welding is used to weld 6mm thick TA2 titanium and 20 steel. The welding process is as described above. The specific welding process parameters are: preheat the base metal to 190°C before welding, the Ar gas flow rate is 11L / min, and the welding current is 80A. Welding speed 55mm / min, Ar gas lag 4s.

[0038] The test found that the weld metal of the obtained joint has good fusion, no cracks in the fusion zone, the weld structure is basically uniform and dense equiaxed crystals and dendrites, and the phase structure is composed of a single fcc and bcc. The tensile strength of the obtained welded joint is 185Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com