Metal-resin composite as well as preparation method thereof and electronic product shell

A technology for electronic products and composites, applied in the field of metal-resin composites and their preparation, can solve problems such as low bonding force, and achieve the effects of strong bonding, high bonding strength and good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

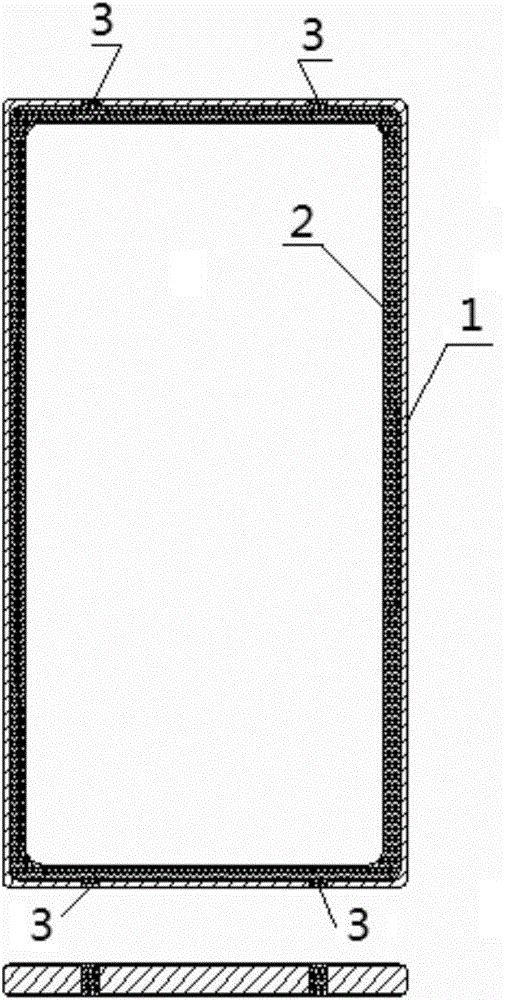

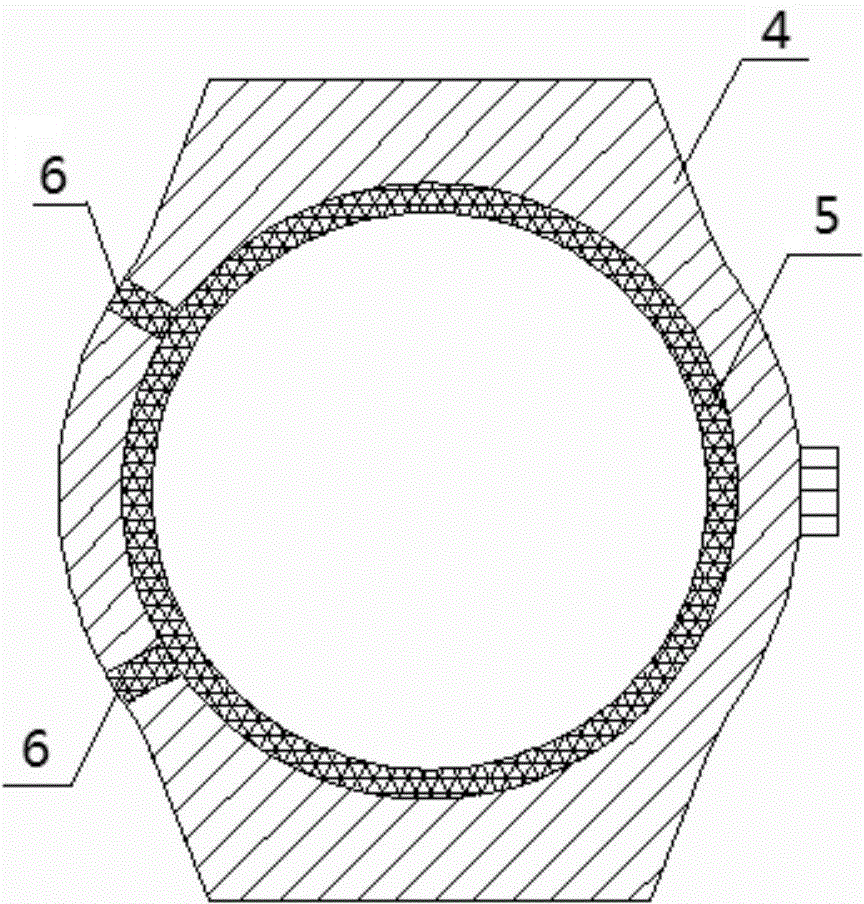

[0035] According to a second aspect of the present invention, the present invention provides a method for preparing a metal-resin composite, the metal being titanium or a titanium alloy, the method comprising an etching step and an injection molding step.

[0036] In the etching step, the metal substrate is immersed in an etching solution to form pits on the surface of the metal substrate to obtain a surface-treated metal substrate, and the etching solution contains at least one alkali metal hydroxide.

[0037] According to the method of the present invention, the etching conditions in the etching step make pits formed on the surface of the obtained surface-treated metal substrate, and the pits are densely distributed on the surface of the substrate. The width of the pits may be 10-100000 nm each, preferably 300-30000 nm each; the depth of the pits may be 10-5000 nm each, preferably 100-3000 nm each.

[0038] According to the method of the present invention, the etching condit...

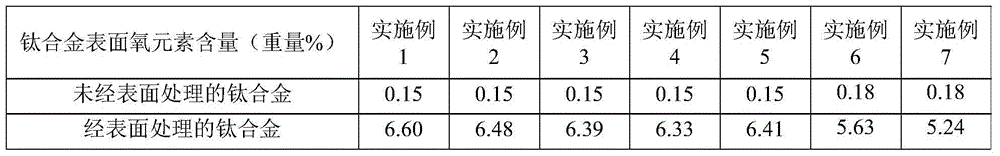

Embodiment 1

[0084] 1. Pretreatment

[0085] Cut a commercially available pure titanium plate with a thickness of 0.8mm into rectangular pieces of 15mm×80mm, put it into a polishing machine for polishing, and then perform degreasing, water washing and drying in sequence.

[0086] 2. Surface treatment

[0087] Put the titanium sheet obtained in step (1) in 500mL etching solution at 25°C for 60 minutes, then take out the titanium sheet, wash it with deionized water for 3 times, then put it in an oven and dry it at 65°C to obtain the surface processed titanium sheet. Wherein, the etching solution is a mixed aqueous solution of sodium hydroxide and boric acid, the concentration of sodium hydroxide is 7 mol / L, and the concentration of boric acid is 0.5 mol / L.

[0088] Observing the surface of the surface-treated titanium sheet with a metallographic microscope, it is determined that densely distributed pits are formed on the surface of the surface-treated titanium sheet, the width of the pits ...

Embodiment 2

[0111] (1) The titanium sheet is pretreated by the same method as in step (1) of Example 1.

[0112] (2) Surface treatment

[0113] Put the titanium sheet obtained in step (1) in 500mL etching solution at 35°C for 30 minutes, then take out the titanium sheet, wash it with deionized water for 3 times, then put it in an oven and dry it at 65°C to obtain the surface processed titanium sheet. Wherein, the etching solution is a mixed aqueous solution of sodium hydroxide and disodium hydrogen phosphate, the concentration of sodium hydroxide is 7 mol / L, and the concentration of disodium hydrogen phosphate is 1 mol / L.

[0114] Observing the surface of the surface-treated titanium sheet with a metallographic microscope, it is determined that densely distributed pits are formed on the surface of the surface-treated titanium sheet, the width of the pits is respectively in the range of 300-30000nm, and the depth is Each in the range of 100-3000 nm. The energy spectrum analysis was carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com