Alloy steel material for high speed train brake disc and preparation method of alloy steel material

A technology of high-speed trains and brake discs, applied in the field of metal materials, can solve the problems of high cost, achieve the effects of improving wear resistance, good comprehensive mechanical properties, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

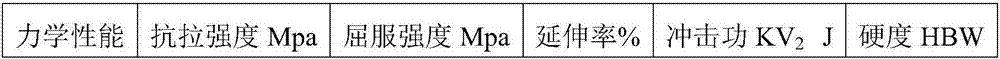

Embodiment 1

[0011] Use a 5000Kg intermediate frequency induction furnace to melt molten steel. The manufacturing process steps are: 1: Put A3 steel scraps into a 300HZ intermediate frequency induction furnace, and at the same time add JSS2# dephosphorization agent developed and produced by the Institute of Metal Research, Chinese Academy of Sciences, and the amount of dephosphorization agent added It accounts for 1.5% of the weight of molten steel and is melted by electricity. 2: With the melting of the charge, keep pounding the charge to avoid bridging the charge. The temperature rises to 1550℃~1560℃, and carbon, ferrochromium, nickel and ferromolybdenum are added. 3: When the temperature reaches 1590 ℃ ~ 1600 ℃, add ferrosilicon and ferromanganese, and take samples to test the components. 4: When the temperature reaches 1640°C to 1650°C, take it out of the furnace and transfer to the LF furnace. 5: In the LF furnace, add limestone to create reducing slag, blow argon, remove inclusions...

Embodiment 2

[0019] Melt molten steel with an 8000Kg medium frequency induction furnace. The manufacturing process steps are: 1: Put A3 steel scraps into a 300HZ medium frequency induction furnace, and add JSS2# dephosphorization agent at the same time. The amount of dephosphorization agent added accounts for 1.5% of the weight of molten steel. Electricity melts. 2: With the melting of the charge, keep pounding the charge to avoid bridging the charge. The temperature rises to 1550℃~1560℃, and carbon, ferrochromium, nickel and ferromolybdenum are added. 3: When the temperature reaches 1590 ℃ ~ 1600 ℃, add ferrosilicon and ferromanganese, and take samples to test the components. 4: When the temperature reaches 1640°C to 1650°C, take it out of the furnace and transfer to the LF furnace. 5: In the LF furnace, add limestone to create reducing slag, blow argon, remove inclusions, deoxidize, desulfurize, and dephosphorize; measure temperature, take samples for testing, add alloy, adjust composi...

Embodiment 3

[0026] Use a 15000Kg intermediate frequency induction furnace to melt molten steel. The manufacturing process steps are: 1: put A3 steel scraps into a 300HZ intermediate frequency induction furnace, and add JSS2# dephosphorization agent at the same time. The amount of dephosphorization agent added accounts for 1.5% of the weight of molten steel. Electricity melts. 2: With the melting of the charge, keep pounding the charge to avoid bridging the charge. The temperature rises to 1550℃~1560℃, and carbon, ferrochromium, nickel and ferromolybdenum are added. 3: When the temperature reaches 1590 ℃ ~ 1600 ℃, add ferrosilicon and ferromanganese, and take samples to test the components. 4: When the temperature reaches 1640°C to 1650°C, take it out of the furnace and transfer to the LF furnace. 5: In the LF furnace, add limestone to create reducing slag, blow argon, remove inclusions, deoxidize, desulfurize, and dephosphorize; measure temperature, take samples for testing, add alloy, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com