Single-phase spinel type high-entropy oxides as well as preparation method and application thereof

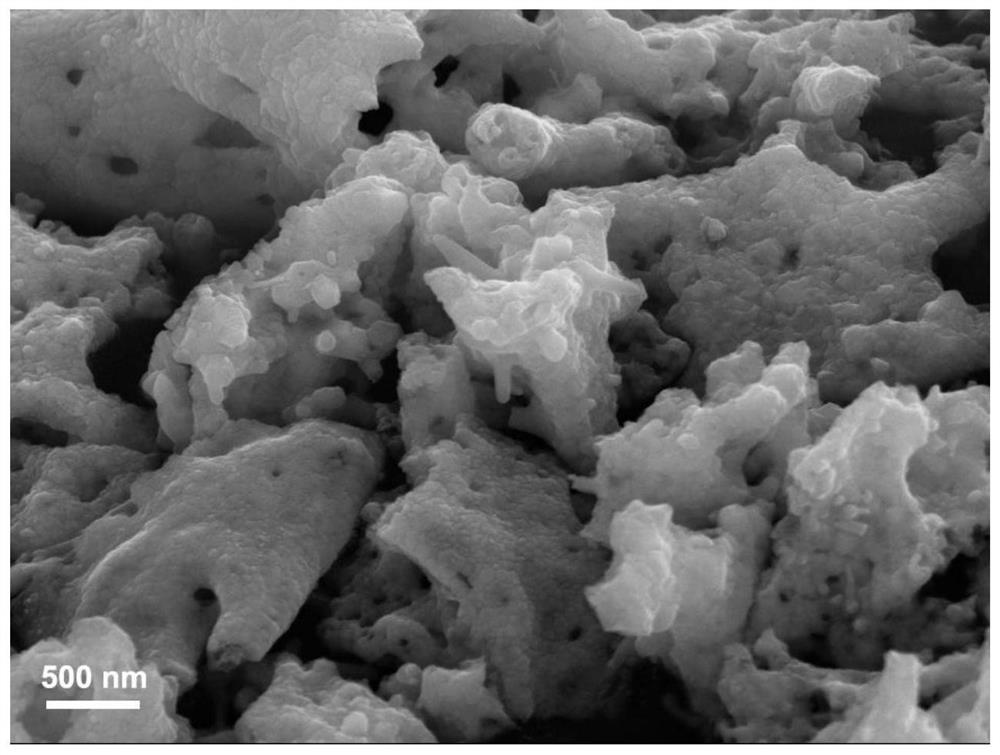

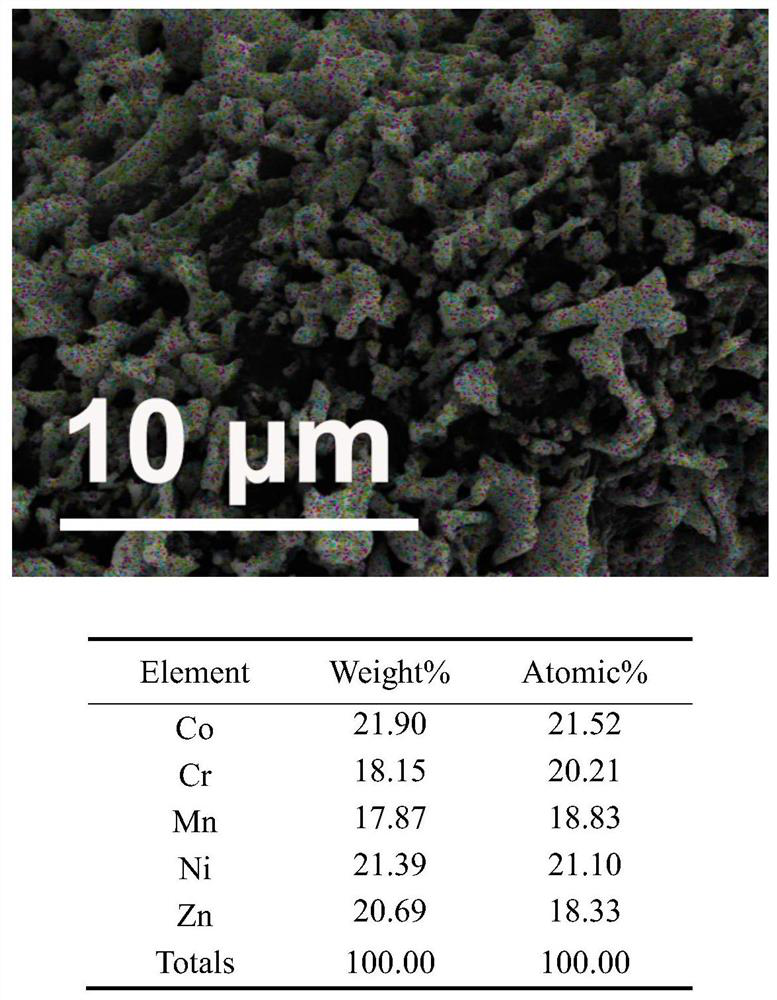

A spinel-type and oxide technology, applied in chemical instruments and methods, nickel compounds, cobalt compounds, etc., can solve the limitations of application range, limited composition range, and less exploration in the application field of spinel-type high-entropy oxides To achieve the effect of expanding the range of ingredients, uniform distribution of elements, and fine particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation (CoCrFeMnNi) 3 o 4 Powder material:

[0033] (1) Weigh Co(NO 3 ) 2 ·6H 2 O, Cr(NO 3 ) 3 9H 2 O, Fe(NO 3 ) 3 9H 2 O, Mn(NO 3 ) 2 4H 2 O, Ni(NO 3 ) 2 ·6H 2 Each 5mmol of 0 five kinds of nitrates; Take glycine 2.5g; Five kinds of nitrates and glycine are dissolved in 10ml deionized water, stir 3h at room temperature, obtain the mixed sol containing five kinds of nitrates;

[0034] (2) Transfer the above mixed sol to a blast drying oven at 90°C for 2 hours to obtain a viscous gel;

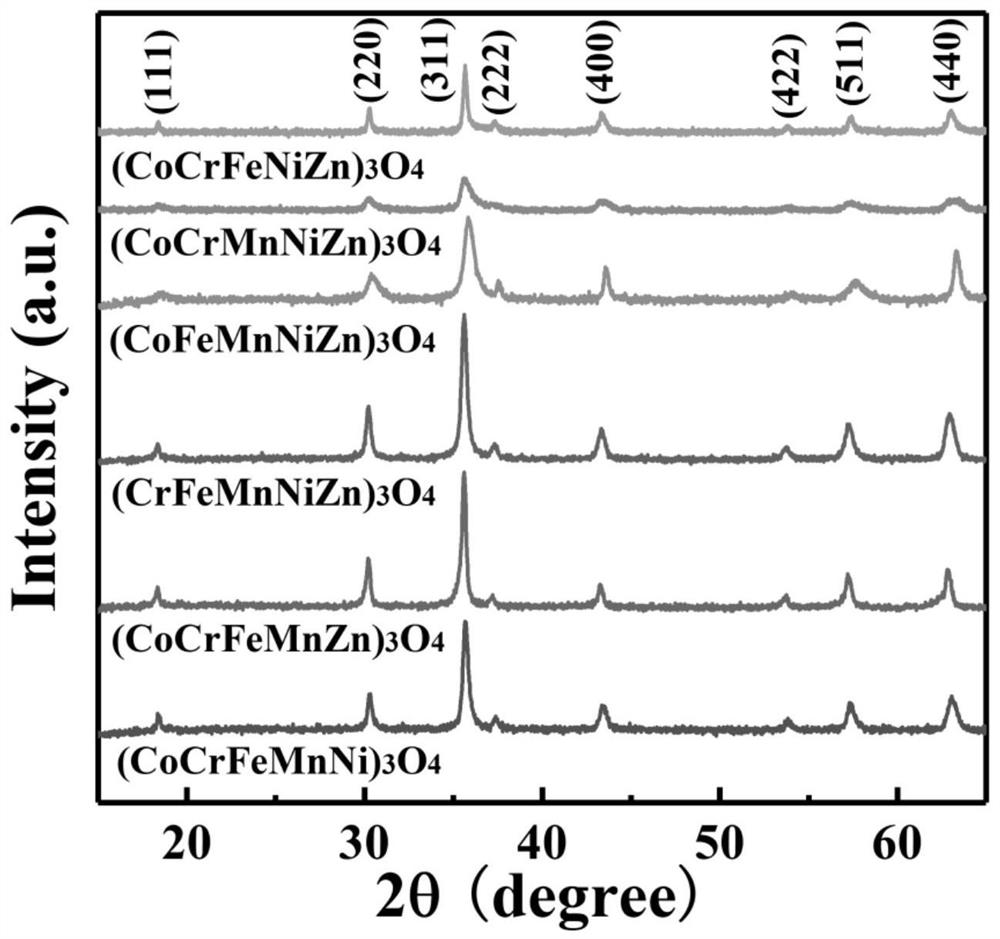

[0035] (3) Put the viscous gel into a crucible, place the crucible in a muffle furnace and raise the temperature to 450°C at a rate of 5°C / min, then calcinate for 30min, air cool to room temperature, and grind to obtain the ( CoCrFeMnNi) 3 o 4 Powder material. Such as figure 1 As shown, the XRD spectrum shows that the synthesized (CoCrFeMnNi) 3 o 4 The powder material belongs to the face-centered cubic (fcc) spinel structure and has the Fd-3m(227) space group. ...

Embodiment 2

[0042] Preparation (CrFeMnNiZn) 3 o 4 Powder material:

[0043] (1) Weigh Cr(NO 3 ) 3 9H 2 O, Fe(NO 3 ) 3 9H 2 O, Mn(NO 3 ) 2 4H 2 O, Ni(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 ·6H 2 Each 5mmol of 0 five kinds of nitrates; Take glycine 2.5g; Five kinds of nitrates and glycine are dissolved in 5ml deionized water, stir 3h at room temperature, obtain the mixed sol that contains five kinds of nitrates;

[0044] (2) Transfer the above mixed sol to a blast drying oven at 70°C for 4 hours to obtain a viscous gel;

[0045] (3) Put the viscous gel into a crucible, place the crucible in a muffle furnace and heat up to 550°C at a heating rate of 5°C / min, then calcinate for 30min, air cool to room temperature, and grind to obtain the ( CrFeMnNiZn) 3 o 4 Powder material. Such as figure 1 As shown, the XRD spectrum shows that the synthesized (CrFeMnNiZn) 3 o 4 The powder material belongs to the face-centered cubic (fcc) spinel structure and has the Fd-3m(227) space group. No ...

Embodiment 3

[0052] Preparation (CoFeMnNiZn) 3 o 4 Powder material:

[0053] (1) Weigh Co(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, Mn(NO 3 ) 2 4H 2 O, Ni(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 ·6H 2 Each 5mmol of 0 five kinds of nitrates; Take glycine 2.5g; Five kinds of nitrates and glycine are dissolved in 5ml deionized water, stir 3h at room temperature, obtain the mixed sol that contains five kinds of nitrates;

[0054] (2) Transfer the above mixed sol to a blast drying oven at 80°C for 3 hours to obtain a viscous gel;

[0055] (3) Put the viscous gel into a crucible, place the crucible in a muffle furnace and raise the temperature to 650°C at a rate of 5°C / min, then calcinate for 30min, air cool to room temperature, and grind to obtain the ( CoFeMnNiZn) 3 o 4 Powder material. Such as figure 1 As shown, the XRD spectrum shows that the synthesized (CoFeMnNiZn) 3 o 4 The powder material belongs to the face-centered cubic (fcc) spinel structure and has the Fd-3m(227) space grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com