A kind of high entropy alloy for hydrogen evolution catalysis and preparation method thereof

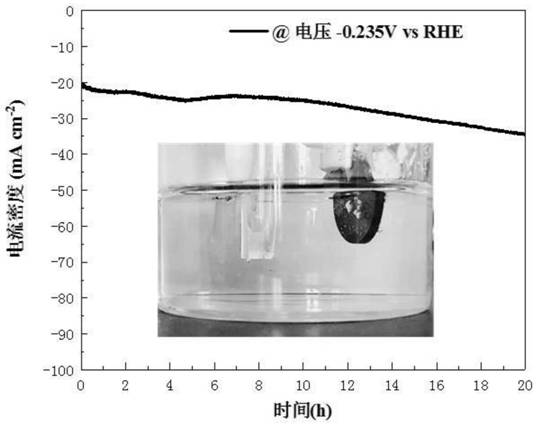

A high-entropy alloy and hydrogen evolution technology, which is applied in the field of electrocatalytic hydrogen evolution reaction catalyst preparation, and achieves the effects of stable catalytic performance, low price and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

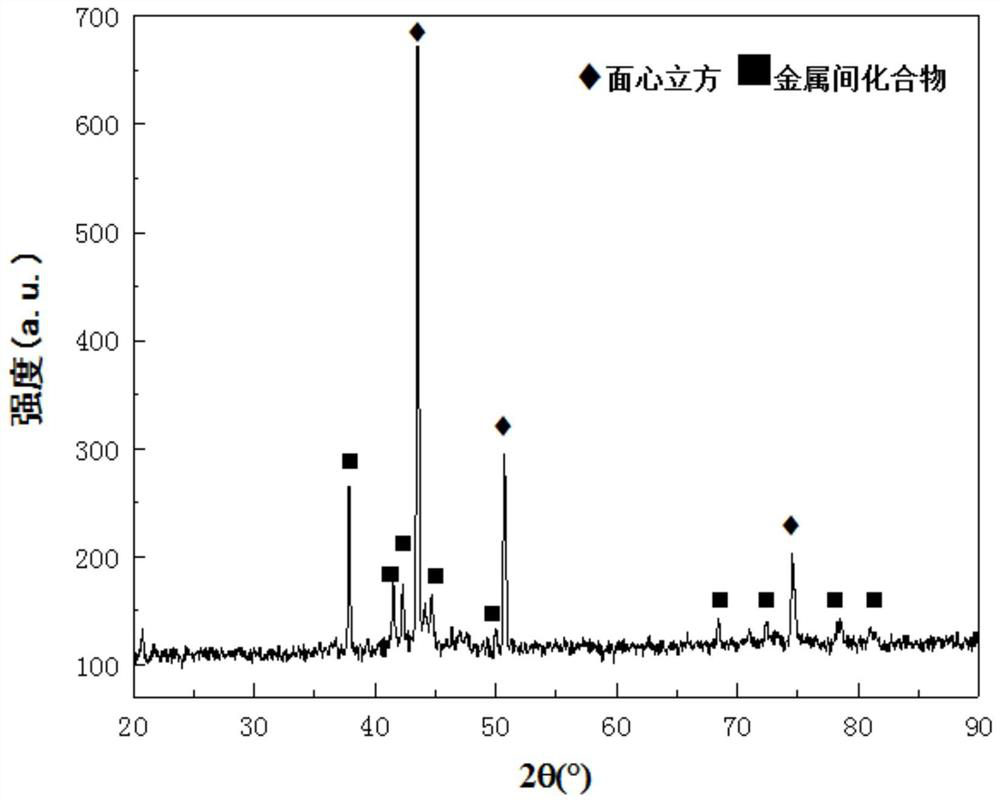

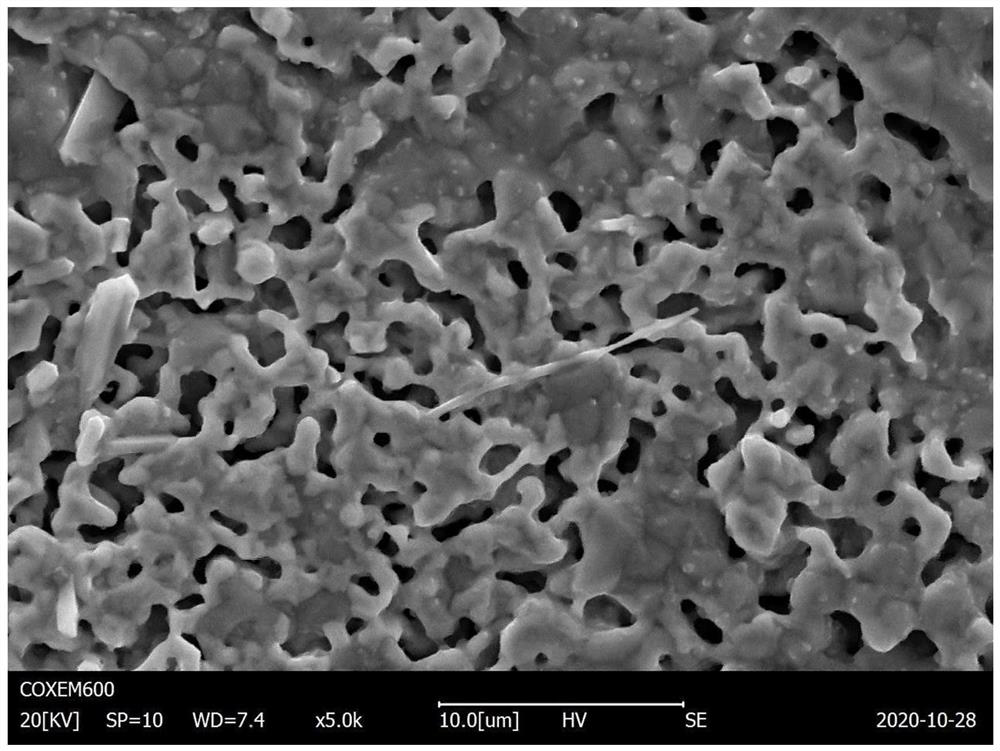

Embodiment 1

[0037] This example gives a high-entropy alloy for hydrogen evolution catalysis. The high-entropy alloy is prepared from iron, cobalt, nickel, tungsten, and molybdenum as metal raw materials, and the atomic number of iron, tungsten, and molybdenum in the metal raw materials is The ratio is 1:1:1, and the atomic number ratio of cobalt and nickel is 1:1, wherein the iron atomic number accounts for 9.5% of the total atomic number of the metal raw material, that is, the percentage of each atomic number in the metal raw material in this example is : Iron 9.5%, Cobalt 35.75%, Nickel 35.75%, Tungsten 9.5%, Molybdenum 9.5%.

[0038] In addition, the preparation method of a high-entropy alloy for hydrogen evolution catalysis given in this example includes the following steps:

[0039] S1. Weigh cobalt powder, tungsten powder, iron powder, nickel powder and molybdenum powder according to the preparation ratio of the metal raw materials of the high-entropy alloy (iron 9.5%, cobalt 35.75%...

Embodiment 2

[0046] In order to better reflect the effect of heat treatment temperature on the hydrogen evolution performance of high-entropy alloys, in this example, only the heat treatment process is changed compared with Example 1 while other process parameters are kept constant. The heat treatment process parameters of this example are: the pressureless sintering is to raise the temperature to 750° C. at a heating rate of 20° C. / min, and keep the temperature for 60 minutes.

[0047] At room temperature, Shanghai Chenhua CHI 660E electrochemical workstation was used to perform electrochemical tests on the high-entropy alloy prepared in this example as an electrode (the same test method as in Example 1).

[0048] From the above tests, the electrocatalytic performance of the high-entropy alloy prepared in this example: at a current density of 50mA / cm 2 , the overpotential is 218mV.

Embodiment 3

[0050] In order to better reflect the effect of heat treatment temperature on the hydrogen evolution performance of high-entropy alloys, in this example, only the heat treatment process is changed compared with Example 1 while other process parameters are kept constant. The heat treatment process parameters of this example are as follows: the pressureless sintering is to raise the temperature to 950° C. at a heating rate of 20° C. / min and keep the temperature for 60 minutes.

[0051] At room temperature, Shanghai Chenhua CHI 660E electrochemical workstation was used to perform electrochemical tests on the high-entropy alloy prepared in this example as an electrode (the same test method as in Example 1).

[0052] From the above tests, the electrocatalytic performance of the high-entropy alloy prepared in this example: at a current density of 10mA / cm 2 and 50mA / cm 2 , the overpotentials were 52mV and 74mV, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com