A single crystal shell of au@ni 3 the s 2 Nanoparticles with core-shell structure and preparation method thereof

A nanoparticle, core-shell structure technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve problems such as poor single crystallinity of the shell layer and complex process system, and achieve good stability. Properties and physical and chemical properties, simple and easy operation process, mild reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

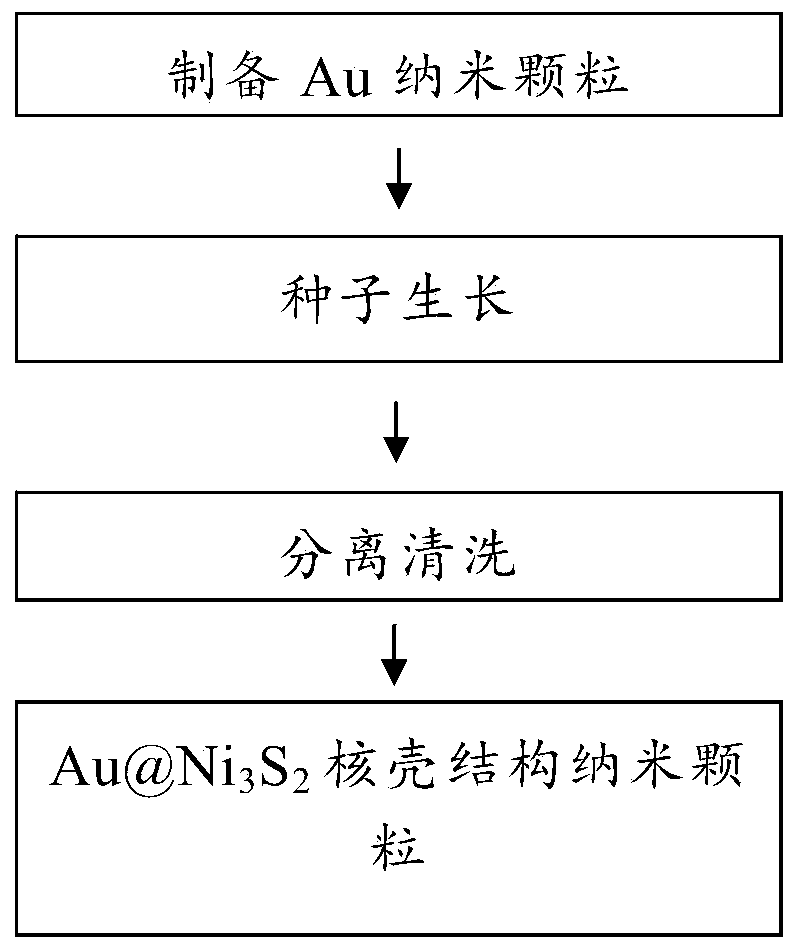

[0039] The present invention prepares Au@Ni 3 S 2 A method for nanoparticles of a core-shell structure, the method comprising the following steps:

[0040] Step 1: Add 0.3g nickel acetylacetonate into 16ml oleylamine, heat up to 100°C, mix and stir until dissolved;

[0041] Step 2: Add the toluene solution of chloroauric acid (dissolve 0.03g of chloroauric acid in 3ml of toluene) into the oleylamine solution of step 1, feed argon gas (flow rate 30ml / min), and react at 100°C for 60min, namely Obtain an oleylamine solution of nickel acetylacetonate containing Au nanoparticles;

[0042] Step 3: Warm up the oleylamine solution in Step 2 to 180°C, add 0.78ml of 1-dodecanethiol, keep the solution temperature at 180°C for 120 minutes to prepare the first reaction solution;

[0043] Step 4: After cooling the first reaction solution prepared in Step 3 to room temperature, centrifuge at a rotational speed of 9000 rpm to 12000 rpm for 5 min to 10 min to obtain the first product;

[0...

Embodiment 2

[0067] The present invention prepares Au@Ni 3 S 2 A method for nanoparticles of a core-shell structure, the method comprising the following steps:

[0068] Step 1: Add 0.3g nickel acetylacetonate into 16ml oleylamine, heat up to 100°C, mix and stir until dissolved;

[0069] Step 2: Add the toluene solution of chloroauric acid (dissolve 0.05g chloroauric acid in 5ml toluene) into the oleylamine solution in step 1, feed argon gas (flow rate 30ml / min), and react at 100°C for 60min, namely Obtain an oleylamine solution of nickel acetylacetonate containing Au nanoparticles;

[0070] Step 3: Warm up the oleylamine solution in Step 2 to 180°C, add 0.78ml of 1-dodecanethiol, keep the solution temperature at 180°C for 180min to prepare the first reaction solution;

[0071] Step 4: After cooling the first reaction solution prepared in Step 3 to room temperature, centrifuge at a rotational speed of 9000 rpm to 12000 rpm for 5 min to 10 min to obtain the first product;

[0072] Step 5: ...

Embodiment 3

[0076] The present invention prepares Au@Ni 3 S 2 A method for nanoparticles of a core-shell structure, the method comprising the following steps:

[0077] Step 1: Add 0.5g nickel acetylacetonate into 20ml oleylamine, heat up to 100°C, mix and stir until dissolved;

[0078] Step 2: Add the toluene solution of chloroauric acid (dissolve 0.03g of chloroauric acid in 3ml of toluene) into the oleylamine solution of step 1, feed argon gas (flow rate 30ml / min), and react at 100°C for 60min, namely Obtain an oleylamine solution of nickel acetylacetonate containing Au nanoparticles;

[0079] Step 3: Warm up the oleylamine solution in Step 2 to 180°C, add 1ml of 1-dodecanethiol, keep the solution temperature at 180°C for 120 minutes to prepare the first reaction solution;

[0080] Step 4: After cooling the first reaction solution prepared in Step 3 to room temperature, centrifuge at a rotational speed of 9000 rpm to 12000 rpm for 5 min to 10 min to obtain the first product;

[0081...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com