Metal phase molybdenum disulfide-based in-plane heterostructure, self-supporting electrode, preparation method and application

A self-supporting electrode, molybdenum disulfide technology, applied in the field of materials, can solve problems such as poor catalytic activity, and achieve the effects of short preparation cycle, broad market prospects, and excellent hydrogen evolution catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

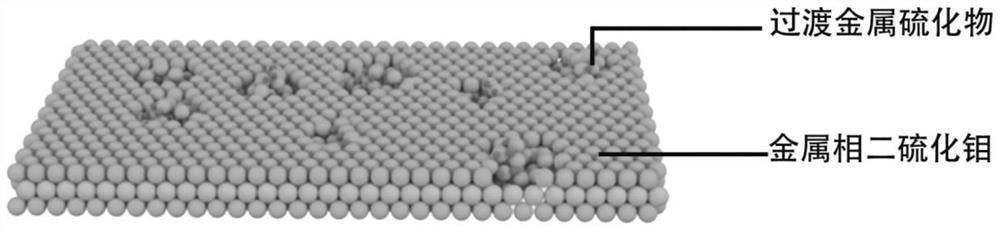

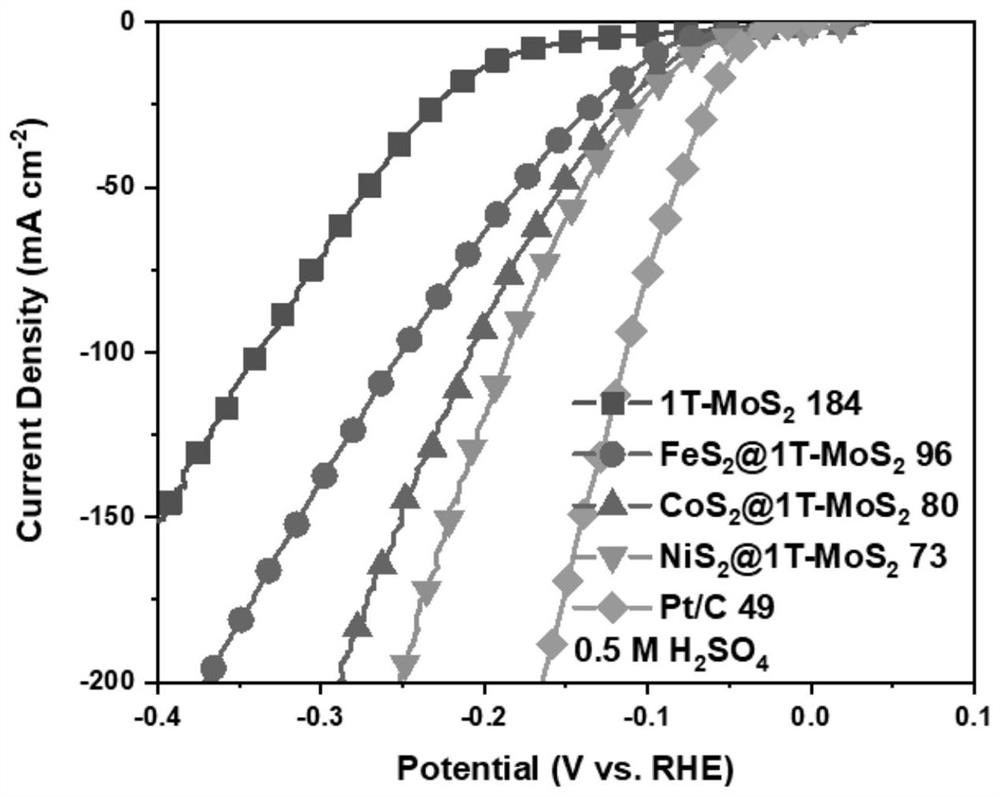

[0030] A metal-phase molybdenum disulfide basal in-plane heterostructure (metal-phase molybdenum disulfide / nickel sulfide in-plane heterostructure), comprising:

[0031] The metal-phase molybdenum disulfide basal in-plane heterostructure is mainly composed of nano-sheets of metal-phase molybdenum disulfide, and the clusters of transition metal sulfides are embedded in the lamellae of metal-phase molybdenum disulfide, namely transition metal sulfides. The clusters replaced part of the molybdenum disulfide clusters in the metallic phase molybdenum disulfide sheets, and in the obtained heterostructure, the transition metal sulfide clusters and the metallic phase molybdenum disulfide were located in the same plane.

[0032] A method for preparing a metal-phase molybdenum disulfide base in-plane heterostructure (metal-phase molybdenum disulfide / nickel sulfide in-plane heterostructure), comprising the following steps:

[0033] Step 1: Weigh 0.1 g of nickel molybdate and 0.8 g of thi...

Embodiment 2

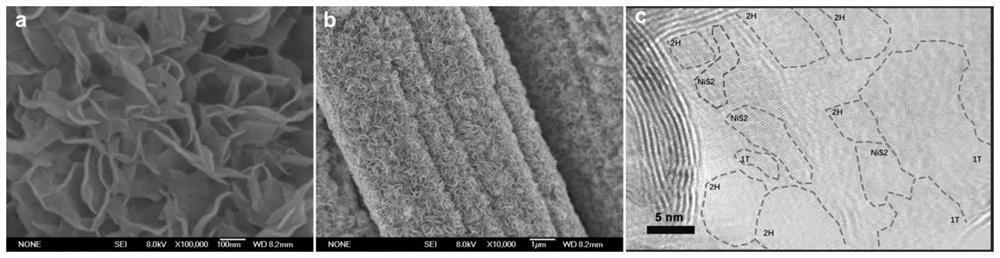

[0037] A self-supporting electrode of a metal phase molybdenum disulfide base in-plane heterostructure (metal phase molybdenum disulfide / nickel sulfide in-plane heterostructure), the self-supporting electrode is specifically grown on a conductive substrate, and is composed of a metal phase Nanosheet array structure formation of molybdenum disulfide-based in-plane heterostructures.

[0038] A preparation method of a self-supporting electrode, comprising the following steps:

[0039] Step 1: Weigh 0.1 g of nickel molybdate and 0.8 g of thiourea into 20 ml of water, and mix well to obtain a solution;

[0040] The second step: transfer the solution into a 50ml reactor, add carbon cloth as a conductive substrate, seal the reactor, and place it in an oven for hydrothermal reaction at 200°C for 24 hours;

[0041] The third step: after the hydrothermal reaction is completed, it is naturally cooled to room temperature, the obtained conductive substrate is taken out, and vacuum dried t...

Embodiment 3

[0043] A self-supporting electrode of a metal phase molybdenum disulfide base in-plane heterostructure (metal phase molybdenum disulfide / nickel sulfide in-plane heterostructure), the self-supporting electrode is specifically grown on a conductive substrate, and is composed of a metal phase Nanosheet array structure formation of molybdenum disulfide-based in-plane heterostructures.

[0044] A preparation method of a self-supporting electrode, comprising the following steps:

[0045] The first step: take nickel molybdate and thiourea by weighing and add them to 20ml of water, and mix well to obtain a mixed solution where nickel molybdate is 0.012 mmol·L-1 and thiourea is 0.24 mmol·L-1;

[0046] The second step: transfer the solution into a 50ml reactor, add carbon cloth as a conductive substrate, seal the reactor, and place it in an oven for hydrothermal reaction at 200°C for 24 hours;

[0047] The third step: after the hydrothermal reaction is completed, it is naturally cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com