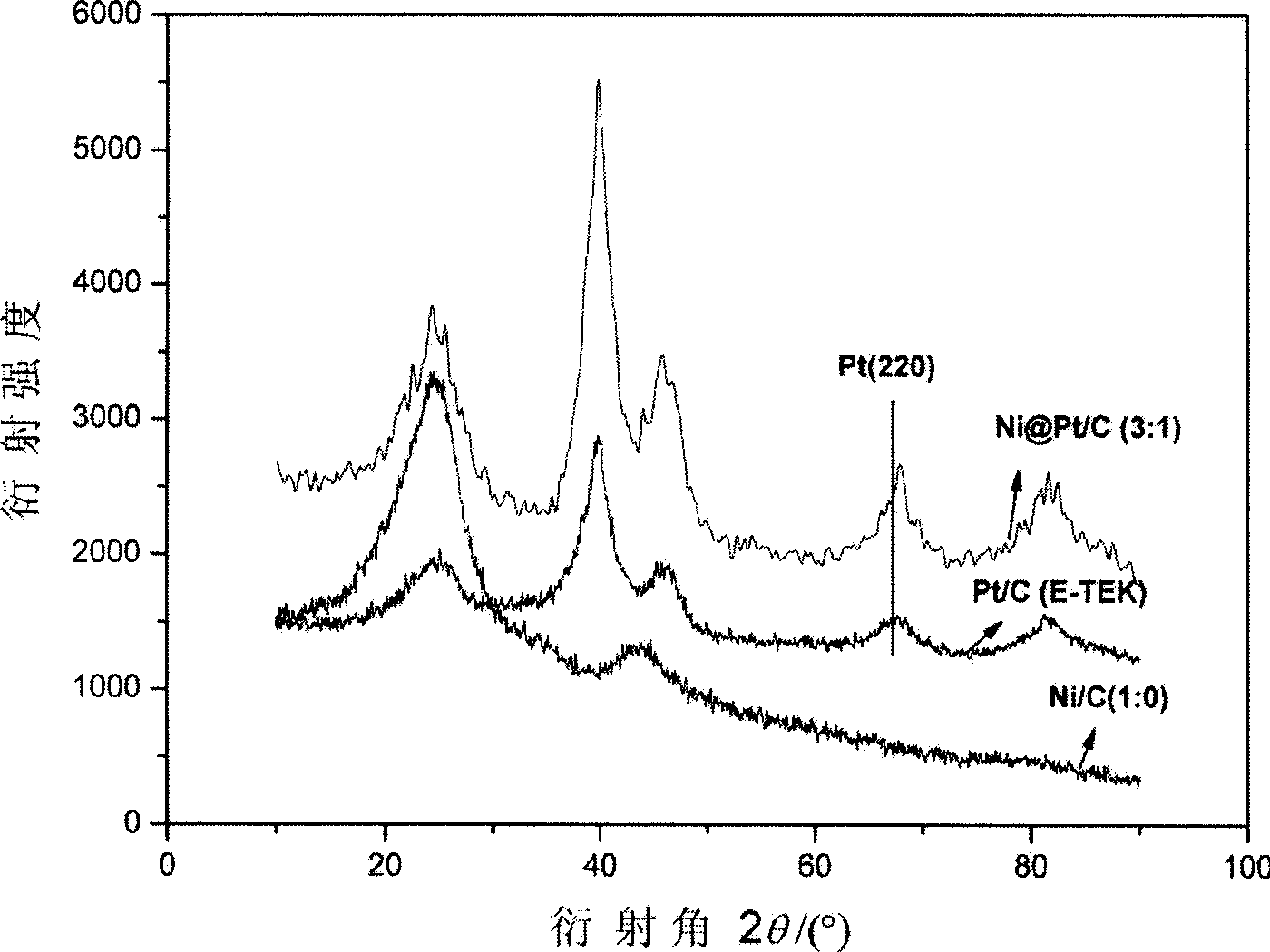

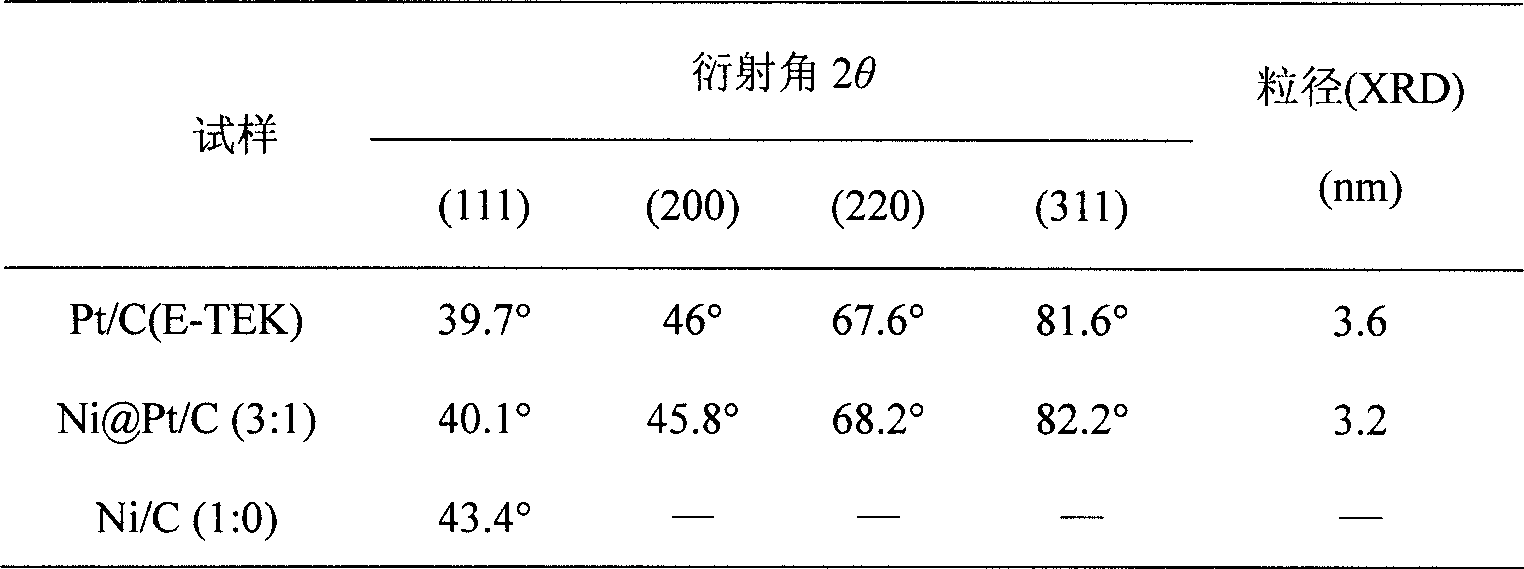

Preparation method of carbon supported core-shell Ni-Pt particles for direct methanol fuel cells

A methanol fuel cell and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. It is difficult to large-scale commercial production, and the size of Pt particles is not uniform, so as to reduce the dosage, improve the electrochemical performance, and improve the catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0018] (1) Take 40mg of XC-72 treated with sodium borohydride, add 20ml of deionized water and 20ml of isopropanol in turn, and sonicate for 10min.

[0019] (2) Under magnetic stirring at 60°C, add 0.1mol / L and 1.5ml of Ni(Ac) in sequence 2 , 0.1mol / L, 1.0ml of sodium citrate and 10mg of CTAB.

[0020] (3) Stir and heat up to 80°C, slowly add 0.1mol / L, 4.5ml of sodium hypophosphite, and react for 1 hour. Cool to room temperature, centrifuge, and wash thoroughly with distilled water and acetone four times to remove excess sodium hypophosphite. The obtained catalyst is denoted as Ni@Pt / C(1:0).

[0021] According to the cyclic voltammetry test, the carbon-supported core-shell platinum catalyst material Ni@Pt / C(1:0) for DMFC of the present invention has almost no catalytic activity for hydrogen oxidation, that is, it exhibits the properties of pure Ni.

specific Embodiment 2

[0022] (1) Take 40mg of XC-72 treated with sodium borohydride, add 20ml of deionized water and 20ml of isopropanol in turn, and sonicate for 10min.

[0023] (2) Under magnetic stirring at 60°C, add 0.038mol / L and 0.6ml of H 2 PtCl 6 , 0.1mol / L, 1.0ml of sodium citrate and 10mg of CTAB.

[0024] (3) Stir and heat up to 80°C, slowly add 0.1mol / L, 4.5ml of sodium hypophosphite, and react for 1 hour. Cool to room temperature, centrifuge, and wash thoroughly with distilled water and acetone four times to remove excess sodium hypophosphite. The obtained catalyst is denoted as Ni@Pt / C(0:1).

[0025] Through the test of cyclic voltammetry, the carbon-supported core-shell platinum catalyst material Ni@Pt / C(0:1) for DMFC of the present invention hardly exhibits electrochemical catalytic activity, and only exhibits the capacitive performance of XC-72, indicating that Pt is generated by a reaction of replacing Ni.

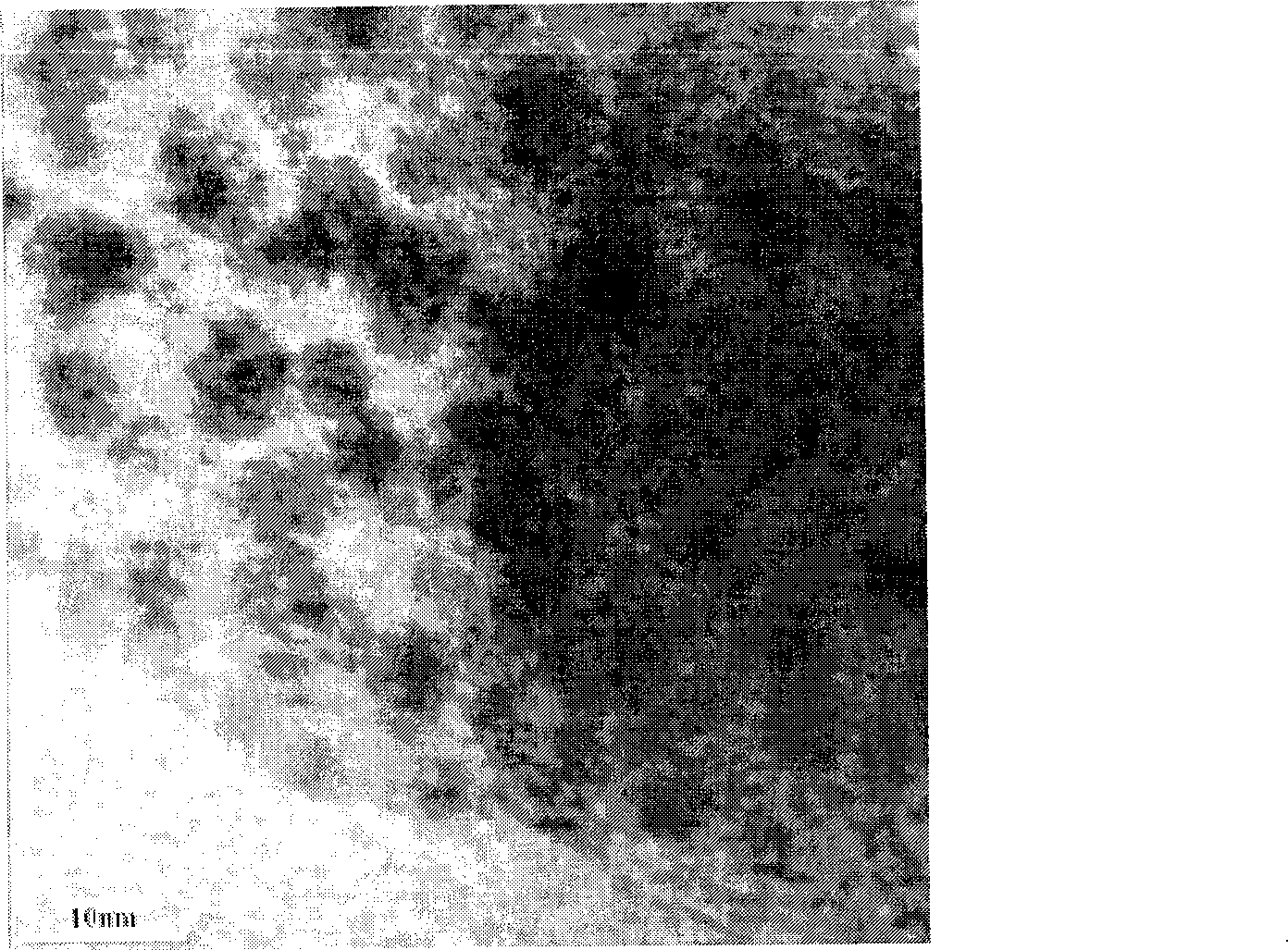

specific Embodiment 3

[0026] (1) Take 40mg of XC-72 treated with sodium borohydride, add 20ml of deionized water and 20ml of isopropanol in turn, and sonicate for 10min.

[0027] (2) Under magnetic stirring at 60°C, add 0.1mol / L and 1.5ml of Ni(Ac) in sequence 2, 0.1mol / L, 1.5ml of sodium citrate and 10mg of CTAB.

[0028] (3) Stir and heat up to 95°C, slowly add 0.1mol / L, 7.5ml sodium hypophosphite, and react for 5 hours. Cool to room temperature, centrifuge, and wash thoroughly with distilled water and acetone four times to remove excess sodium hypophosphite.

[0029] (4) Disperse the centrifuged product with water and isopropanol, add 5 mg of CTAB, heat up to 60° C., and stir for 10 min.

[0030] (5) Adjust the pH value to 5-6 with 0.2mol / L HCl.

[0031] (6) Add 0.038mol / L, 0.35ml of H 2 PtCl 6 The solution was replaced, and the reaction time was 5h. Cool to room temperature, centrifuge, wash with acetone, and dry under vacuum at 80°C for 12h. The obtained catalyst is denoted as Ni@Pt / C(5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com