Preparation method of integral type catalyst with low content of noble metal and application thereof

A monolithic catalyst, precious metal technology, applied in metal/metal oxide/metal hydroxide catalysts, catalyst supports, chemical instruments and methods, etc., can solve the problem of few catalysts, achieve uniform distribution and simplify operation procedures. Effect

Active Publication Date: 2010-06-16

FOSHAN SHUNDE KINGLEI ENVIRONMENT & TECH CO LTD

View PDF0 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, at present, electroless precious metal plating is mainly used for surface modification of materials, and is rarely used for the preparation of catalysts, and the precious metal content used in electroless plating of precious metals such as Pt and Pd is very high, and the concentration of precious metals in the plating solution is generally greater than 2g / L. The materials are mainly dense and non-porous flat materials (such as ceramic sheets, glass sheets and stainless steel sheets, etc.), and the regular and porous cordierite honeycomb ceramics are rarely used as substrates.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

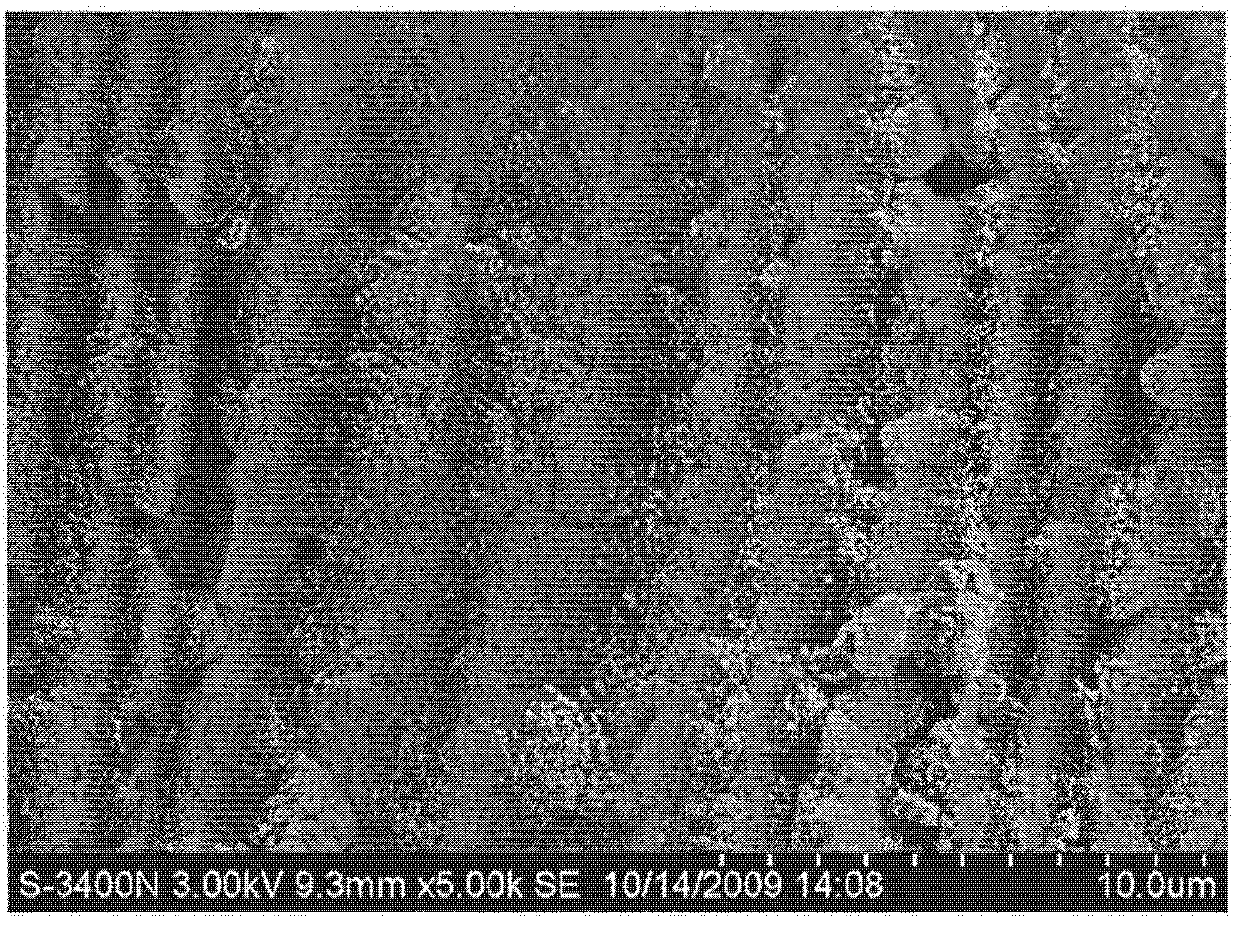

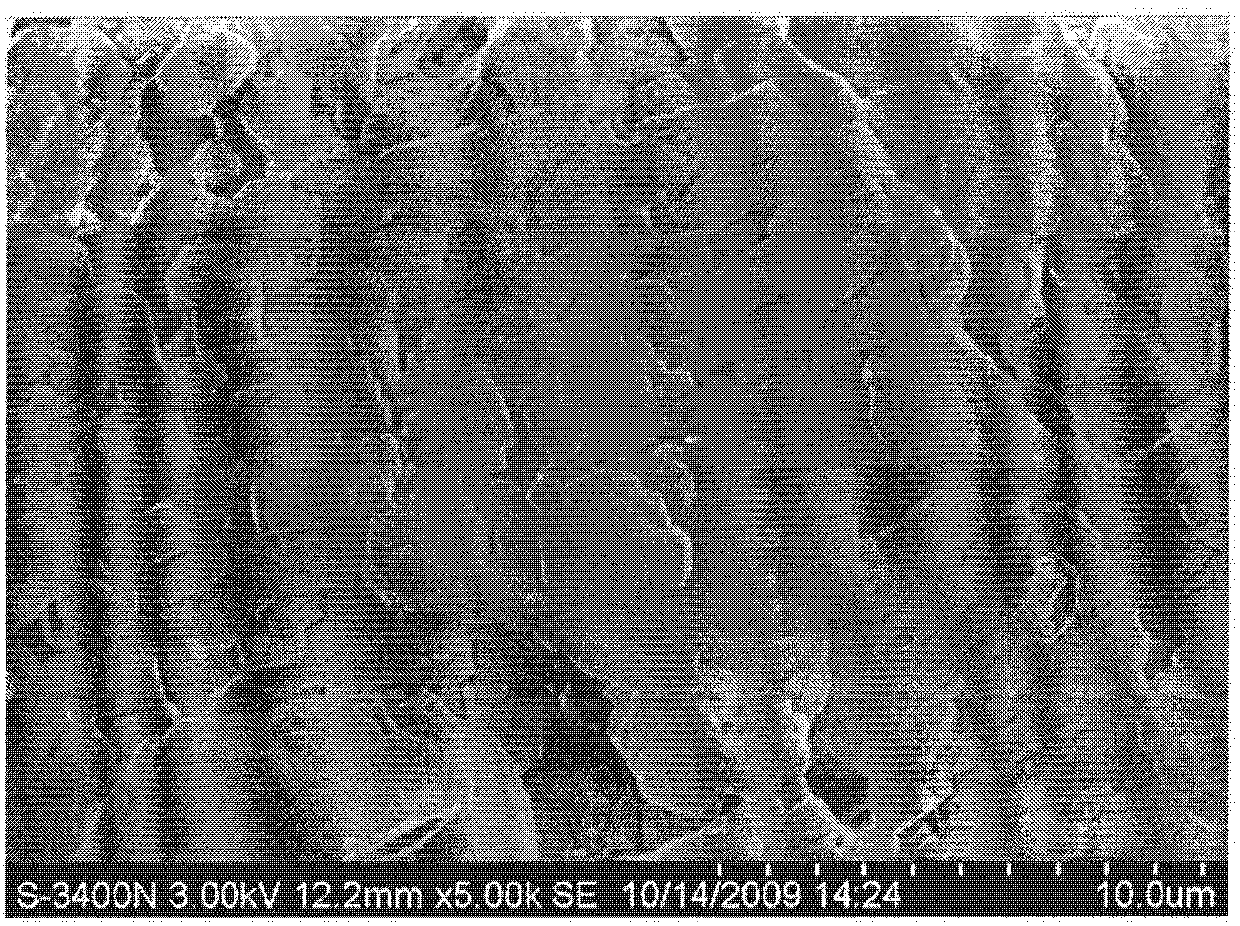

The invention discloses a preparation method of an integral type catalyst with low content of noble metal and an application thereof. In the invention, the preparation method comprises the following steps of: adopting a chemical plating method, utilizing hydrazine or sodium hypophosphite as a reducer, generating an oxidation-reduction reaction with palladium chloride or chloroplatinic acid in a plating bath and depositing metallic Pd and / or Pt on the surface of a cordierite honeycomb ceramic pore canal directly under the autocatalytic action of Pd or Pt simultaneously so as to obtain a load-type integral type catalyst with low content of the noble metal of the Pt and / or the Pd; the integral type catalyst with the noble metal, which is prepared by the invention, is applied to the purifying treatment of the catalytic combustion of toluene; though the content of the noble metal in the integral type catalyst prepared by the invention is only 0.12-0.60wt%, the conversion rate of the toluene reaches 99% at the lower temperature of 186-244 DEG C when the integral type catalyst is used for the purifying treatment of the catalytic combustion of the toluene, and the concentration of the toluene is lowered below 40mg / m<3>; and the invention is the integral type catalyst for treating VOCs (volatile organic chemicals) by low-temperature catalytic combustion, which has lower cost, simple preparation and obvious purifying effect.

Description

technical field The invention relates to a method for preparing monolithic catalysts by loading low-content Pt and Pd precious metals on cordierite honeycomb ceramics and its application. Background technique Because of its regular pore structure, good thermal stability, low price, and convenient processing and molding, cordierite honeycomb ceramics are currently one of the main skeleton substrates for supported noble metal monolithic catalysts used in the catalytic combustion and purification of VOCs (such as toluene, etc.) . Compared with supported noble metal granular catalysts, this type of monolithic catalyst has a large number of hollow pores on the macro scale due to its unique skeleton structure, and there is no radial body transmission of fluid between parallel pores, so the pressure drop is 2~ lower than that of granular catalysts. 3 orders of magnitude, good heat and mass transfer performance, and simple industrial scale-up. At present, the impregnation method i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J32/00B01J35/04B01J23/42B01J23/44B01D53/86B01D53/72

Inventor 李永峰刘祖超余林麦荣坚胡光辉孙明潘霁飞

Owner FOSHAN SHUNDE KINGLEI ENVIRONMENT & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com