Preparation method of cellulose fabric having antibacterial and inflaming-retarding functions

A cellulose fabric and functional technology, applied in the field of preparation of cellulose fabrics, can solve the problems of easy adsorption of fabrics, affecting human health, breeding bacteria, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Chitosan phosphate is according to following parts by weight:

[0030] Chitosan 15 parts

[0031] 20 parts of urea

[0032] Phosphoric acid 90 parts

[0033] Dimethylformamide 360 parts

[0034] Mix and prepare, place at 95°C for 4 hours, filter, then wash with 50% (w / w) isopropanol aqueous solution for 3 times, and dry at 55°C;

[0035] Then dissolve chitosan phosphate with a concentration of 2% in a solution of 2% butane tetracarboxylic acid, add sodium hypophosphite with a concentration of 2% to the solution to prepare a fabric treatment solution, and then immerse the cotton fabric in the fabric treatment solution and take it out Afterwards, it was rolled dry, treated at 80°C for 3 minutes to remove water, and then treated at 150°C for 2 minutes to further remove water.

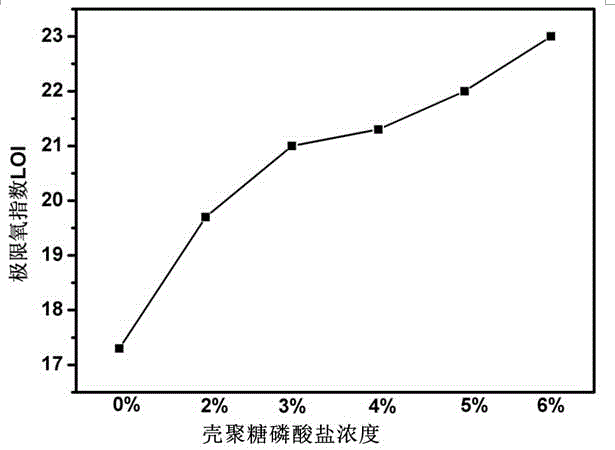

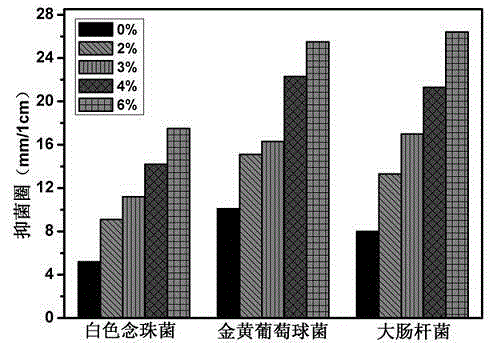

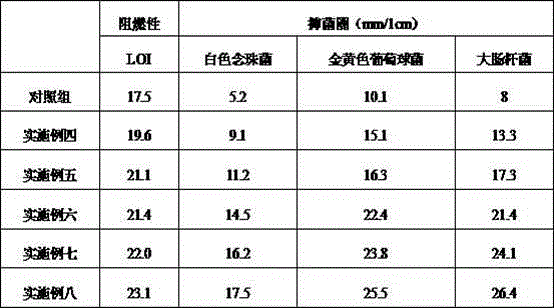

[0036] The cotton fabrics prepared above were subjected to limiting oxygen index measurement and antibacterial test respectively, compared with cotton fabrics treated with chitosan phosphate, ...

Embodiment 2

[0041] Chitosan phosphate is according to following parts by weight:

[0042] Chitosan 30 parts

[0043] 60 parts of urea

[0044] Phosphoric acid 60 parts

[0045] Dimethylformamide 300 parts

[0046] Prepare by mixing, place at 105°C for 6 hours, filter, then wash 4 times with 50% (w / w) isopropanol aqueous solution, and dry at 65°C;

[0047] Then dissolve chitosan phosphate with a concentration of 6% in a solution of 8% butane tetracarboxylic acid, add sodium hypophosphite with a concentration of 8% to the solution to prepare a fabric treatment solution, and then immerse the cotton fabric in the fabric treatment solution and take it out Afterwards, it was rolled dry, treated at 90°C for 5 minutes to remove water, and then treated at 170°C for 3 minutes to further remove water.

[0048] The above-mentioned cotton fabrics were carried out to measure the limiting oxygen index respectively, and carried out the antibacterial test, compared with the cotton fabrics without addi...

Embodiment 3

[0053] Chitosan phosphate is according to following parts by weight:

[0054] Chitosan 23 parts

[0055] 40 parts of urea

[0056] Phosphoric acid 75 parts

[0057] 332 parts of dimethylformamide

[0058] Mix and prepare, place at 100°C for 5 hours, filter, then wash with 50% (w / w) isopropanol aqueous solution for 4 times, and dry at 60°C;

[0059]Then dissolve chitosan phosphate with a concentration of 2% in a solution of 6% butane tetracarboxylic acid, add sodium hypophosphite with a concentration of 6% to the solution to prepare a fabric treatment solution, and then immerse the linen fabric in the fabric treatment solution and take it out Afterwards, it was dried by rolling, treated at 85°C for 3 minutes to remove water, and then treated at 160°C for 2 minutes to further remove water.

[0060] The flax fabrics prepared above were measured for limiting oxygen index respectively, and antibacterial test was carried out, compared with the flax fabrics treated with chitosan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com