Method for performing antibacterial and antivirus treatment on textiles by utilizing natural biomaterials

A technology of biomaterials and textiles, which is applied in the field of antibacterial and antiviral finishing of textiles, can solve the problems of weak antibacterial ability, and achieve the effect of non-toxic side effects, good affinity, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

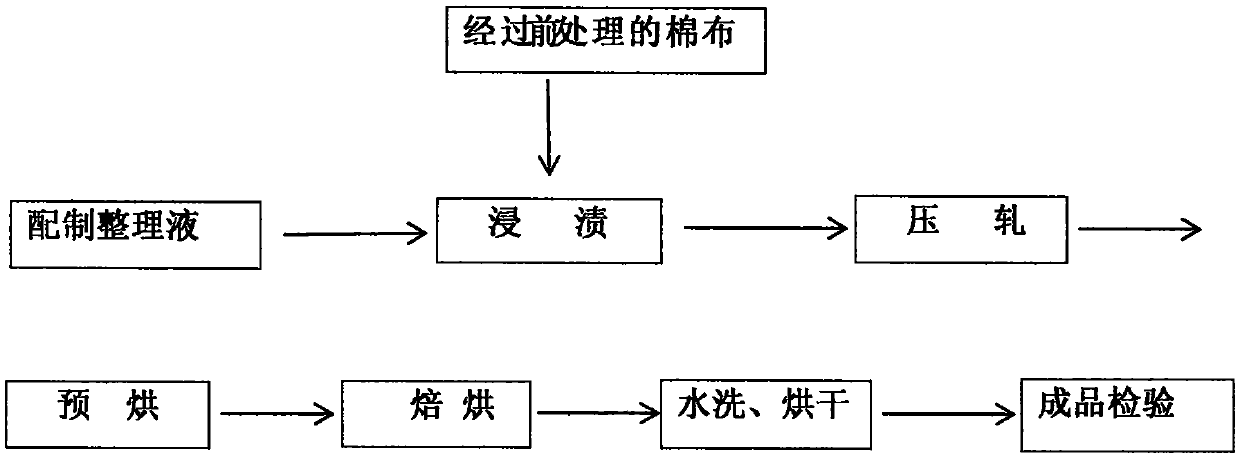

Method used

Image

Examples

Embodiment 1

[0036] Example 1, chitosan 1%, honeysuckle extract 0.8%, citric acid 2%, tartaric acid 1.5%, sodium hypophosphite 2%. Preparation method: ①Add a certain amount of water in advance into the reaction kettle with agitator, put the required chitosan into the water, stir and disperse, and heat to 50-70℃; ②In 1-2 hours, slowly dissolve the chitosan Add citric acid and tartaric acid into the kettle to react with chitosan to dissolve the chitosan. After the dissolution, continue to stir and keep warm for 2 hours; ③ Add the honeysuckle extract into the kettle and stir to dissolve; ④ Add sodium hypophosphite and stir; ⑤ Make up the required water to make the chitosan concentration 1%.

Embodiment 2

[0037] Example 2, N, N, N-trimethylammonium chloride chitosan 1.5%, citric acid 4%, wild chrysanthemum extract 0.8%, rhubarb extract 0.3%, sodium hypophosphite 2.5%. Preparation method: ① Put N, N, N-trimethylammonium chloride chitosan into a reaction kettle with a stirrer, then add the required amount of water to stir and heat to 30-70°C to dissolve it; ② Slowly add citric acid into the kettle, after adding, continue to keep warm and stir for 2 hours; ③Add sodium hypophosphite and stir; ④Add plant extracts in turn and stir to dissolve.

Embodiment 3

[0038] Embodiment three, 0.5% of hydroxypropyl chitosan, 0.6% of O-carboxymethyl-N, N, N-trimethylammonium chloride chitosan, 2.5% of butane tetracarboxylic acid, 1% of citric acid; Wild chrysanthemum flower extract 0.5%, dandelion extract 0.4%, tea leaf extract 0.6%, mugwort leaf extract 0.6%, clove extract 1%, aloe extract 0.8%, sodium hypophosphite 2%. Preparation method: ① Put hydroxypropyl chitosan and N, N, N-trimethylammonium chloride chitosan in turn into a reaction kettle with a stirrer, then add the required amount of water to stir and heat to 40 Dissolve it at -80°C; ② slowly add butane tetracarboxylic acid and citric acid into the kettle, and continue to heat and stir for 2 hours; ③ add sodium hypophosphite and stir; ④ at 20-60°C, add in sequence The plant extract is stirred and dissolved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com