Polycarboxylic acid water reducer and preparation method thereof

A technology of water reducer and polycarboxylate, applied in the field of polycarboxylate water reducer and its preparation, can solve the problems of unfavorable operation for workers, heavy taste, etc., achieve good slump retention, high water reducing rate, and improve the production workshop environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

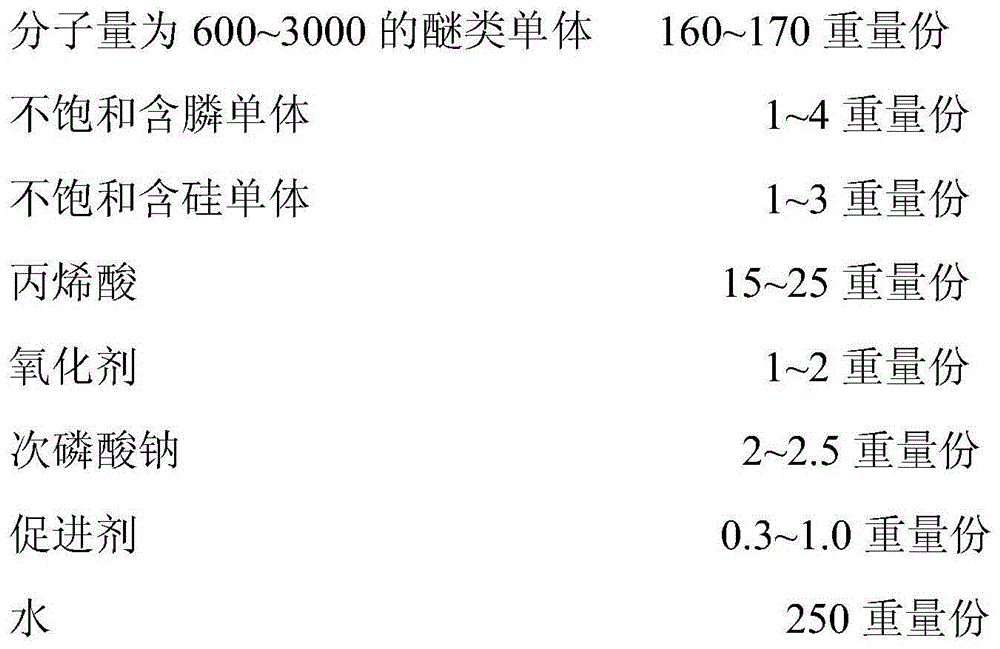

[0027] (1) Take each raw material component by weighing as follows:

[0028]

[0029]

[0030] (2) Copolymerization reaction: Add TPEG, isopropenylphosphonic acid, vinyltrimethoxysilane and 190 parts by weight of water into the reactor, stir and dissolve at 5-35°C, then add aqueous sodium persulfate ( Sodium persulfate and 30 parts by weight of water) and the mixed aqueous solution (acrylic acid, ferrous chloride, sodium hypophosphite and 30 parts by weight of water) of acrylic acid, sodium hypophosphite and ferrous chloride, the time of dropping is 2.5 hours, dropwise After the end, the temperature was kept constant for 1.5 hours, and the concentration of the product obtained from the reaction was about 40%;

[0031] (3) After the copolymerization reaction, adjust the pH value in the range of 6.0 to 7.0 with sodium hydroxide to obtain a clear solution which is the polycarboxylate water reducer.

Embodiment 2

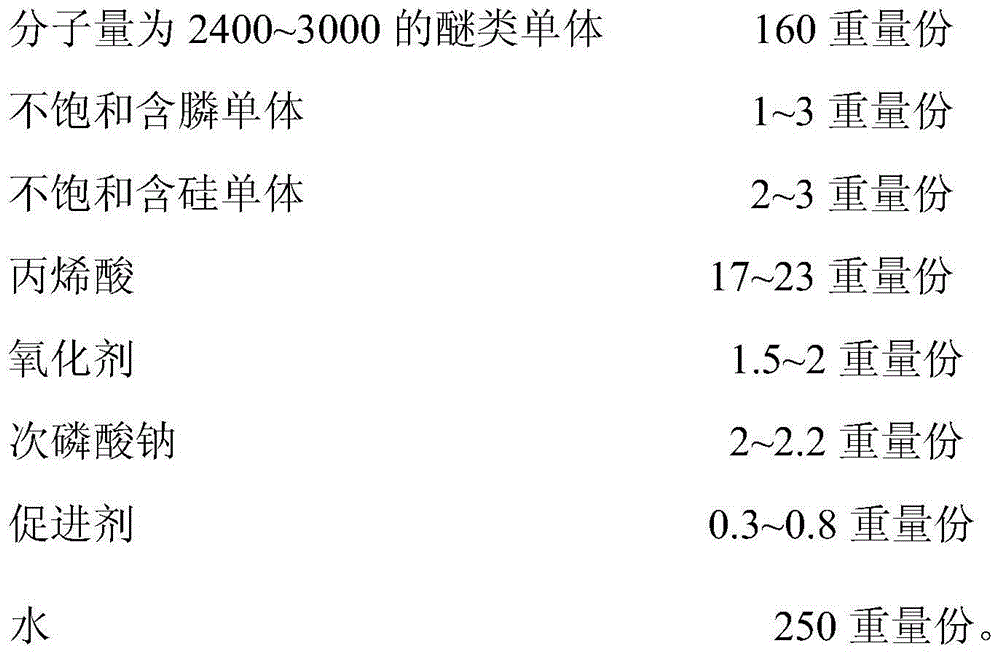

[0033] (1) Take each raw material component by weighing as follows:

[0034]

[0035] (2) Copolymerization reaction: Add TPEG, 2-acrylamide-2-methylpropylphosphonic acid, vinyltriethoxysilane and 190 parts by weight of water into the reactor, stir and dissolve at 5-35°C Afterwards, dropwise the mixed aqueous solution (acrylic acid, ferrous sulfate, sodium hypophosphite and 30 parts by weight of water) of ammonium persulfate aqueous solution (ammonium persulfate and 30 parts by weight of water) and acrylic acid, sodium hypophosphite and ferrous chloride respectively, The dropping time is 3 hours, and the temperature is kept constant for 1 hour after the dropping, and the concentration of the product obtained from the reaction is about 40%;

[0036] (3) After the copolymerization reaction, adjust the pH value in the range of 6.0 to 7.0 with potassium hydroxide to obtain a clear solution which is the polycarboxylate water reducer.

Embodiment 3

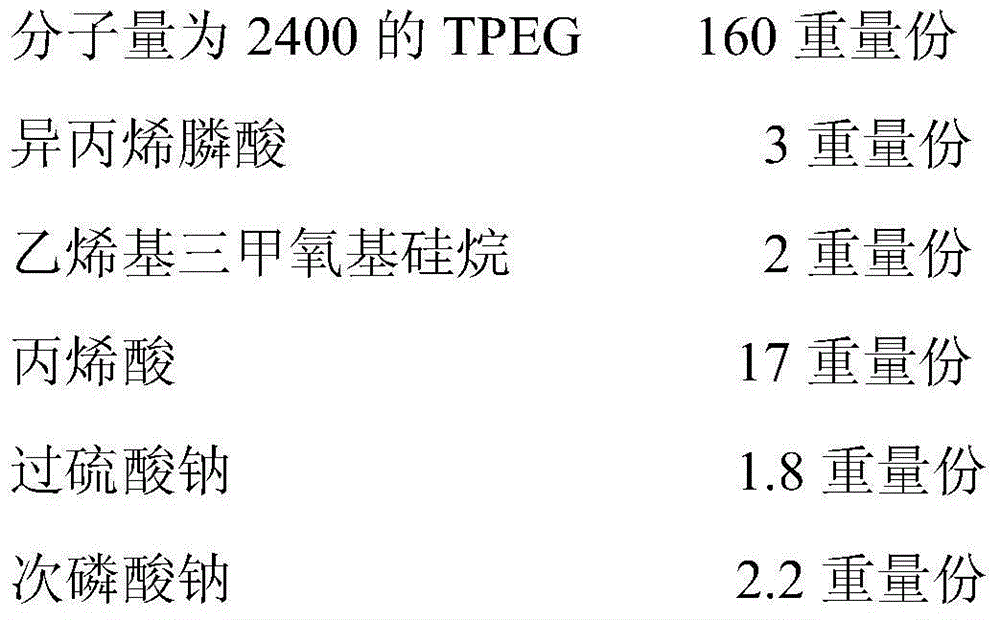

[0038] (1) Take each raw material component by weighing as follows:

[0039]

[0040] (2) Copolymerization reaction: Add HPEG, ethylenediamine-dimethylphosphonic acid, vinyltriisopropoxysilane and 190 parts by weight of water into the reaction kettle together, stir and dissolve at 5-35°C, respectively Add dropwise the mixed aqueous solution of aqueous hydrogen peroxide (hydrogen peroxide and 30 parts by weight of water) and acrylic acid, sodium hypophosphite, ferrous chloride and ferrous sulfate (acrylic acid, ferrous chloride, ferrous sulfate, sodium hypophosphite and 30 parts by weight water), the dropping time was 4 hours, and the constant temperature was 1 hour after the dropping, and the concentration of the product obtained from the reaction was about 40%;

[0041] (3) After the copolymerization reaction, adjust the pH value in the range of 6.0 to 7.0 with triethanolamine to obtain a clear solution which is the polycarboxylate water reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com