Preparation method of Ni-Cu-P/nano TiO2 chemical composite coating on surface of magnesium alloy

A chemical composite plating, ni-cu-p technology, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., to achieve the effect of good wear resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

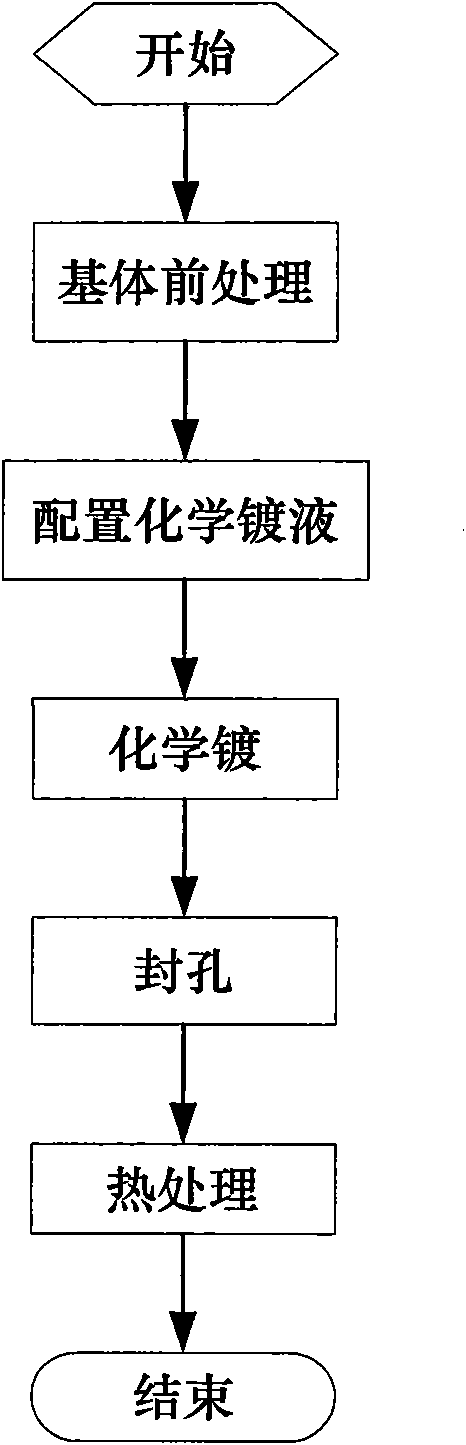

Method used

Image

Examples

preparation example Construction

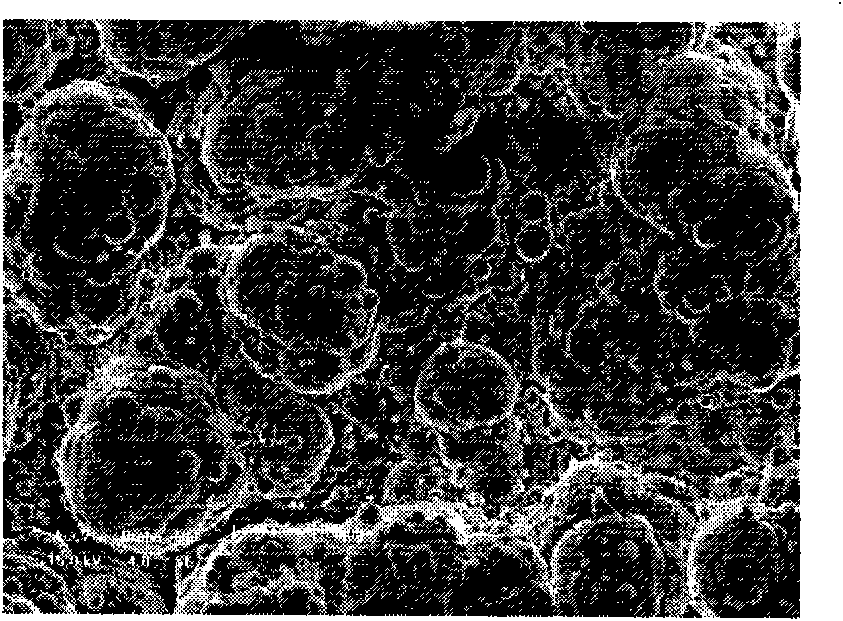

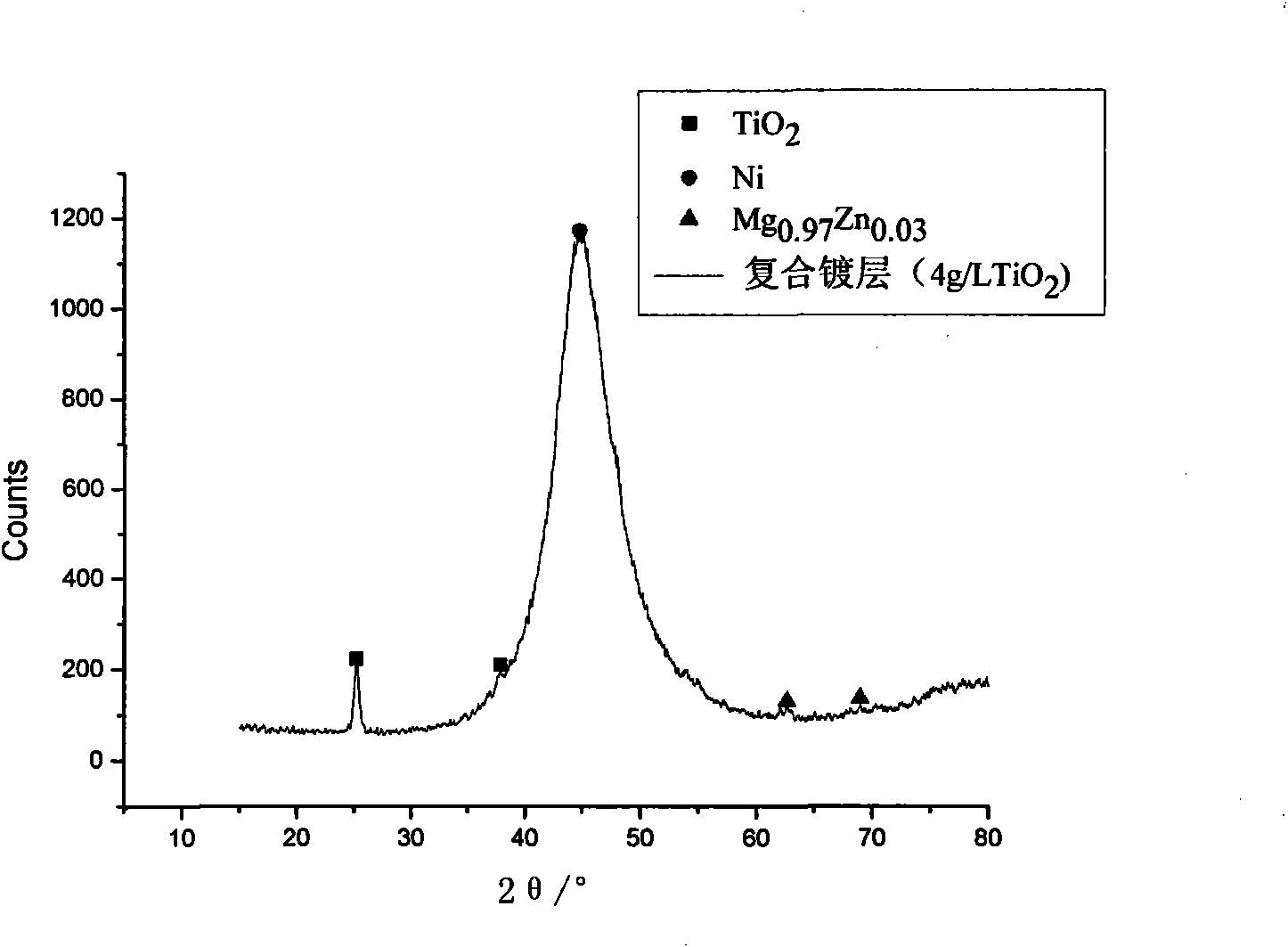

[0044] For the nanocomposite coating prepared by the preparation method of the present invention, carry out morphology observation, component analysis and performance test, the result finds: the coating surface has a metallic luster, and the crystal grains are fine; energy spectrum analysis results show that the composition of the chemical composite coating is Ni Mainly, the content is about 80wt%, the P content is about 10wt%, and the rest is basically Ti; X-ray analysis shows that Ni-Cu-P / nano-TiO 2 The chemical composite coating appeared TiO at 25.108° 2 After the chemical composite coating was heat-treated at 250°C, the coating appeared Cu 3 Stable phases such as P and Ni peaks, and form new CuP2 、NiP 2 Mutually.

[0045] The antibacterial test shows that when the chemical composite coating is irradiated by ultraviolet light, it has excellent photocatalytic performance and the degradation rate is obvious. With the prolongation of photocatalysis time, the decolorization r...

Embodiment 1

[0048] The first step is the pretreatment of the base AZ91D magnesium alloy.

[0049] Sanding - Acetone Cleaning - Alkaline Cleaning - Pickling - Activation.

[0050] The second step is to configure the chemical plating solution.

[0051] Nickel sulfate content 30g / L; sodium hypophosphite content 25g / L; citric acid content 18g / L; ammonium bifluoride content 15g / L; thiourea 0.5mg; sodium lauryl sulfate 0.02g / L; copper sulfate content 0.2 g / L, Nano TiO 2 4g·L -1 .

[0052] The third step is electroless plating.

[0053] Immerse the substrate AZ91D magnesium alloy pretreated in the first step into the plating solution configured in the second step, and use a magnetic stirrer to evenly disperse the nano-TiO in the plating solution 2 Powder, the electroless plating temperature is 85°C, the pH is 7, and the plating is performed for 2 hours.

[0054] The plating speed of electroless plating is 0.22706mg.mm -2 .h -1 .

[0055] The fourth step is to seal the hole.

[0056] M...

Embodiment 2

[0065] The composition of the plating solution in Example 1 was adjusted, and the rest of the steps were the same, and the bacteriostatic rate test of the chemical composite coating was continued. Wherein the bath composition contains in every liter bath: nickel sulfate content 12g / L; sodium hypophosphite content 11g / L; citric acid content 27g / L; ammonium bifluoride content 8g / L; thiourea 1.2mg; Sodium sulfate 0.05g / L; copper sulfate content 0.08g / L, nano TiO 2 6g·L -1 . The test results show that the composite coating has excellent photocatalytic performance, and TiO 2 The photocatalytic effect of the powder is comparable, which is TiO 2 The powder has found a carrier that can increase the reusability of antibacterial properties, which is the perfect combination of antibacterial technology and electroless plating technology. In the comparison of different times, the longer the contact time between the coating and the bacteria, the more significant the antibacterial effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com