Pd/Ce0.8Zr0.2O2/cordierite honeycomb ceramic monolithic catalyst, preparation method and application thereof

A monolithic catalyst and cordierite honeycomb technology, applied in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., to achieve the effects of improving oxygen storage performance, improving palladium utilization, and uniform thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Surface pretreatment of honeycomb ceramics: set the hole density to 400 holes / inch 2 Boil cordierite honeycomb ceramics with a wall thickness of 0.1mm in 10wt% dilute hydrochloric acid solution for 30 minutes, take it out, rinse it with distilled water, and dry it at 120°C for 1 hour;

[0027] (2) Preparation of cerium-zirconium composites by impregnation method: configure 0.16moL / LCe(NO 3 ) 3 ·6H 2 O, 0.04moL / LZr(NO 3 ) 4 ·5H 2 A mixed solution of O and 0.24moL / L citric acid, stirred in a water bath at 40°C for 60min, then soak the honeycomb ceramic carrier treated in step (1) into the mixed solution for 3h, take out and blow off the remaining solution in the holes , air-dried naturally, dried at 120°C for 2h, calcined in a muffle furnace at 400°C for 1h, and repeated the above process twice to obtain Ce 0.8 Zr 0.2 o 2 / cordierite honeycomb ceramic carrier;

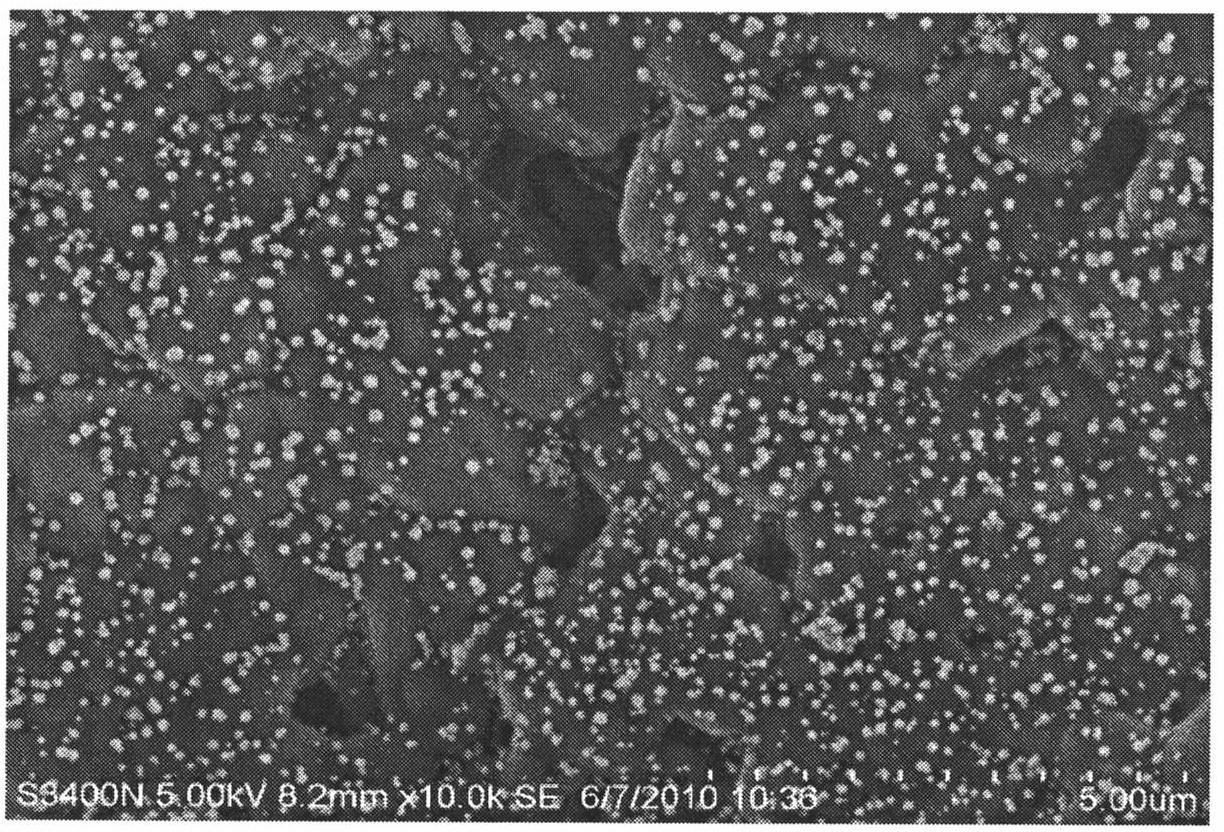

[0028] (3) Ce 0.8 Zr 0.2 o 2 Sensitization and activation treatment of cordierite honeycomb ce...

Embodiment 2

[0034] (1) honeycomb ceramic surface pretreatment: operate by the method in embodiment 1;

[0035] (2) Preparation of cerium-zirconium composite by impregnation method: operate according to the method in Example 1;

[0036] (3) Ce 0.8 Zr 0.2 o 2 Sensitization and activation treatment of cordierite honeycomb ceramic carrier: operate according to the method in Example 1;

[0037] (4) Preparation of electroless palladium plating solution: prepared according to the method in Example 1, PdCl 2 The concentration is 0.10g / L;

[0038] (5) electroless palladium plating: operate according to the method in embodiment 1, can obtain 0.12wt%Pd / Ce 0.8 Zr 0.2 o 2 / cordierite honeycomb ceramic monolithic catalyst;

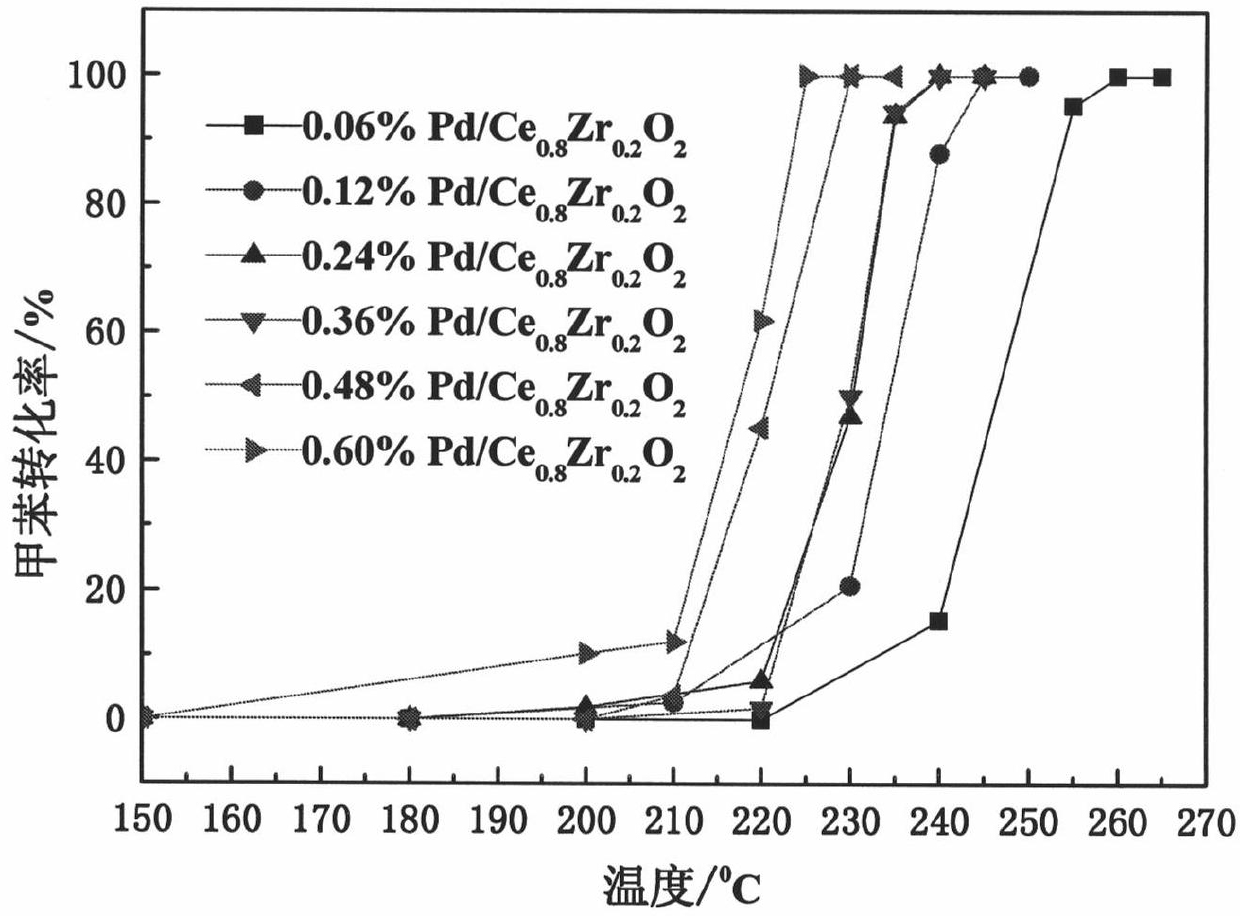

[0039] (6) Catalytic combustion performance evaluation of monolithic catalyst: operate by the method in embodiment 1, evaluation result sees attached figure 2 .

Embodiment 3

[0041] (1) honeycomb ceramic surface pretreatment: operate by the method in embodiment 1;

[0042] (2) Preparation of cerium-zirconium composite by impregnation method: operate according to the method in Example 1;

[0043] (3) Ce 0.8 Zr 0.2 o 2 Sensitization and activation treatment of cordierite honeycomb ceramic carrier: operate according to the method in Example 1;

[0044] (4) Preparation of electroless palladium plating solution: prepared according to the method in Example 1, PdCl 2 The concentration is 0.20g / L;

[0045] (5) electroless palladium plating: operate according to the method in embodiment 1, can obtain 0.24wt%Pd / Ce 0.8 Zr 0.2 o 2 / cordierite honeycomb ceramic monolithic catalyst;

[0046] (6) Catalytic combustion performance evaluation of monolithic catalyst: operate by the method in embodiment 1, evaluation result sees attached figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com