Modified naphthalene water reducer preparation method

A naphthalene-based water reducer and modification technology, applied in the field of concrete admixtures, can solve problems such as difficult construction and large slump loss, and achieve good effect, high fluidity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

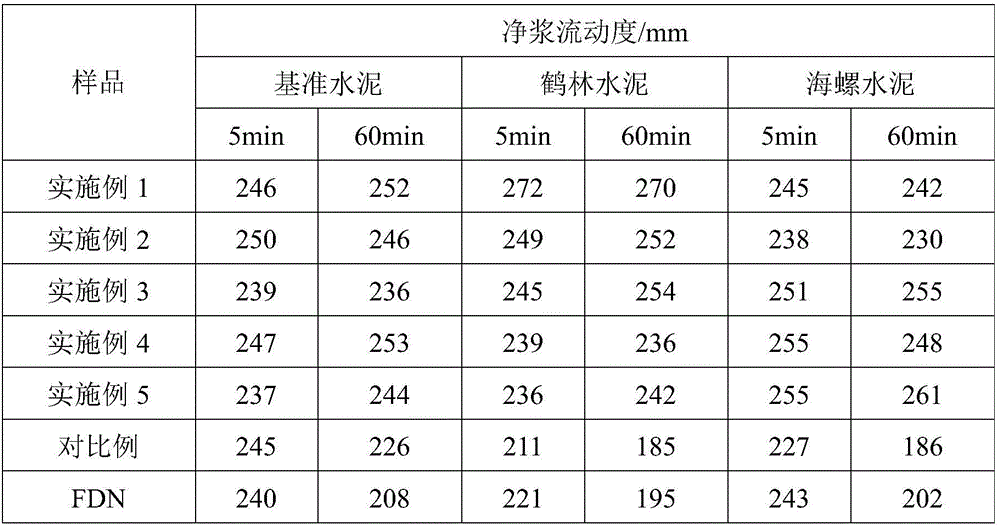

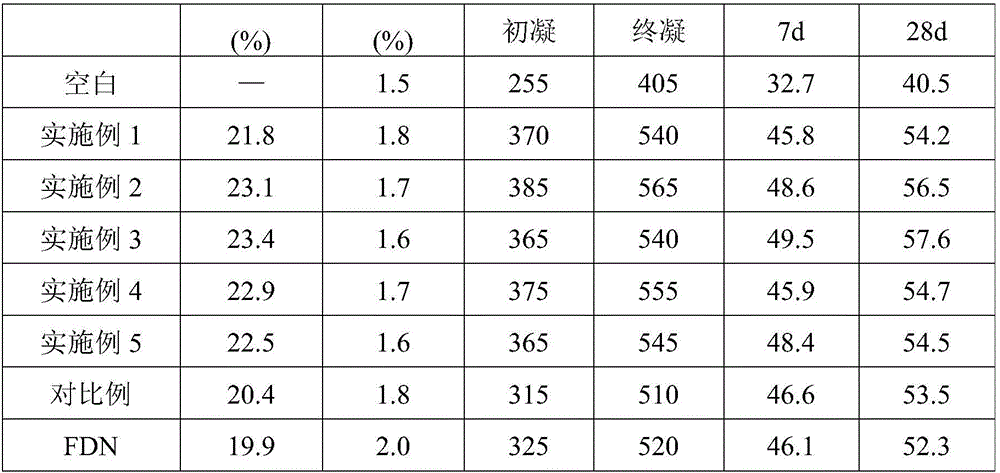

Examples

Embodiment 1

[0028] (1) Preparation of polycondensation monomer:

[0029] Put 163.3 parts of fumaric acid, 40.4 parts of styrene, 59.1 parts of sodium hypophosphite and 255.5 parts of water into the reactor, and heat it to 60-70°C while stirring; add 65.0 parts of 32% liquid caustic soda to adjust the pH value of the reaction system 5~7; add 210.5 parts of hydroxyethyl acrylate and 6.2 parts of ammonium persulfate to 200 parts of water to make a mixed solution, and drop it in 3~4 hours; Discharge at about 40°C to obtain co-condensation monomer A.

[0030] (2) A modified naphthalene-based water reducer, the preparation steps of which are as follows:

[0031] (1) Sulfonation: put 138 parts of industrial naphthalene and 28 parts of methylnaphthalene into the reaction kettle and heat and melt to 130-135°C, add 145 parts of 98% concentrated sulfuric acid, and sulfonate at 160°C for 3-4 hours;

[0032] (2) Hydrolysis: cool down to 120°C, add 9.7 parts of phosphoric acid and 100 parts of water,...

Embodiment 2

[0036] (1) Preparation of polycondensation monomer:

[0037] Put 148.6 parts of maleic anhydride, 67.1 parts of styrene, 57.0 parts of sodium hypophosphite and 258.2 parts of water into the reaction kettle, and heat to 60-70°C while stirring; add 62.0 parts of 32% liquid alkali to adjust the pH value of the reaction system 5~7; add 200.3 parts of hydroxypropyl acrylate and 6.8 parts of ammonium persulfate to 200 parts of water to form a mixed solution, and drop it in 3~4 hours; Discharge at about 40°C to obtain co-condensation monomer B.

[0038] (2) A modified naphthalene-based water reducer, the preparation steps of which are as follows:

[0039] (1) Sulfonation: Put 128 parts of industrial naphthalene and 46 parts of β-naphthol into the reaction kettle and heat and melt to 130-135°C, add 150 parts of 98% concentrated sulfuric acid, and perform sulfonation reaction at 160°C for 3-4 hours;

[0040] (2) Hydrolysis: cool down to 120°C, add 10.4 parts of phosphoric acid and 10...

Embodiment 3

[0044] (1) Preparation of polycondensation monomer:

[0045] Put 137.5 parts of citraconic acid, 51.8 parts of styrene, 72.4 parts of sodium hypophosphite and 261.4 parts of water into the reaction kettle, and heat to 60-70°C while stirring; add 56.8 parts of 32% liquid caustic soda to adjust the pH value of the reaction system 5~7; add 212.6 parts of hydroxypropyl acrylate and 6.3 parts of potassium persulfate to 200 parts of water to form a mixed solution, and drop it in 3~4 hours; Discharge at about 40°C to obtain co-condensation monomer C.

[0046] (2) A modified naphthalene-based water reducer, the preparation steps of which are as follows:

[0047] (1) Sulfonation: Put 162 parts of industrial naphthalene into the reaction kettle and heat and melt to 130-135°C, add 163.7 parts of 98% concentrated sulfuric acid, and perform sulfonation reaction at 160°C for 3-4 hours;

[0048] (2) Hydrolysis: cool down to 120°C, add 8.2 parts of phosphoric acid and 100 parts of water, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com