Electrodeposition preparation method of carbon nanotube/transition metal compound composite material

A technology of carbon nanotubes and transition metals, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the limitations of practical applications, catalyst performance is not ideal, catalyst particles are small and easy to agglomerate, etc. problems, to achieve the effects of easy mass production, improved application value, and high current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

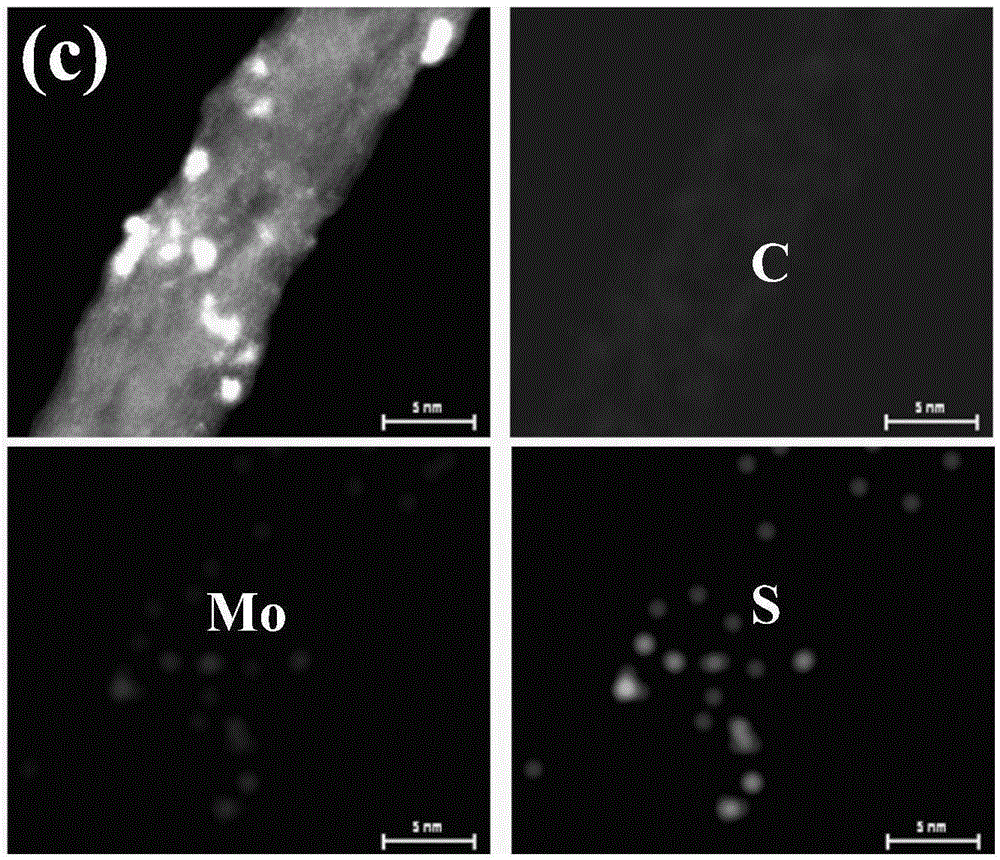

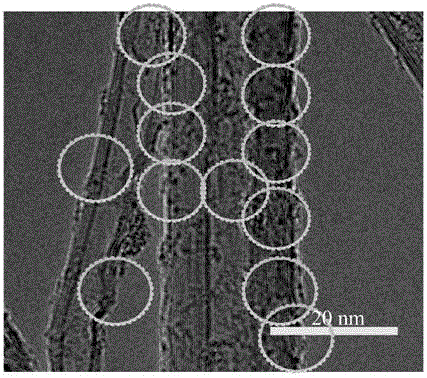

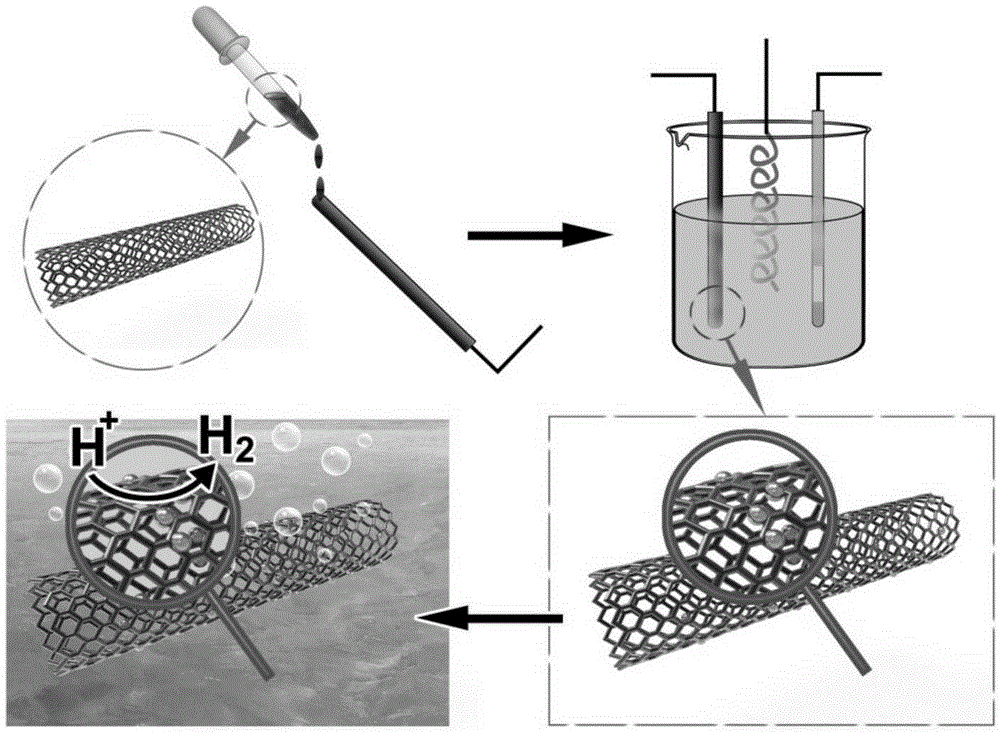

[0047] Embodiment 1: prepare carbon nanotube / molybdenum sulfide composite material (MoS 4 / CNTs)

[0048] (1) Electrode pretreatment: take a glassy carbon electrode (Shanghai Chenhua, CHI104, 3mm in diameter), and perform polishing, water washing, and 20KHz ultrasonic pretreatment for 60s in sequence;

[0049] (2) Preparation of carbon nanotube-modified glassy carbon electrodes: Add arrayed carbon nanotubes (1mg) to a mixture (1mL) of ethanol and water with a volume ratio of 1:1, and form a suspension by ultrasonication at 40KHz for 2h. The suspension is added dropwise on the surface of the glassy carbon electrode pretreated in step (1), and dried naturally to form a uniform thin layer of carbon nanotubes (the thin layer is about 40 μg of carbon nanotubes), to obtain carbon nanotube-modified Glassy carbon electrode;

[0050] (3) Preparation of electroplating solution: Add precursor ammonium tetrathiomolybdate (0.104g), ammonium molybdate (0.392g), supporting electrolyte sodi...

Embodiment 2

[0054] Embodiment 2: prepare carbon nanotube / molybdenum sulfide composite material (MoS 3 / CNTs)

[0055] (1) Electrode pretreatment: take a glassy carbon electrode (Shanghai Chenhua, CHI104, 3mm in diameter), and perform polishing, water washing, and 20KHz ultrasonic pretreatment for 60s in sequence;

[0056] (2) Preparation of carbon nanotube-modified glassy carbon electrodes: Add arrayed carbon nanotubes (1mg) to a mixture (1mL) of ethanol and water with a volume ratio of 1:1, and form a suspension by ultrasonication at 40KHz for 2h. The suspension is added dropwise on the surface of the glassy carbon electrode pretreated in step (1), and dried naturally to form a uniform thin layer of carbon nanotubes (the thin layer is about 40 μg of carbon nanotubes), to obtain carbon nanotube-modified Glassy carbon electrode;

[0057] (3) Preparation of electroplating solution: Add precursor ammonium tetrathiomolybdate (0.5g), ammonium molybdate (0.392g), supporting electrolyte sodium...

Embodiment 3

[0060] Embodiment 3: prepare carbon nanotube / molybdenum selenide composite material (MoSe 2 / CNTs)

[0061] (1) Electrode pretreatment: take a glassy carbon electrode (Shanghai Chenhua, CHI104, 3mm in diameter), and perform polishing, water washing, and 20KHz ultrasonic pretreatment for 60s in sequence;

[0062] (2) Preparation of carbon nanotube-modified glassy carbon electrodes: Add single-walled carbon nanotubes (1mg) to ethanol (1mL), form a suspension at 40KHz for 2h, and add the suspension dropwise to the step ( 1) The surface of the pretreated glassy carbon electrode is naturally dried to form a uniform thin layer of carbon nanotubes (the thin layer is about 40 μg of carbon nanotubes), to obtain a carbon nanotube-modified glassy carbon electrode;

[0063] (3) Preparation of electroplating solution: Add precursor ammonium molybdate (3.9g), selenium oxide (2.2g), supporting electrolyte sodium perchlorate (1.2g), sodium citrate (0.7g) in deionized water (250mL) ), adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com