Bamboo charcoal-diatomite composite ceramic material and preparation method thereof

A technology of composite ceramics and diatomite, applied in ceramic products, other household utensils, applications, etc., can solve the problems of complex processing technology, complex composition, high processing cost, etc., and achieve simple processing technology, good dispersion, and many holes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A bamboo charcoal diatomite composite ceramic material is prepared from the following raw materials in parts by weight: 10-90 parts of bamboo powder, 10-90 parts of diatomite, and 5-20 parts of water-soluble polymer binder.

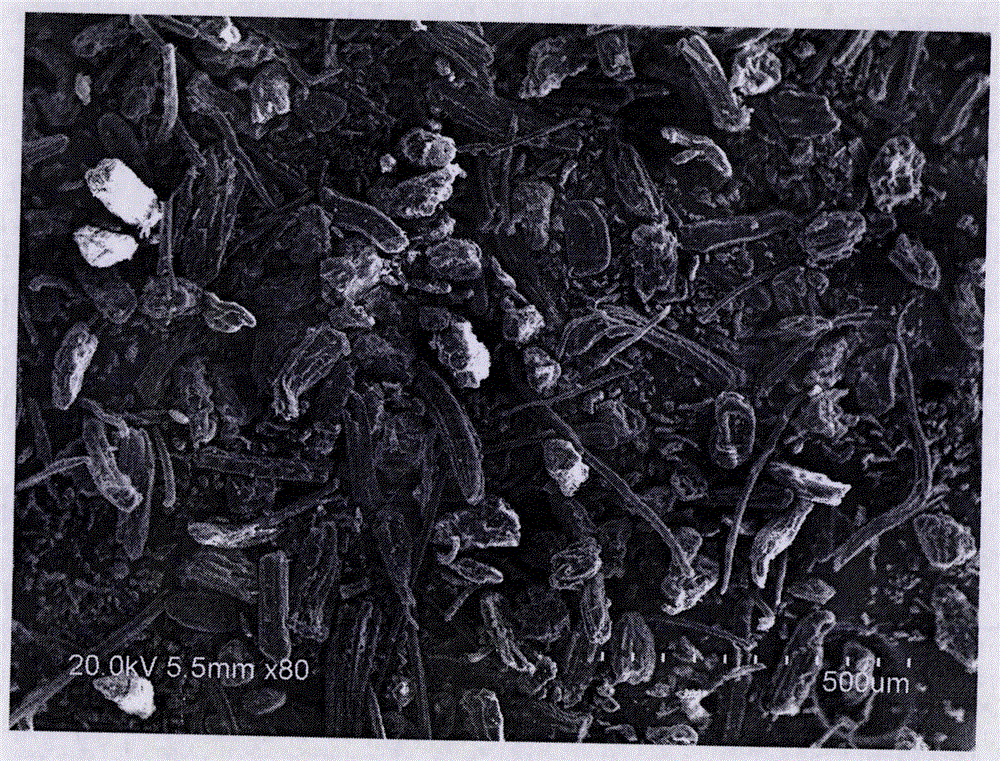

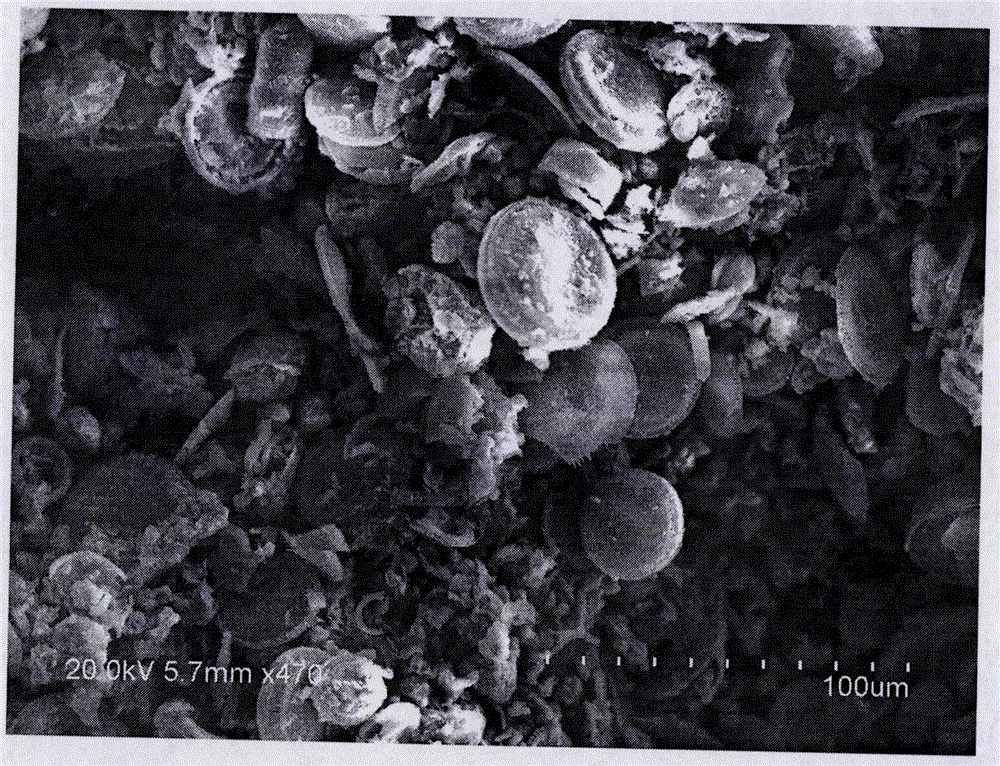

[0022] In this embodiment, its proportioning is: 40 parts of bamboo powder, 60 parts of diatomaceous earth, 5 parts of water-soluble polymer binder. Electron microscope picture of bamboo powder figure 1 As shown, the electron microscope picture of diatomite raw material is as follows figure 2 shown.

[0023] The preparation method of this bamboo charcoal diatomite composite ceramic material comprises the following steps:

[0024] (1) drying the bamboo powder at 60-80°C for 1-2 hours, and passing through a 200-mesh sieve;

[0025] (2) Dry diatomaceous earth at 60-80°C for 1-2 hours, and pass through a 200-mesh sieve;

[0026] (3) Mix 5 parts of water-soluble polymer binder with 100 parts of water, fully dissolve;

[0027] (4) The raw material ...

Embodiment 2

[0041] A bamboo charcoal bentonite composite ceramic material is prepared from the following raw materials in parts by weight: 10-90 parts of bamboo powder, 10-90 parts of diatomite, and 5-20 parts of water-soluble polymer binder.

[0042] In this embodiment, the proportioning ratio is: 20 parts of bamboo powder, 70 parts of diatomaceous earth, and 10 parts of water-soluble polymer binder.

[0043] Refer to Example 1 for preparation and experimental methods.

[0044] After testing, the performance parameters of the product prepared in this embodiment are as follows:

[0045] The specific surface area is greater than 80m 2 / g; compressive strength greater than 11Mpa; porosity greater than 60%, filtration rate 28ml / hr.cm 2 (Water level drop 300mm). The effective removal rate of hexavalent chromium is between 85% and 95%.

[0046] It can be seen that increasing the proportion of diatomite increases the hardness of the product, and decreasing the proportion of bamboo powder de...

Embodiment 3

[0048] A bamboo charcoal bentonite composite ceramic material is prepared from the following raw materials in parts by weight: 10-90 parts of bamboo powder, 10-90 parts of diatomite, and 5-20 parts of water-soluble polymer binder.

[0049] In this embodiment, its proportioning is: 60 parts of bamboo powder, 40 parts of diatomaceous earth, 20 parts of water-soluble polymer binder.

[0050] Refer to Example 1 for preparation and experimental methods.

[0051] After testing, the performance parameters of the product prepared in this embodiment are as follows:

[0052]The specific surface area is greater than 110m 2 / g; compressive strength greater than 5Mpa; porosity greater than 70%, filtration rate 35ml / hr.cm 2 (Water level drop 300mm). The effective removal rate of hexavalent chromium is between 95% and 100%.

[0053] It can be seen that reducing the proportion of diatomite reduces the hardness of the product, and increasing the proportion of bamboo powder increases the ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com