High adsorption performance composite flocculant aerogel and preparation method thereof

A composite flocculant and high adsorption technology, applied in the field of material science, can solve the problems of harmful human health and ecological environment, large amount of flocculant, limited adsorption capacity, etc., to achieve the effects of easy penetration, high adsorption efficiency, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

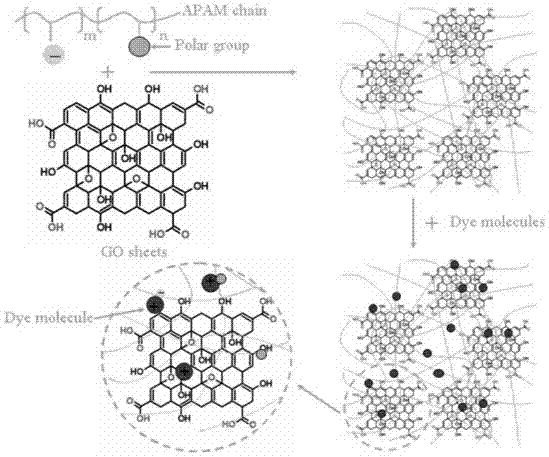

[0027] First, dissolve 2 g of anionic polyacrylamide in deionized water to prepare a dilute solution with a mass fraction of 0.5%, then add 0.5 g of graphene oxide into it, and after slight stirring, let it stand for 24 hours to form a suspended polyacrylamide / graphene oxide colloidal floc; Next, the prepared mixture is irradiated by microwave ovens (brand: Haier; model: MW-2070M; firepower: medium fire) for a short period of 10 seconds, and then filter to remove the raffinate. Put the colloidal floc into a sealed bag and freeze in the refrigerator for 24 hours; finally put the frozen mixture into a vacuum freeze dryer (model: FD-1-50; vacuum degree: 10Pa; cold trap coil temperature: -50 ℃) after drying, the flocculant composite graphene oxide airgel is obtained, wherein the graphene oxide content is 20%.

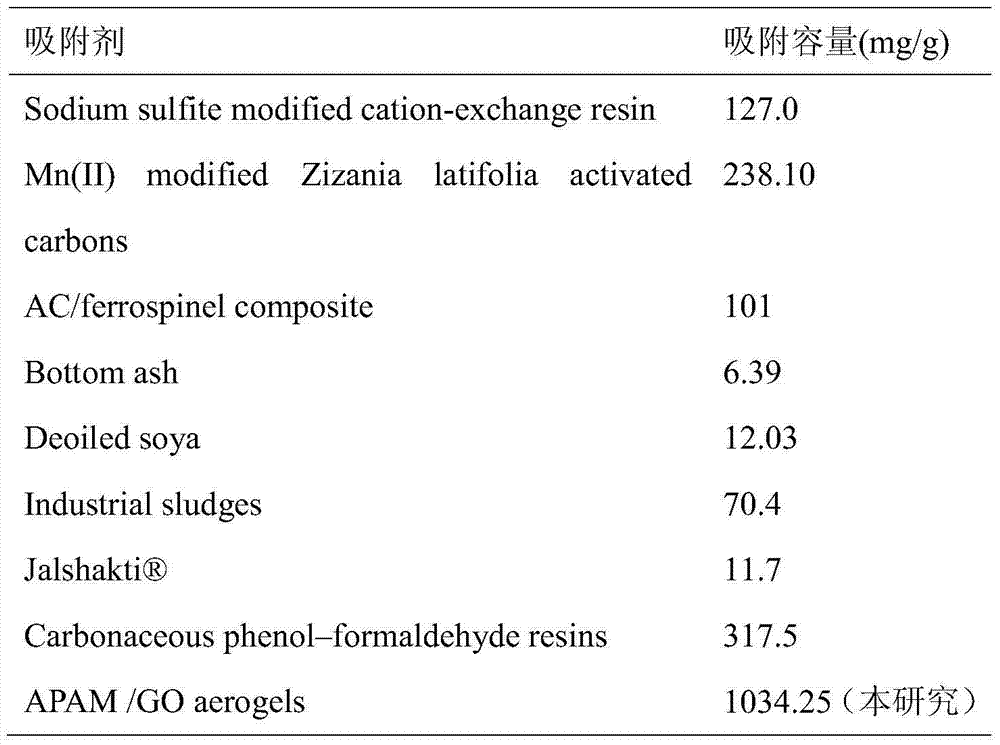

[0028] When 25 mg of flocculant-composite graphene oxide airgel obtained by the above method was added to 50 mL of basic fuchsin solution with a concentration of 400 mg / L,...

Embodiment 2

[0030] First, dissolve 2 g of anionic polyacrylamide in deionized water to prepare a dilute solution with a mass fraction of 0.75%, then add 0.25 g of graphene oxide into it, and after slight stirring, let it stand for 24 hours to form a suspended polyacrylamide / graphene oxide colloidal floc; Next, the prepared mixture is irradiated by microwave ovens (brand: Haier; model: MW-2070M; firepower: medium fire) for a relatively short period of time for 5 seconds, and then filter and remove the raffinate. Put the colloidal floc into a sealed bag and freeze in the refrigerator for 24 hours; finally put the frozen mixture into a vacuum freeze dryer (model: FD-1-50; vacuum degree: 10Pa; cold trap coil temperature: -50 ℃) after drying, the flocculant composite graphene oxide airgel is obtained, wherein the graphene oxide content is 11%. Finally, the prepared flocculant-composite graphene oxide airgel is reduced to obtain the flocculant-composite graphene aerogel.

[0031] Adding 25 mg...

Embodiment 3

[0033] First, dissolve 2 g of anionic polyacrylamide in deionized water to prepare a dilute solution with a mass fraction of 1%, then add 0.75 g of graphene oxide into it, and after slight stirring, let it stand for 24 hours to form a suspended polyacrylamide / graphene oxide colloidal floc; Next, the prepared mixture is irradiated with microwaves for a short period of time for 20 seconds through a common microwave oven (brand: Haier; model: MW-2070M; firepower: medium fire), and then filter to remove the raffinate. Put the colloidal floc into a sealed bag and freeze in the refrigerator for 24 hours; finally put the frozen mixture into a vacuum freeze dryer (model: FD-1-50; vacuum degree: 10Pa; cold trap coil temperature: -50 ℃) after drying, the flocculant composite graphene oxide airgel is obtained, wherein the graphene oxide content is 27%.

[0034] When 25 mg of flocculant-composite graphene oxide airgel obtained by the above method was added to 100 mL of methylene blue sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com