Regeneration method of zinc oxide desulfurizer

A technology of desulfurization agent and zinc oxide, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., to achieve good economic benefits, pure by-products, and good oil removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

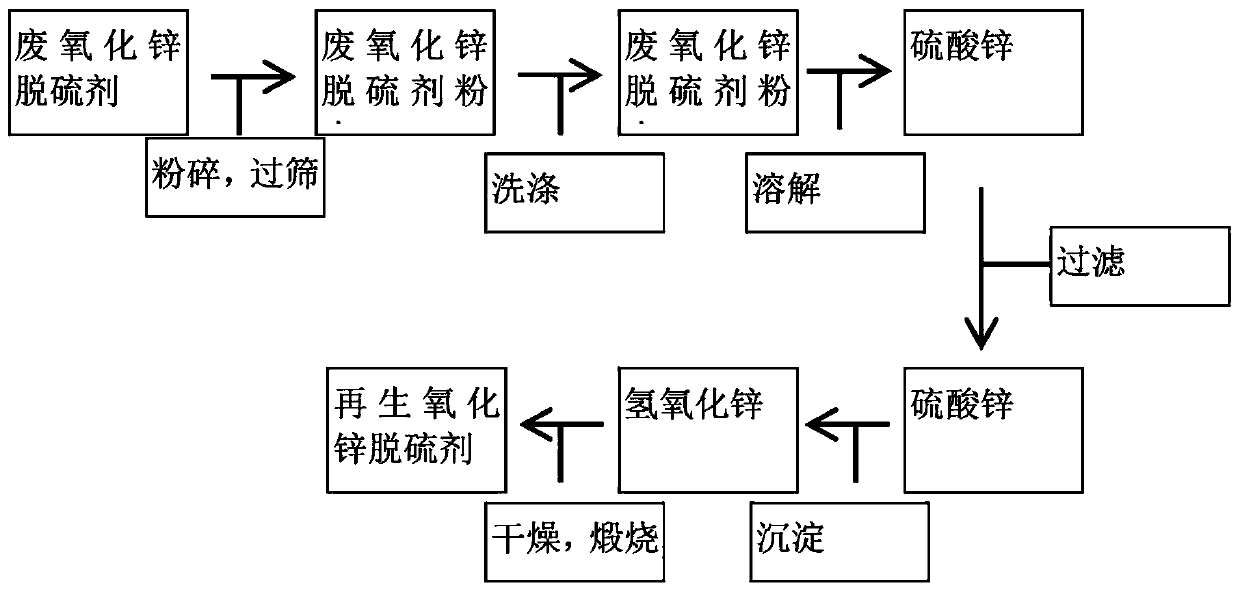

Image

Examples

Embodiment 1

[0051] A kind of regeneration method of zinc oxide desulfurizer, the steps are as follows:

[0052] (1) Pulverize the waste zinc oxide desulfurizer, sieve it through a 100-mesh sieve, and take the undersieve.

[0053] (2) The undersize is washed with a mixed aqueous solution of polyvinylpyrrolidone and sodium carbonate, and then rinsed with clear water.

[0054] (3) Slowly add 100 g of the washed undersize into the sulfuric acid-hydrogen peroxide-potassium permanganate mixture for dissolving to obtain filtrate and filter residue.

[0055] Wherein, the sulfuric acid-hydrogen peroxide-potassium permanganate mixed solution is the sulfuric acid of 3mol / L by 344mL concentration, 120g concentration is the hydrogen peroxide of 30wt% and 22g concentration is 5wt% potassium permanganate, 1g disodium ethylenediaminetetraacetic acid (EDTA -2Na) mixed.

[0056] (4) The filtrate is precipitated with ammonia water, the pH value needs to be controlled at about 8.0 (±0.2), and after stirrin...

Embodiment 2

[0060] A kind of regeneration method of zinc oxide desulfurizer, the steps are as follows:

[0061] (1) Pulverize the waste zinc oxide desulfurizer, sieve it through a 100-mesh sieve, and take the undersieve.

[0062] (2) The undersize is washed with a mixed aqueous solution of polyvinylpyrrolidone and sodium carbonate, and then rinsed with clear water.

[0063] (3) Slowly add 100 g of the washed undersize into the sulfuric acid-hydrogen peroxide-potassium permanganate mixed solution for dissolving to obtain filtrate and filter residue.

[0064] Wherein, the sulfuric acid-hydrogen peroxide-potassium permanganate mixed solution is 4mol / L sulfuric acid by 258mL concentration, 120g concentration is 30wt% hydrogen peroxide and 22g concentration is 5wt% potassium permanganate, 1g disodium ethylenediaminetetraacetic acid (EDTA -2Na) mixed.

[0065] (4) The filtrate is precipitated with ammonia water, the pH value needs to be controlled at about 8.5 (±0.2), and after stirring for 1...

Embodiment 3

[0069] A kind of regeneration method of zinc oxide desulfurizer, the steps are as follows:

[0070] (1) Pulverize the waste zinc oxide desulfurizer, sieve it through a 100-mesh sieve, and take the undersieve.

[0071] (2) The undersize is washed with a mixed aqueous solution of polyvinylpyrrolidone and sodium carbonate, and then rinsed with clear water.

[0072] (3) Slowly add 100 g of the washed undersize into the sulfuric acid-oxidizing agent mixture for dissolving to obtain filtrate and filter residue.

[0073] Wherein, the sulfuric acid-oxidizing agent mixed solution is the sulfuric acid that 258mL concentration is 4mol / L, 131.75g concentration is the hydrogen peroxide of 30wt%, 30g concentration is 5wt% potassium permanganate, 3g disodium ethylenediamine tetraacetate (EDTA-2Na) mixing made.

[0074] (4) The filtrate is precipitated with ammonia water, the pH value needs to be controlled at about 8.0 (±0.2), and after stirring for 1 hour, filter again, and the precipit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com